Tight coupling ring rectangular hole gas nozzle atomizer capable of improving atomization efficiency

A gas nozzle and atomization efficiency technology, applied in the field of pressure gas atomization liquid, can solve the problems of increased production cost, difficulty in realizing industrialized production, large nitrogen source and gas compressor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

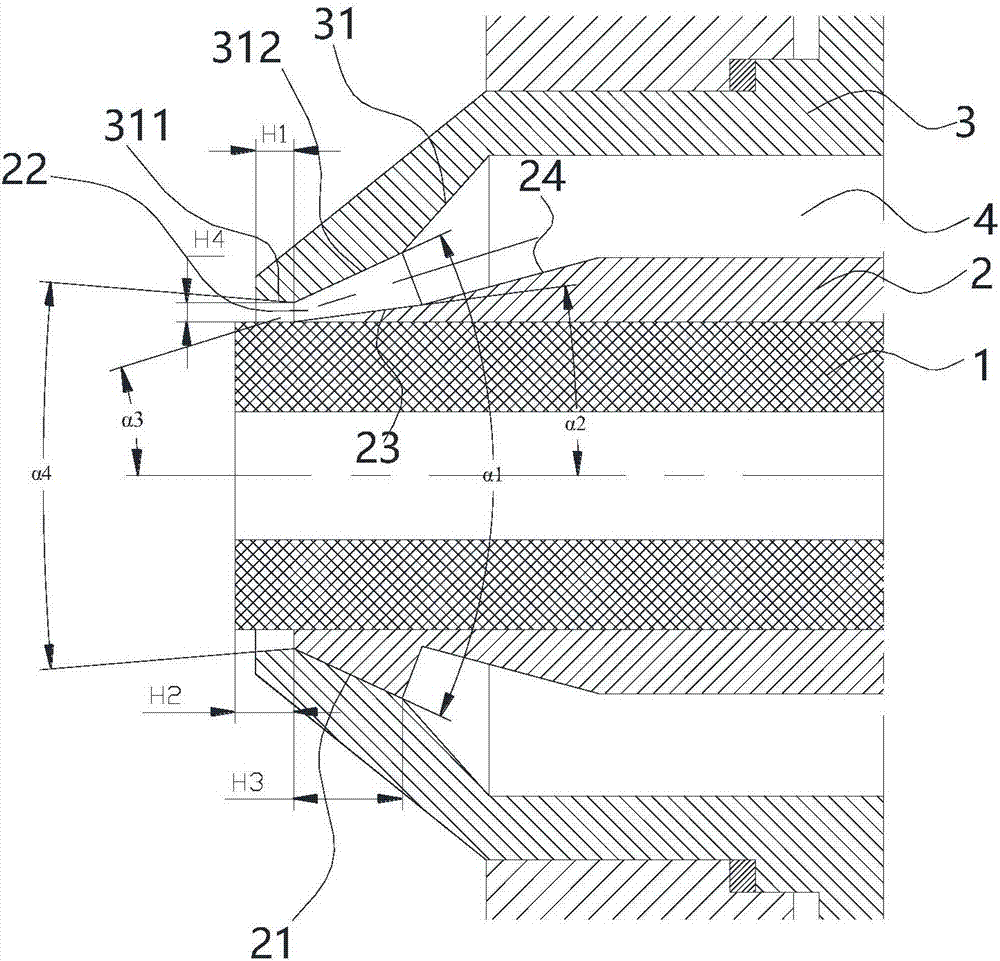

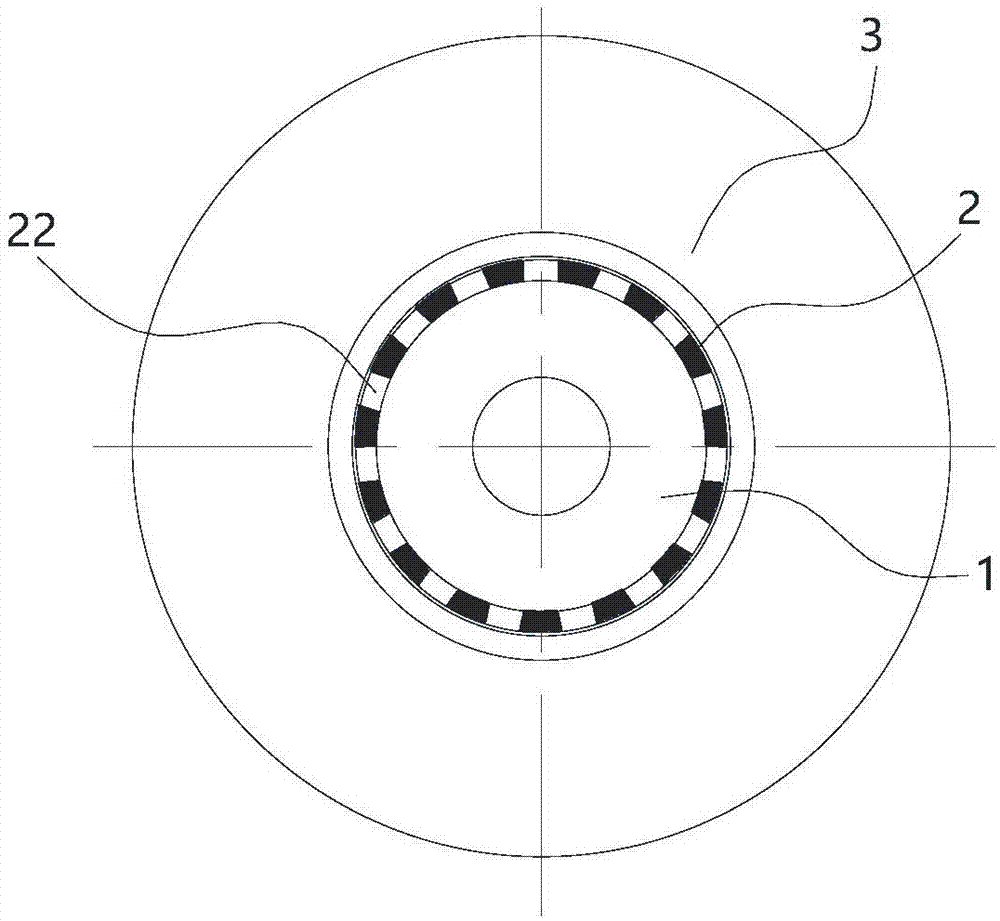

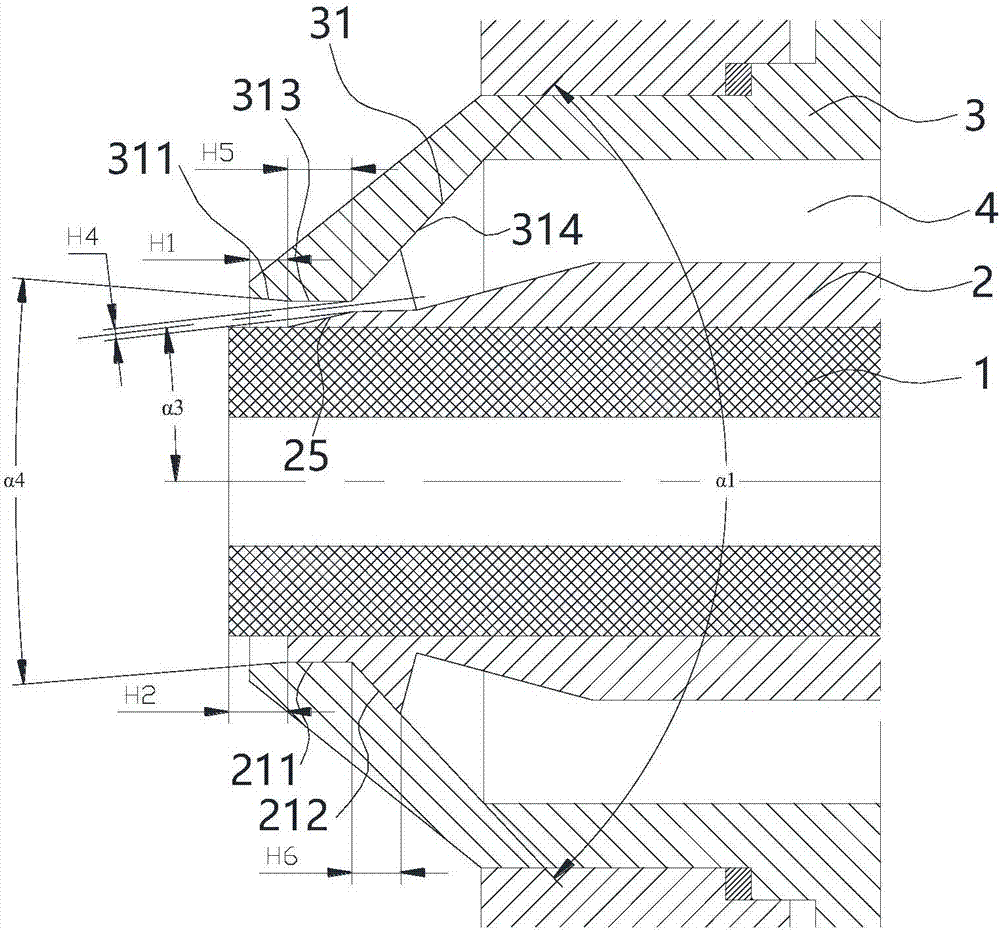

[0028] Embodiment one, as figure 1 , 2As shown, this embodiment provides a tightly coupled ring rectangular hole gas nozzle atomizer that improves atomization efficiency, including a catheter 1 with a hollow tube structure, and a lower body 2 and an upper body 3 with a hollow tube structure , the lower body 2 is set on the outer surface of the catheter 1, and the upper body 3 is sleeved outside the lower body 2 and forms a closed gas resident space 4 capable of stabilizing the gas pressure between the lower body 2; the catheter 1, the lower body 2 and the upper body The body 3 forms a layer-by-layer socket structure.

[0029] The inner surface of the port of the upper body 3 is a conical surface 31 that shrinks toward the port of the liquid guide tube 1, and the outer conical surface of the port of the lower body 2 is in sealing contact with the conical surface 31 of the upper body 3 through the corresponding frustum 21, so that the upper body 3 and the lower body The outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com