Patents

Literature

120results about How to "Improve thermal cycle efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

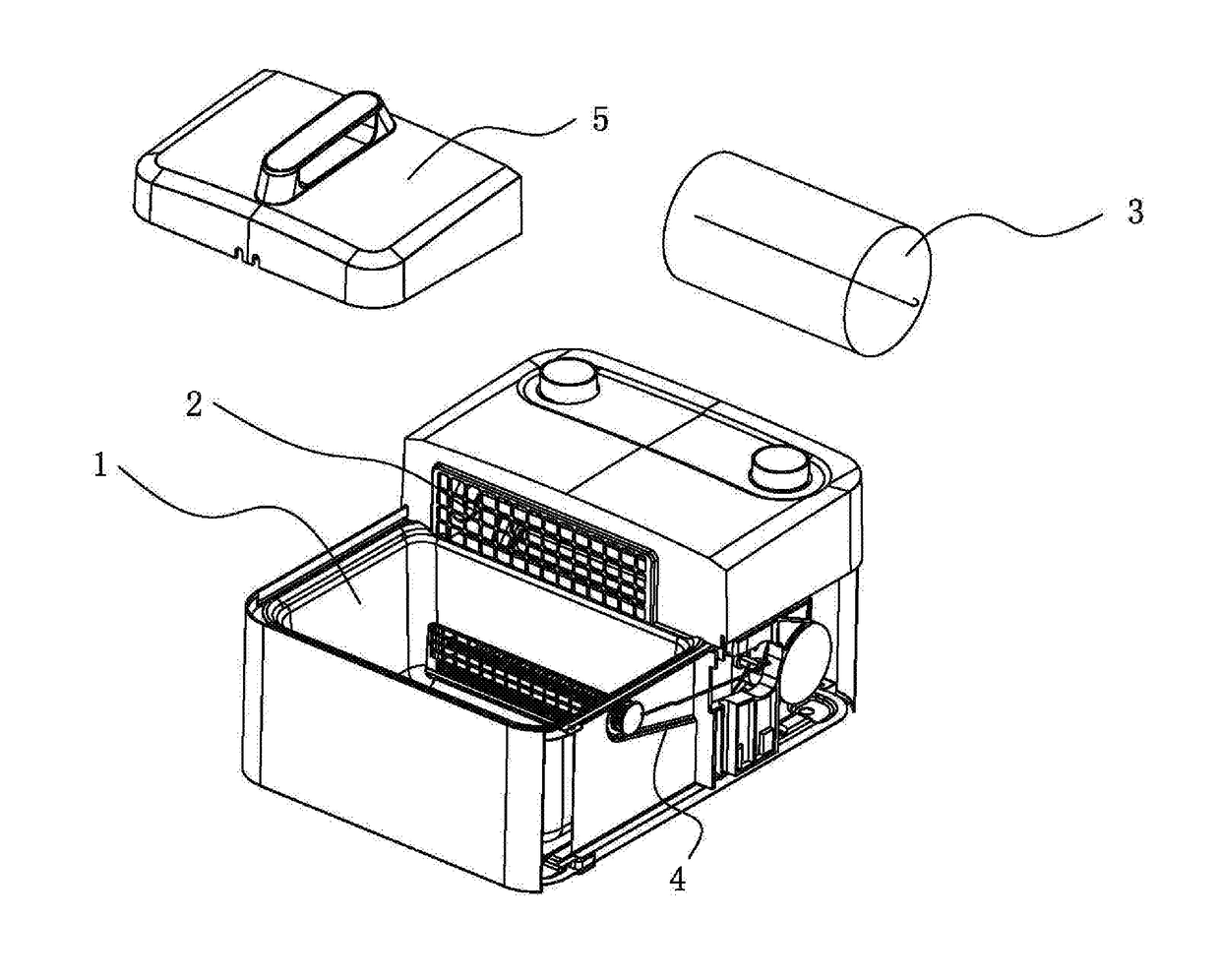

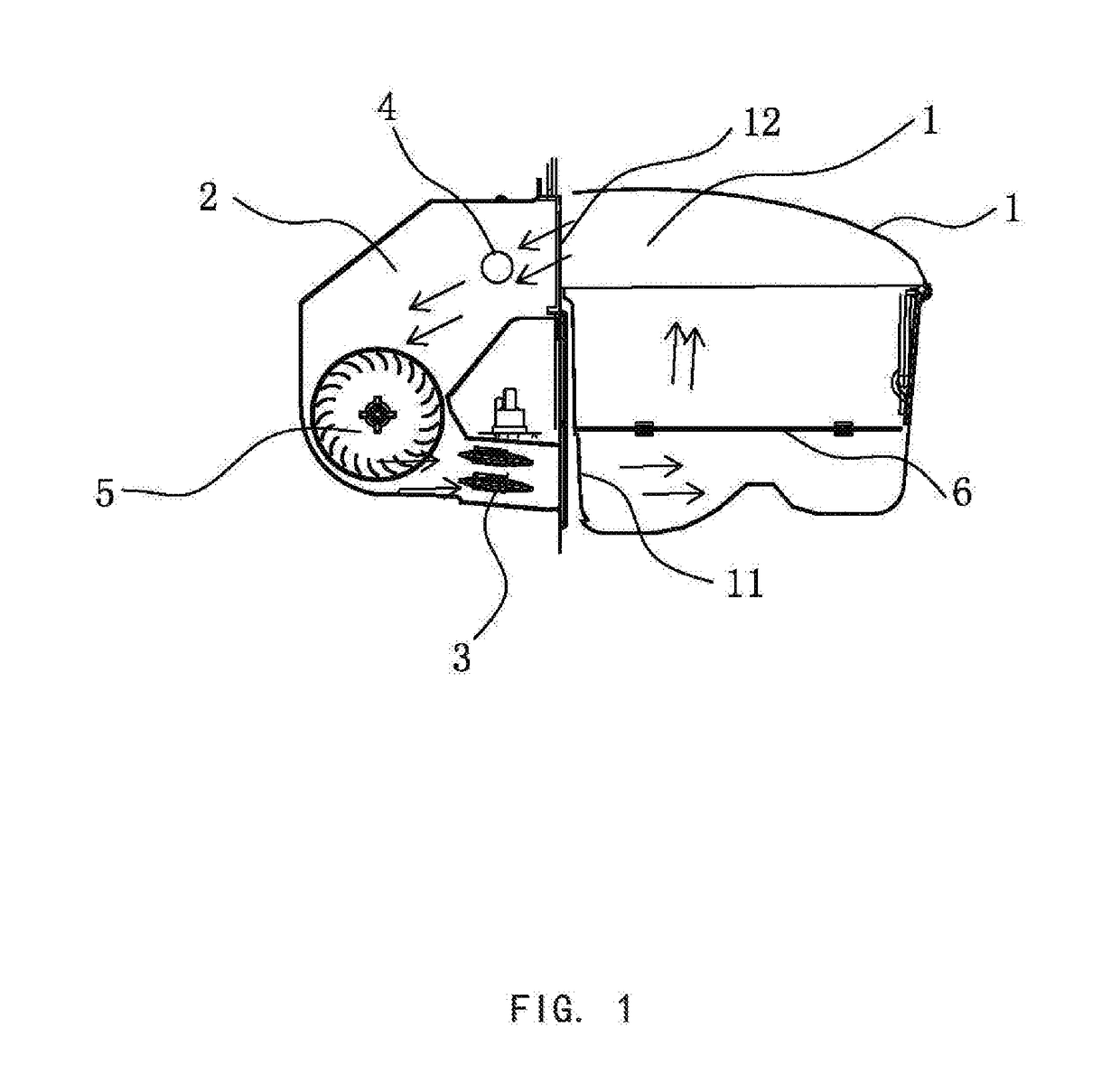

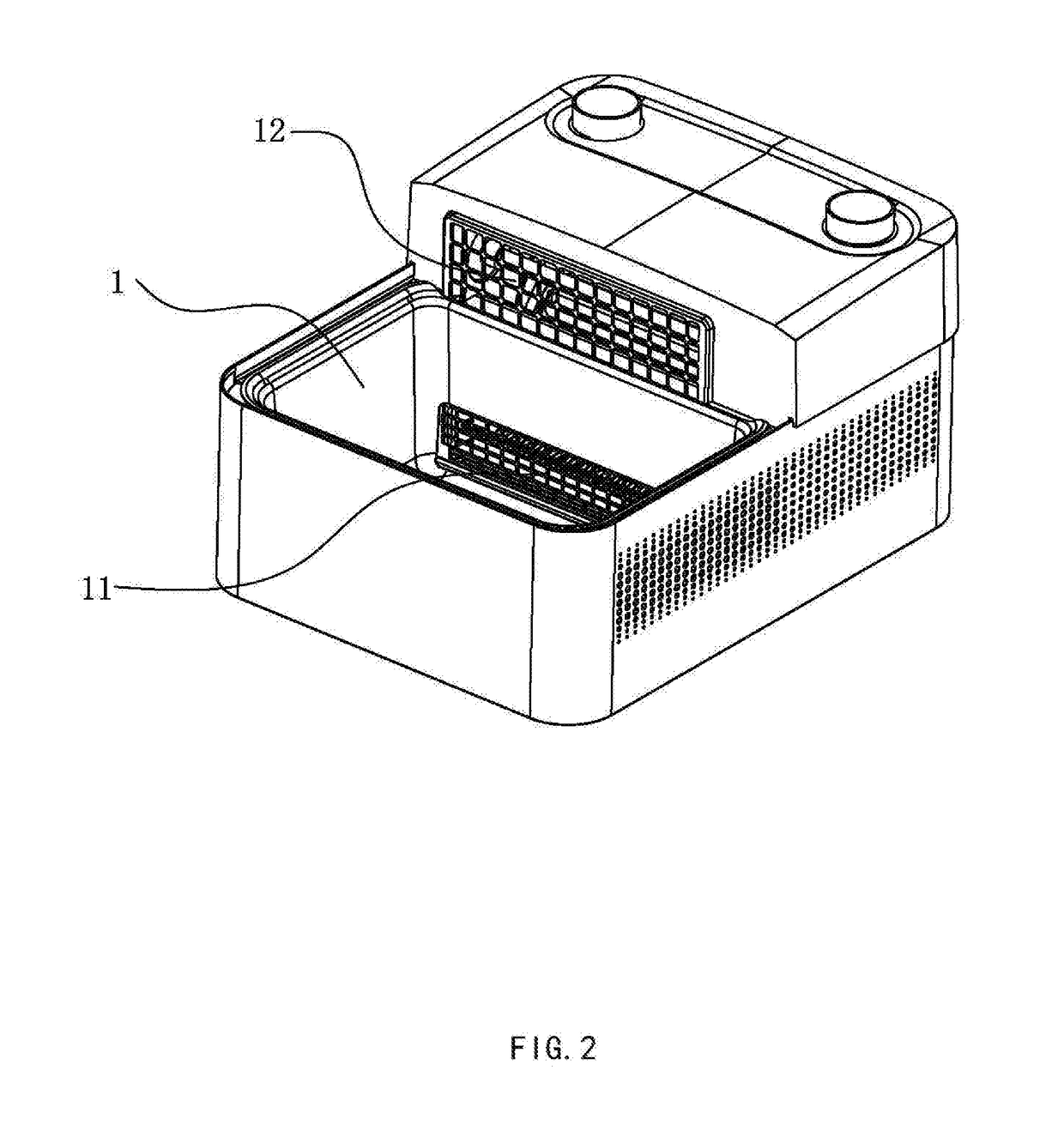

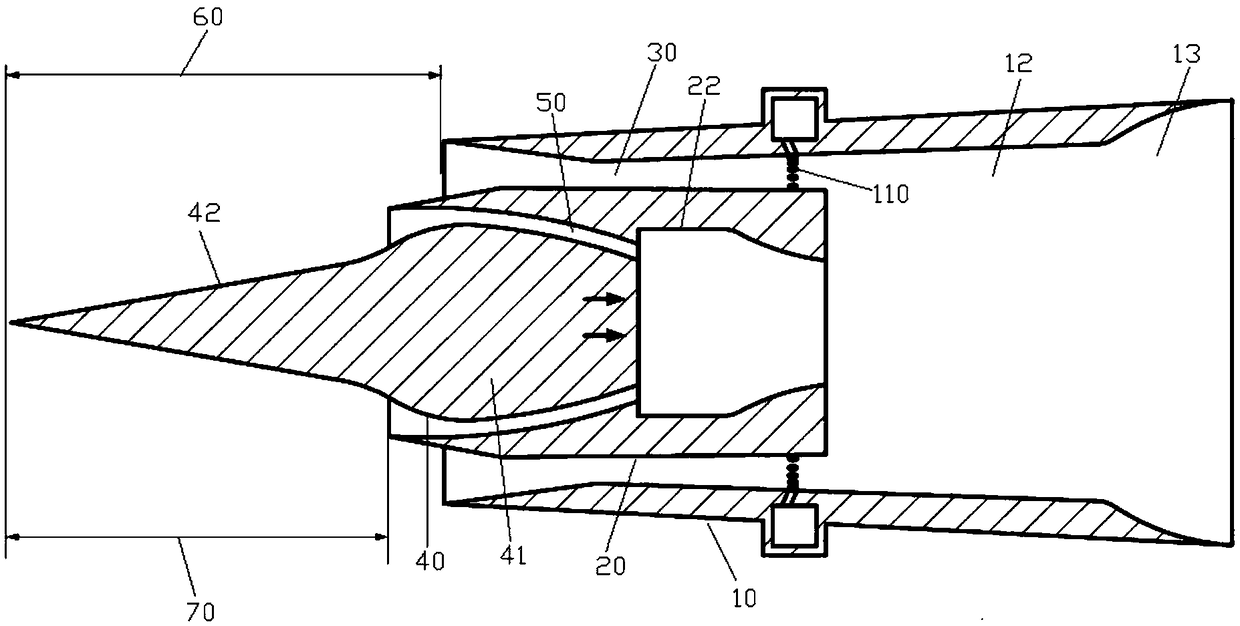

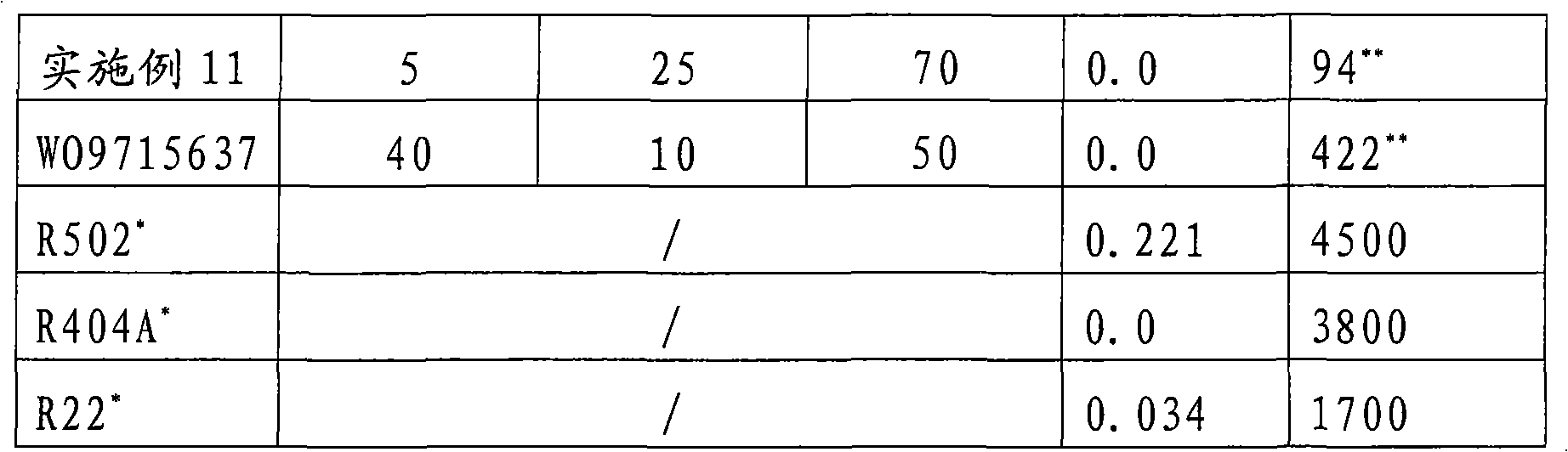

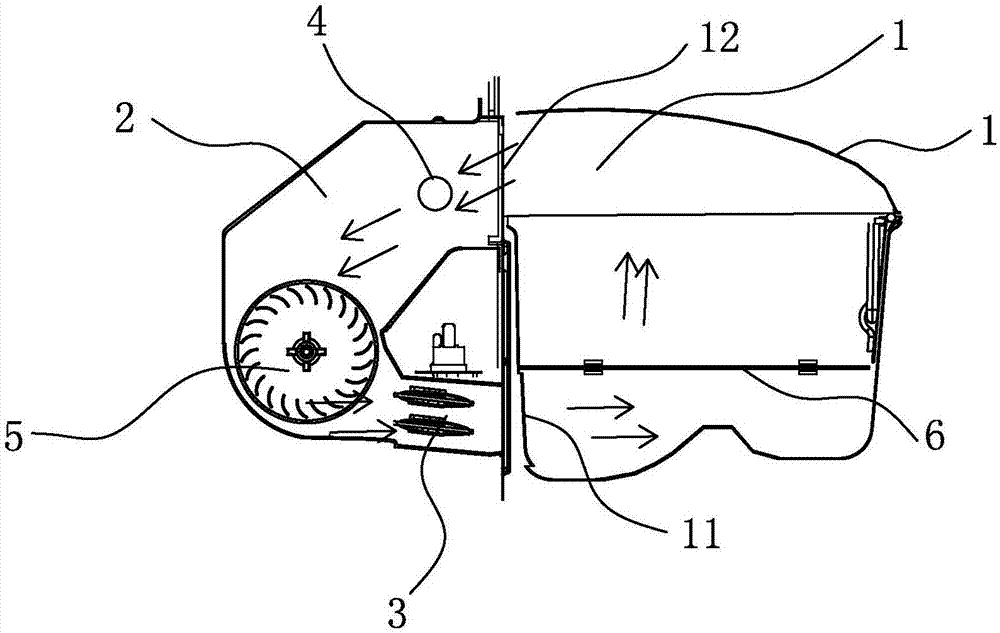

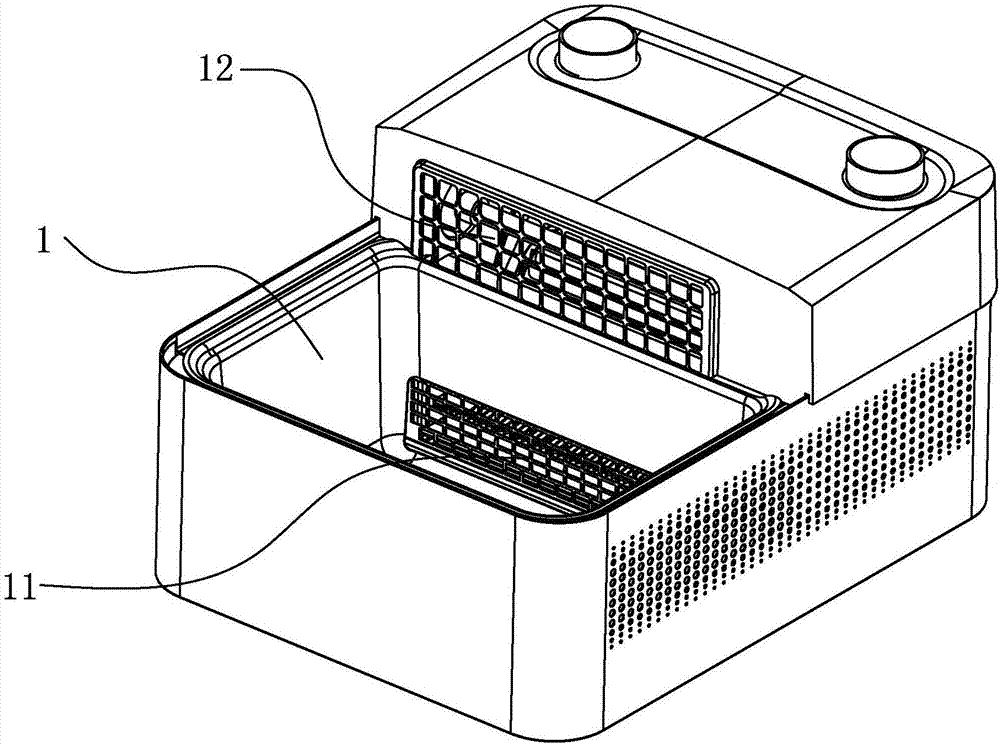

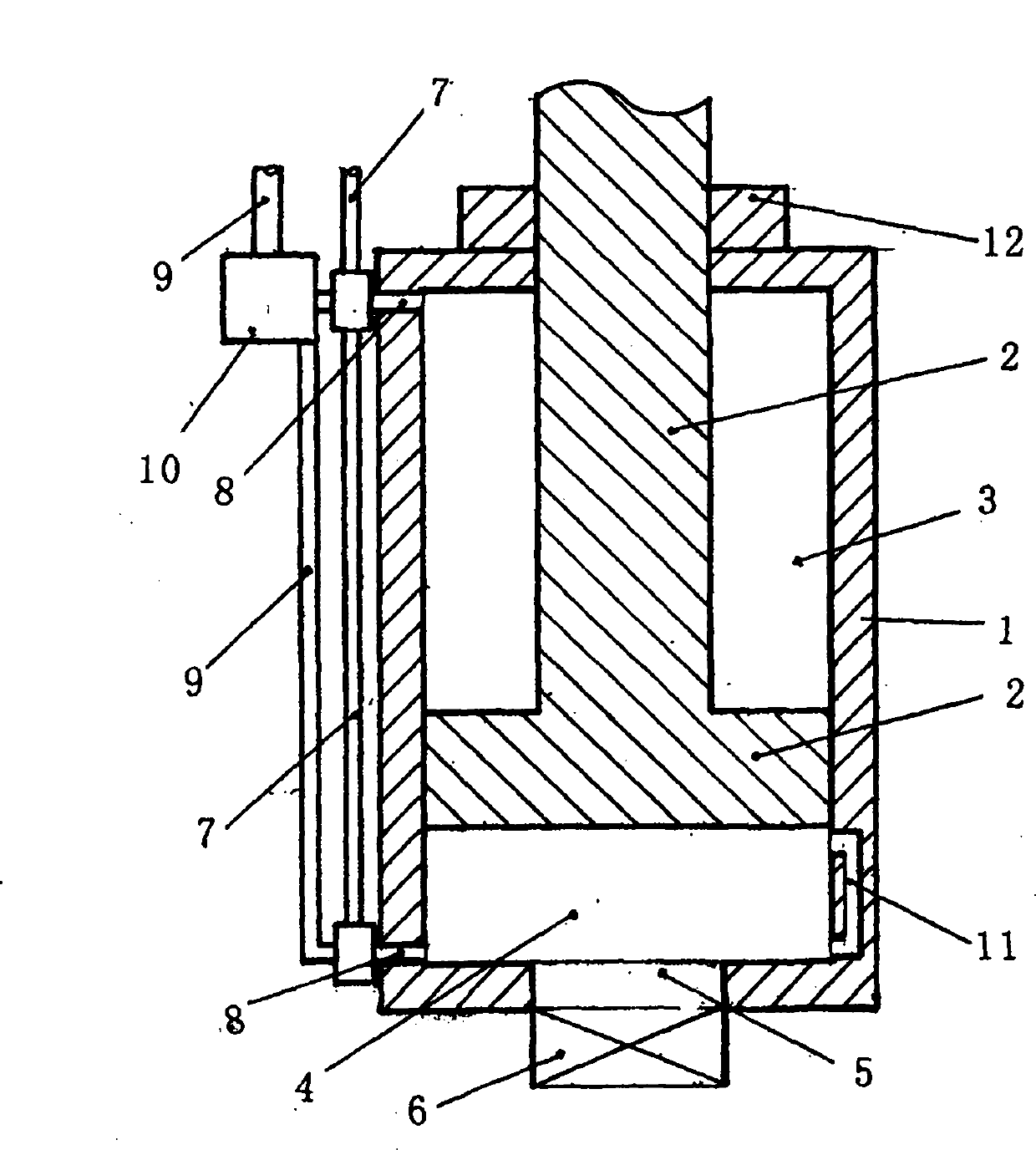

Air fryer

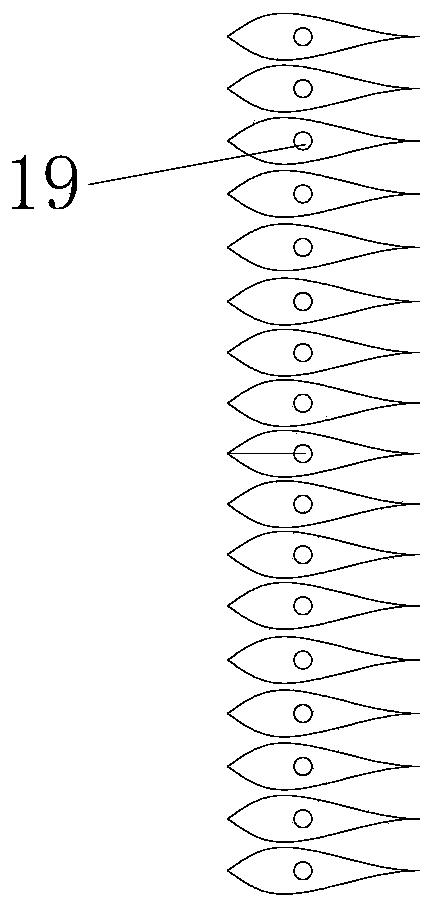

InactiveUS20180303285A1Improve thermal cycle efficiencyDrawback can be solvedCooking-vessel lids/coversRoasters/grillsImpellerHorizontal axis

The present invention discloses an air fryer, which comprises a fryer housing, a first chamber and a second chamber, wherein the first chamber is communicated with the second chamber, a bottom of the first chamber is provided with an air exhaust and a top of the second chamber is provided with an air intake; a heating element, which is arranged in the second chamber; a cross flow fan, which is located in the second chamber, wherein the cross flow fan comprises an impeller with a horizontal axis, and when the cross flow fan is in operation, air passes through the air intake horizontally and exits the air exhaust horizontally. The air fryer disclosed in the present invention is able to enhance the thermal cycle efficiency and the food could be heated even, crispy and tasting good.

