Magnetic lock control ball valve

A ball valve and magnetic technology, applied in the field of magnetic lock control ball valve, can solve the problems of accidental opening, misappropriation of gas, gas leakage, etc., and achieve the effect of preventing accidental opening, preventing misappropriation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

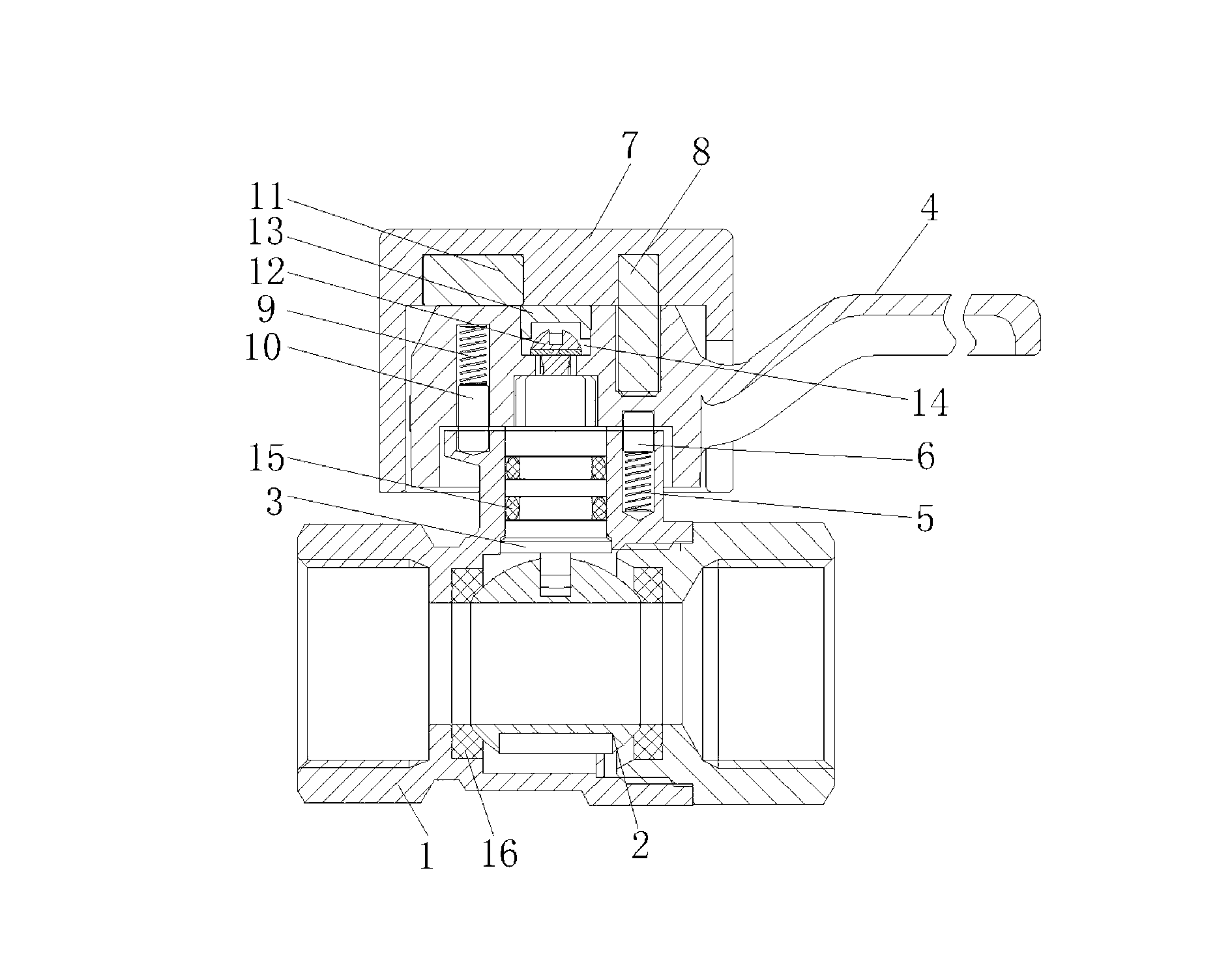

[0021] Such as figure 1 As shown, a magnetic lock control ball valve includes a valve body 1, a ball 2 is arranged inside the valve body 1, a valve stem 3 is connected to the upper end of the ball 2, and a handle 4 is connected to the upper end of the valve stem 3, and the valve body 1 is covered with The upper part of the valve stem 3 is provided with a first blind hole, the first blind hole is provided with a first spring 5, and the lower end of the handle 4 is provided with a second blind hole corresponding to the first blind hole, and the second blind hole is connected to the first blind hole. A first strong magnet 6 is provided between the springs 5, a third blind hole is provided on the top of the handle 4, a lock cap 7 is provided on the handle 4, and a lock cap 7 is provided with one end inserted into the third blind hole. The second strong magnet 8, when the valve needs to be opened, the lock cap 7 is based on the second strong magnet 8, and the lock cap 7 is covered ...

Embodiment 2

[0026] In this embodiment, the upper part of the valve body 1 is provided with a fourth blind hole on the side symmetrical to the first blind hole, and the lower part of the handle 4 is provided with a fifth blind hole corresponding to the fourth blind hole. A second spring 9 is arranged in the blind hole, a positioning pin 10 is arranged between the second spring 9 and the fourth blind hole, and a third strong magnet 11 corresponding to the positioning pin 10 is arranged in the lock cap 7. In this implementation Example can be used alone or in combination with Embodiment 1. When used alone, when the valve needs to be opened, the lock cap 7 is covered on the upper end of the handle 4, and the third strong magnet 11 moves the positioning pin 10 upward under the action of the magnetic force to release the positioning. The pin 10 blocks the handle 4, so that the handle 4 can be pulled. When the valve needs to be locked, the handle 4 is moved to a suitable position, and the lock ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com