Liquid propellant conveying system of blow-down rocket engine

A rocket engine and liquid propellant technology, which is applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of complex pump pressure structure, high cost of high-pressure gas cylinders, high development time and cost, and achieves high processing efficiency. And the effect of low development difficulty, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with the accompanying drawings, the present invention will be further described with embodiments.

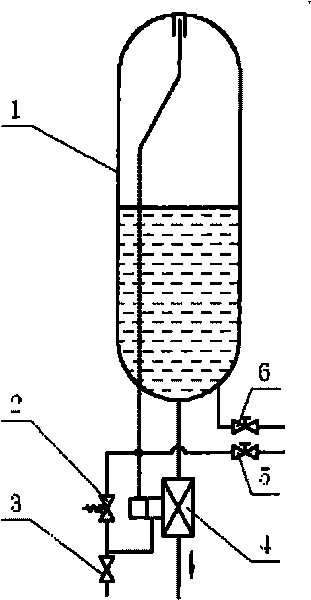

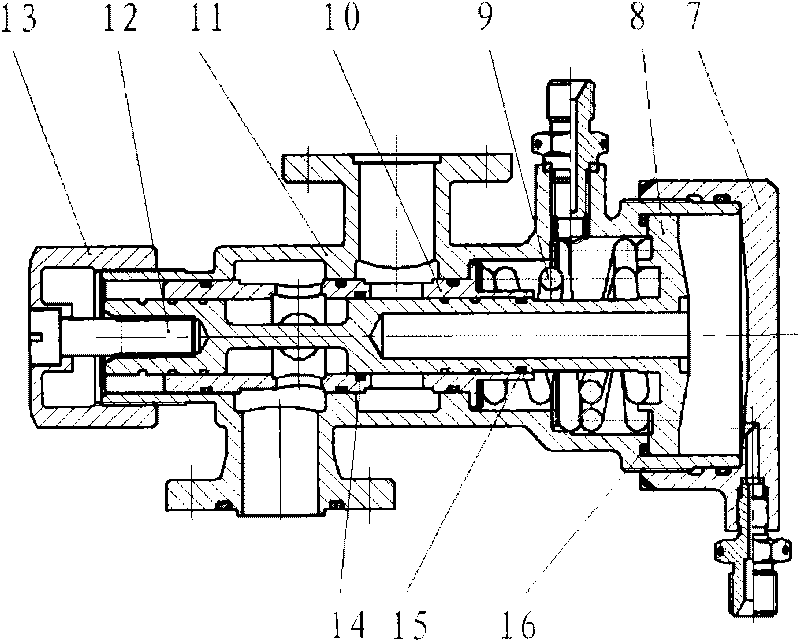

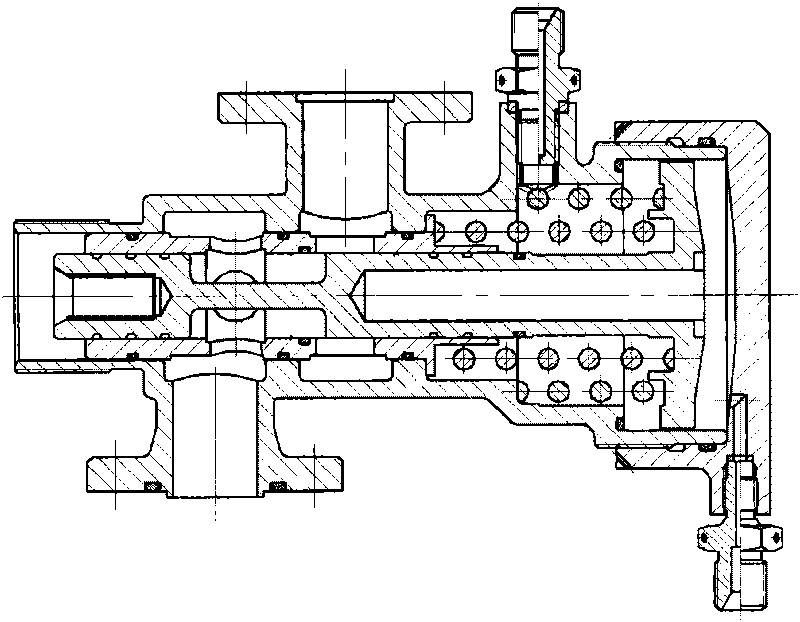

[0013] The schematic diagram of the system is as follows figure 1 As shown in the figure, the device for realizing the functions of the conveying system mainly includes: a storage tank 1, an electric explosion valve 2, an orifice 3, a flow control valve 4, a booster valve 5, a filling valve 6 and the connecting pipelines between them. devices and electro-explosive valve control systems. Flow control valves such as figure 2 As shown, it consists of a valve cover 7, a valve core 8, a spring 9, a bushing 10, a valve body 11, a tie rod 12, a mounting nut 13, an O-ring 14, an O-ring 15, and an O-ring 16. ; There is an oil storage tank on the valve core 8, which can store the sealing grease; the bushing 10 is designed with a type hole.

[0014] The space between the valve core and the valve cover is called the front cavity, and the space where the sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com