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

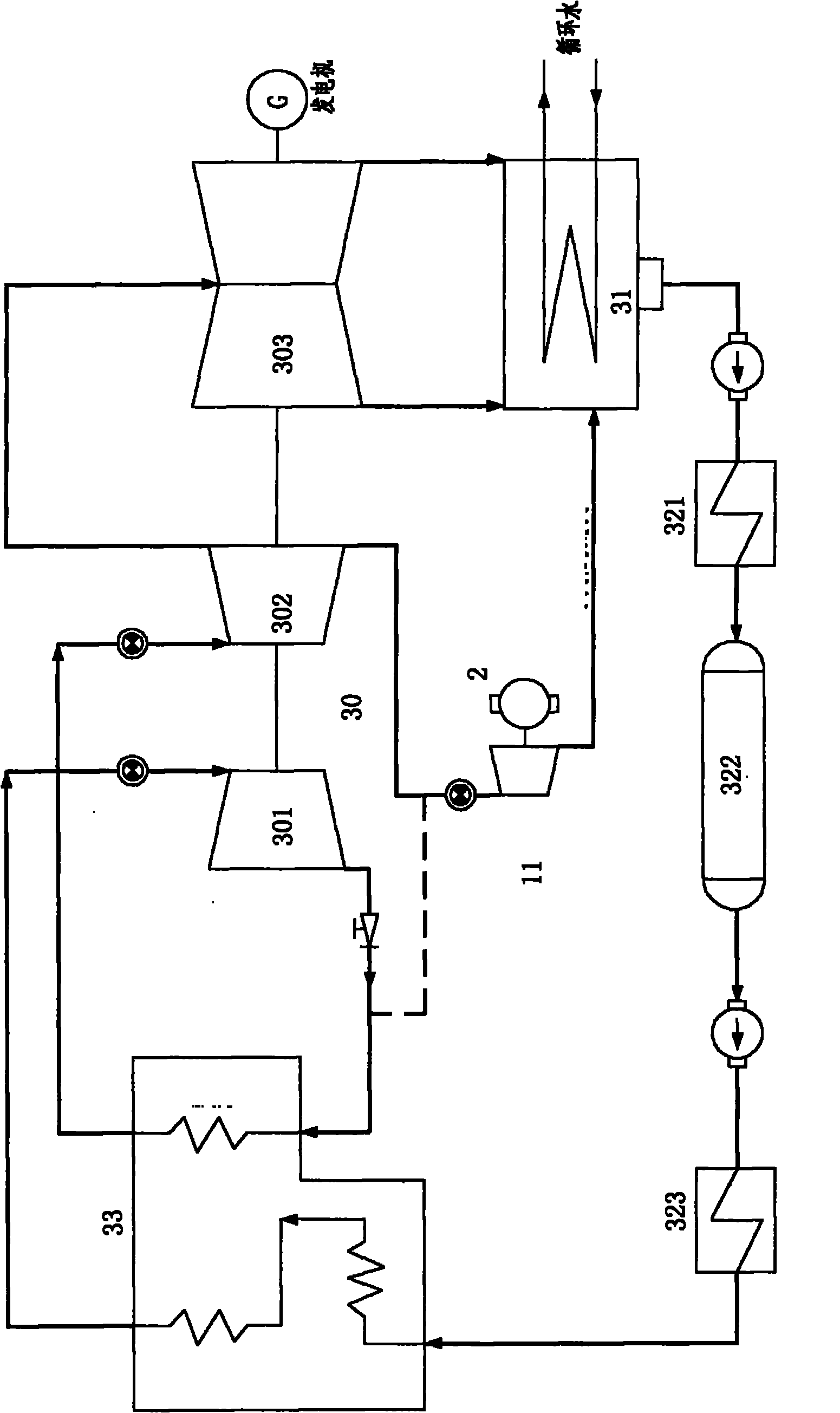

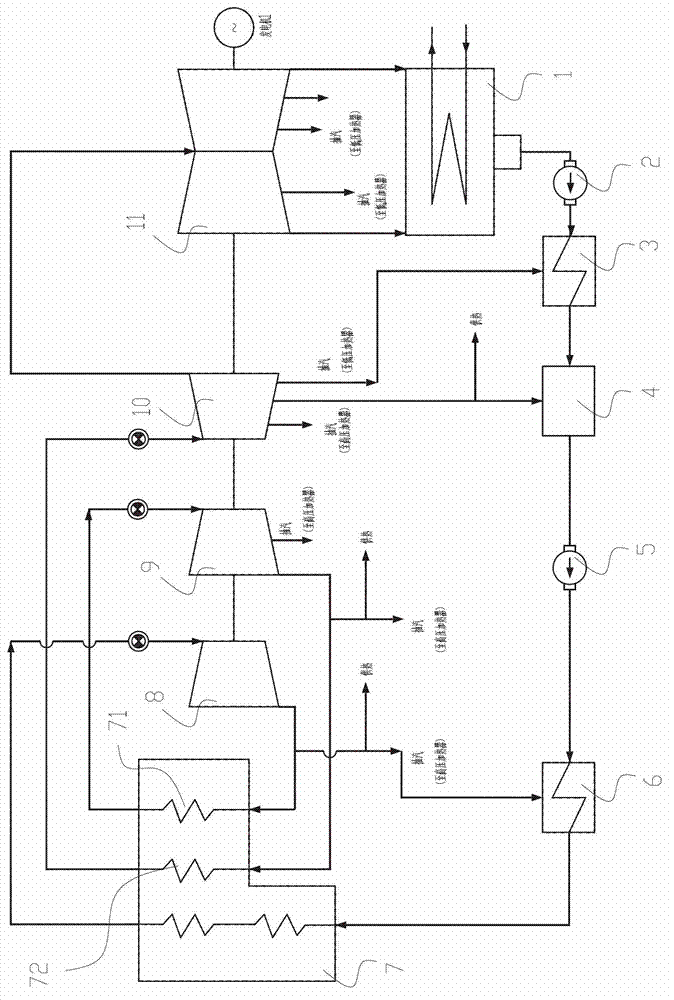

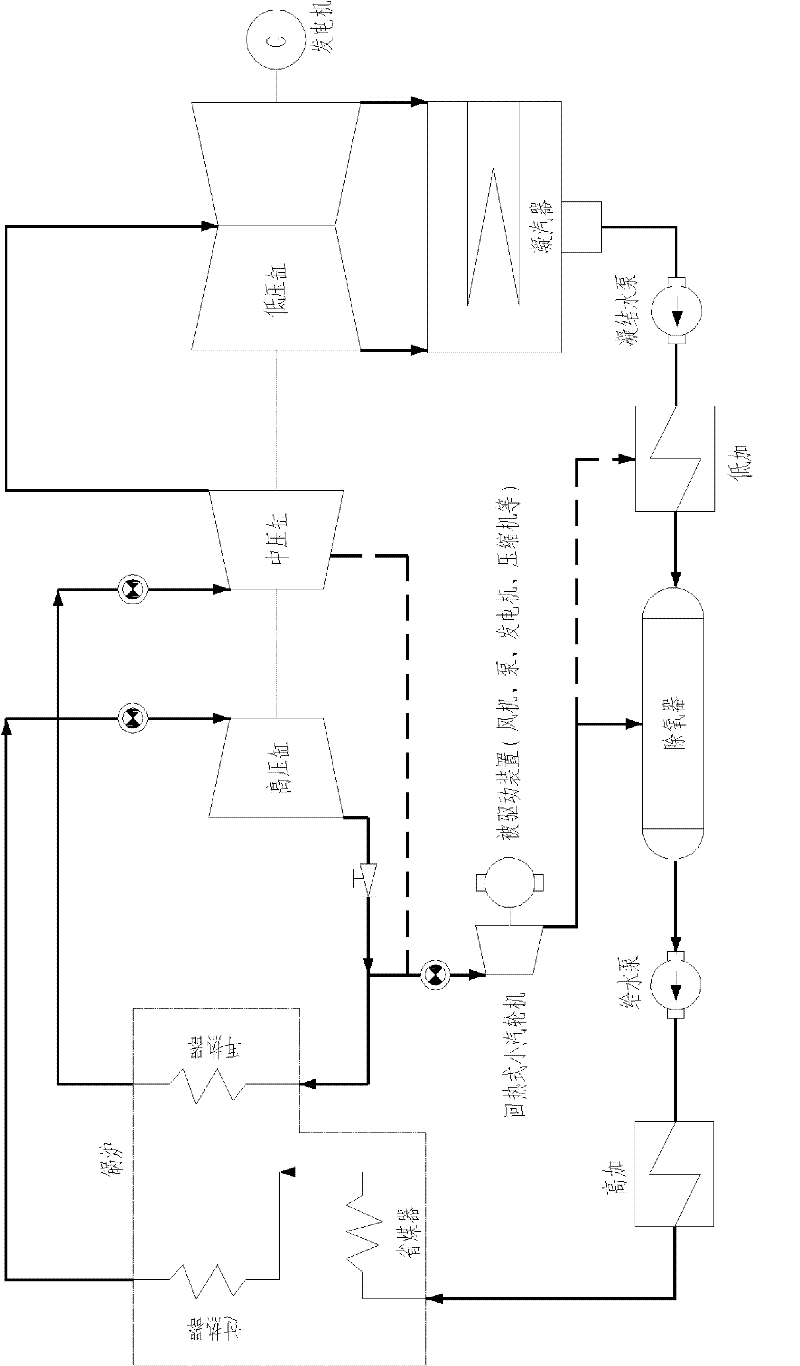

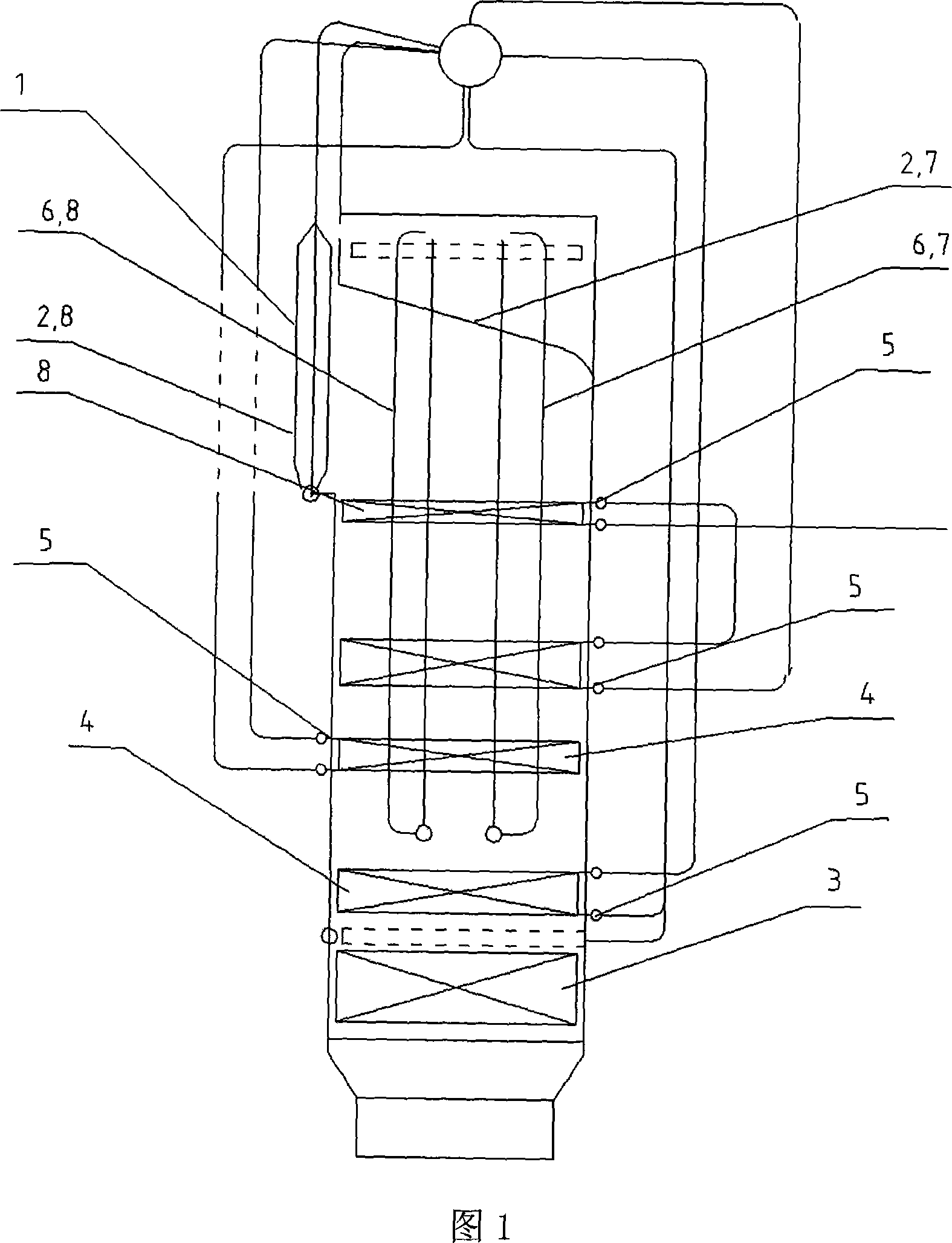

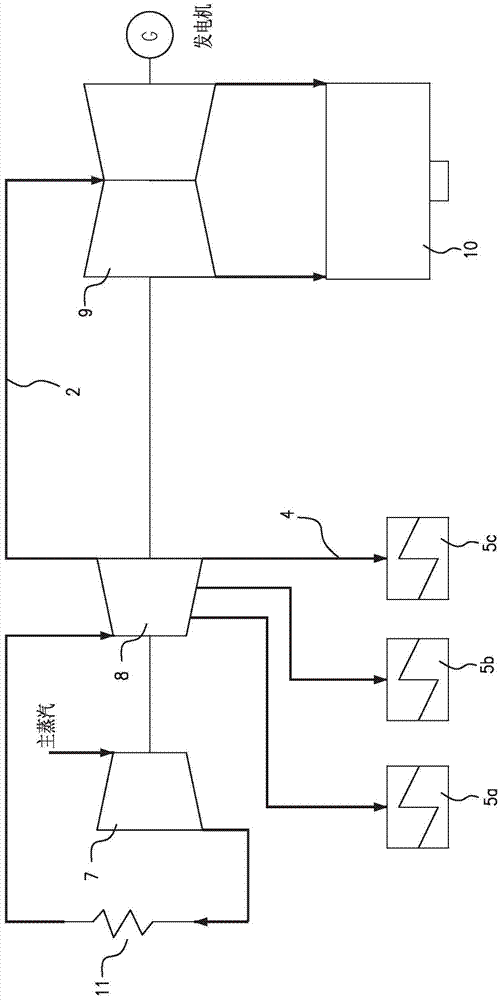

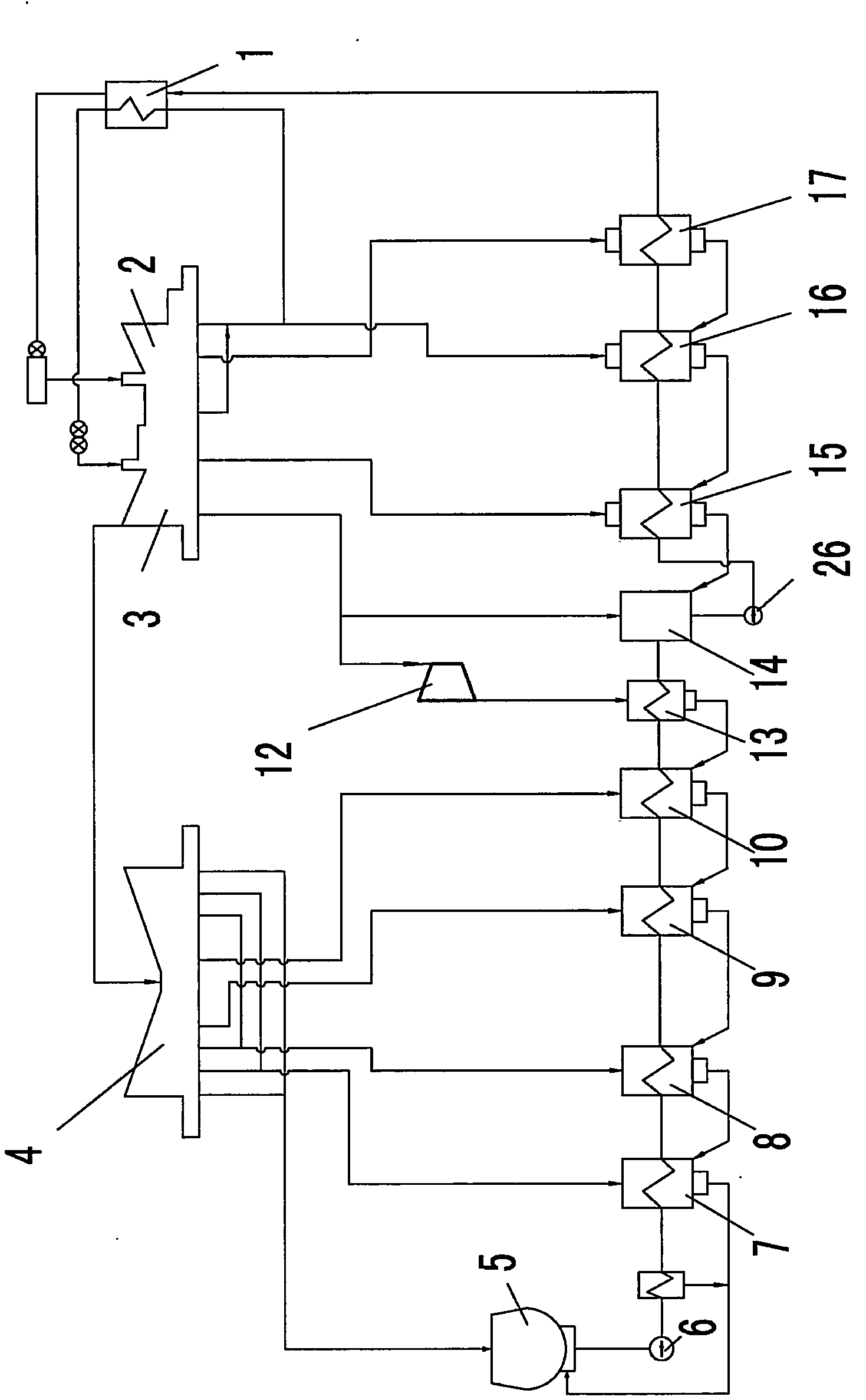

Small turbine system in power plant and thermal cycle system in power plant containing same

InactiveCN101899999ASave electricityImprove power supply efficiencyFeed water supplyEnergy industryPower stationEngineering

The invention provides a small turbine system in a power plant for recovering the exhaust steam heat to the thermal cycle system in the power plant. The system comprises a backheating-type small turbine unit and a driven device driven by the backheating-type small turbine unit. The backheating-type small turbine unit comprises a small turbine, a small turbine admission pipe system and a small turbine exhaust pipe system. The small turbine admission pipe system is arranged on the upstream of the small turbine and receives steam source from the thermal cycle system in the power plant; the small turbine exhaust pipe system is arranged on the downstream of the small turbine; the exhaust steam of the small turbine exhaust pipe system enters to the backheating unit of the thermal cycle system in the power plant so that the exhaust heat is recovered. The invention further provides a backheating system and a thermal cycle system in the power plant containing the small turbine system in the power plant. The systems can greatly improve the power supply efficiency of the unit.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

