Electric drive propellant feeding system liquid-propellant rocket engine

A supply system and liquid rocket technology, applied in the field of aerospace science, can solve the problems of high development cost, long development cycle, complex structure, etc., and achieve the effects of short development cycle, low investment cost and simple system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

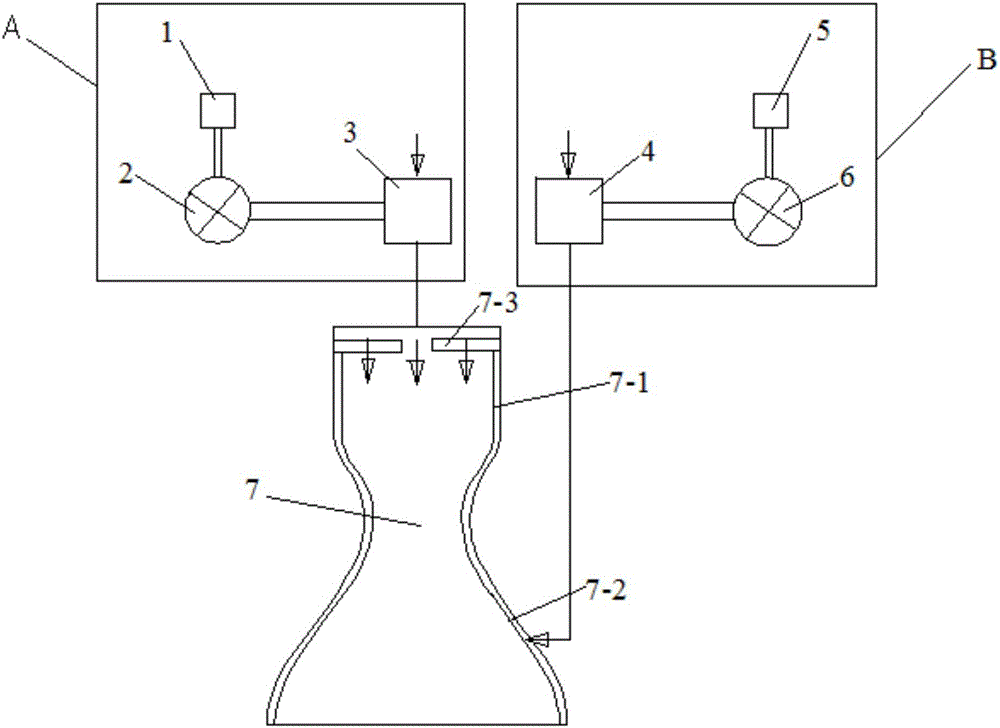

[0013] The electric drive propellant supply system liquid rocket engine of the present invention, such as figure 1 As shown, it includes an oxidant delivery system A, a fuel delivery system B, and a thrust chamber 7, and the oxidant delivery system A and the fuel delivery system B are independently communicated with the thrust chamber 7, so as to deliver corresponding oxidant and fuel into the thrust chamber 7 , and mixed and burned in the thrust chamber 7, and sprayed out from the nozzle to generate reverse thrust. The above-mentioned oxidant delivery system A includes an oxidant cell 1 , an oxidant motor 2 and an oxidant pump 3 connected in sequence, and the oxidant pump 3 is used to connect with the oxidant storage tank and the thrust chamber 7 in pipelines.

[0014] The above-mentioned fuel delivery system B includes a fuel cell 5 , a fuel motor 6 and a fuel pump 4 connected in sequence, and the fuel pump 4 is used to connect the fuel storage tank and the thrust chamber 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com