High-efficiency compact type mixer with asymmetric blade grid structure

A grid structure, asymmetric technology, used in fluid mixers, mixers, chemical instruments and methods, etc., to achieve the effect of reducing the degree of turbulence, large turbulent pulsation, and avoiding excessive turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

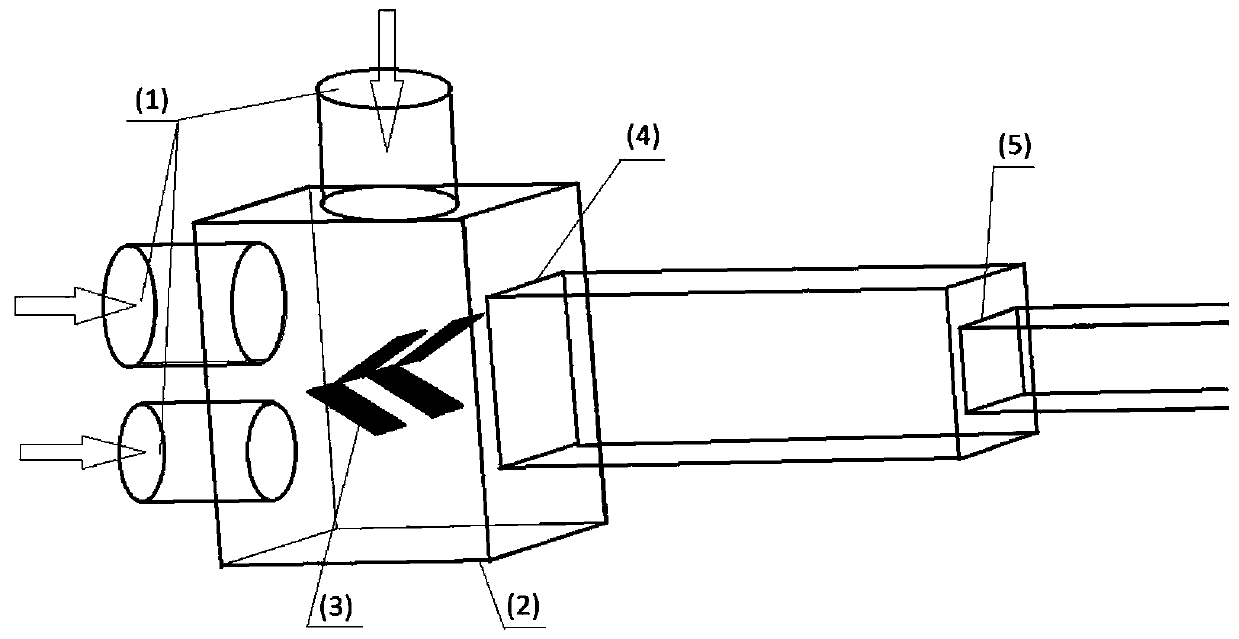

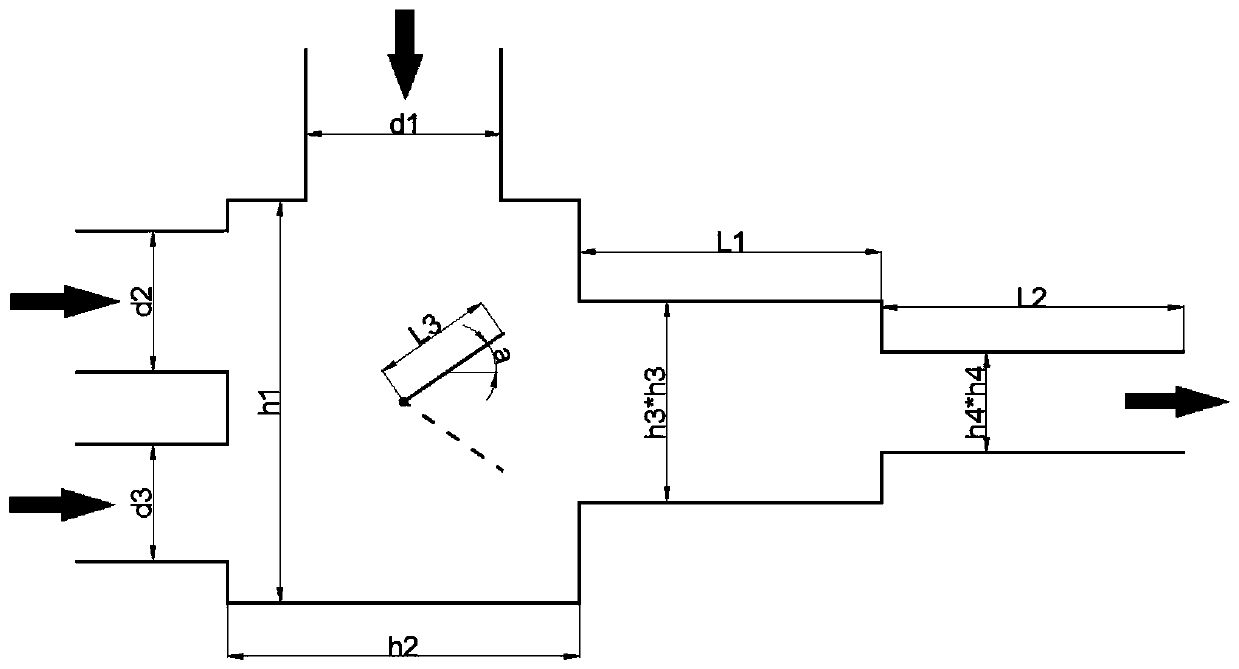

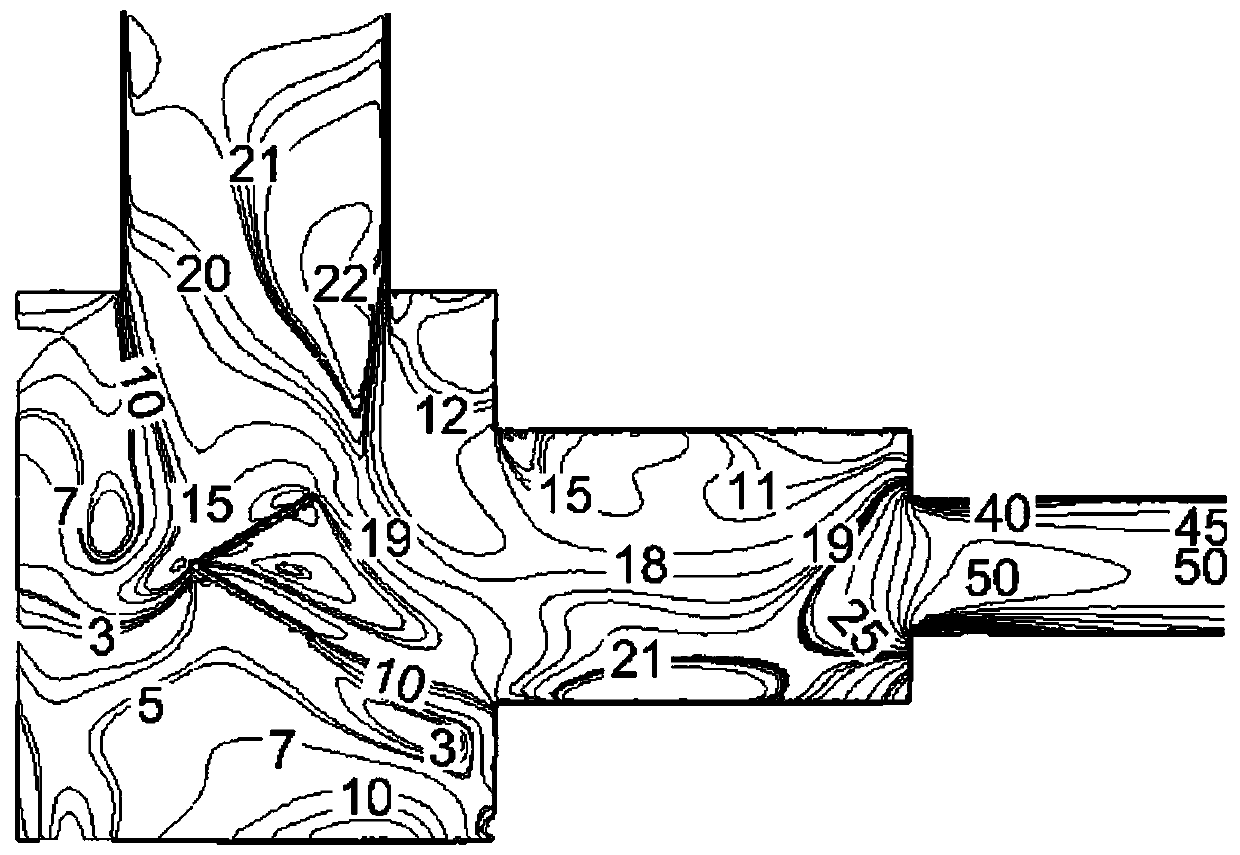

[0025] Such as Figure 1-2 Shown is a high-efficiency compact mixer with an asymmetric cascade structure, including a mixing chamber 2 and a multi-channel multi-directional inlet 1 connected to the mixing chamber 2;

[0026] Wherein, the asymmetric cascade structure 3 is arranged in the mixing chamber 2 (its asymmetry is reflected in the fact that there is no cascade symmetrically arranged with it in the pitch direction and adjacent cascades are arranged in a staggered pitch), and the mixing chamber 2 The outlet is connected successively with a first-level sudden contraction section 4 and a second-level sudden contraction section 5 .

[0027] In this embodiment, the multi-channel multi-directional inlet 1 includes a single-surface single inlet on the top side of the mixing chamber 2 and a single-surface double inlet on the left side of the mixing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com