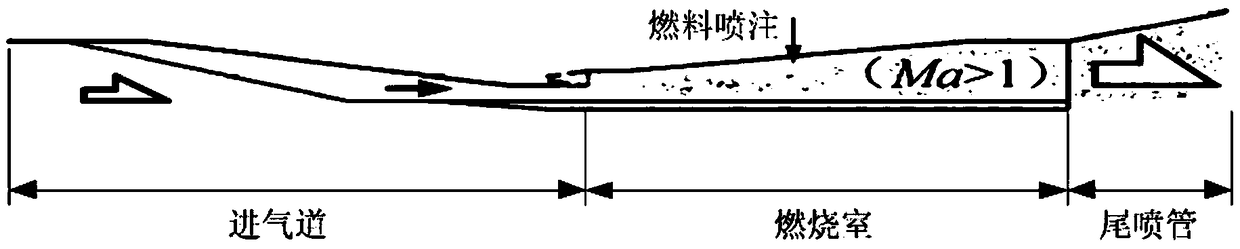

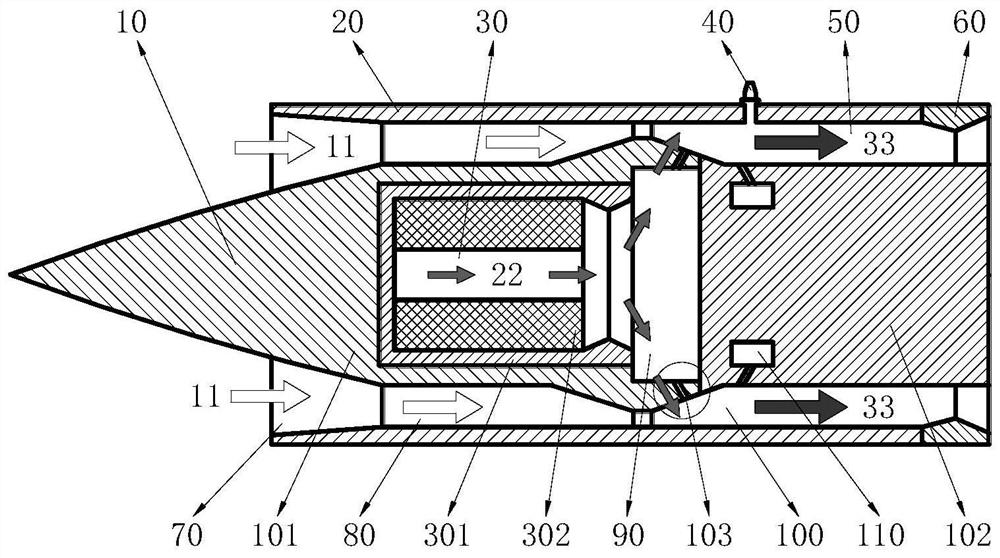

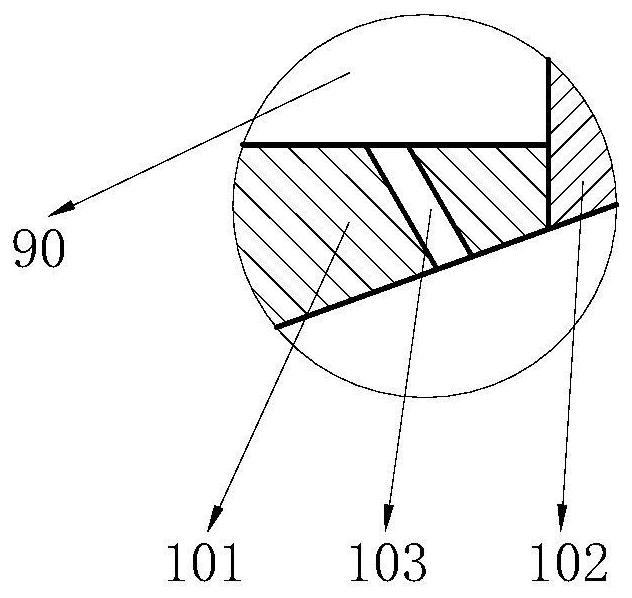

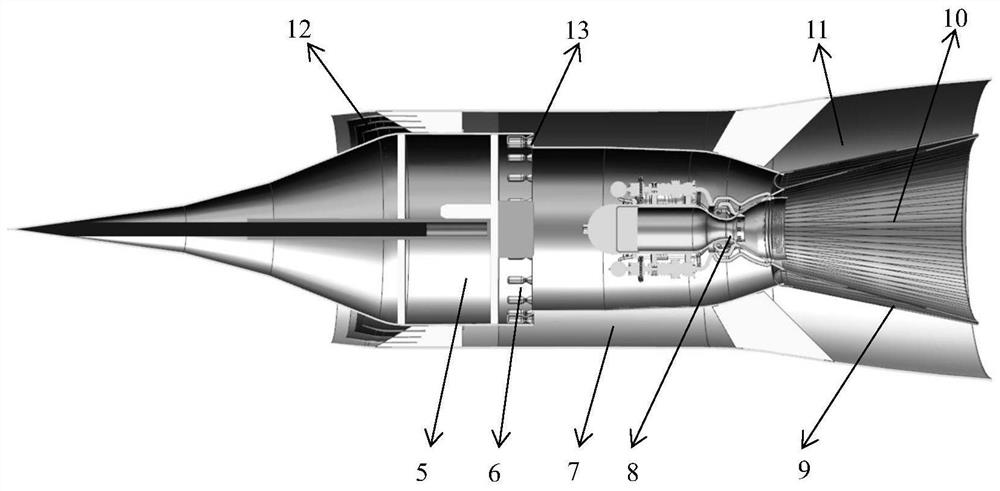

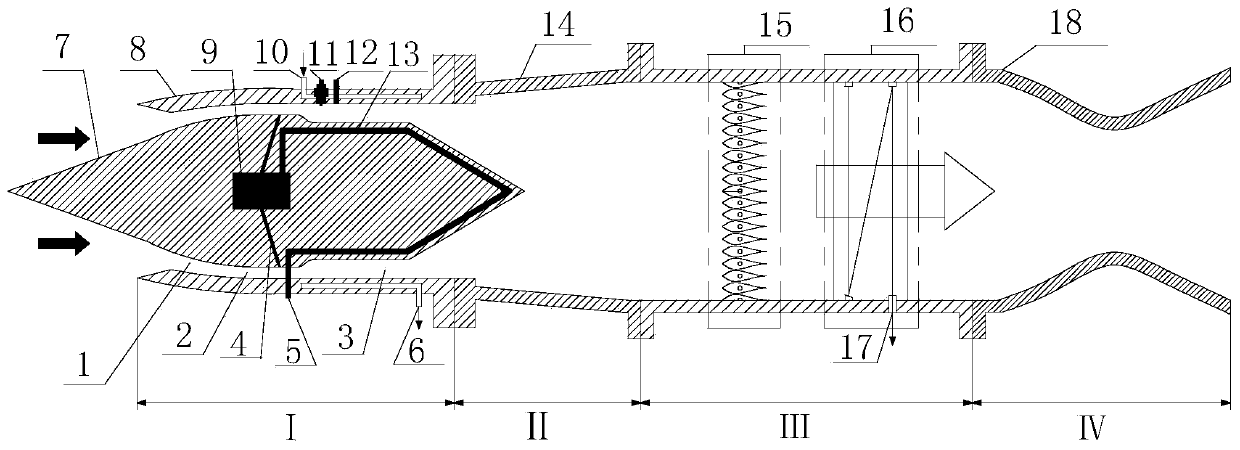

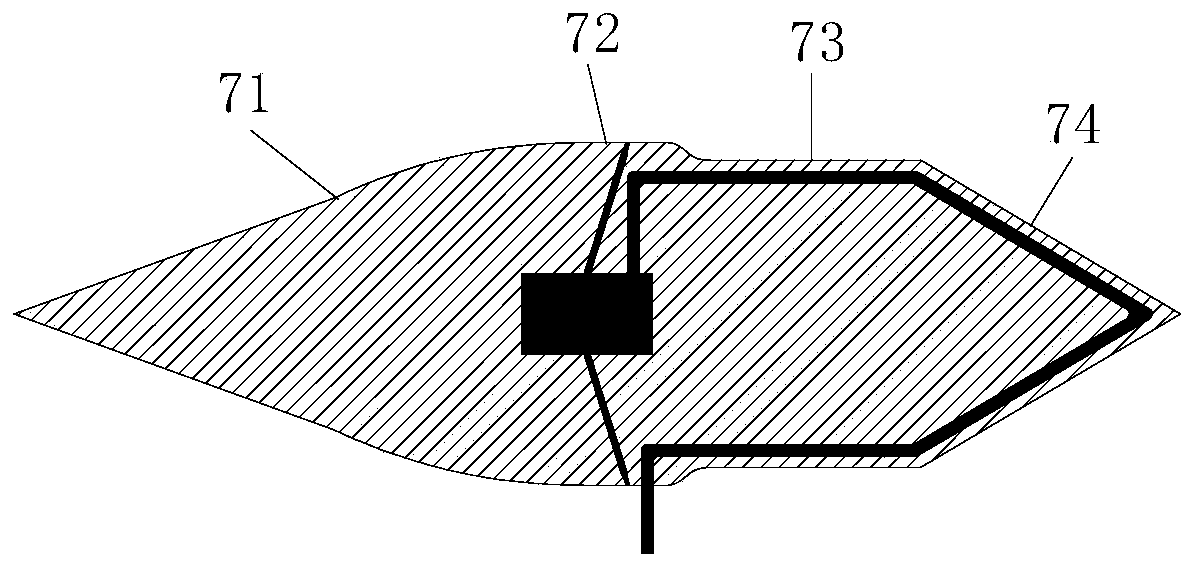

Combined cycle engine and hypersonic aircraft

ActiveCN108757179AThe overall structure is simpleImprove efficiencyTurbine/propulsion engine coolingGas turbine plantsFuel supplyRamjet

The invention discloses a combined cycle engine and a hypersonic aircraft which includes a rotary detonation ramjet engine and a rocket engine arranged therein. The rotary detonation ramjet engine includes a shell and a conical inner body, wherein the shell is in a hollow cylindrical shape and two ends communicate, and the after body of the conical inner body stretches into the shell from an air inlet end of the shell and is connected with the shell. And a gap between the shell and the after body forms a drainage channel for air to be led in the shell. A cavity between the rear end surface ofthe after body and the inner wall of the shell forms a detonation chamber which communicates with the drainage channel, and a first exhaust nozzle communicates with the detonation chamber. The rocketengine includes a combustion chamber arranged in the conical inner body, a second exhaust nozzle communicating with the combustion chamber, and the nozzle of the second exhaust nozzle communicates with the detonation chamber. The outer wall of the shell is machined with an outer nozzle, the two ends of the outer nozzle correspondingly communicates with a fuel supply device and the drainage channel. The outer wall of and / or the after body is machined with multiple internal nozzles, two ends of the internal nozzles correspondingly communicate with the fuel supply device and the drainage channel.

Owner:NAT UNIV OF DEFENSE TECH

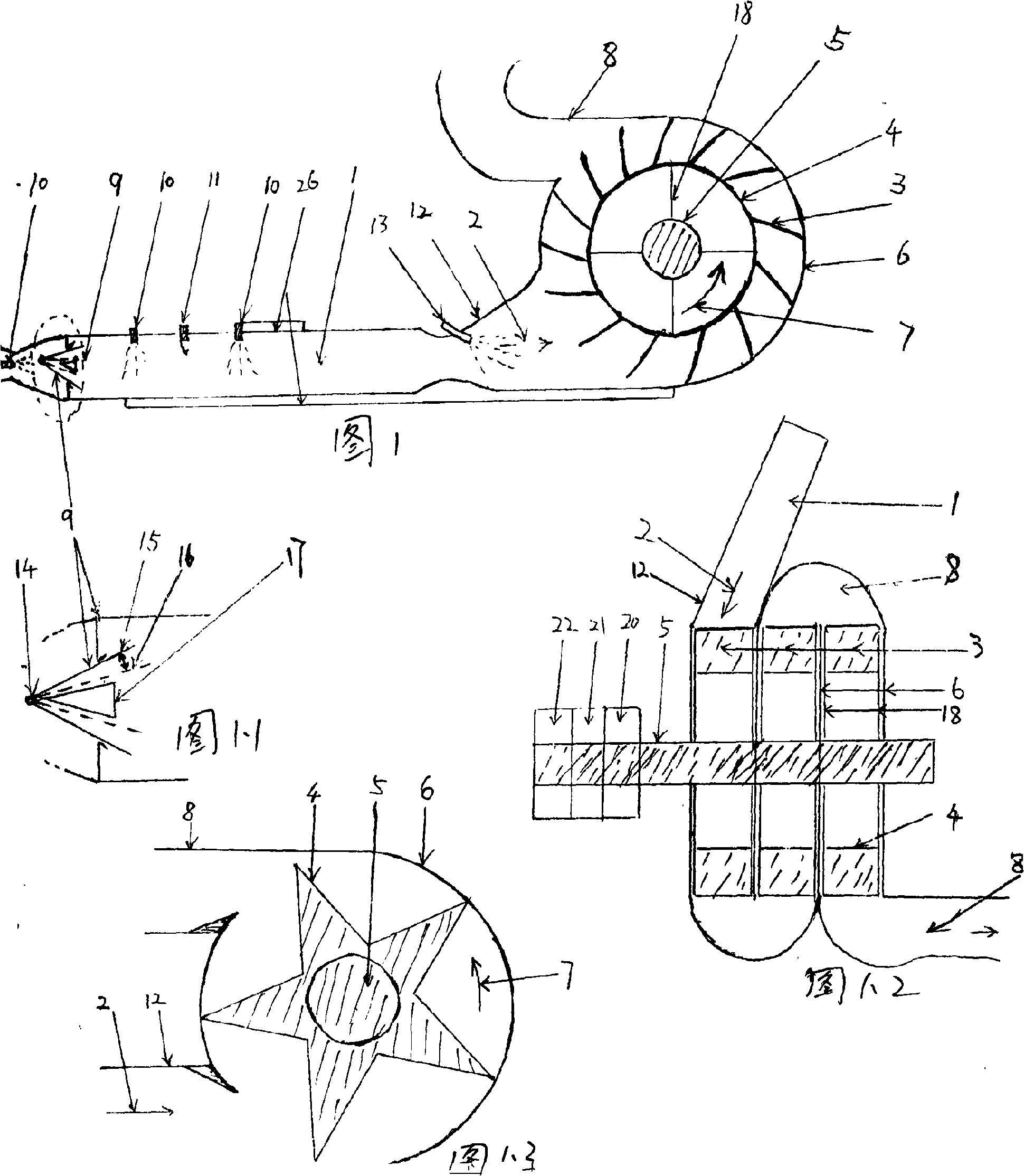

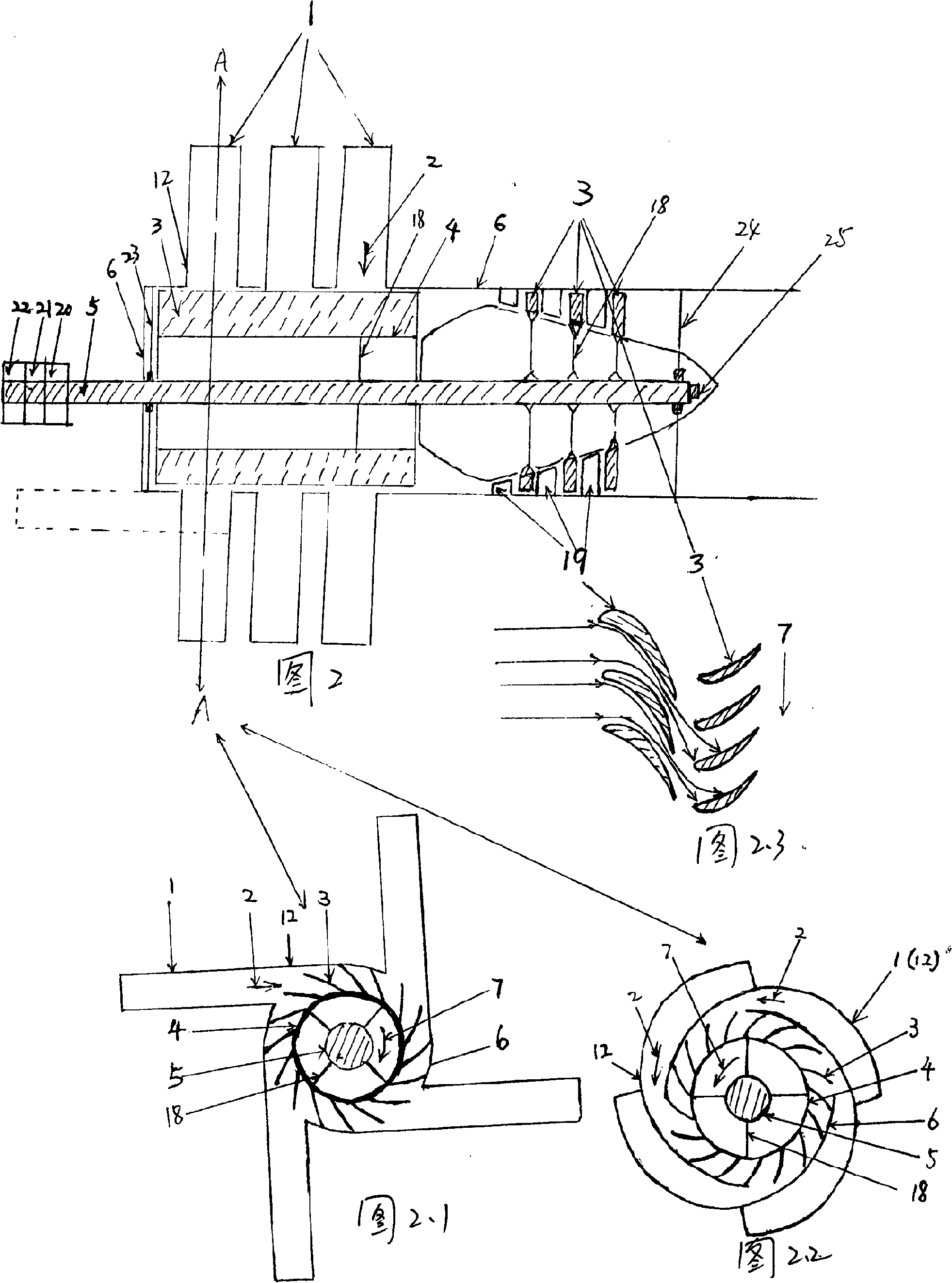

Pulse knock rotor spindle engine

InactiveCN101338702AIncrease useSingle purposeTurbine/propulsion engine coolingGas turbine plantsHigh pressureSubmarine

The present invention relates to a pulse detonation rotor shaft engine. In the technical proposal, the pulse detonation rotor shaft engine mainly consists of a pulse detonation engine, a rotor and an output shaft; propulsive gas with the high temperature and high pressure expansion of pulse which is ejected when the pulse detonation engine works is used as a power source to push the rotor to rotate; the rotor drives the output shaft to rotate; a pulse detonation rotor shaft engine uses the output shaft to output most energy produced by the pulse detonation engine by outputting torsion continuously; the output shaft drives various kinds of loads to work. The pulse detonation rotor shaft engine has the beneficial effects as follows: firstly, the pulse detonation rotor shaft engine can be used as a shaft engine to be widely applied in various kinds of dynamic systems, such as ship, submarine, tank, tractor, automobile, train, and the like and has wide purposes; secondly, the pulse detonation rotor shaft engine overcomes the disadvantage of the large noise of the prior pulse detonation engine; thirdly, compared with a piston type engine, the pulse detonation rotor shaft engine has the obvious advantages of simple structure, low cost, high reliability, long service life, light weight, less fraction resistance loss, etc.

Owner:RUGAO HUAYANG ALUMINUM PROD

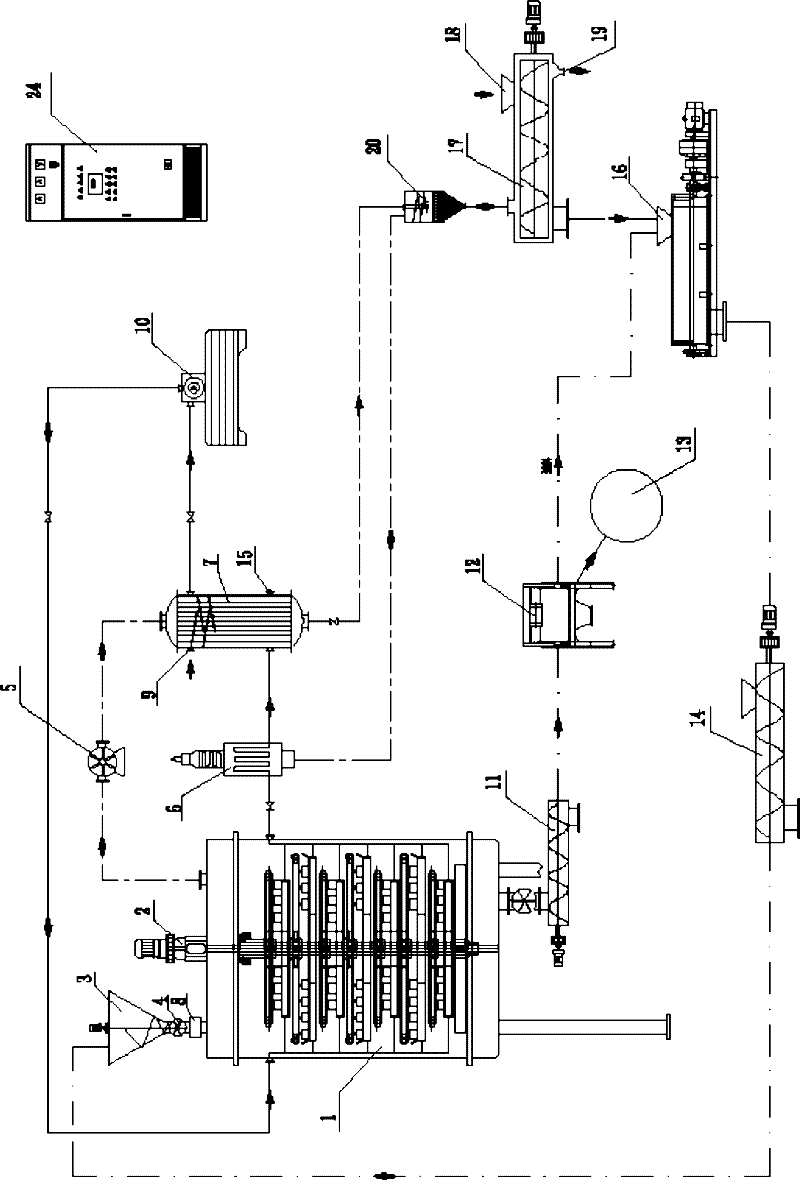

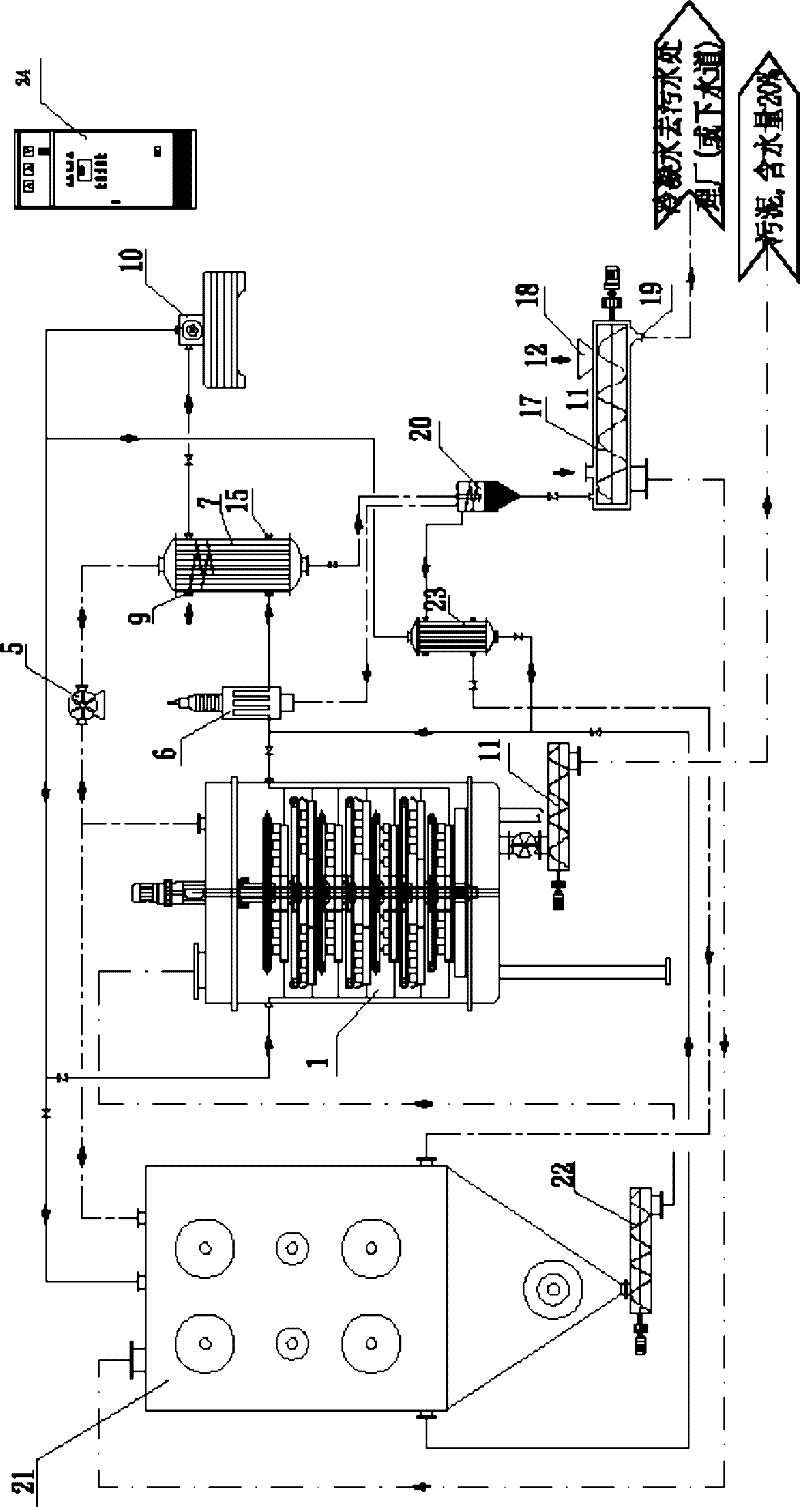

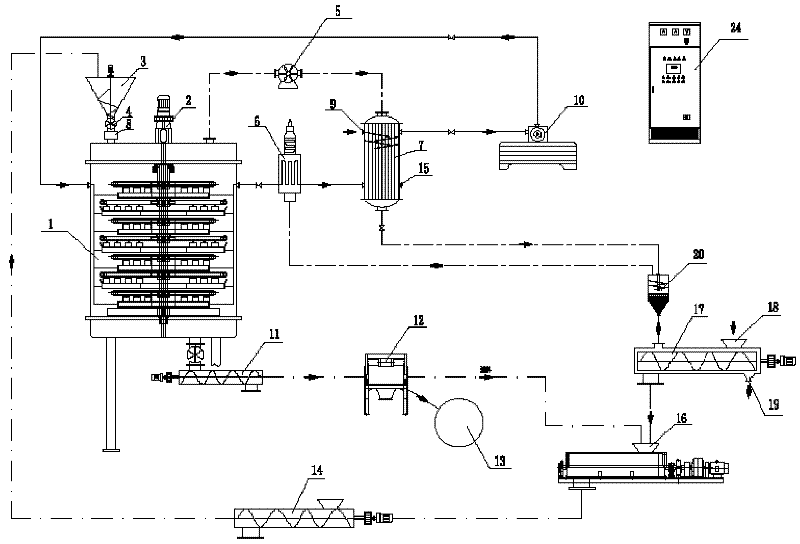

Separated thermal cycle sludge dry method and device thereof

InactiveCN102311216AReduce energy consumptionGuaranteed uptimeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningIsolation effectWorking fluid

The invention relates to a treatment technique of sludge produced by sewage treatment, in particular to a separated thermal cycle sludge dry method and a device thereof. The method comprises the following steps: putting wet sludge in a drying tank for drying, leading out the steam produced by drying through a fan, letting the steam enter an evaporator be condensed into water, letting the peripheral water of tubes as working fluid be subject to evaporation to generate secondary steam, compressing the secondary steam by a vapor compressor to heat, then putting the secondary steam processed by heating as an outer heating source of the drying tank in a heat transfer of the drying tank; supplying heat to sludge indirectly, letting the steam after the heat supply be condensed into water, letting the water enter the evaporator through the heat absorption of the tubes of the combustion furnace to form a closed cycle of the working fluid. According to the invention, evaporation latent heat of water and heat value of non-condensable gas are fully recycled, to that the energy consumption is minimized; and because of the isolation effect of the evaporator, the vapor compressor is separated from the products formed by anhydration of the sludge, so that the system can stably run in long-term, and the investment cost is greatly reduced.

