Oiling device and method for improving oil stability

A technology of stability and oil agent, which is applied in textiles and papermaking, filament/thread forming, fiber treatment, etc., can solve the problems of continuous use performance decline of oil tank, oil agent can not be removed in time, easy to adhere to oil stains, etc., to improve the total The effect of mixing efficiency, reducing the possibility of oxidation, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

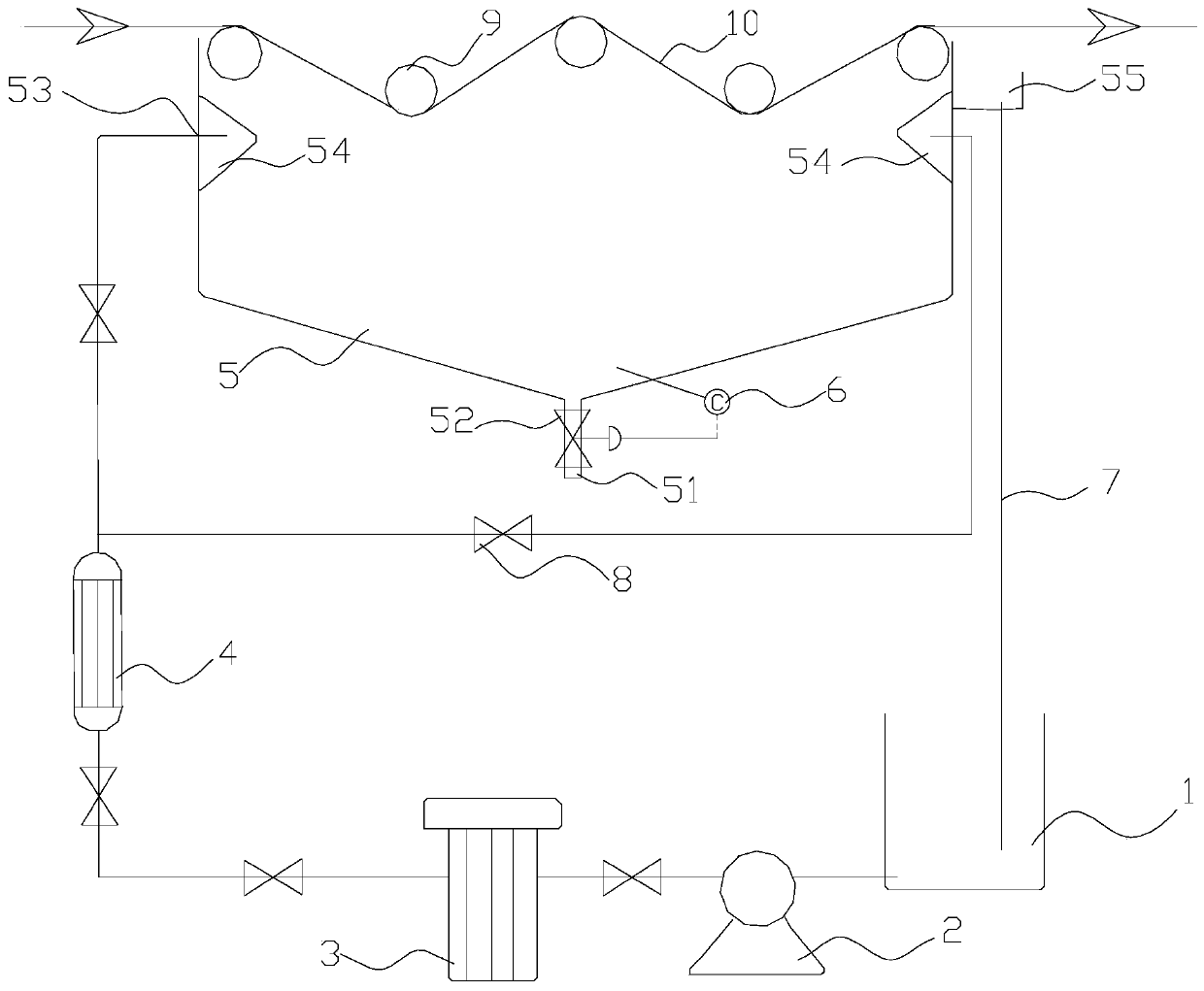

[0042] In acrylic fiber wet spinning, the bottom of the oil tank 5 is arranged in a V shape, the maximum depth of the oil tank 5 is 150mm, the angle between the V-shaped tank body and the tank wall at the bottom of the oil tank 5 is 120°, and the length of the oil tank 5 is 1000mm. A concentration tester 6 is provided at the bottom of the oil tank 5 close to the emptying pipe 51. The oil inlet 53 in the oil tank 5 is arranged on both sides of the oil tank 5. The aperture of the through hole on the baffle plate 54 is 6 mm; the oil tank 5 uses a filter with a precision of 5um The folded metal filter rod filter is used for external circulation filtration, and the shell and tube heat exchanger is used as the external circulation heat exchanger 4 to cool down. The oil agent delivery pump 2 adopts a diaphragm pump. Other structures of the oiling device used in this embodiment Same as above oiling device.

[0043] The method that present embodiment improves oil agent stability compri...

Embodiment 2

[0050] During the carbon fiber precursor dry-spray wet spinning process, the bottom of the oil tank 5 is set in a V shape, the maximum depth of the oil tank 5 is 190 mm, the angle between the V-shaped tank body at the bottom of the oil tank 5 and the tank wall is 150°, and the length of the oil tank 5 is It is 1200mm. A concentration tester 6 is provided at the bottom of the oil tank 5 close to the emptying pipe 51. The oil inlet 53 in the oil tank 5 is arranged on both sides of the oil tank 5. The aperture of the through hole on the baffle plate 54 is 6 mm; the oil tank 5 uses a filter with a precision of 5um The folded metal filter rod filter is used for external circulation filtration, and the shell and tube heat exchanger is used as the external circulation heat exchanger 4 to cool down. The oil agent delivery pump 2 adopts a diaphragm pump. Other structures of the oiling device used in this embodiment Same as above oiling device.

[0051] The method that present embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com