Test unit for hydrogen-rich/ oxygen-rich gas multinozzle gas-gas injector

A test device and multi-nozzle technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as unfavorable nozzle installation and replacement, complicated connection methods, etc., and achieve compact structure, simple and reliable sealing, The effect of convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

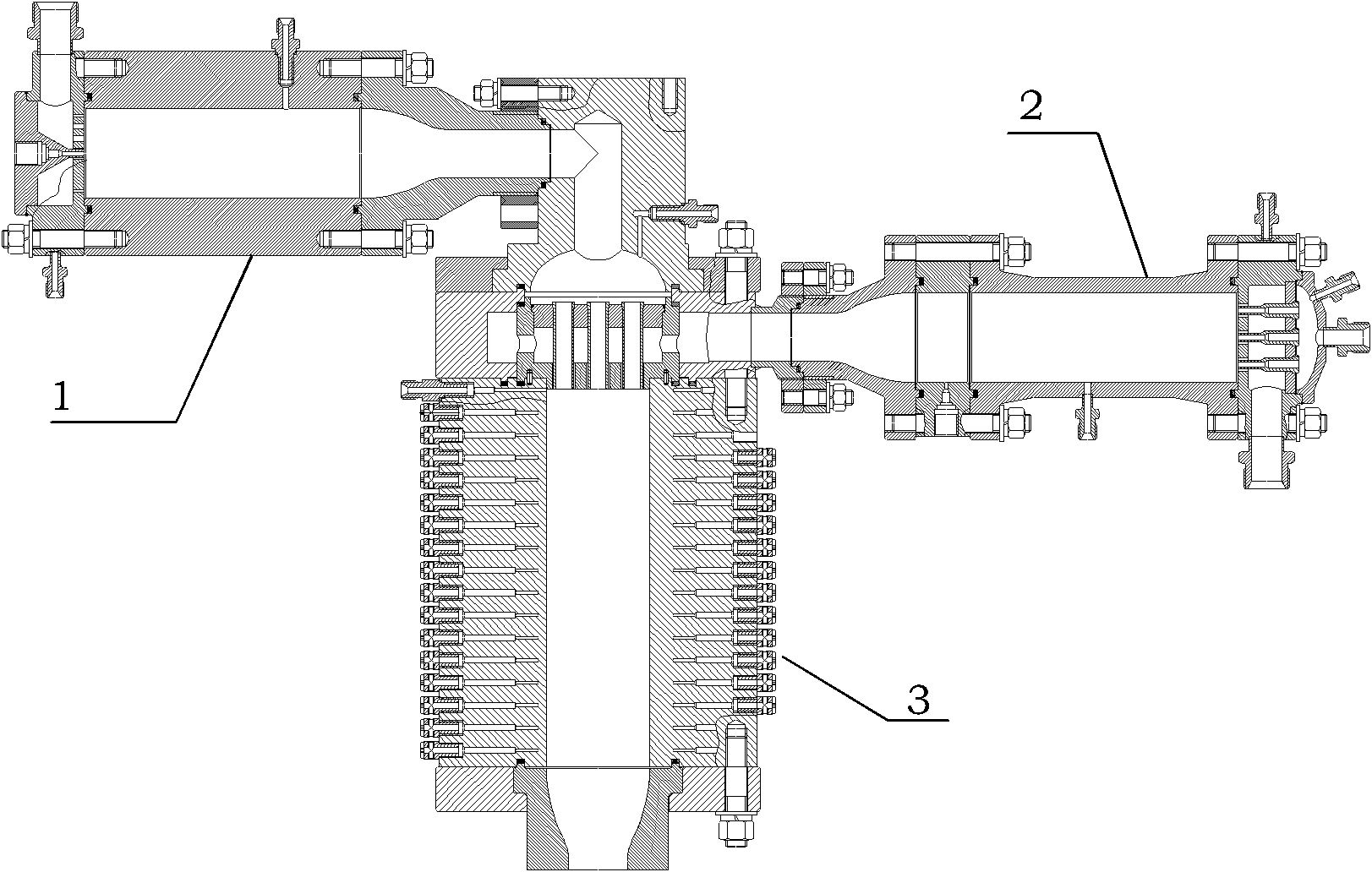

[0026] Hydrogen-enriched / oxygen-enriched gas multi-nozzle gas injector test device of the present invention, such as figure 1 As shown, it mainly includes three parts: an oxygen-enriched pre-chamber 1 , a hydrogen-enriched pre-chamber 2 and a main combustion chamber 3 .