Owner:郭少仪 +1

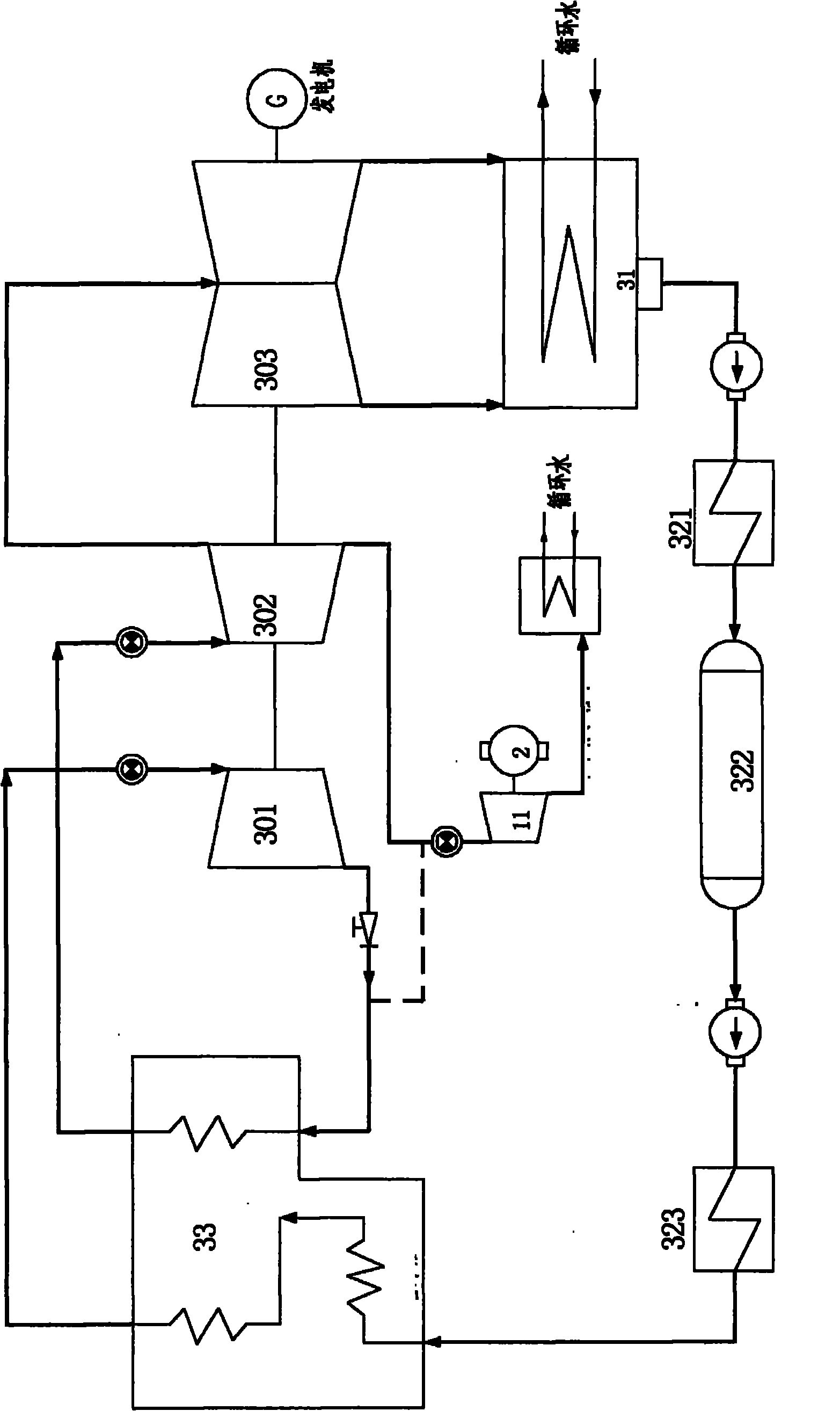

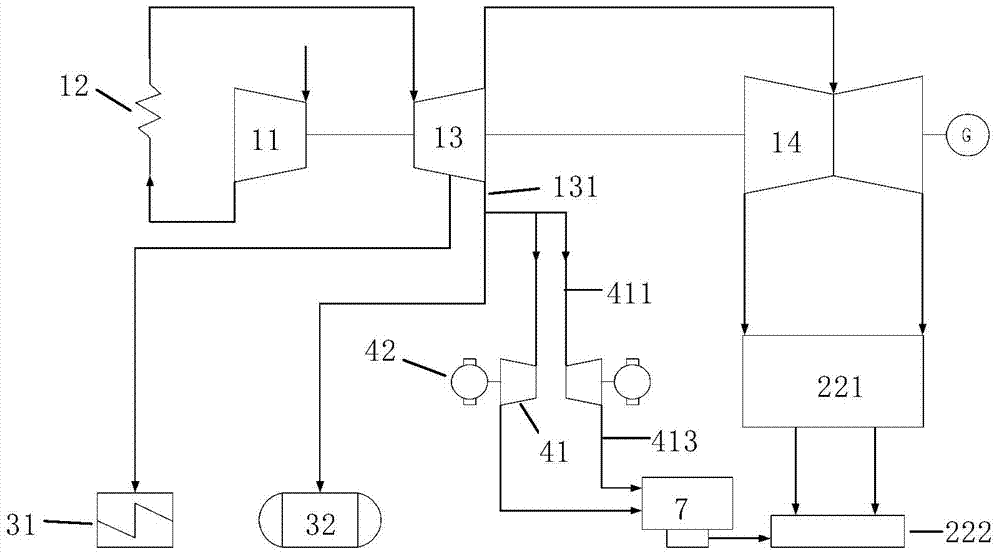

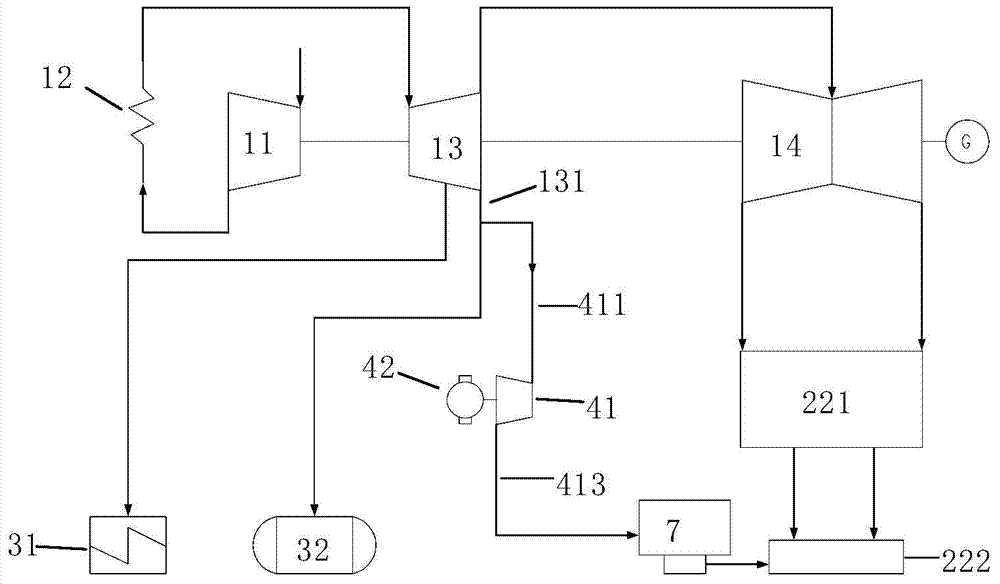

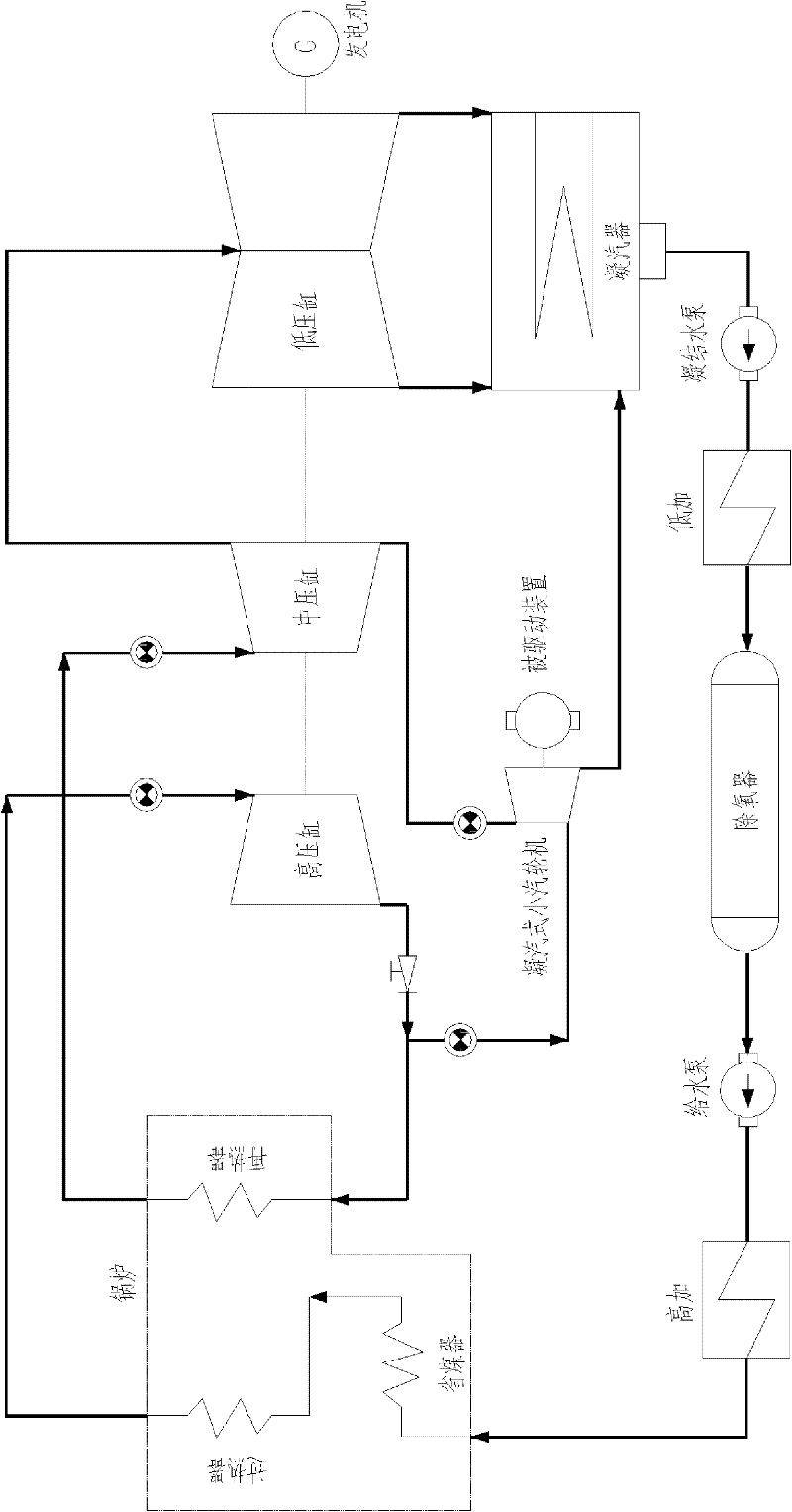

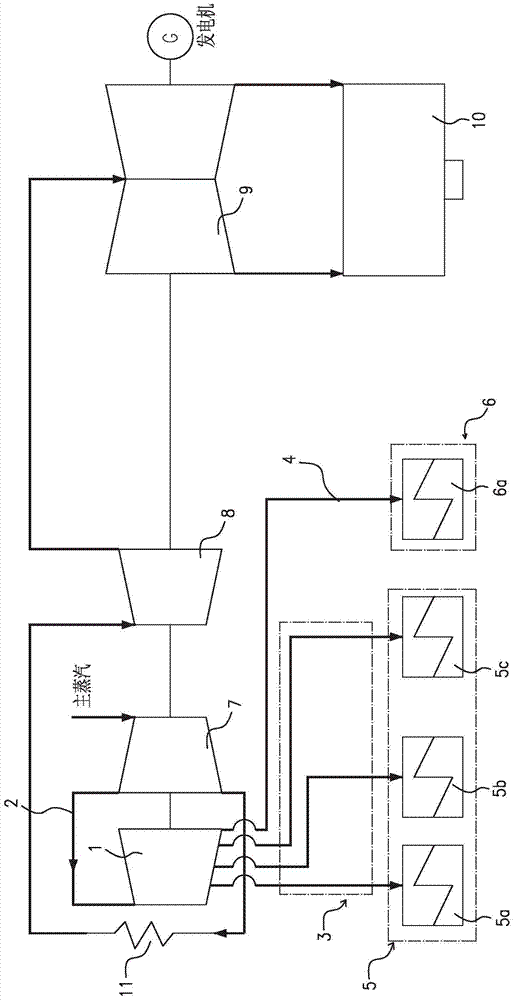

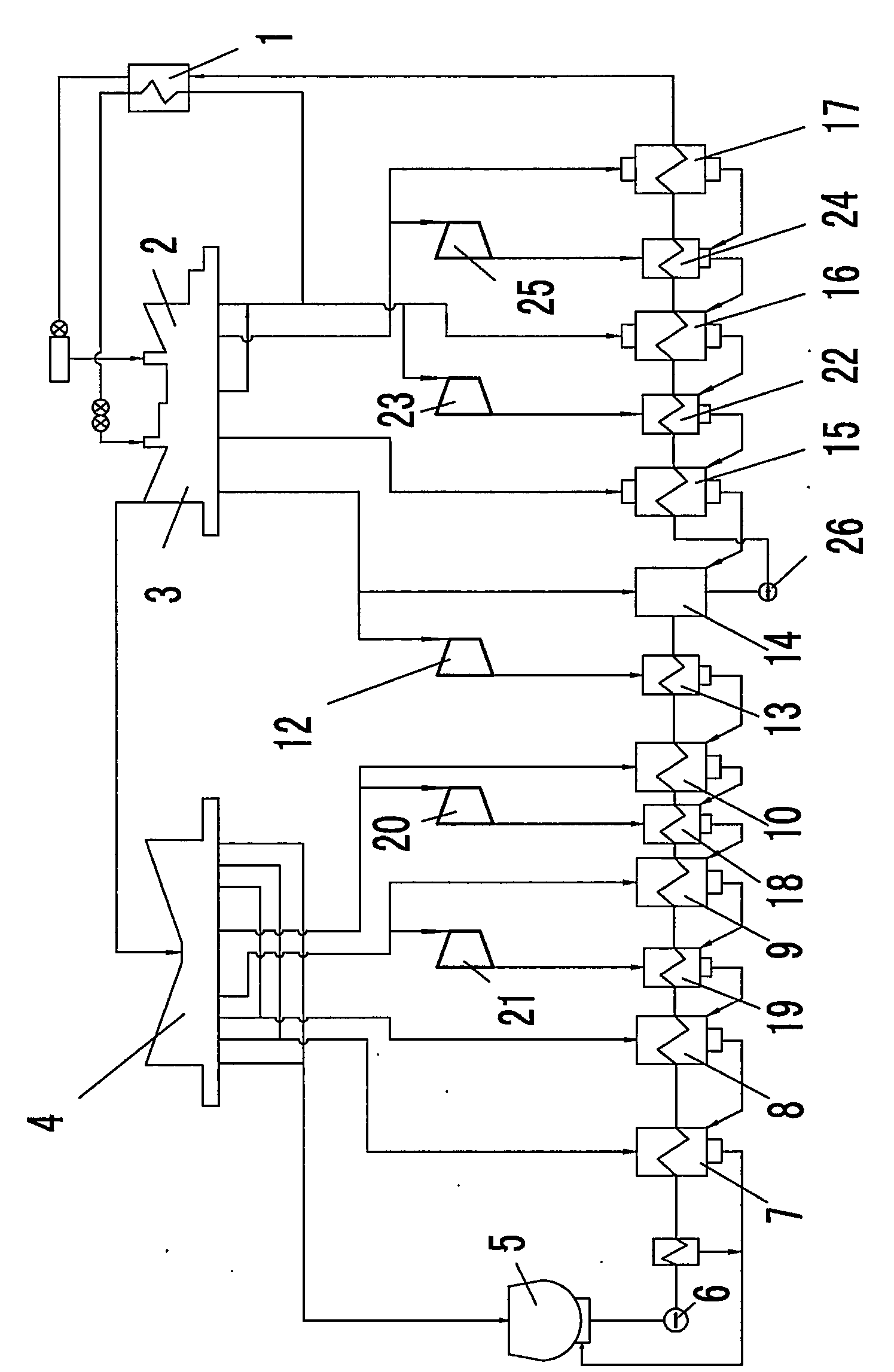

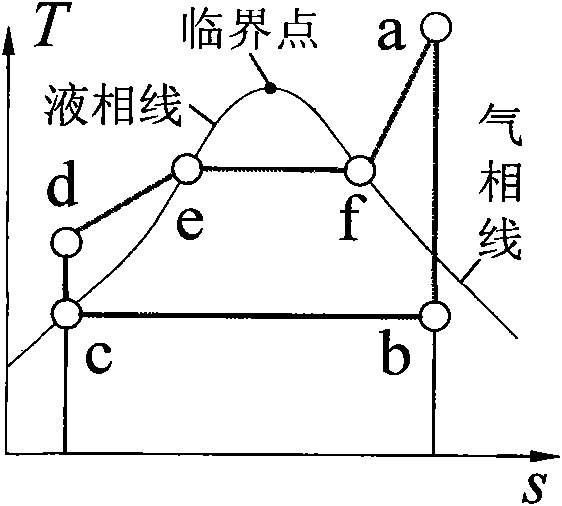

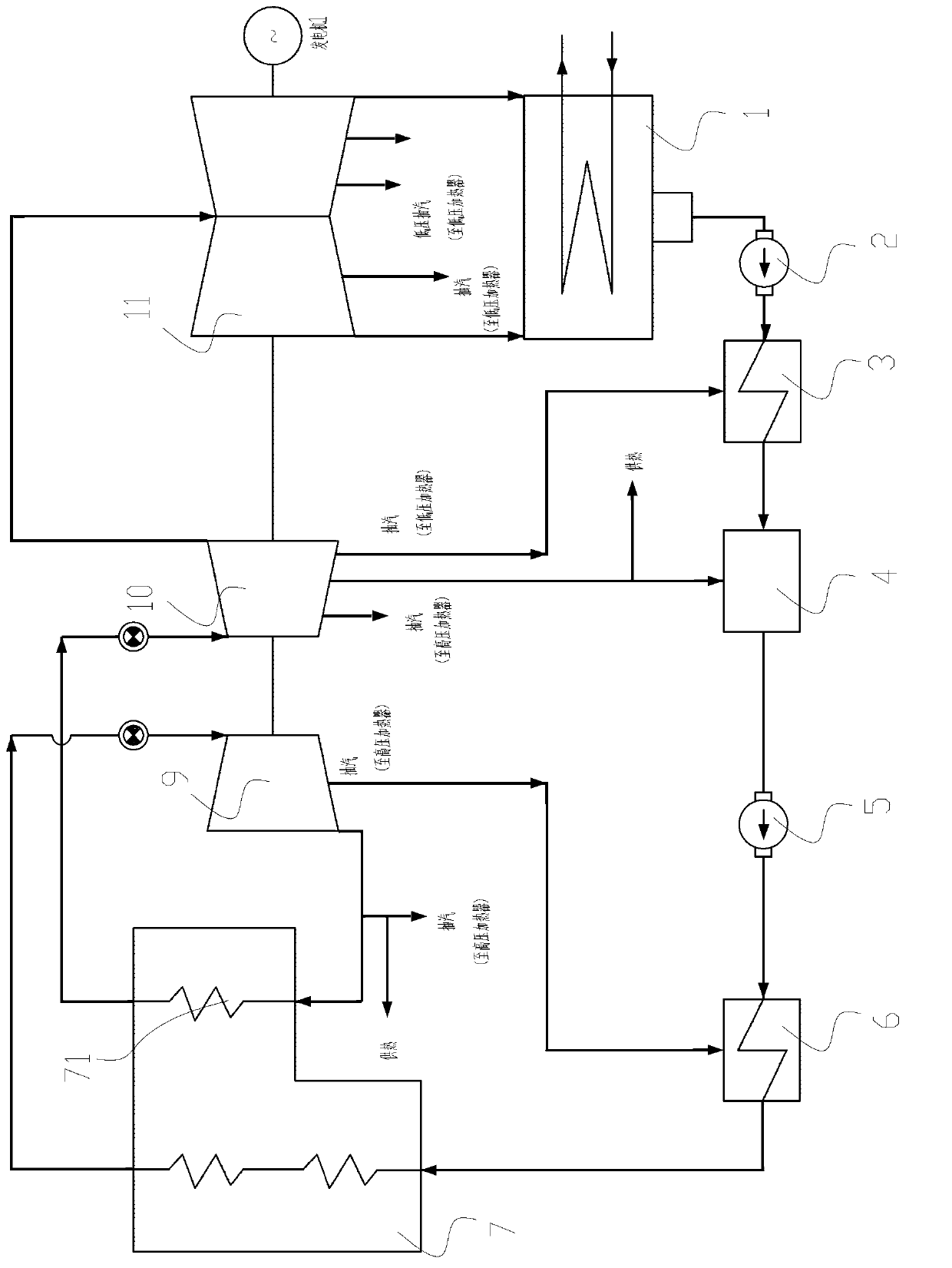

Thermal power plant and united thermodynamic system for thermal power plant

ActiveCN102828791AImprove thermal cycle efficiencyReduce consumptionSteam useCombined combustion mitigationPollutant emissionsDeaerator

The invention discloses a thermal power plant and a united thermodynamic system for the thermal power plant. The thermal power plant comprises a secondary reheating coagulated steam unit and a backpressure unit; the united thermodynamic system comprises a thermodynamic system of the secondary reheating coagulated steam unit and the thermodynamic system of the backpressure unit; a reheating system from a condenser to a deaerator is shared by the thermodynamic system of the secondary reheating coagulated steam unit and the thermodynamic system of the backpressure unit; the condensed water of the secondary reheating coagulated steam unit and the replenished desalted water of the backpressure unit pass through the shared reheating system and then are divided into two paths; one path enters the secondary reheating coagulated steam unit; and the other path enters the backpressure unit. The united thermodynamic system provided by the invention can meet the industrial requirements of large capacity and high parameter heat supply; the thermodynamic cycle efficiency is greatly increased; the fuel consumption is reduced; the pollutant emission is reduced; and meanwhile, the investment of the thermal power plant is greatly reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

