Traveling wave ultrasonic motor similar to the gear transmission and control method thereof

A technology of gear transmission and ultrasonic motor, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of ultrasonic motor resonance frequency drift, large friction loss, unfavorable ultrasonic Motor stability and long-term problems, to achieve the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

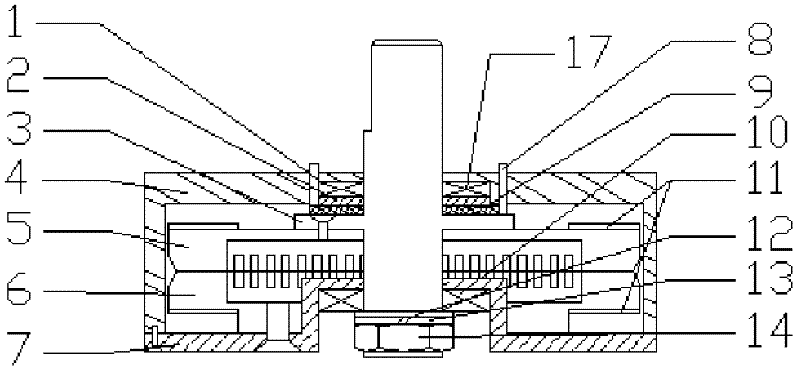

[0026] Such as figure 1 As shown, the gear transmission traveling wave ultrasonic motor of the present invention consists of a first brush 1, a first copper ring 2, a motor output shaft 3, a casing 4, a rotor 5, a stator 6, a base 7, a second brush 8, The second copper ring 9, base bearing 10, pressure sensor 12, elastic washer 13, preload nut 14, housing bearing 17 and other components are composed.

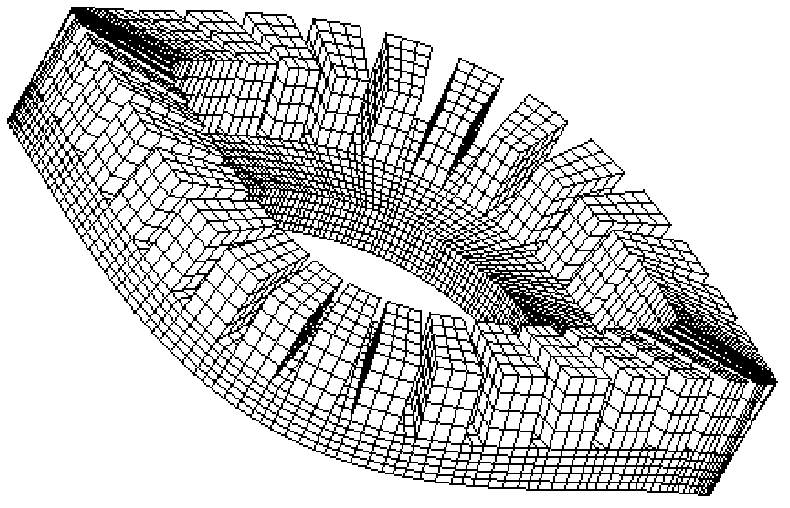

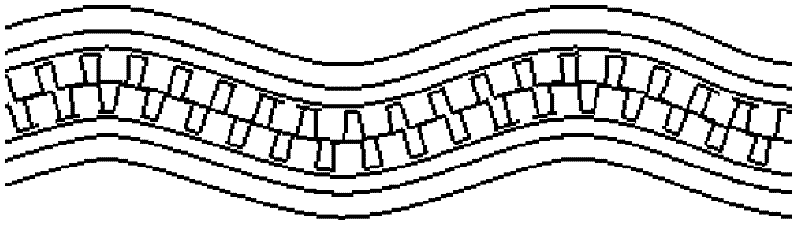

[0027] Wherein, the stator 6 includes a metal elastic body, an annular piezoelectric ceramic 11 and two semi-annular silver-plated electrodes 15 and 16 . Wherein, the annular piezoelectric ceramic 11 is pasted on the lower surface of the metal elastic body. The annular piezoelectric ceramic 11 is evenly partitioned into 16 parts an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com