Combustion chamber wall temperature gradient measurement module

A temperature gradient and measurement module technology, applied in thermometers, measuring devices, heat measurement, etc., can solve the problems of large difference in heat transfer state of coolant, prone to defects, large application errors, etc., and achieve heat transfer process and structural bearing capacity The effect of small impact, good contact guarantee and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the drawings and specific embodiments.

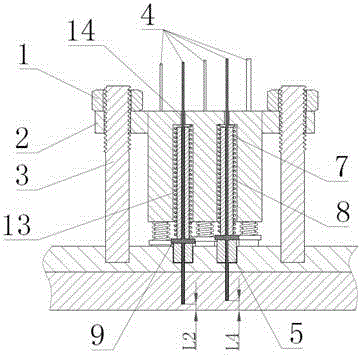

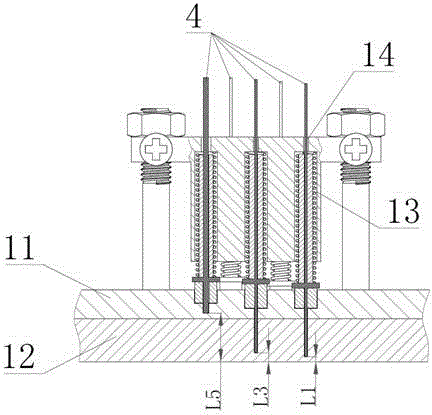

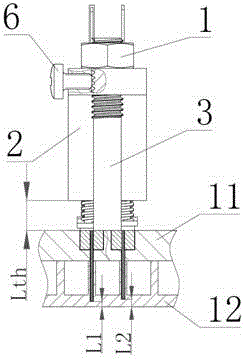

[0026] Such as figure 1 As shown, the temperature gradient measurement module of the cylindrical section of the liquid rocket engine combustion chamber wall of the present invention is a flat structure, including a flat pressure plate 2, 5 thermocouple sensors 4, a spring 8, a baffle 9, and a thermal insulation bush 5. Support sleeve 7, nut 1, stud 3, compression screw 6; each thermocouple sensor 4 is welded with a disc-shaped baffle 9 at the temperature sensing end, and the thermocouple sensor 4 passes through the support at the upper end of the baffle 9 The sleeve 7 and the spring 8, the support sleeve 7 is sleeved into the spring 8, and they are also sleeved in the blind hole 13 on the flat pressure plate 2, wherein the thermocouple sensor 4 passes through the flat pressure plate 2 in advance at the thinner part above the spring 8 The U-shaped groove 15 pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com