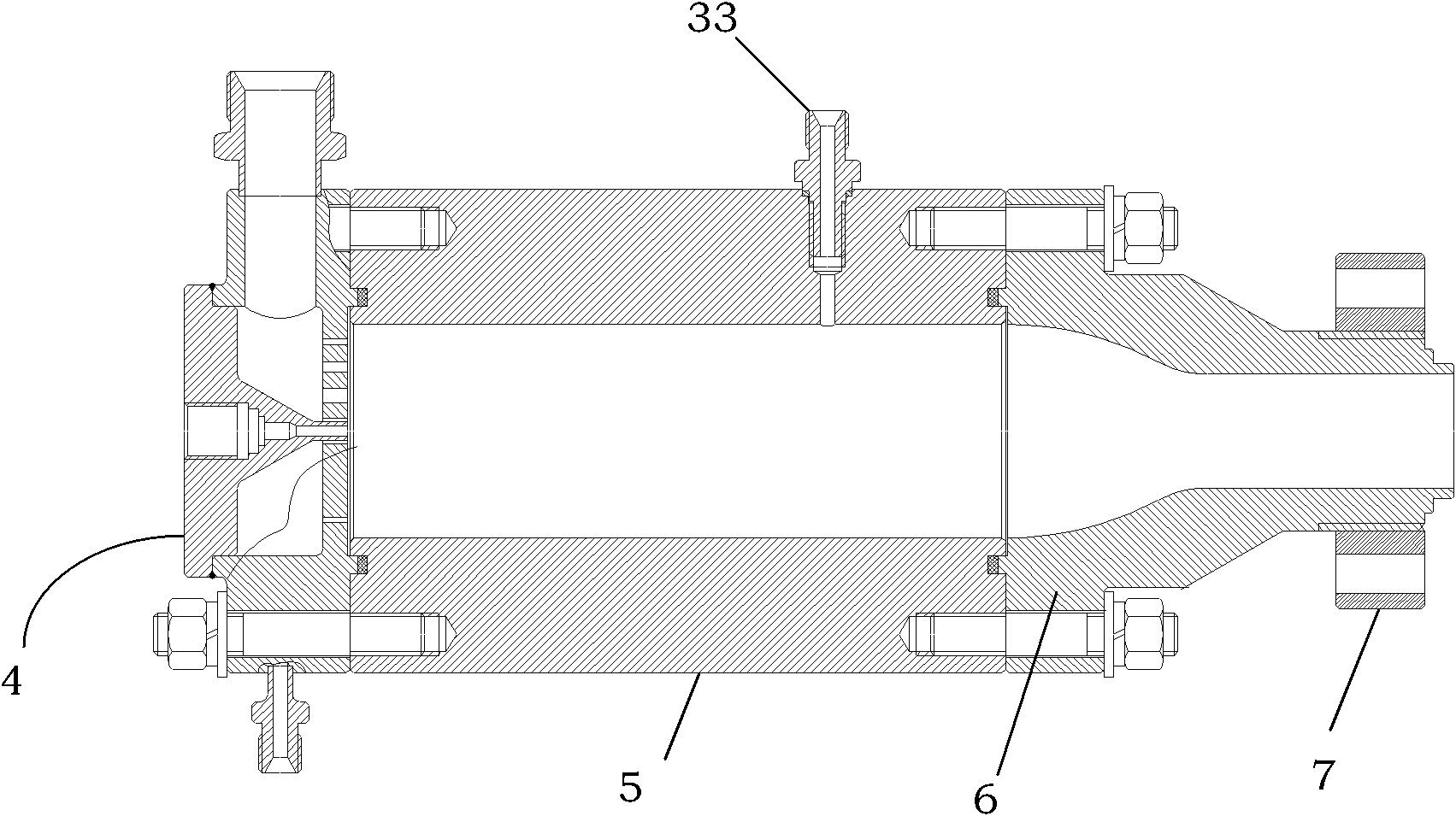

[0027] Oxygen-enriched pre-combustion chamber 1 is used to generate oxygen-enriched gas, such as figure 2 As shown, the main components are: the head 4 of the oxygen-enriched chamber, the body 5 of the oxygen-enriched chamber, the outlet section 6 of the oxygen-enriched chamber and the outlet flange 7 of the oxygen-enriched chamber. The head 4 of the oxygen-enriched chamber is connected with the body 5 of the oxygen-enriched chamber with bolts, and the body 5 of the oxygen-enriched chamber is connected with the outlet section 6 of the oxygen-enriched chamber with bolts, and the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com