Modular rocket engine propellant offset jetting panel capable of achieving threaded connection

A rocket engine and propellant technology, which is applied to rocket engine devices, jet propulsion devices, machines/engines, etc., to facilitate assembly and maintenance, reduce processing difficulty, and achieve uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

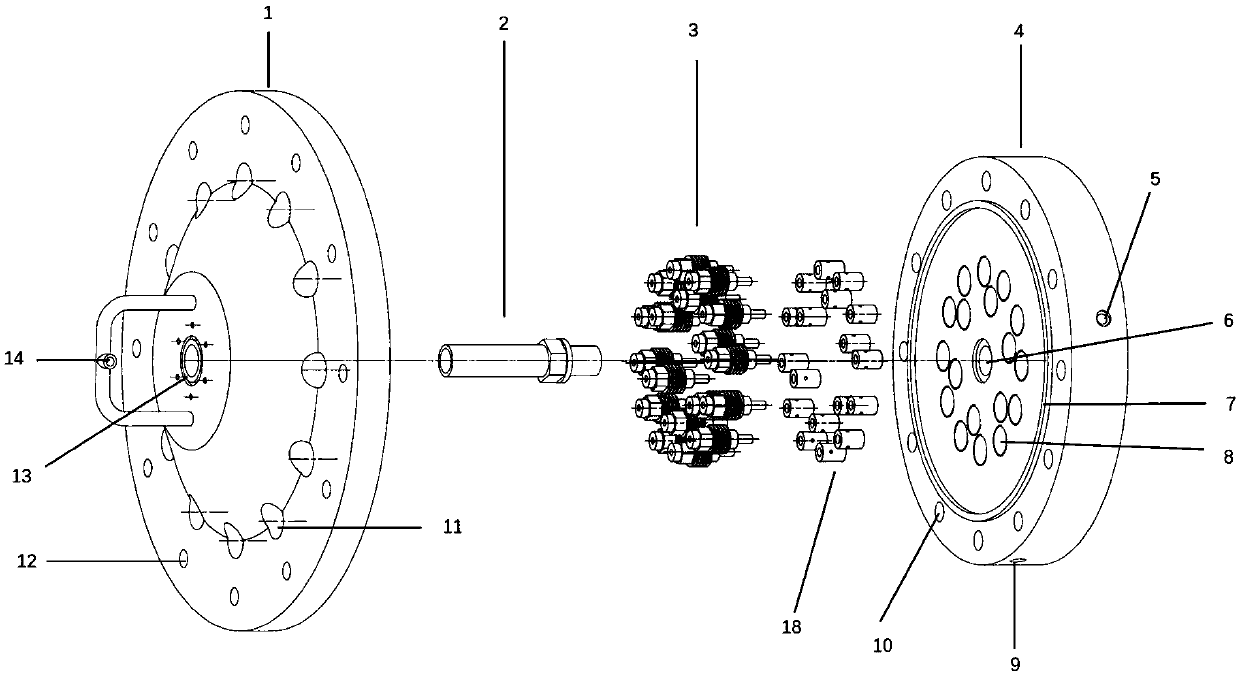

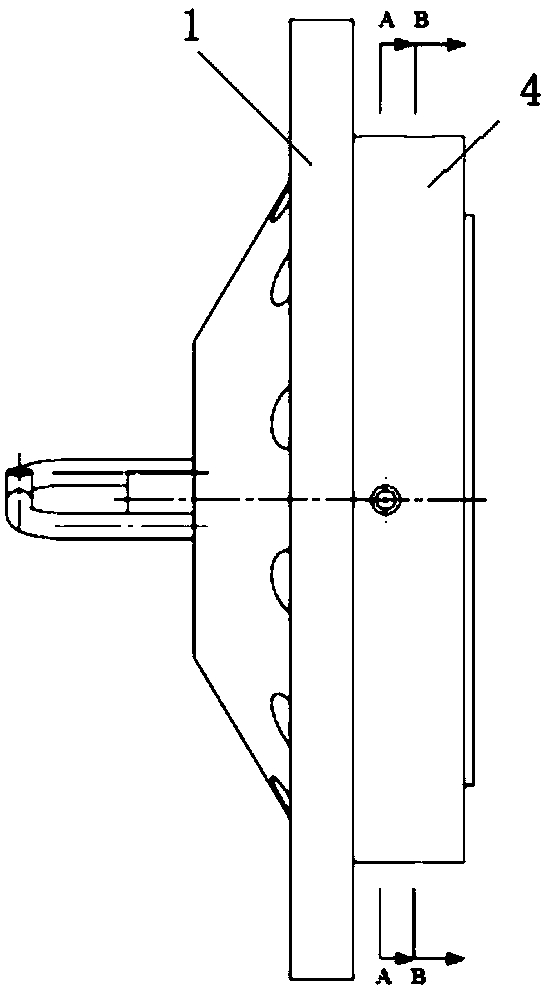

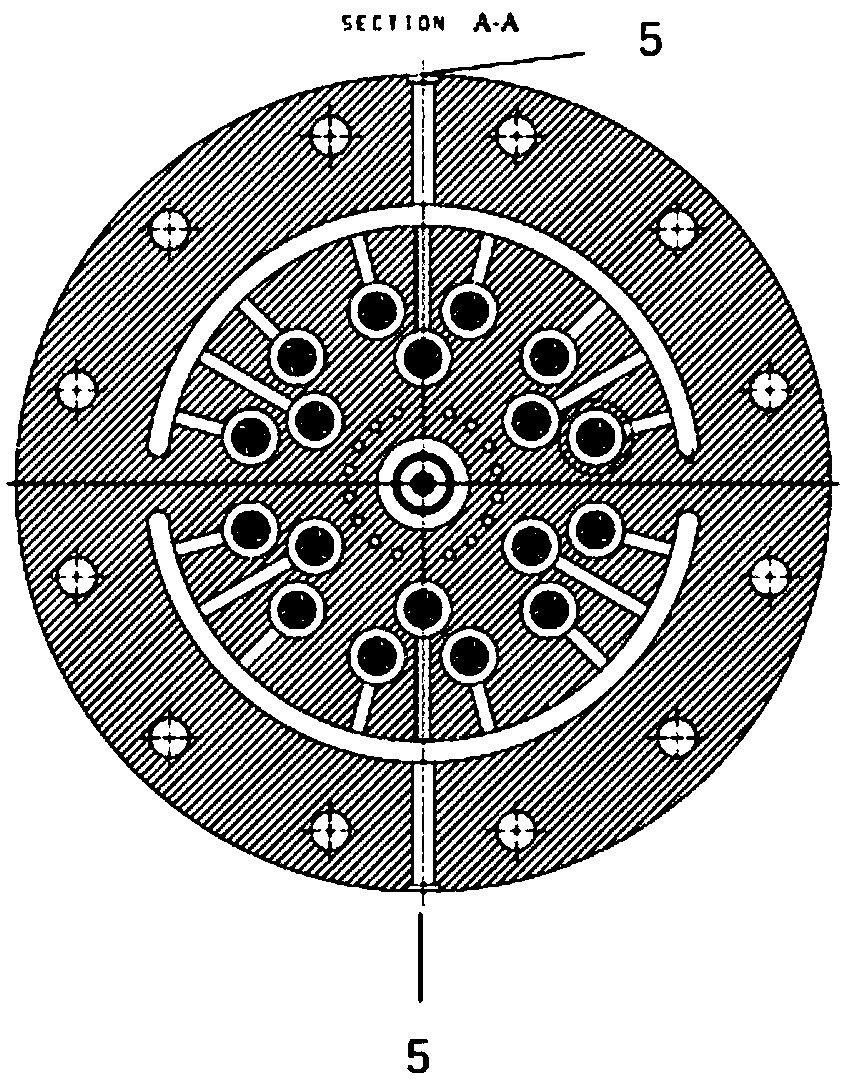

[0034] Such as figure 1 As shown, the rocket engine injection panel of the present invention adopts a modular form, including an end cover 1 , a nozzle assembly, a spark plug 2 and a propellant guide panel 4 . Wherein, the end cover 1 and the propellant deflector panel 4 are arranged sequentially and pressed together, as figure 2 shown. The spark plug 2 passes through the center hole of the end cap 1 and the propellant guide panel 4 in sequence, and the ignition end penetrates the outer end surface of the propellant guide panel 4 .

[0035] A sealing ring 7 is arranged between the propellant deflector panel 4 and the end cover 1 to form a sealed cavity for containing oxidant or fuel after being compressed; the end cover 1 is provided with an inlet 14 for passing the oxidant or fuel into the sealed cavity. Fuel; propellant deflector panel 4 is axially d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com