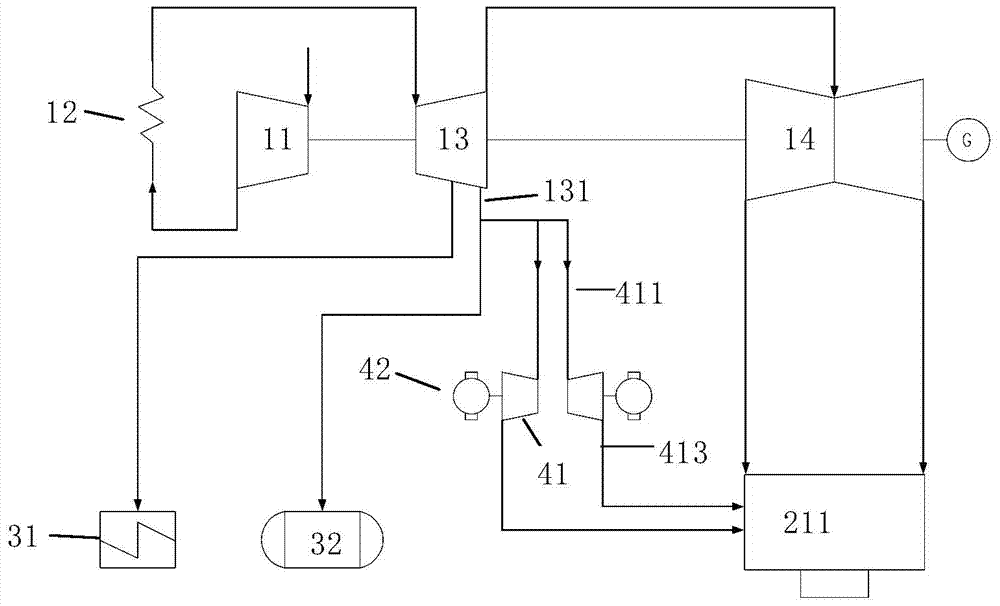

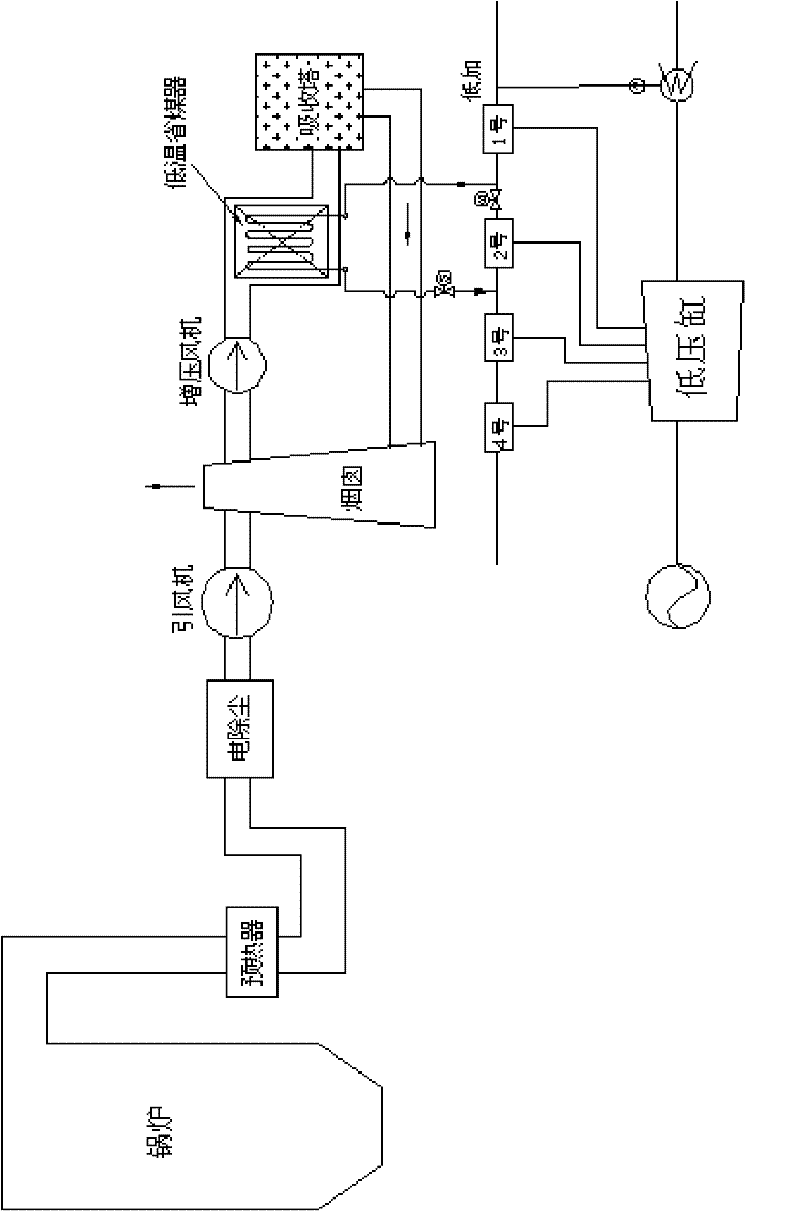

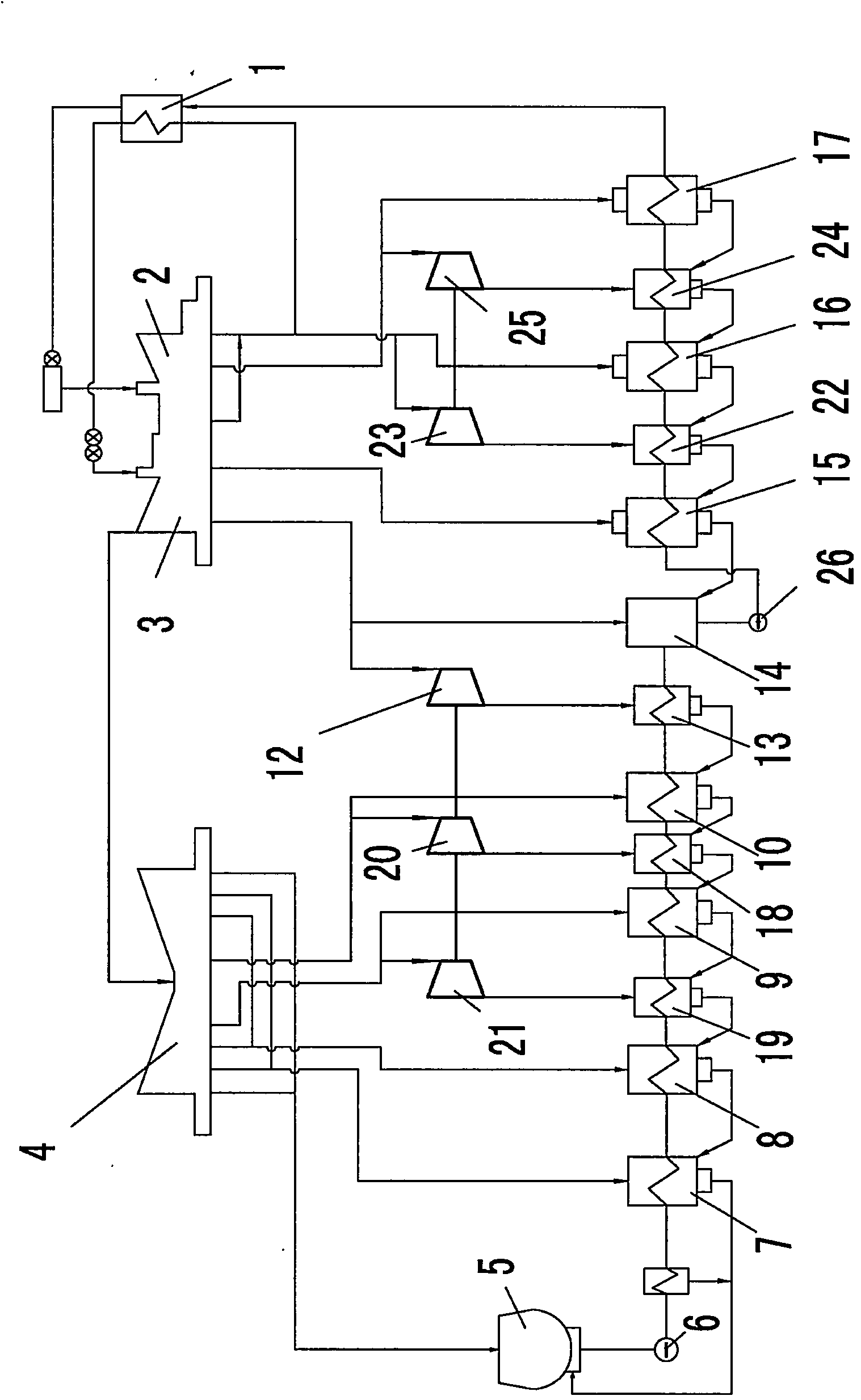

Air-cooling reheating unit system arranged in small back-pressure type steam turbine and used for driving feed pump

ActiveCN103498708AImprove efficiencyImprove thermal cycle efficiencySteam engine plantsCooling towerUnit system

The invention discloses an air-cooling reheating unit system arranged in a small back-pressure type steam turbine and used for driving a feed pump. Specifically, the air-cooling reheating unit system comprises a reheating system, an air cooling system, a back-pressure type pneumatic feed pump system and a heat regenerative system, wherein a steam inlet pipeline of the small back-pressure type steam turbine is connected with an exhaust steam pipeline of a steam turbine high pressure cylinder or a steam turbine ultrahigh pressure cylinder in the reheating system. An exhaust steam pipeline of the small back-pressure type steam turbine is connected with the heat regenerative system. According to the air-cooling reheating unit system arranged in the small back-pressure type steam turbine and used for driving the feed pump, steam before reheating is supplied for the small back-pressure type steam turbine to drive the feed pump and then the small back-pressure type steam turbine with the low superheat degree is utilized to pump the steam and exhaust the steam. A heater and / or a deaerator is used for heating condensation water and feedwater, the thermodynamic cycle efficiency of the system is improved and the heat exchange area of a reheater is reduced. Moreover, for a direct air cooling unit, a small steam turbine condenser and a small steam turbine indirect air cooling tower do not need to be arranged; for an indirect air cooling unit, the heat exchange area of an indirect air cooling tower of a main engine is saved.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

Method for improving thermodynamic cycling quality of waste sinter heat power generation system

ActiveCN101699207AImprove thermoelectric conversion efficiencyImprove stabilityIncreasing energy efficiencySteam engine plantsEvaporationEngineering

The invention relates to the technical field of waste heat power generation, in particular to a method for improving the thermodynamic cycling quality of a waste sinter heat power generation system. The method comprises the following steps of: coupling the thermodynamic cycle of waste sinter heat power generation with the thermodynamic cycle of conventional blast furnace gas power generation, using a waste heat boiler as an external economizer of a blast furnace gas boiler; mixing saturated water generated by the waste heat boiler with hot water generated by an internal economizer of the blast furnace gas boiler and directly delivering the mixed water to a steam manifold of the blast furnace gas boiler; performing evaporation and superheating on the mixed water in the blast furnace gas boiler and allowing the mixed water to enter a steam turbine to apply work; and dividing the discharged smoke of the waste heat boiler into two parts, wherein one part is recycled as waste gas and is returned to a fan of a sinter cooler, while the other part enters the blast furnace gas boiler to support the combustion of fuels. The method utilizes the thermodynamic cycle of thermal power generation to develop the thermodynamic cycle of the waste heat power generation, solves the problems of poor stability and low thermo-electric conversion efficiency in the prior low-temperature waste sinter heat power generation system, and greatly improves the thermodynamic cycling quality of the waste heat power generation.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

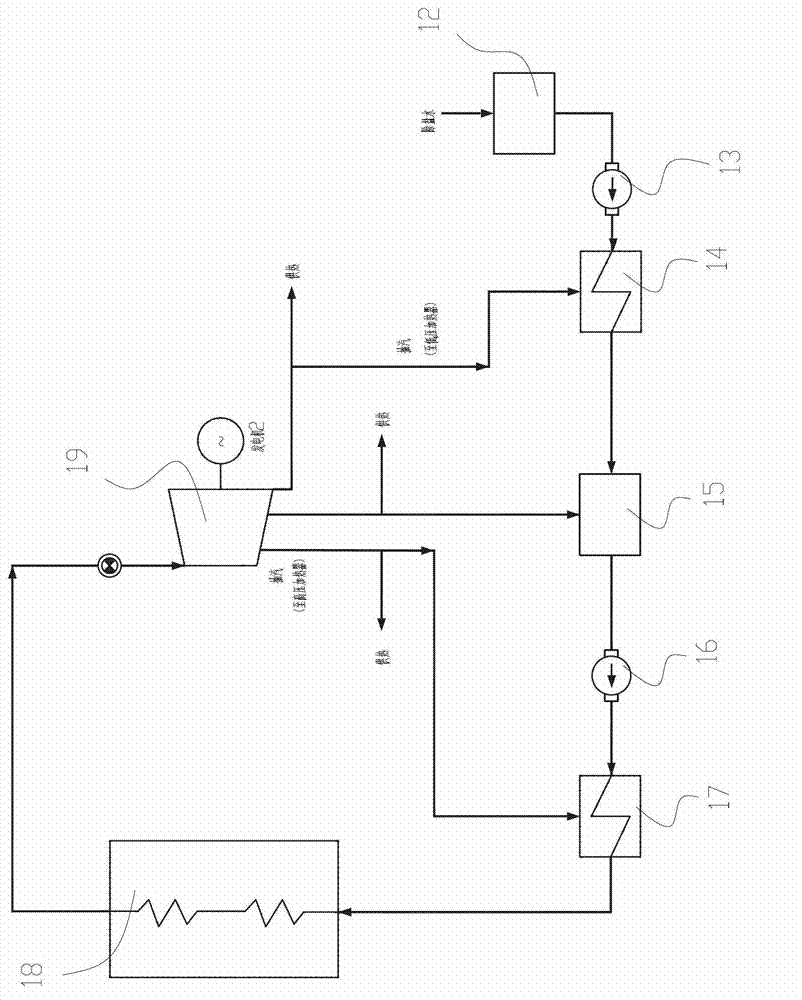

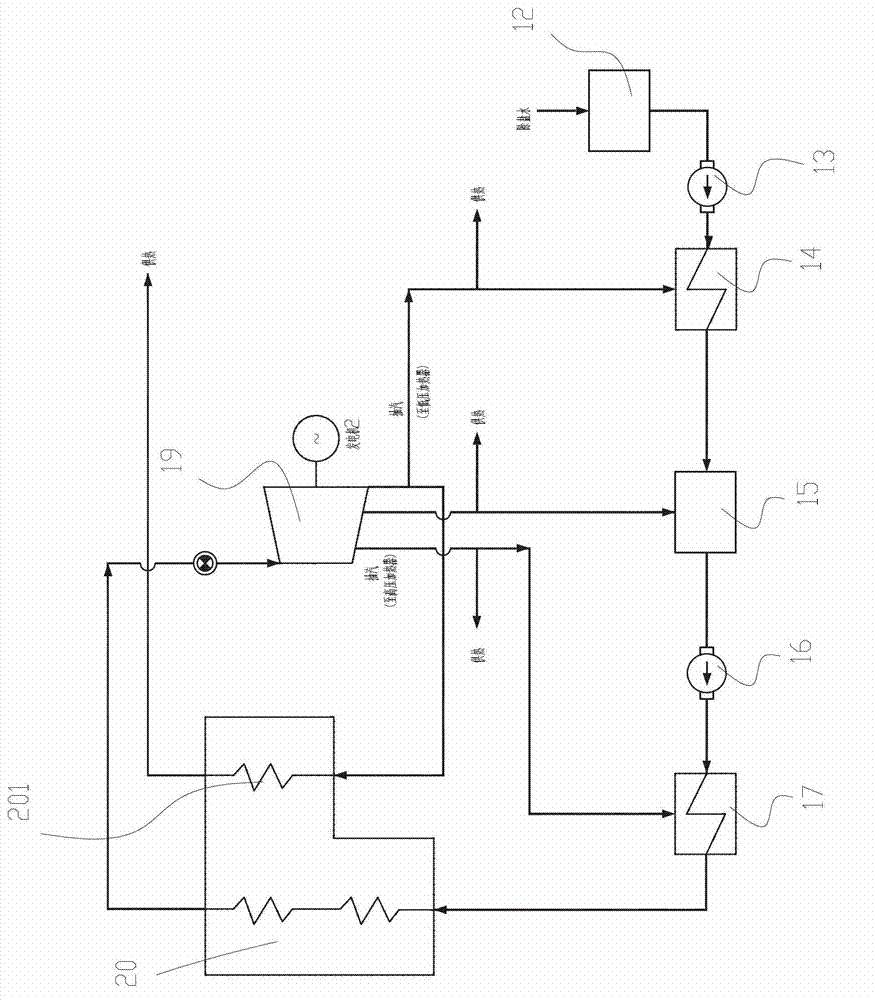

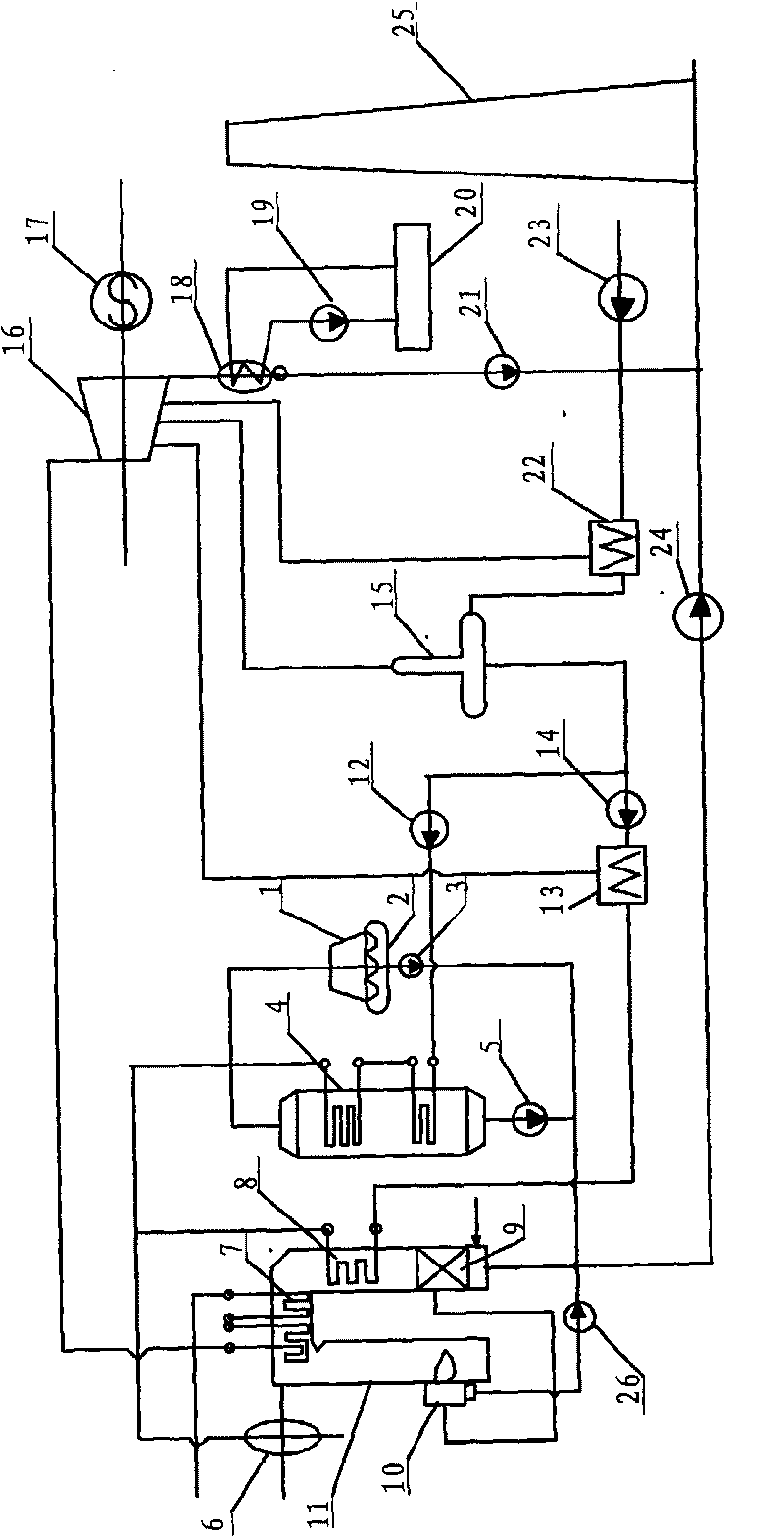

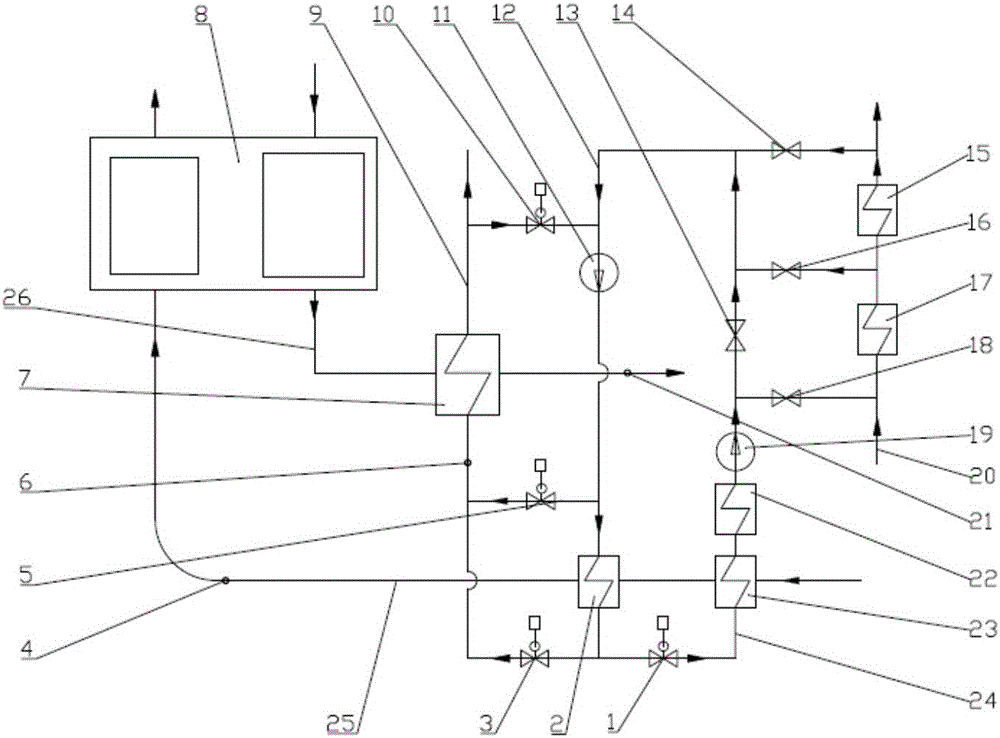

Thermodynamic system for combined heat recovery of power plant

ActiveCN102678206AImprove thermal cycle efficiencyReduce lossesSteam useCombined combustion mitigationPower stationEngineering

The invention discloses a thermodynamic system for combined heat recovery of a power plant. A smoke heat recovery system and a small exhaust system of turbine driven equipment are optimized for combined recovery. The technical scheme is as follows: the system comprises a fan exhaust afterheat recovery heater located on the fan side, a drainage pump and a smoke afterheat recovery device, wherein steam in a thermodynamic cycle system of the power plant is accessed into a regenerative driving steam turbine on the fan side to act; exhaust steam of the regenerative driving steam turbine enters the fan exhaust afterheat recovery heater, and the exhaust afterheat is utilized by the fan exhaust afterheat recovery heater to heat the water for heating; the drainage pump is connected with a water pipe at the outlet of the fan exhaust afterheat recovery heater or a water pipe at the inlet of the fan exhaust afterheat recovery heater for returning the water to the outlet or inlet of the fan exhaust afterheat recovery heater; and the smoke afterheat recovery device is used for receiving the water for heating at the outlet of the heater in the thermodynamic cycle system of the power plant and exchanging heat with the smoke.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

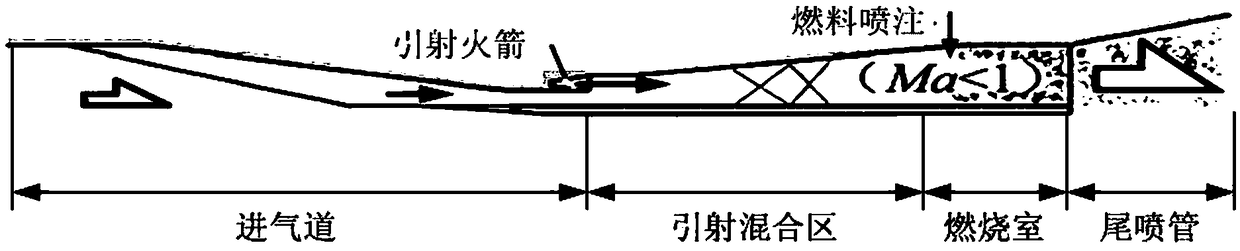

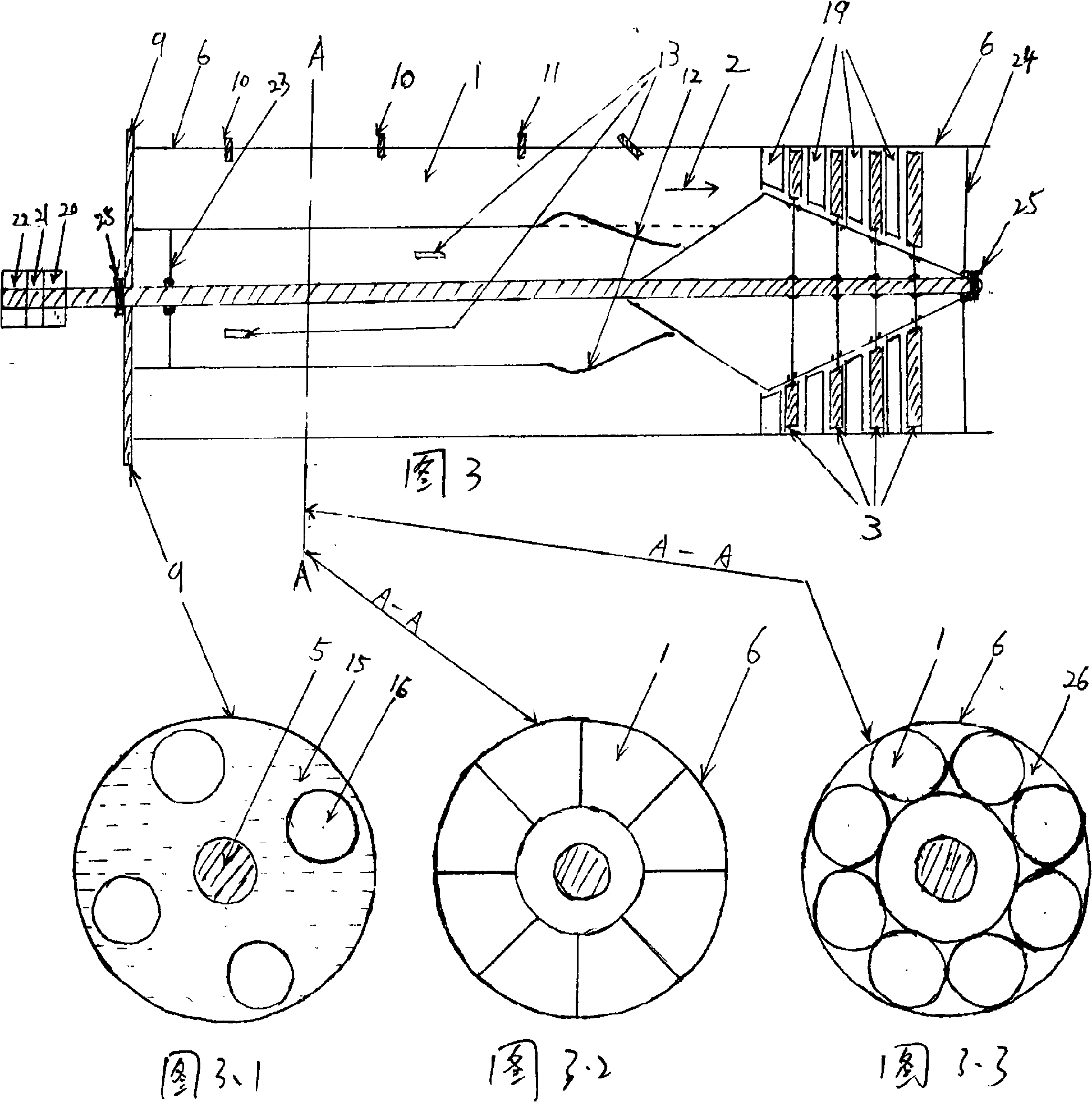

Solid rocket ramjet based on detonation combustion

ActiveCN112879178AImprove work efficiencyImprove convenienceGas turbine plantsIntermittent jet plantsRamjetCombustion chamber

The invention discloses a solid rocket ramjet based on detonation combustion. The solid rocket ramjet comprises an outer shell, an inner core, an air inlet channel, an isolation section channel, a detonation combustion channel, a gas generator, a flow stabilizing ring cavity, a main fuel injection system, a rotary detonation combustion chamber, a tail spray pipe and other structures, wherein the air inlet channel, the isolation section channel and the detonation combustion channel are formed between the inner wall of the outer shell and the outer wall of the inner core; air captured by the air inlet channel is decelerated and pressurized in an isolation section and then enters the rotary detonation combustion chamber; the front portion of the inner core is of a hollow structure, the gas generator is arranged in the inner core, an oxygen-deficient solid propellant is combusted in the gas generator and forms fuel-rich gas, and the fuel-rich gas enters an expansion section of the isolation section channel through a main fuel injector, is fully mixed with fresh air and then is sprayed into the ring cavity of the rotary detonation combustion chamber; and the rotary detonation combustion chamber is provided with an ignition device, the tail spray pipe is installed at an outlet, chemical energy is converted into kinetic energy, and thrust is generated. The solid rocket ramjet has higher combustion efficiency and work performance.

