Internal heating nitrous oxide monopropellant gas generator

A nitrous oxide single gas generator technology, applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as low power supply, achieve energy saving, improve heating efficiency, and high decomposition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

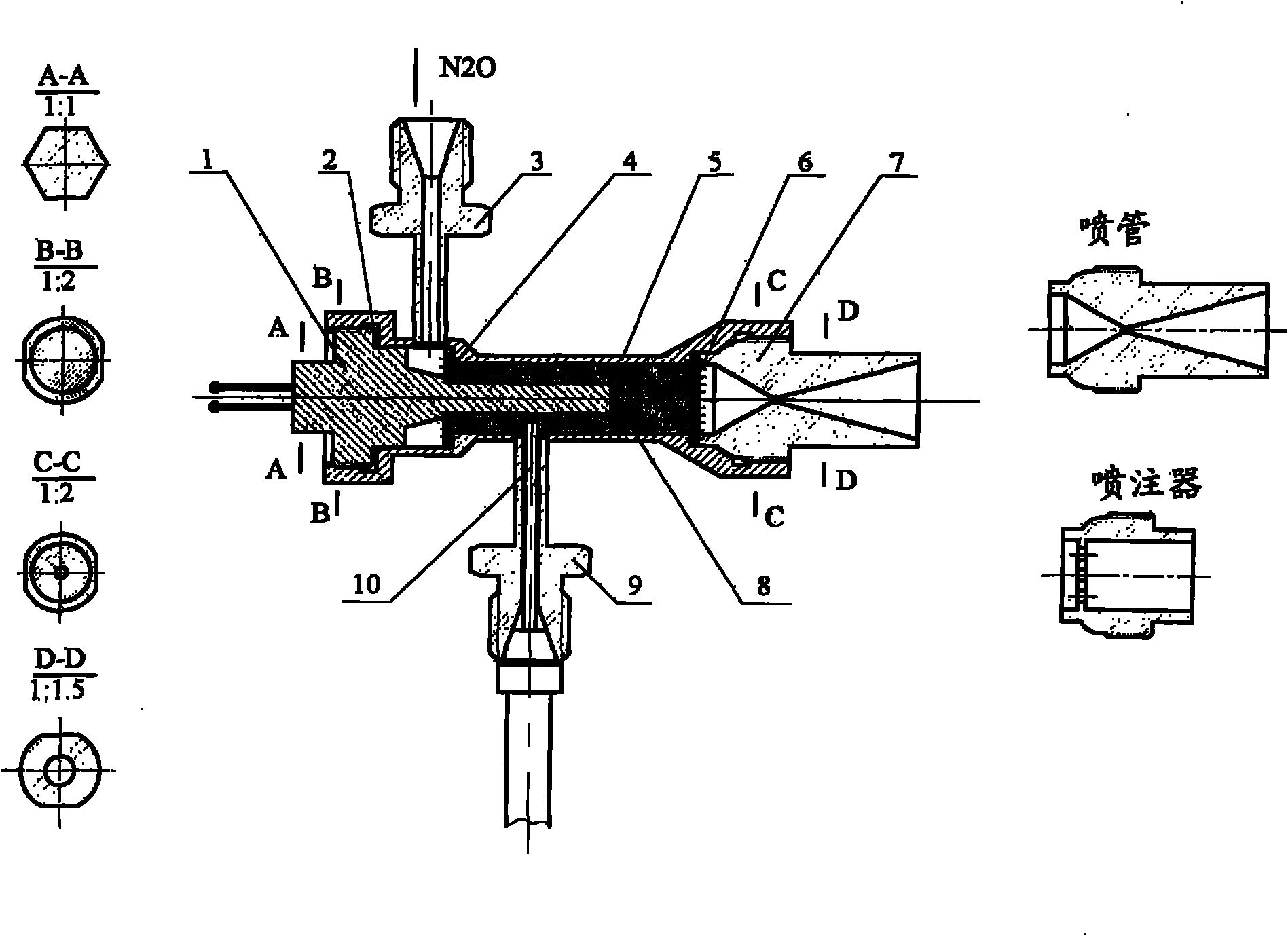

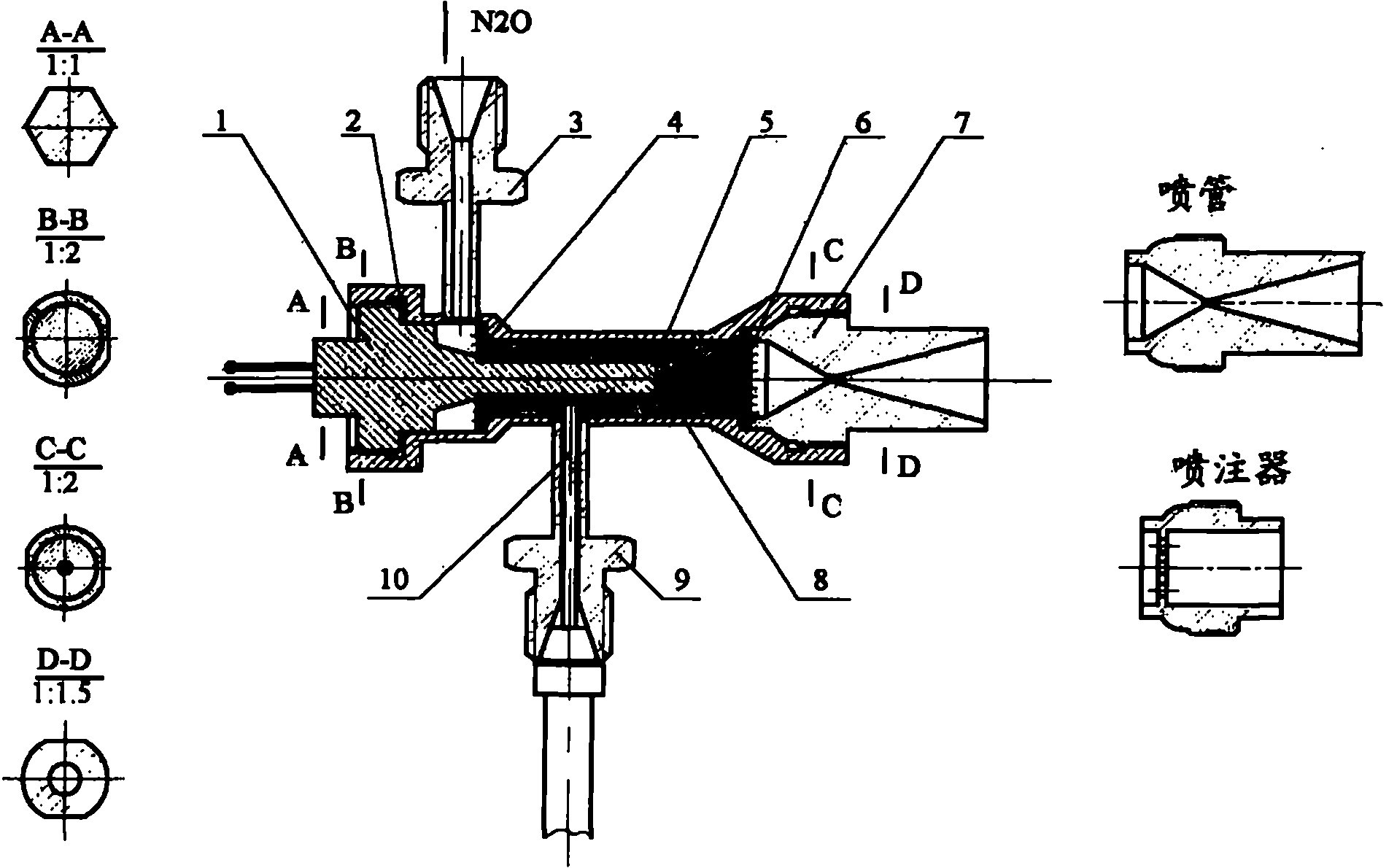

[0012] The use mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Shown is an internally heated nitrous oxide monocomponent gas generator related to the present invention, including: 1. Armored internal heater, 2. Copper gasket, 3. Propellant conduit, 4. Front orifice plate , 5. Catalytic decomposition chamber, 6. Rear orifice plate, 7. Nozzle, 8. Catalytic bed, 9. Thermocouple nozzle, 10. Thermocouple.

[0014] The installation sequence of the gas generator is as follows: first install the thermocouple (10) from the side; then install the front orifice plate (4), copper gasket (2), armored inner heating Install the device (1) and tighten the thread; then fill the catalyst from the rear end of the catalytic decomposition chamber to form a catalytic bed (8), and install the rear orifice plate (6); finally install the nozzle pipe (7) from the rear end and tighten the thread.

[0015] During work, the two electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com