Hand-operating unlocking mechanism for sliding door

A technology of manual unlocking and sliding doors, which is applied to building locks, building structures, railway car body parts, etc., can solve the problems of inconvenient use, and achieve the effects of preventing others from opening by mistake, reducing weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

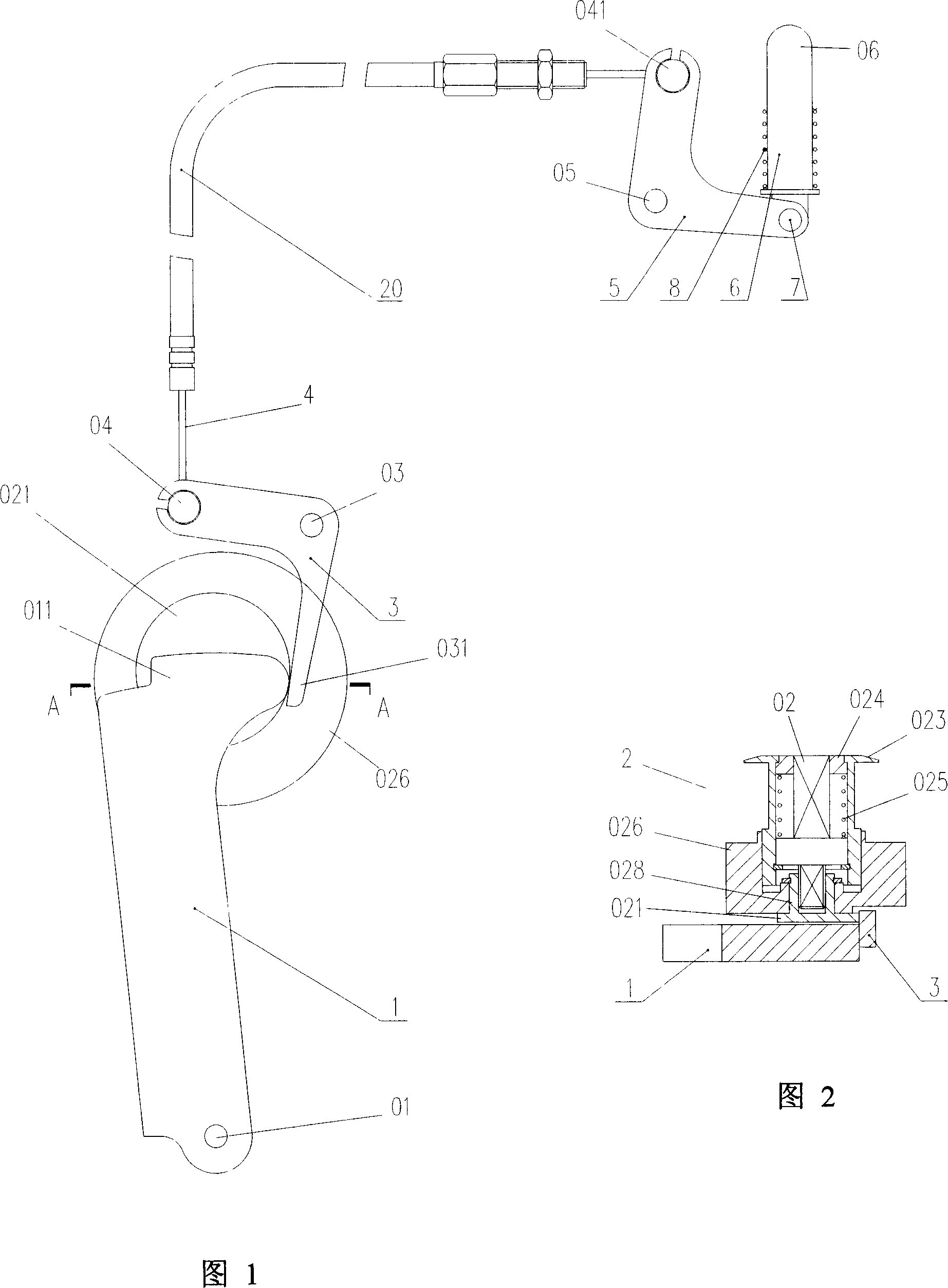

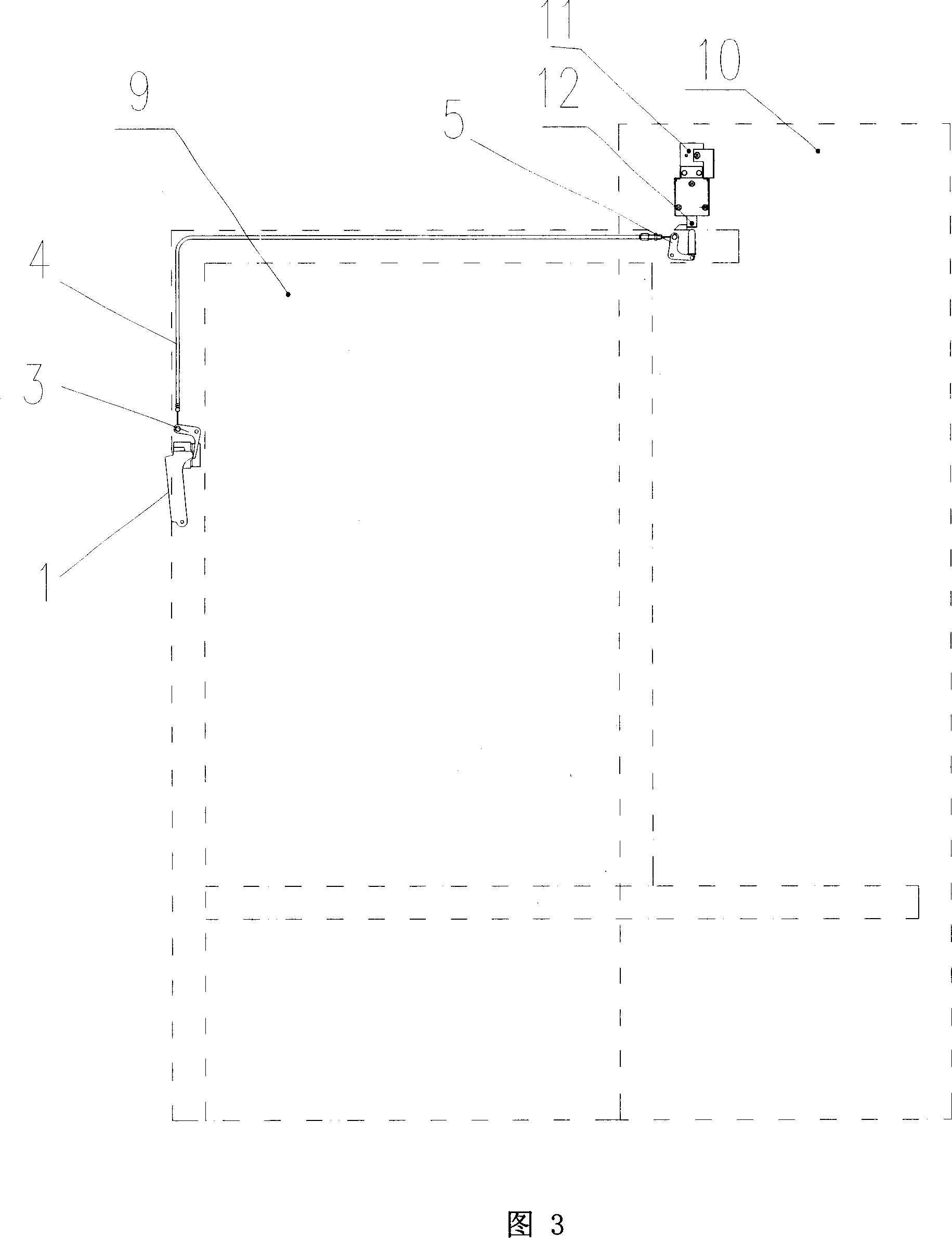

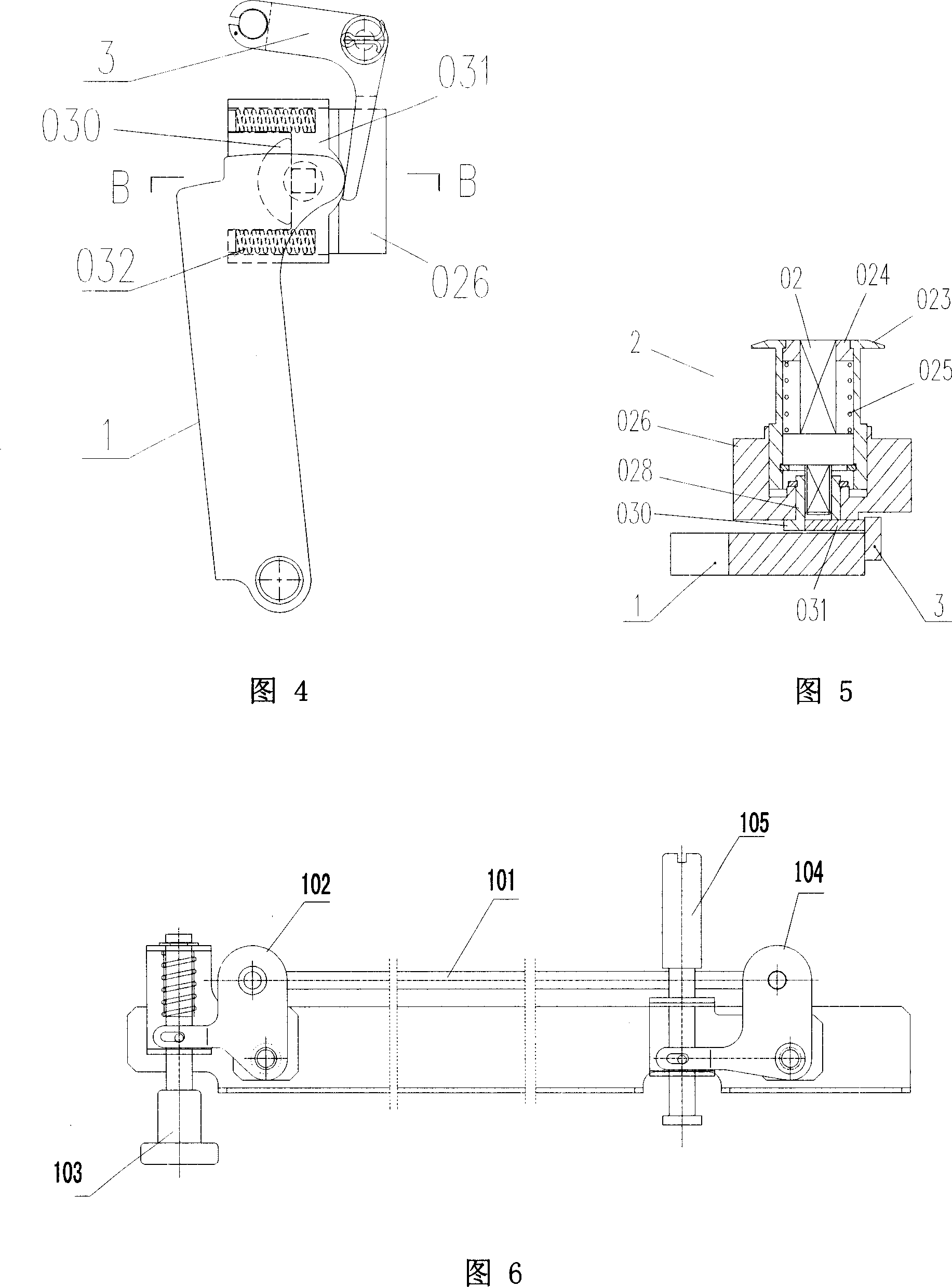

[0024] Fig. 1 shows the basic structure of a preferred embodiment of the present invention, the described sliding door manual unlocking mechanism includes an unlocking handle 1, a first crank arm 3, and a second crank arm 5 arranged on the side of the sliding door facing the track , and a steel cable 4 with a sheath 2 0. The lower end of the unlocking handle 1 is hinged on the sliding door through the rotating shaft 01. In this embodiment, the first crank arm 3 and the second crank arm 5 are both "V" shaped lever structures (also can be set to other shaped lever structures) , the "V"-shaped sharp corners of the first crank arm 3 and the second crank arm 5 are respectively hinged on the sliding door through the rotating shafts 03 and 05. The two ends of the steel cable 4 are hinged to one end of the first crank arm and one end of the second crank arm through the rotating shafts 04 and 041 respectively. The unlocking handle 1 can swing left and right around the rotating shaft 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com