Owner:NANJING UNIV OF SCI & TECH

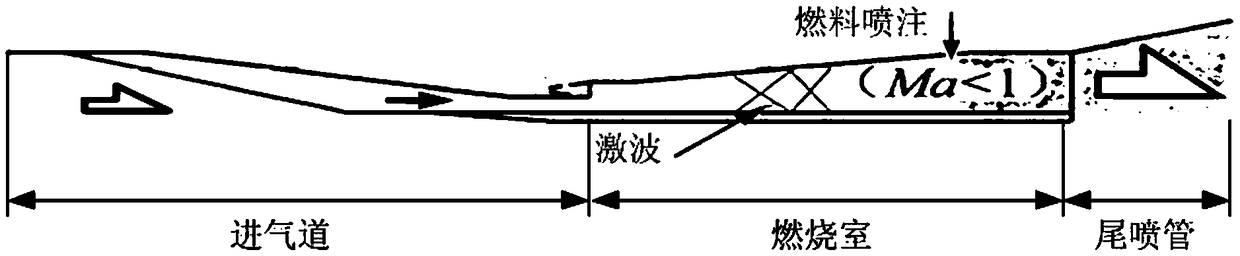

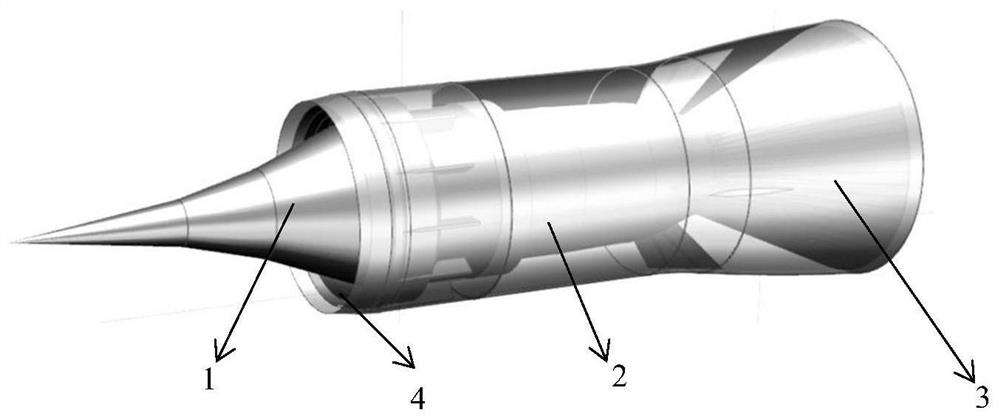

Double-combustion-chamber ramjet and hypersonic aerocraft

ActiveCN108708788AImprove thermal cycle efficiencyExcellent thrust performanceTurbine/propulsion fuel flow conduitsGas turbine plantsRamjetCombustion chamber

The invention discloses a double-combustion-chamber ramjet and a hypersonic aerocraft. The double-combustion-chamber ramjet comprises an outer shell; and the outer shell is a hollow cylinder with twocommunicating ends. The double-combustion-chamber ramjet further comprises a center shell; the center shell is arranged in a shaft hole of the outer shell, and is connected with the outer shell; a gapbetween the center shell and the outer shell forms an outer drainage channel; a cavity between the back end surface of the center shell and the inner wall of the outer shell forms a knocking chamber;and a tail spraying pipe communicates with the knocking chamber. The double-combustion-chamber ramjet further comprises a center cone; the back body of the center cone extends into the center shell,and is connected with the center shell; a gap between the center cone and the center shell forms a center drainage channel; a cavity between the back end surface of the center cone and the inner wallof the center shell forms a sub-combustion chamber; and the sub-combustion chamber is connected with a fuel source, and communicates with the knocking chamber. Multiple outer nozzles are formed in theouter wall of the outer shell; and the two ends of the outer nozzles communicate with the fuel source and the outer drainage channel. And / or multiple inner nozzles are formed in the outer wall of thecenter shell; and the two ends of the inner nozzles communicate with the fuel source and the outer drainage channel respectively.

Owner:NAT UNIV OF DEFENSE TECH

High-temperature high-pressure natural circulation dry coke-quenching exhaust-heat boiler

This invention relates to a high temperature high pressure used heat boiler with natural circulation and dry extinguished coke including a coal-saving device, an evaporator, a film water-cooling wall, a vapour steam superheater, a boiler level and a tail flue characterizing that a dreg-coagulating tube of the water cooling wall of the front wall is set at the inlet of the boiler for increasing its heat-absorbing volume and safety of water circulation of the wall and the film water cooling walls of a suspending structure are set at the boiler level and tail flue, a boiling coal-saving device is set under the boiler levelly and the boiling rate of which is greater than or equal to 10% and a natural circulated evaporator of a vapour-water circulation mode is set levelly on the coal saving device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Rocket-based detonation and ramjet combined cycle engine and using method and application thereof

ActiveCN112228246AImprove cycle performanceRaise the potentialRam jet enginesComposite engine plantsRamjetCombustion chamber

The invention belongs to the technical field of aerospace engines, and particularly relates to a rocket-based detonation and ramjet combined cycle engine and a using method and application thereof. The combined cycle engine comprises a center cone (1), a shell (2) and an exhaust nozzle (3) which are connected in sequence, the bottom of the center cone (1) extends into the shell (2) to be connectedwith a fixed partition plate (5), and an adjustable air inlet channel (4) is formed by the cone part of the center cone (1) and the inner wall of the shell (2). A rocket engine (8) and an annular detonation and ramjet combustion chamber (7) annularly surrounding the rocket engine (8) are arranged in the shell (2). The advantages of the rocket engine, a ramjet and rotary detonation combustion propulsion can be brought into full play, and the multi-mode combined propulsion requirements of efficient air-suction flight of a non-aerospace vehicle in the atmosphere and cross-atmosphere rocket orbitinjection flight can be met.

Owner:HUAZHONG UNIV OF SCI & TECH

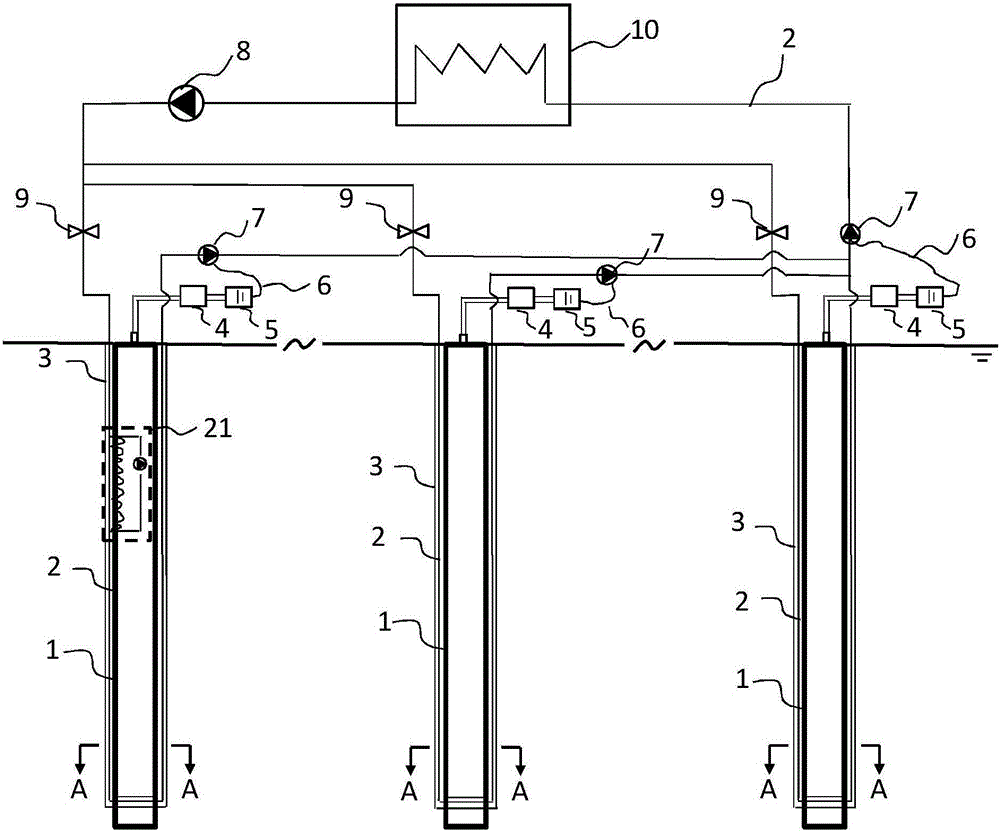

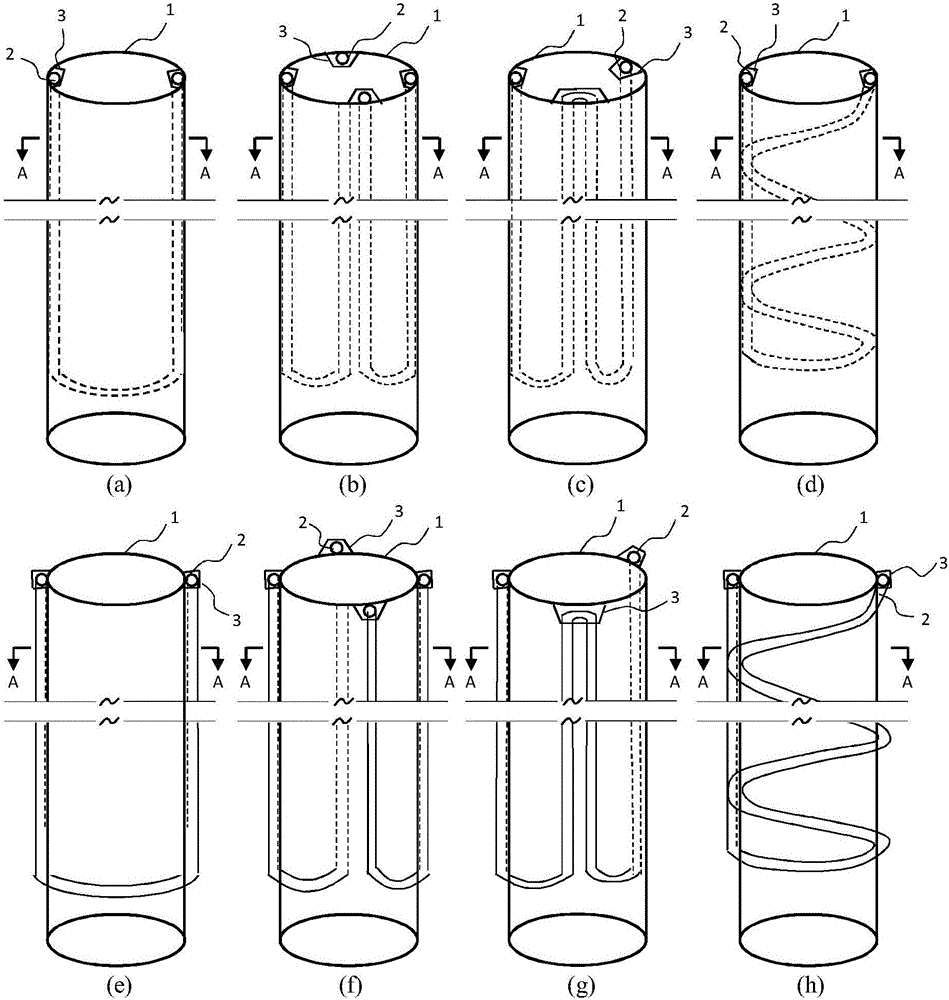

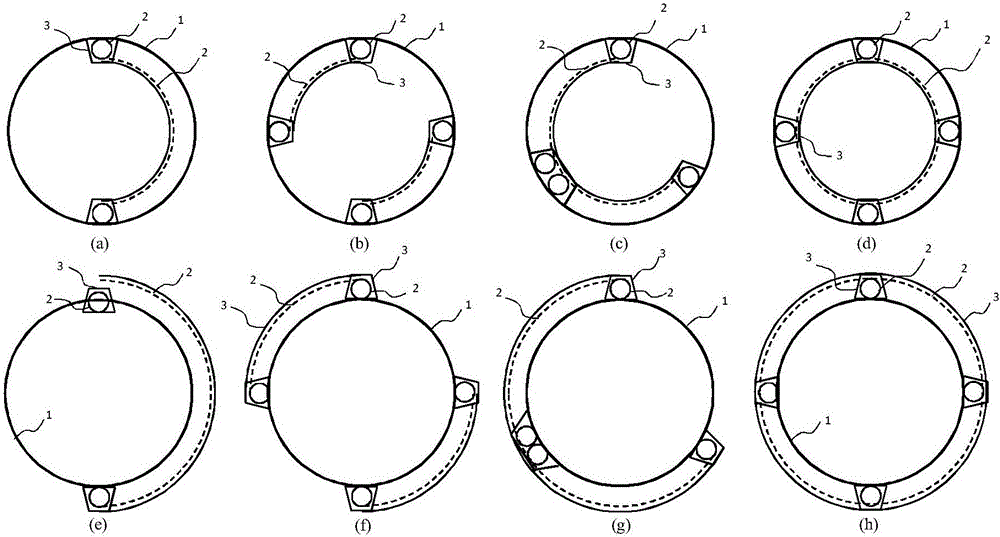

Novel steel pipe energy pile capable of improving utilization efficiency of shallow layer geothermal energy and manufacturing method thereof

ActiveCN106223312AEfficient use ofReduce consumptionOther heat production devicesGeothermal energy generationEngineeringCycle efficiency

The invention discloses a novel steel pipe energy pile capable of improving the utilization efficiency of shallow layer geothermal energy and a manufacturing method thereof. The device comprises steel pipe pile bodies, heat transfer tubes, heat transfer tube sleeves, an air-conditioning system, a semiconductor temperature difference power generation system and a semiconductor temperature difference power generation cooling system. The air-conditioning system comprises heat-exchange equipment. Liquid in each heat transfer tube conducts heat exchange with the soil mass at first, and then the indoor air temperature of a building can be adjusted through the upper heat-exchange equipment. Electric energy obtained by the semiconductor temperature difference power generation system and the semiconductor temperature difference power generation cooling system can supply electricity to earth surface electric equipment. The semiconductor temperature difference power generation technology is adopted in the system, and the temperature difference between the liquid in the heat transfer tubes and the soil mass is used for power generation. The electric energy generated by the temperature difference power generation cooling system can drive underground radiating tubes, the electric energy generated by the temperature difference power generation system can provide driving force for a medium and small-power water pump of the air-conditioning system, and therefore the circular flow speed of the liquid in the heat transfer tubes is increased, and heat cycle efficiency and heat exchange efficiency of the energy pile heat transfer tubes are improved.

Owner:HOHAI UNIV

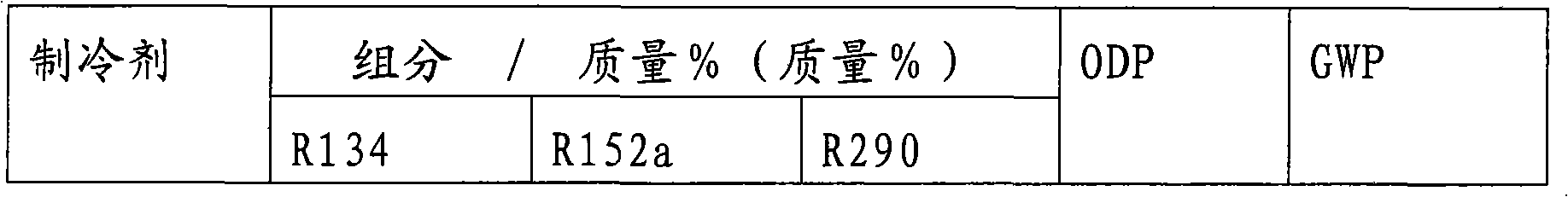

Mix refrigerant, preparing method and uses thereof

ActiveCN101270275ASmall temperature glideImprove thermal cycle efficiencyHeat-exchange elementsDischarge rateRefrigerant

The invention provides a ternary near azeotropic refrigerant, which comprises tertiary mixture consisting of 1, 1, 2, 2-tetra fluoro ethane, 1, 1-difluoroethane and propane. The total of the mass percent concentration of all components of the mixed refrigerant is 100 percent, including 1, 1, 2, 2-tetra fluoro ethane with the condensation of 1 percent to 20 percent, dimethyl ether with the condensation of 1 percent to 50 percent, and propane with the condensation of 30 percent to 90 percent. The invention further provides a method for preparing the mixed refrigerant and a use of the mixed refrigerant. The mixed refrigerant has high efficiency and high evaporating pressure with large refrigerating capacity when the compressor discharge rate is the same; the ODP is zero, and compared with R502 and R404A, the GWP of the refrigerant is significantly reduced.

Owner:青岛中科未来健康研究院有限公司

Air fryer

PendingCN106901617AEfficient cycleLarge air duct areaCooking-vessel lids/coversRoasting apparatusImpellerEngineering

The invention discloses an air fryer which comprises a shell, a heating device and a cross-flow fan, wherein the shell comprises a first chamber and a second chamber; the first chamber communicates with the second chamber; an air outlet is formed in the bottom of the first chamber; an air inlet is formed in the top of the second chamber; the heating device is arranged in the second chamber; the cross-flow fan is arranged in the second chamber and comprises an impeller and the axis of the impeller is horizontal; after the cross-flow fan is started, the air inlet is used for carrying out horizontal air inlet and the air outlet is used for carrying out horizontal air outlet. According to the air fryer, the thermal cycle efficiency can be effectively improved and the food can be uniform in baking color, crisp in surface and better in taste.

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

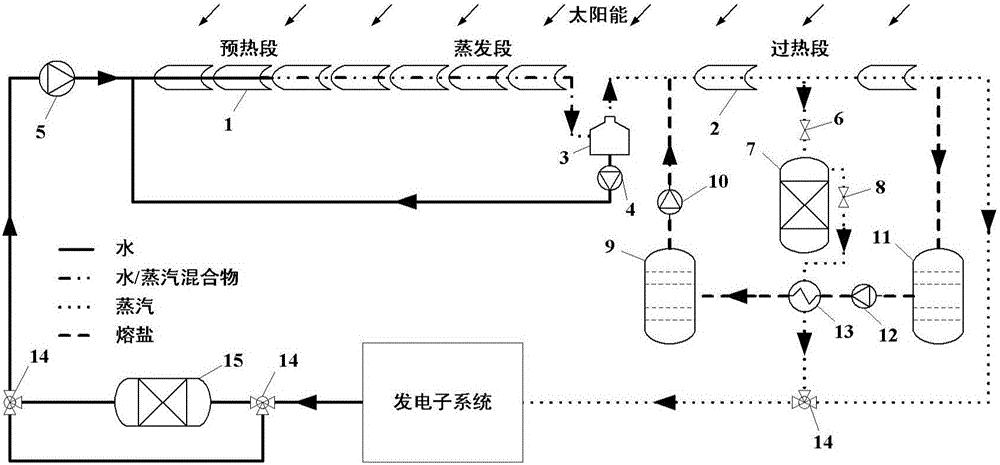

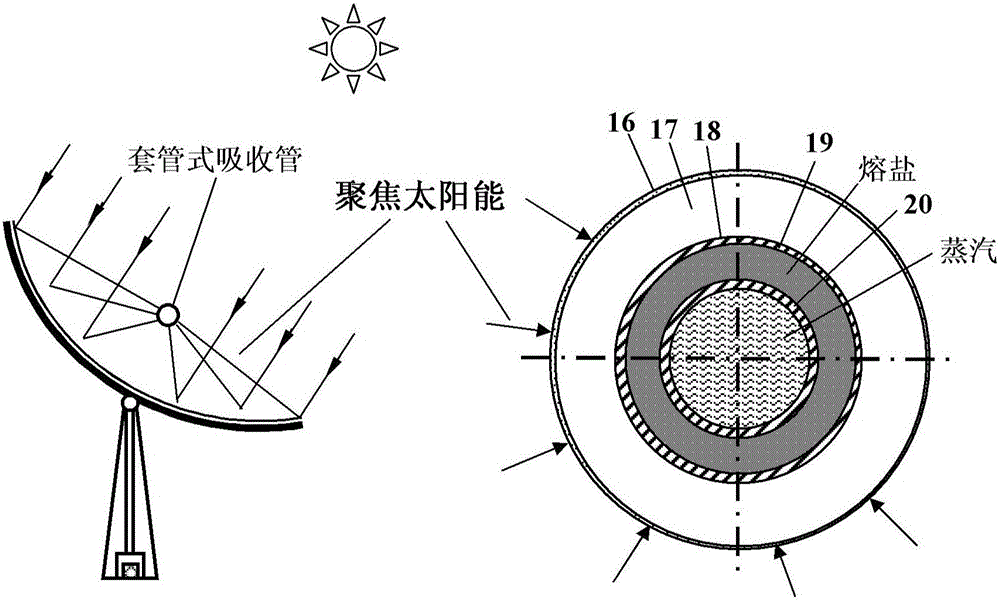

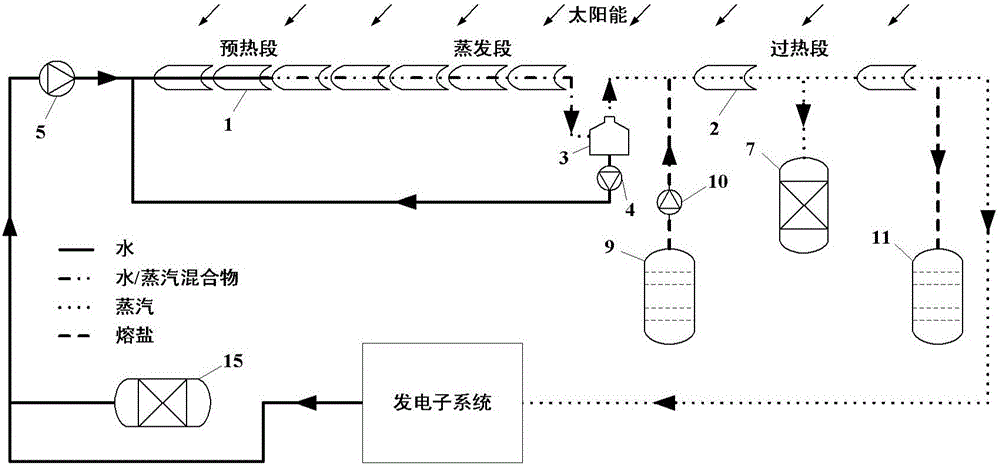

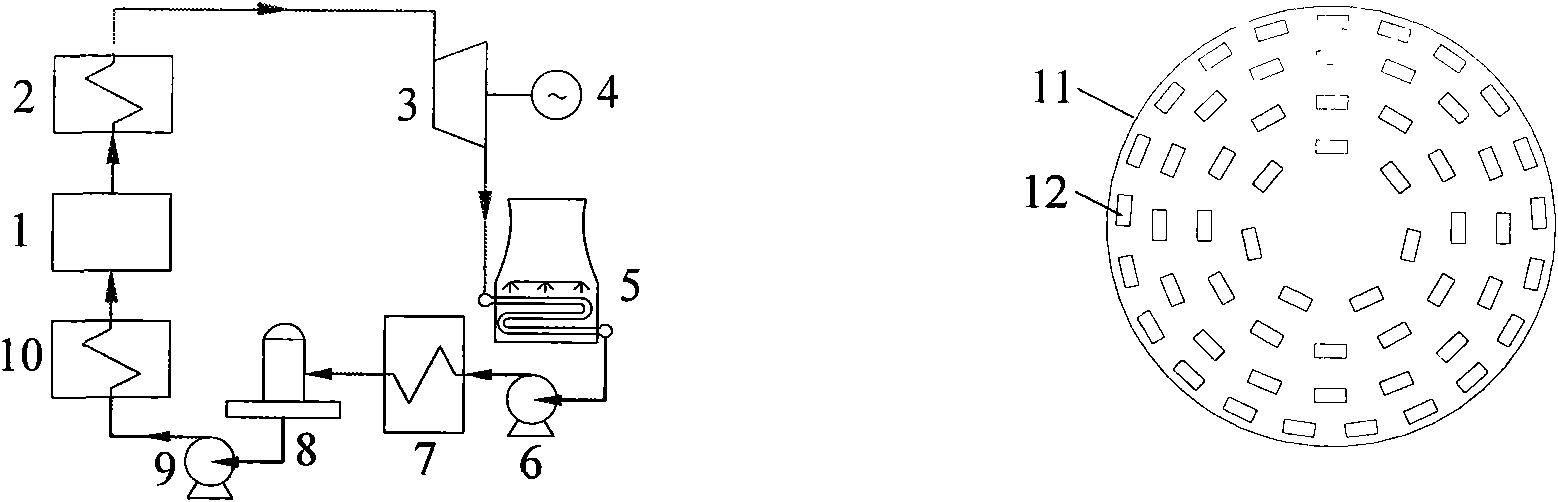

Solar steam direct power generation system with heat storage function

ActiveCN105756873AReduce investmentRealize uninterrupted continuous power generation day and nightSolar heating energyFrom solar energyMolten saltEngineering

