Fuel supplying system for liquid-propellant rocket engine test

A liquid rocket and engine technology, which is applied in the field of fuel supply system devices, can solve the problems of system danger, waste of remaining gas in hydrogen cylinders, and increase direct contact of hydrogen medium, so as to achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

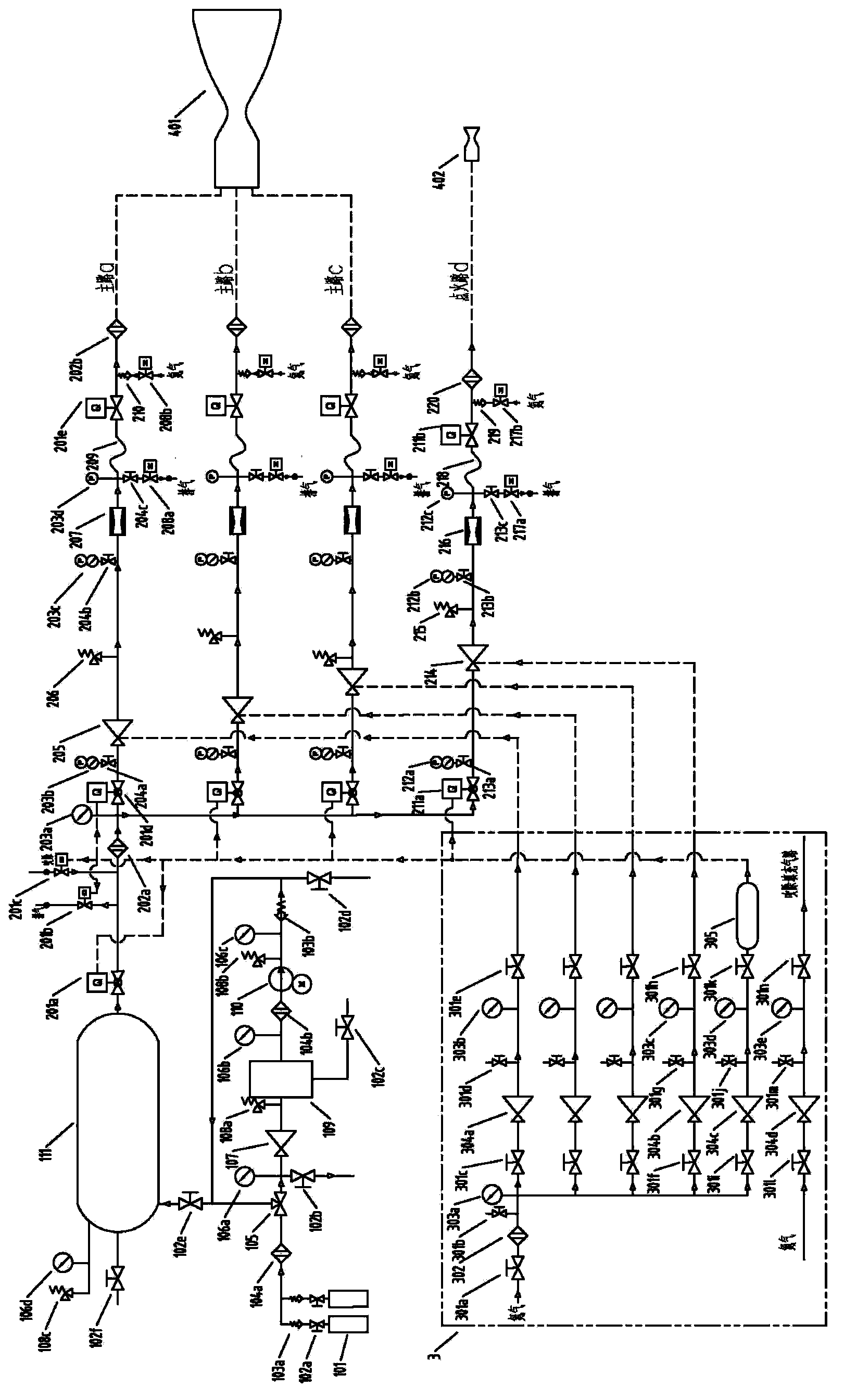

[0052] The present invention is a fuel supply system for liquid rocket motor tests, such as figure 1 As shown, it includes hydrogen source system, hydrogen transportation pipeline system and gas distribution platform system 3.

[0053] The hydrogen source system includes a large-scale high-pressure gas storage tank 111, a high-pressure gas cylinder 101, a filter 104a, a manual pressure reducer 107, a hydrogen pump 110, and pipelines.

[0054] The main function of the high-pressure gas cylinder 101 is to provide the source of initial hydrogen. The outlet of the high-pressure gas cylinder 101, the manual shut-off valve 102a, and the one-way valve 103a are sequentially connected through pipelines to form a high-pressure gas cylinder group. The valve 103a can achieve the purpose of controlling the gas flow direction. In order to improve the gas supply ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com