Welding method for multi-part structure of head injector in thrust chamber of liquid-propellant rocket engine

A liquid rocket, welding method technology, applied in welding equipment, electron beam welding equipment, metal processing equipment, etc., can solve the problems of decreased solder welding force, loss of solder material, and high risk of product scrap, and reduce thermal stress. The effect of concentration, reducing welding deformation and reducing the risk of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

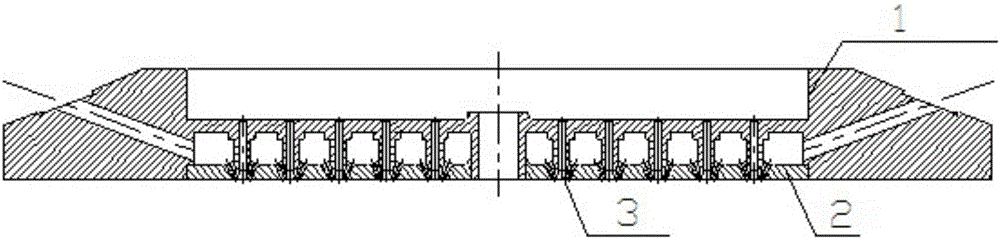

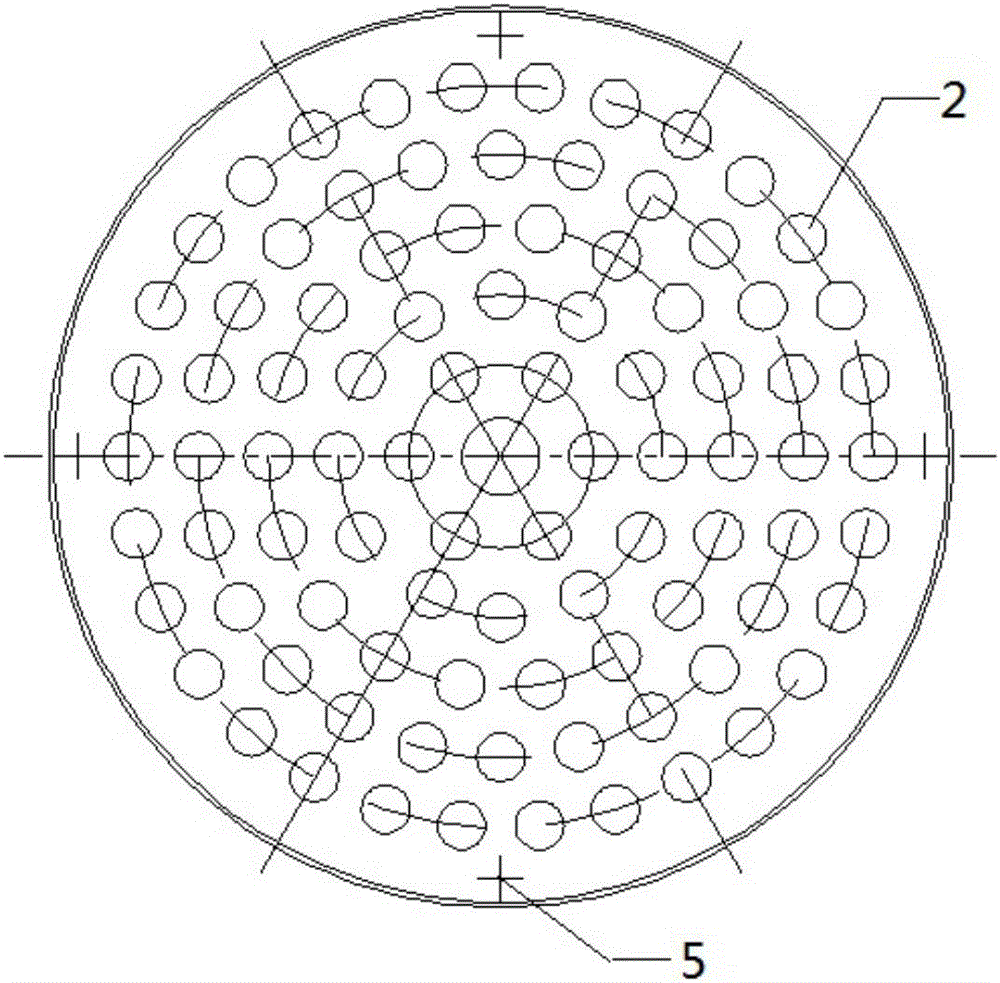

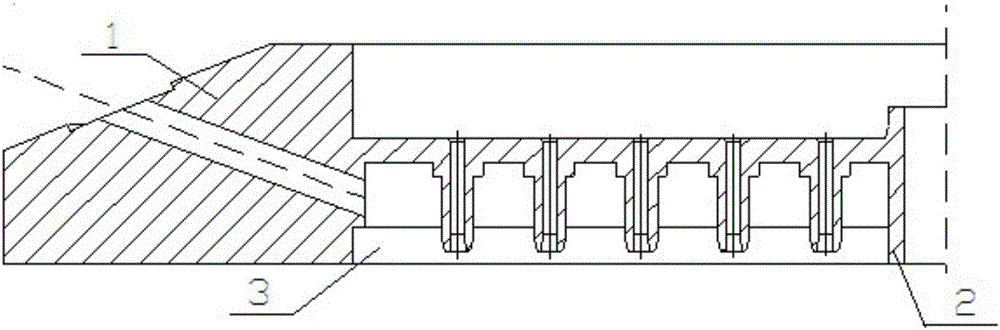

[0040] For a certain type of liquid engine thrust chamber head injector, its structure is as follows figure 1 As shown, the materials are all GH4169, which contains 90 nozzle units, and the 90 nozzle units are arranged in 5 circles in a honeycomb shape. The diameter of the index circle of each circle of nozzle units is Φ38mm, Φ67mm, and Φ96mm from the inside to the outside. . figure 2 , the welding and testing method and process of the injector of the nozzle are as follows:

[0041] 1) Process welding parts: process and manufacture welding parts according to the technical requirements of the head injector, including the overall structure of the injector 1 (see attached image 3 ) and round base 2 (see attached Figure 4 ), the circular base 2 takes the center of the circle as a dot and contains 3 groups of multi-circle nozzle unit grooves from the inside to the outside. The shaped base 2 is arranged in a honeycomb shape, and the assembly gap of the parts is less than 0.1mm...

Embodiment 2

[0053] For a certain type of liquid engine thrust chamber head injector, which contains 60 nozzle units,

[0054] The steps of this embodiment and embodiment 1 are basically the same, the difference is:

[0055] 1) In step 5), the vacuum electron beam welding parameters are selected as:

[0056]

[0057] 2) In step 6), the corresponding vacuum electron beam welding parameters are selected as:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com