The invention discloses a solar steam direct power generation system with a heat storage function. The solar steam direct power generation system comprises a heat collection subsystem, a heat storage subsystem and a power generation subsystem. Under irradiation conditions in the daytime, high-temperature and high-pressure saturated steam enters the inner pipe side of a sleeve type line focusing solar heat collector, and low-temperature molten salt enters the sleeve side. Focusing solar energy firstly heats the molten salt, and the steam is heated to an overheated state after the temperature rise of the molten salt. Part of the overheated steam enters a high-pressure storage tank for heat storage, and the rest of overheated steam enters the power generation subsystem for power generation. Meanwhile, the molten salt enters a high-temperature molten salt tank for heat storage. Under irradiation-free conditions in the nighttime, the molten salt in the high-temperature molten salt tank enters a low-temperature molten salt tank after heat release by an overheater; the high-pressure saturated steam flows out from the high-pressure storage tank and is heated by the overheater to form overheated steam to enter the power generation subsystem for power generation. The solar steam direct power generation system disclosed by the invention realizes the all-weather power generation by adopting a solar steam direct power generation technology through taking water / steam as not only a working medium but also a main heat storage medium and as an auxiliary heat storage medium with coordinate application of the small amount of molten salt.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

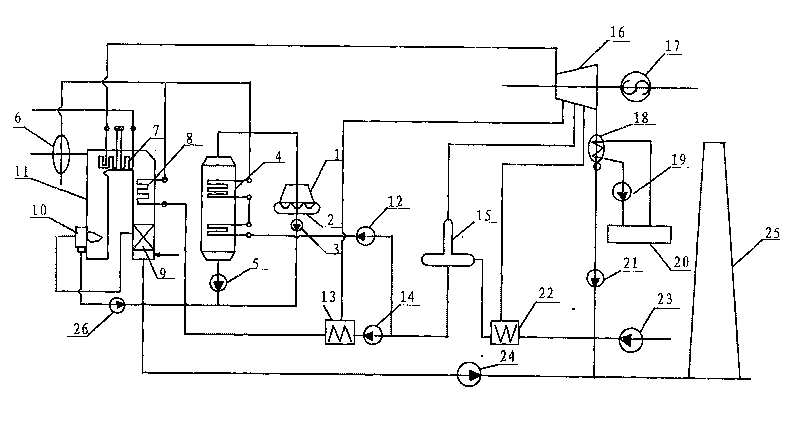

Backpressure steam extraction small turbine thermal system which is coaxial with single reheating main turbine

The invention provides a thermal system of a backpressure steam extraction small turbine which is coaxial with a single reheating main turbine. A single reheating main turbine set is provided with a high-pressure cylinder, a moderate-pressure cylinder, a low-pressure cylinder and a reheating device. The thermal system of the backpressure steam extraction small turbine comprises a backpressure steam extraction small turbine, a steam inlet pipe system, a steam extraction pipe system and a heat returning device. Steam, which is to be reheated, of the single reheating main turbine is used as a steam source by the thermal system to drive the backpressure steam extraction small turbine. Steam extraction and exhausting of the backpressure steam extraction small turbine are used for heating supplied water and condensate water. The backpressure steam extraction small turbine and the single reheating main turbine are coaxially arranged. The thermal system of the backpressure steam extraction small turbine can reduce the manufacturing cost of the system and meanwhile, improve the thermodynamic cycle efficiency.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

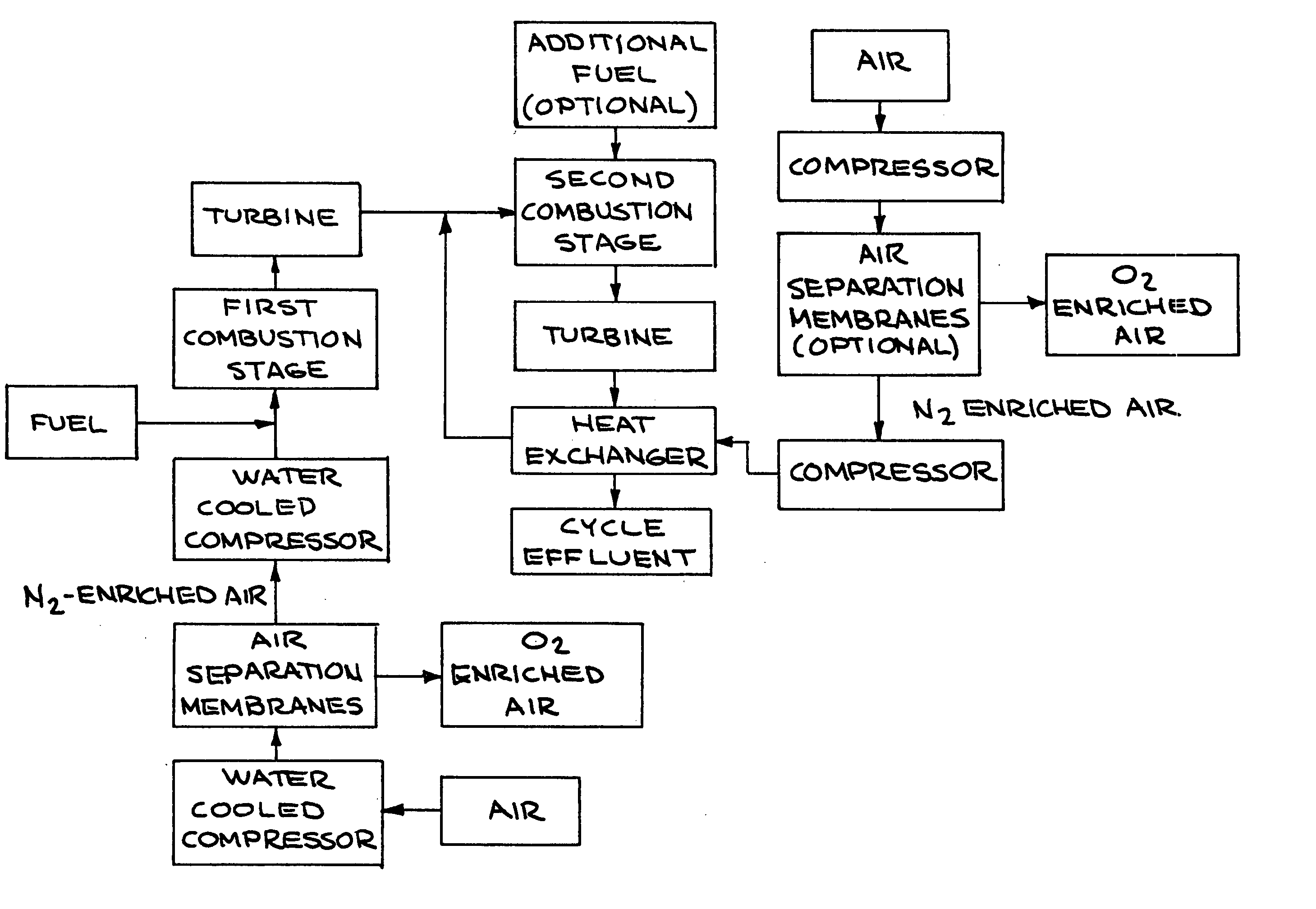

Multi-stage combustion using nitrogen-enriched air

InactiveUS20050026095A1Improve fuel efficiencyReducing polluting exhaust emissionContinuous combustion chamberNon-fuel substance addition to fuelNitrogen gasInternal combustion engine

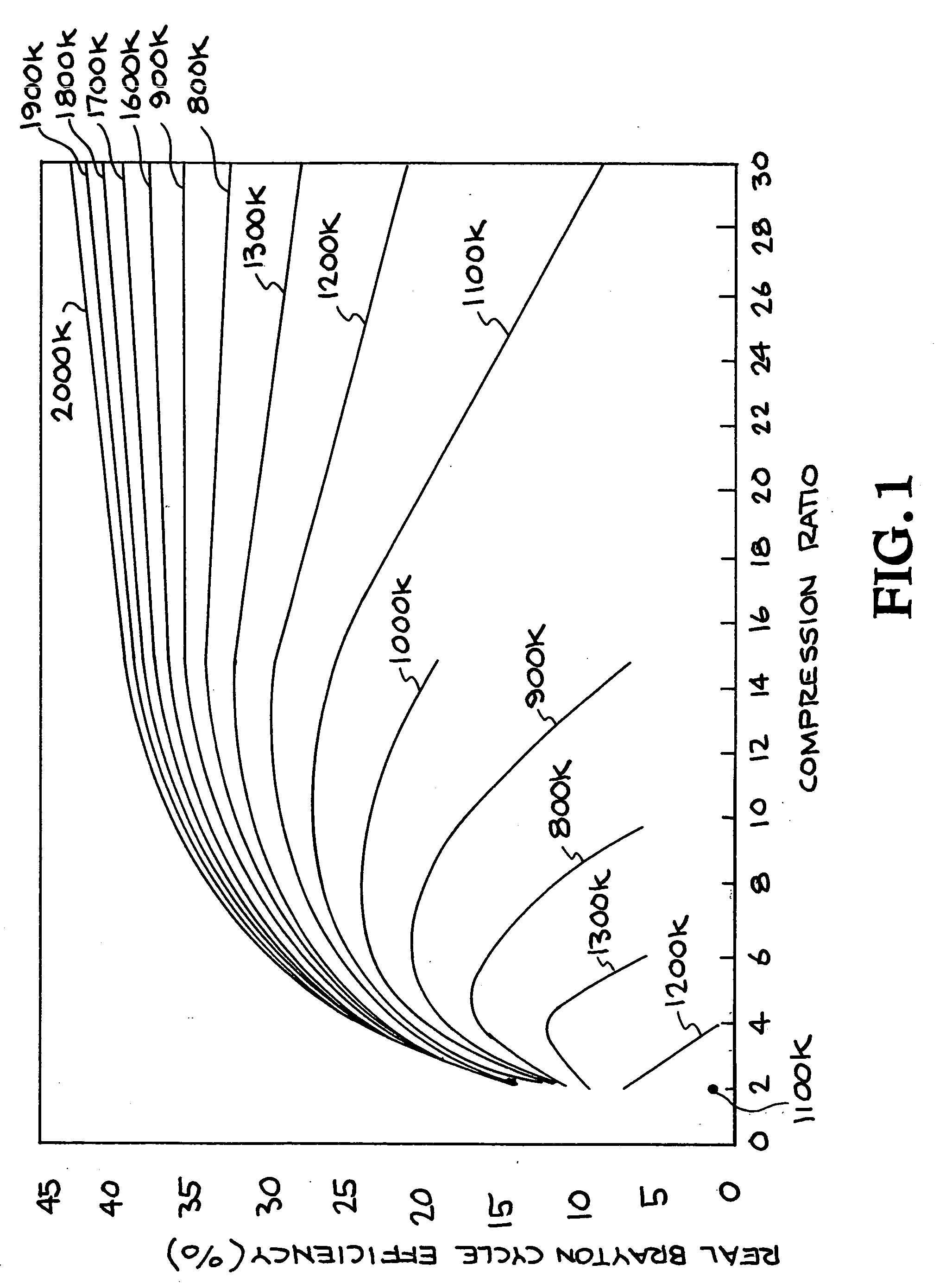

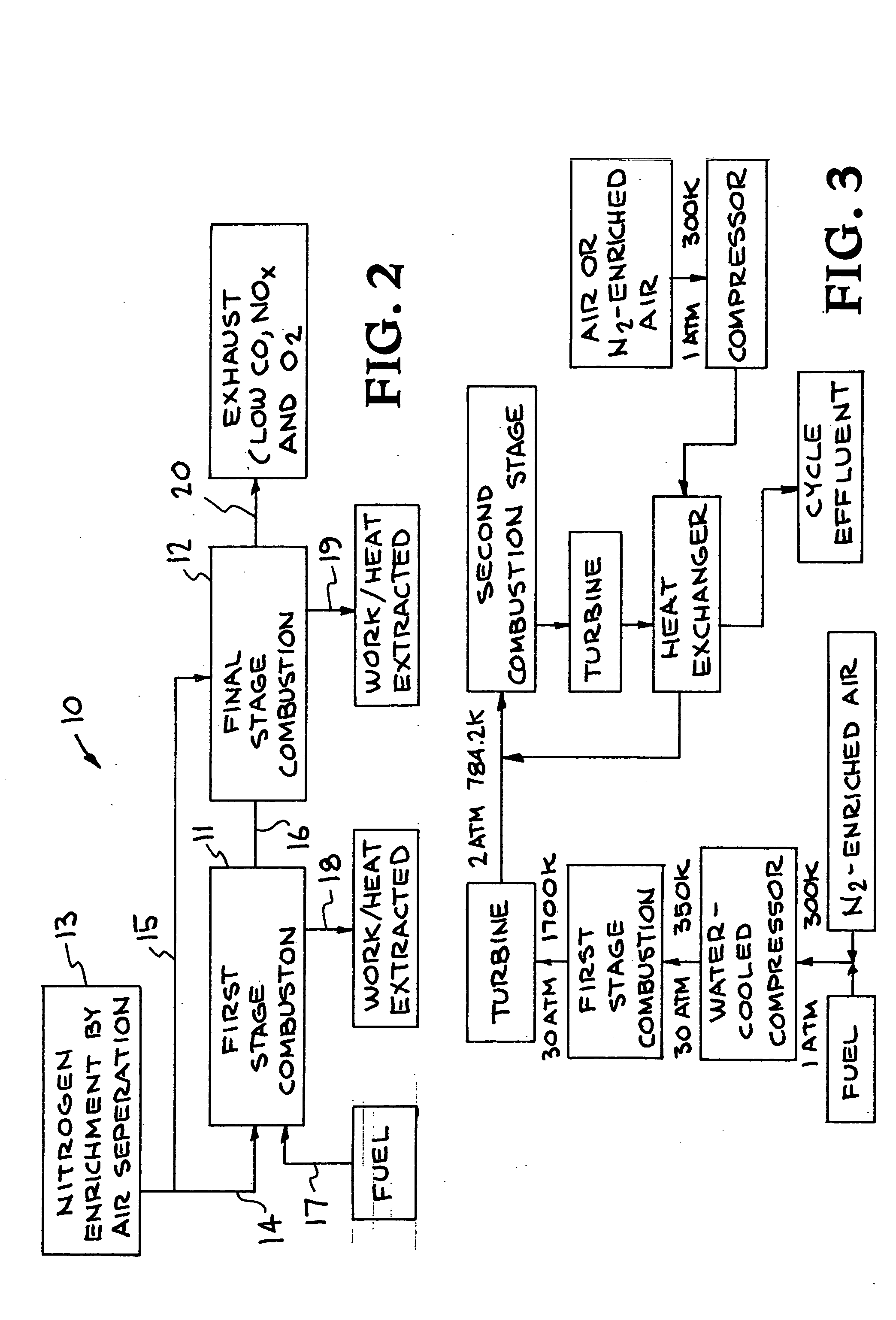

Multi-stage combustion technology combined with nitrogen-enriched air technology for controlling the combustion temperature and products to extend the maintenance and lifetime cycles of materials in contact with combustion products and to reduce pollutants while maintaining relatively high combustion and thermal cycle efficiencies. The first stage of combustion operates fuel rich where most of the heat of combustion is released by burning it with nitrogen-enriched air. Part of the energy in the combustion gases is used to perform work or to provide heat. The cooled combustion gases are reheated by additional stages of combustion until the last stage is at or near stoichiometric conditions. Additional energy is extracted from each stage to result in relatively high thermal cycle efficiency. The air is enriched with nitrogen using air separation technologies such as diffusion, permeable membrane, absorption, and cryogenics. The combustion method is applicable to many types of combustion equipment, including: boilers, burners, turbines, internal combustion engines, and many types of fuel including hydrogen and carbon-based fuels including methane and coal.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

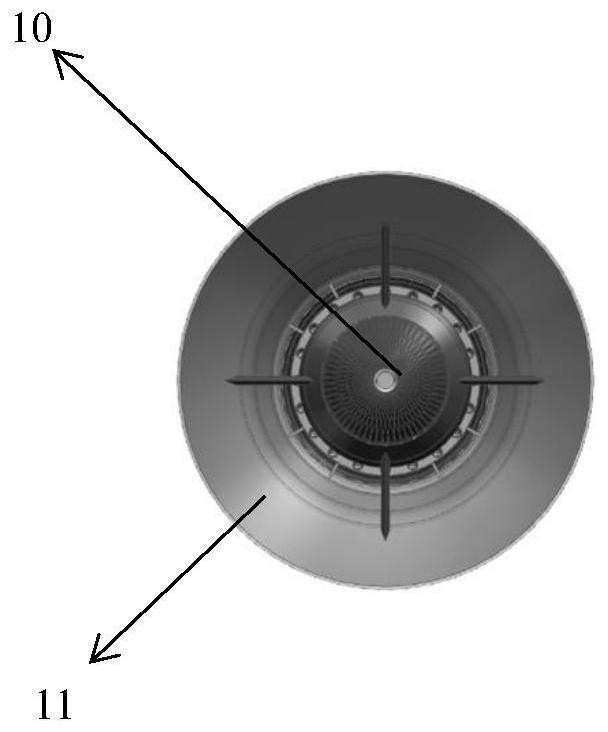

Air-breathing premixed carbon dioxide pneumatic laser driven by continuous rotary detonation combustion

ActiveCN110718843ADetonation combustion achievedDetonation combustion hasLaser detailsCombustion chamberFlight vehicle

The invention discloses an air-breathing premixed carbon dioxide pneumatic laser driven by continuous rotary detonation combustion. The laser comprises an air-breathing continuous rotary detonation combustion device, a transition section, a CO2 pneumatic laser generation device and an exhaust section. The air-breathing continuous rotary detonation combustion device is used for generating a high-temperature and high-pressure fuel gas heat source serving as total energy for downstream output laser, and comprises a center body and a cylindrical shell. The center body comprises an air inlet cone part, a large cylinder part, a small cylinder part and a tail cone part which are sequentially arranged from front to back. An air inlet channel is formed by a gap between the air inlet conical part and the front-end conical shell, and a rotary detonation combustion chamber is formed by a gap between the small cylindrical part and a rear-end cylindrical shell. The laser is applied to an air-breathing aircraft, and the air-breathing continuous rotary detonation combustion device is adopted as a pumping source; the generated laser is high in efficiency, and energy is saved. The same air-breathingcontinuous rotary detonation combustion device is adopted without increasing the load, so not only can thrust be generated, but also laser can be generated.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Power generating system

InactiveCN103835778ASmall temperature differenceImprove thermal cycle efficiencySteam useBoiler feedwater pumpEngineering

The invention relates to a power generating system which comprises a boiler, a main steam turbine, a steam extraction heater and a generator. A steam cylinder of the main steam turbine is provided with a steam extraction opening, and steam is extracted from the steam extraction opening. Supply water of a condensate pump and feed water of a boiler feed water pump are heated through the steam extraction heater. The steam extracted from the steam extraction opening is divided into two ways, one way is connected to the steam extraction heater and used for heating the condensation water or the boiler feed water, and the other way is connected to an auxiliary steam extraction heater through a back-pressure type expansion machine. In the auxiliary steam extraction heater, the heated water is connected with a water channel outlet of a later-stage steam extraction heater closest to the main steam turbine through a water channel inlet. The water channel outlet of the auxiliary steam extraction heater is connected with the water channel inlet of a same-stage steam extraction heater. According to the power generating system, by means of the back-pressure steam turbine, more heat is converted into power, more temperature gradients are obtained through the auxiliary steam extraction heater to lower the temperature difference between the two sides of the steam water of the steam extraction heater, and therefore the whole thermodynamic cycle efficiency is higher.

Owner:俞述茜

Air-cooled steam condensing system with natural ventilation and direct water film evaporation

InactiveCN101776401AImprove cycle efficiencySave electricitySteam/vapor condensersCooling towerSteam condensation

The invention relates to an air-cooled steam condensing system with natural ventilation and direct water film evaporation, which comprises a natural ventilation cooling tower and a direct water film evaporation type air-cooled cluster steam condenser arranged above the water pool of the cooling tower. Waste steam from a steam turbine flows through the tube of the steam condenser to release heat so as to be condensed into water to be discharged; and spray water forms a water film outside of the tube, flowing air sweeps the water film, and the water film absorbs the heat of the waste steam in the tube and transmit sensible heat and the latent heat generated in the evaporation of the water film to the flowing air. The spray water then falls into the water pool of the cooling tower, and is delivered to a spray water distribution device above each tube bundle of the steam condenser by a circulating pump. The system consumes a certain amount of evaporated water, thereby significantly improving the heat cycling efficiency. No fan is applied to consume power, thereby reducing the service power. Moreover, the system can overcome the defect that the direct dry-air-cooled steam condensation can not be completed and realized in the high-temperature environment. Compared with the water-cooled steam condensation, the system can obtain a steam condensation temperature lower than the water-cooled steam condensation, achieve higher heat cycling efficiency, and significantly reduce water consumption. Therefore, the system is applicable to areas with abundant water resources but stricter and stricter water-saving requirements.

Owner:HUAZHONG UNIV OF SCI & TECH

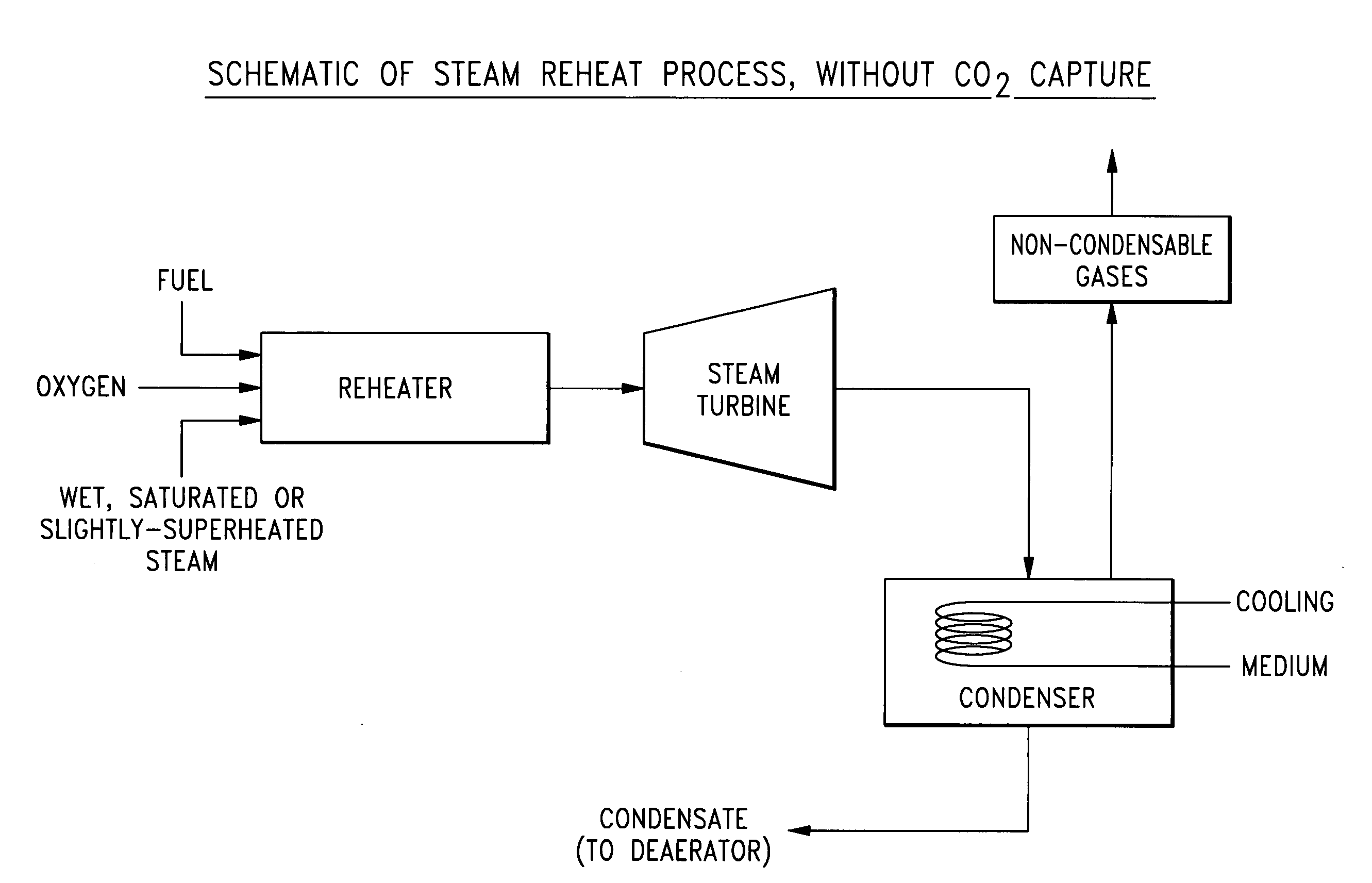

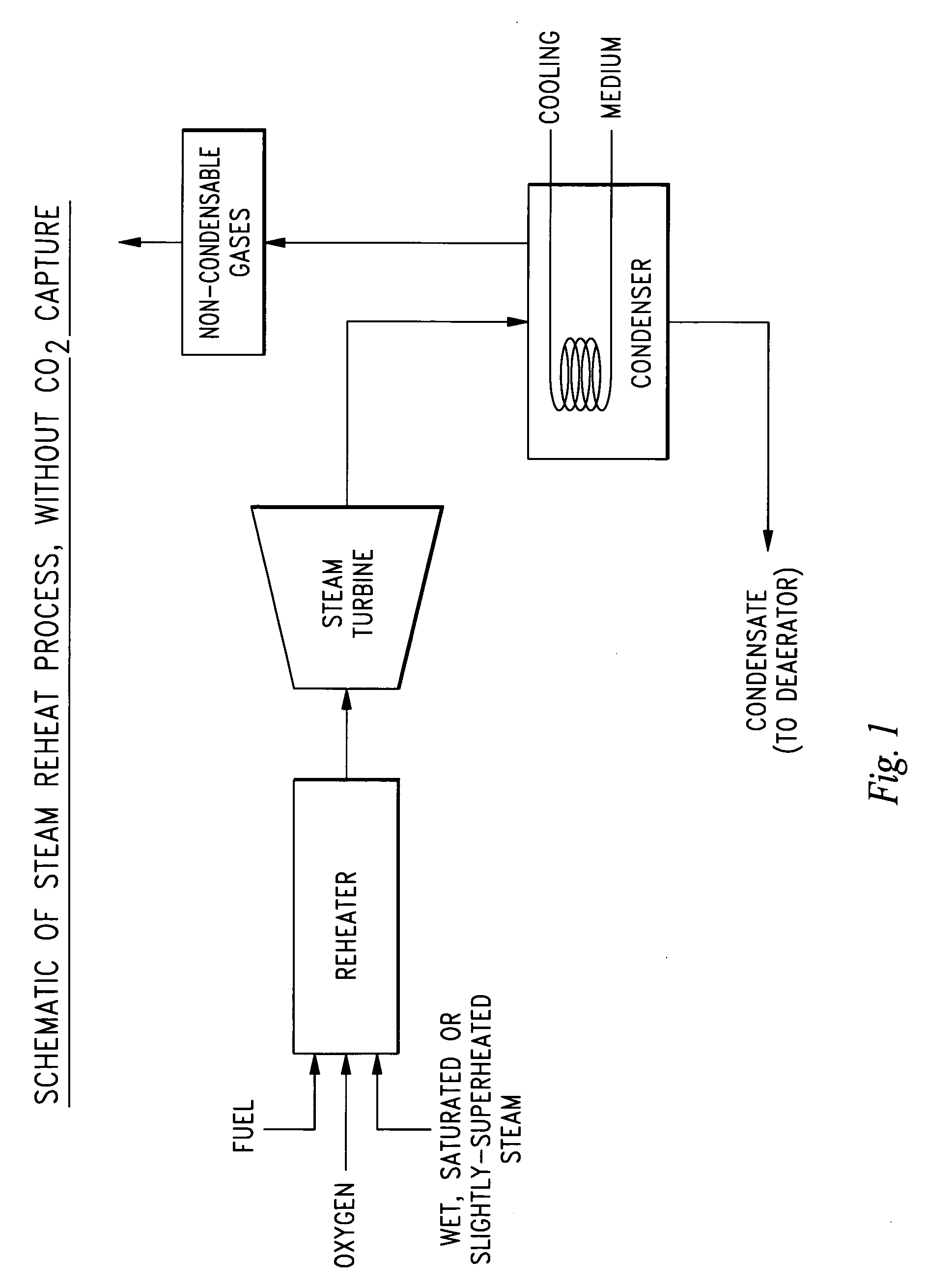

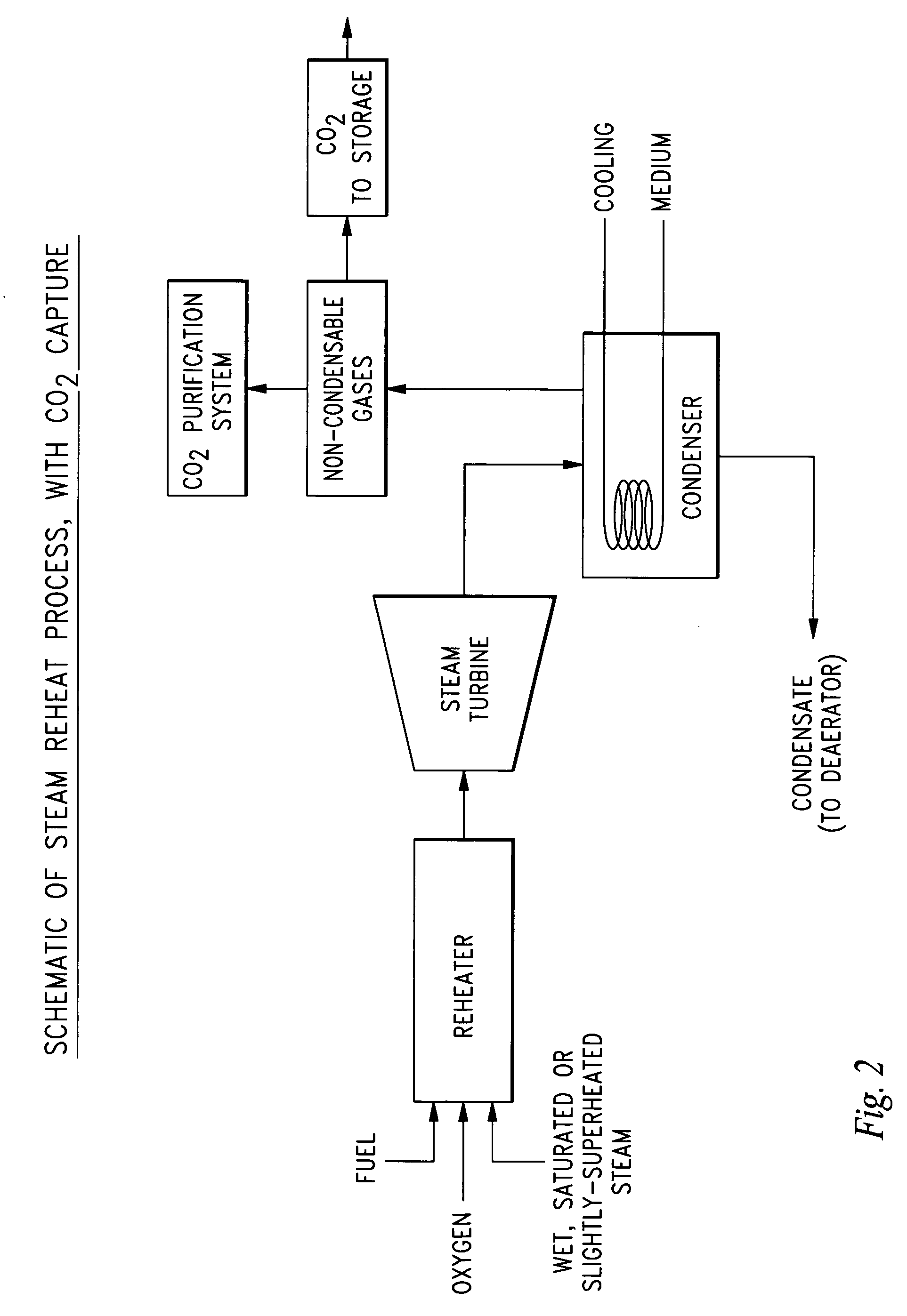

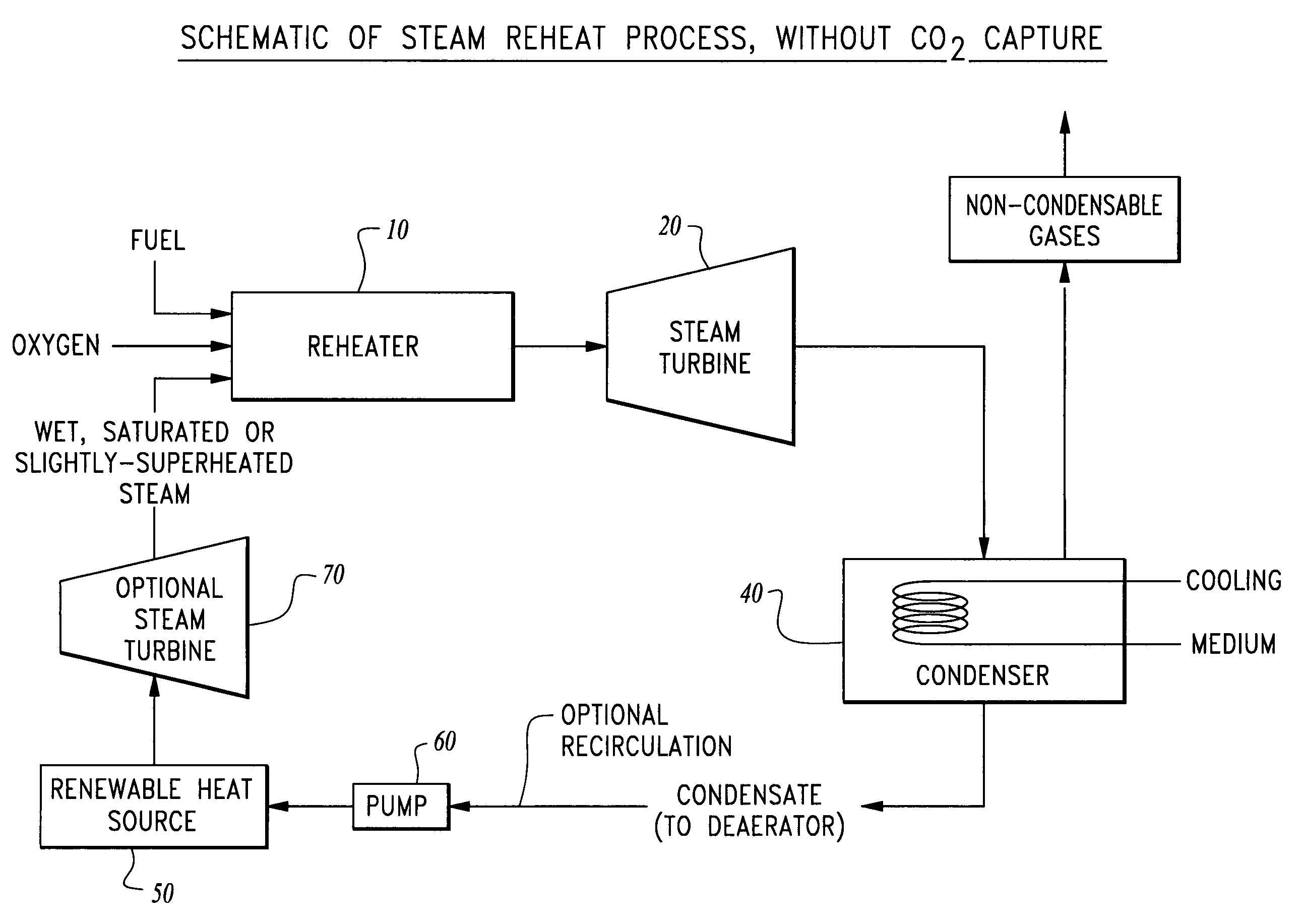

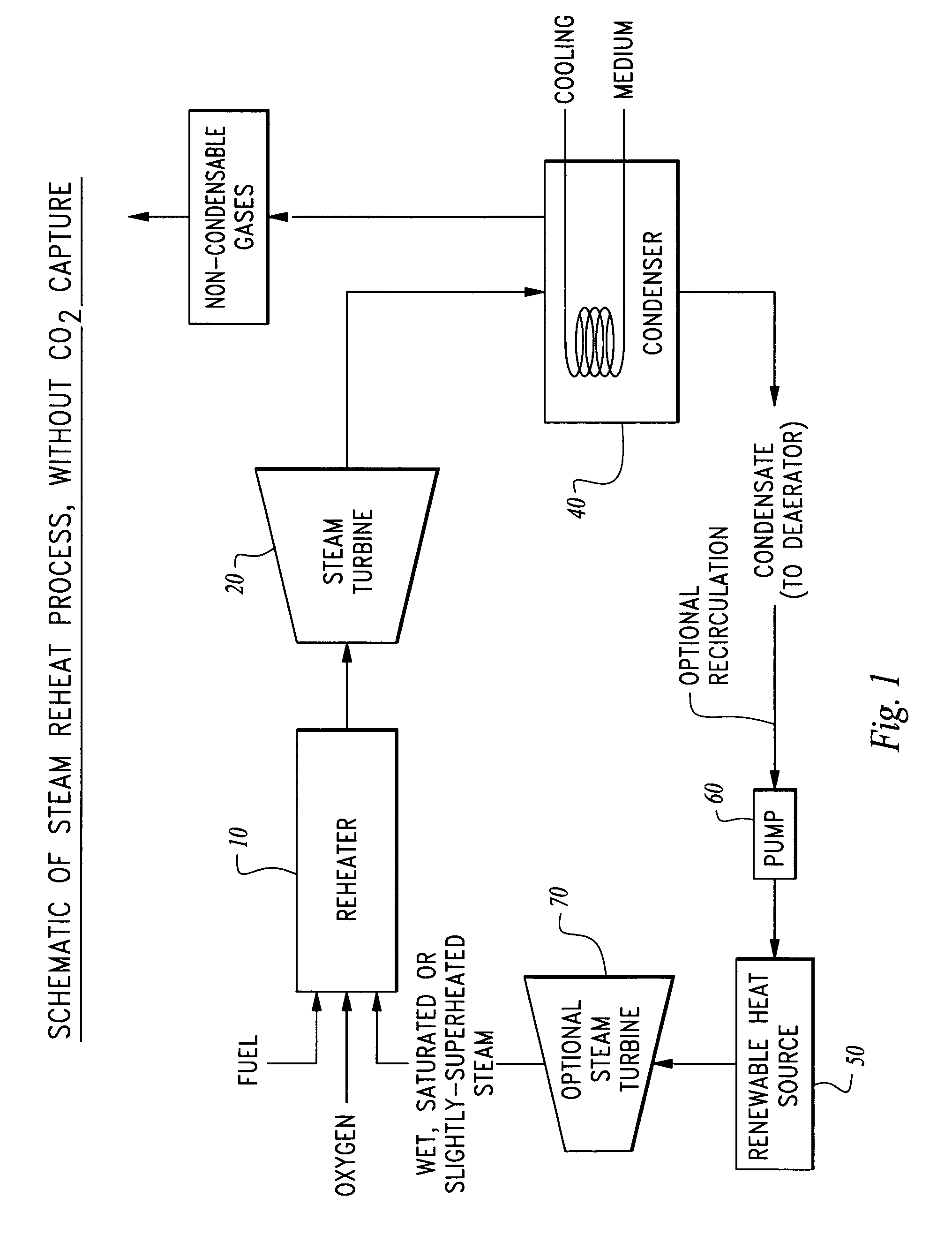

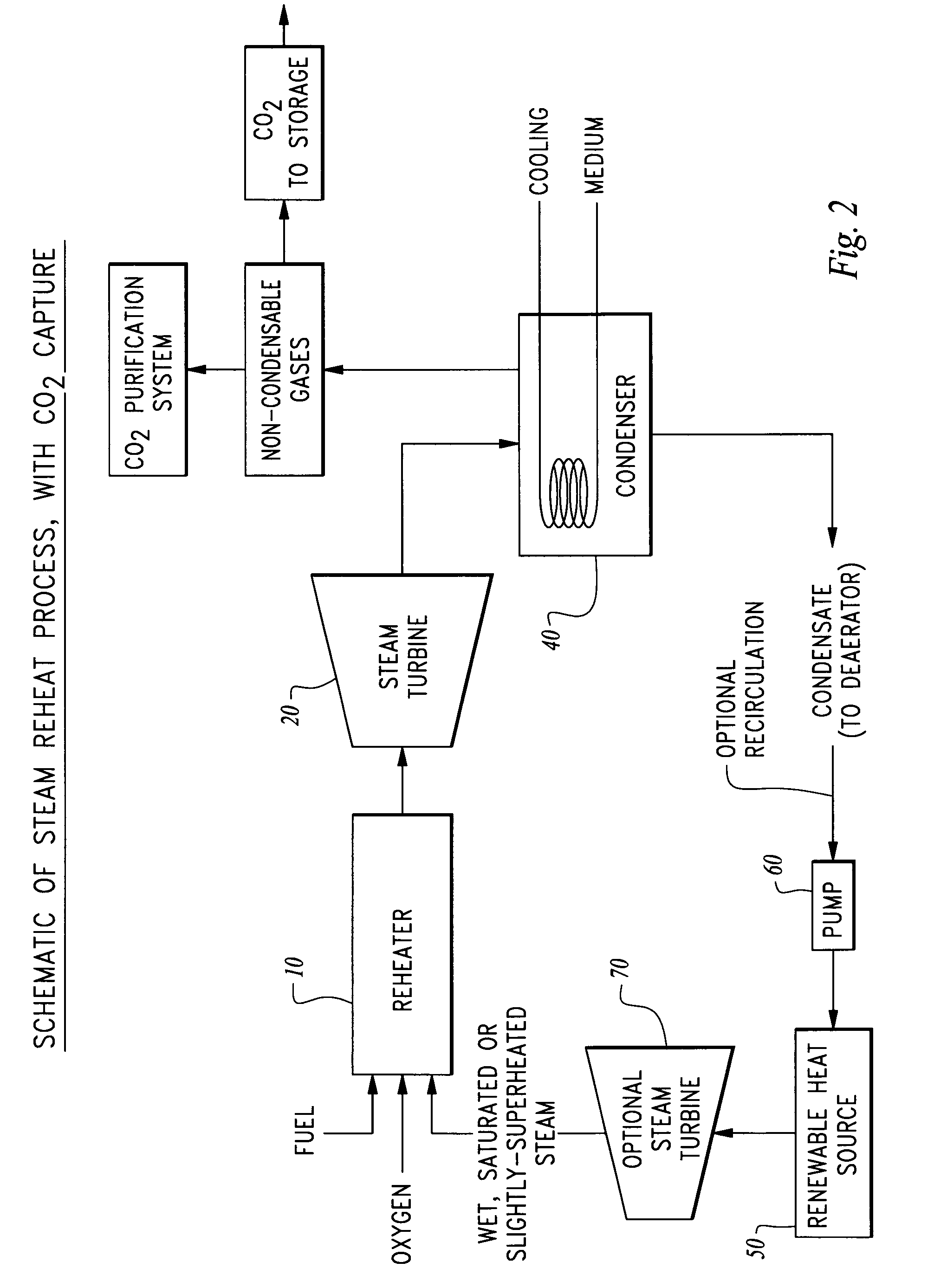

Method and system for enhancing power output of renewable thermal cycle power plants

InactiveUS20100146970A1High power outputImprove thermal cycle efficiencyDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationAtmospheric emissionsWorking fluid

A steam reheat process is provided to enhance a thermal power cycle, and particularly a renewable steam thermal cycle. An oxyfuel combustion gas generator is provided which combusts a hydrogen and / or carbon containing fuel with an oxidizer of primarily oxygen to generate products of combustion including steam and / or carbon dioxide. Water from the thermal cycle is directed to the reheater for mixing with the products of combustion within the reheater to generate a working fluid containing steam. This steam is routed through a turbine or other expander and power is outputted from the system. The water is optionally thereafter condensed and at least partially routed back to the thermal cycle. Any carbon dioxide within the working fluid can be separated in a condenser downstream of the expander for capture of the carbon dioxide, such that increased power output for the thermal power cycle is achieved without atmospheric emissions.

Owner:CLEAN ENERGY SYST

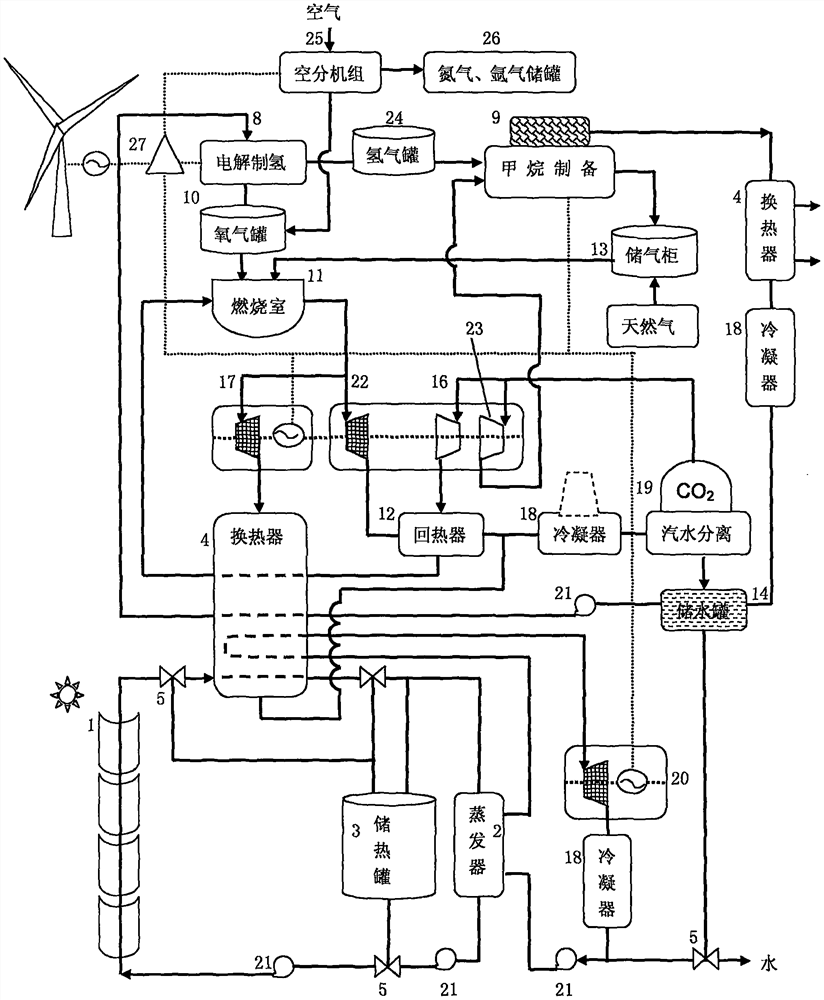

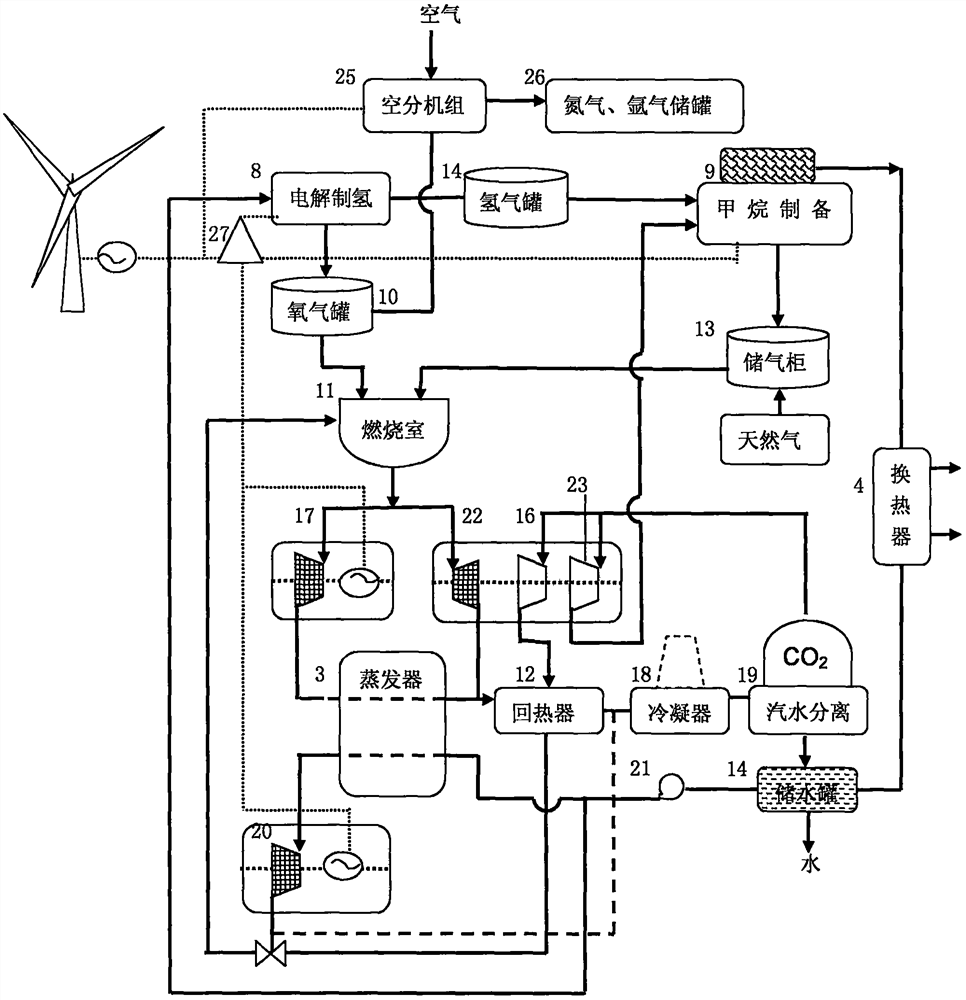

Solar energy, wind energy and fuel gas complementation combined hydrogen production and methane production circulating thermal power generation device

PendingCN112832963AIncrease the hours of thermal power generationImprove thermal power generation efficiencySolar heating energyElectrolysis componentsElectrolysisMethanation

The invention discloses a solar energy, wind energy and fuel gas complementation combined hydrogen production and methane production circulating thermal power generation device. A groove type solar thermal power generation technology is organically grafted in a semi-closed supercritical carbon dioxide fuel gas Brayton thermal power generation system, and the congenital defect that solar thermal power generation is unstable and discontinuous is overcome through complementation heat storage circulating power generation; meanwhile, water generated by pure oxygen gas power generation is used for electrolytic hydrogen production and oxygen production, carbon dioxide obtained through steam-water separation serves as a power working medium, other parts are subjected to hydrogenation methanation preparation, and prepared methane gas is stored; oxygen obtained by hydrogen production through renewable energy electrolysis water is used for pure oxygen fuel gas Brayton efficient power generation of the system; and water generated by condensation of the system and water generated by hydrogenation methanation are directly supplied to a groove type solar thermal power generation system for recycling after being stored and serve as a water source for cleaning a solar mirror field. The invention belongs to the technical field of solar thermal power generation and high-temperature thermochemistry interdisciplinary.

Owner:张建城

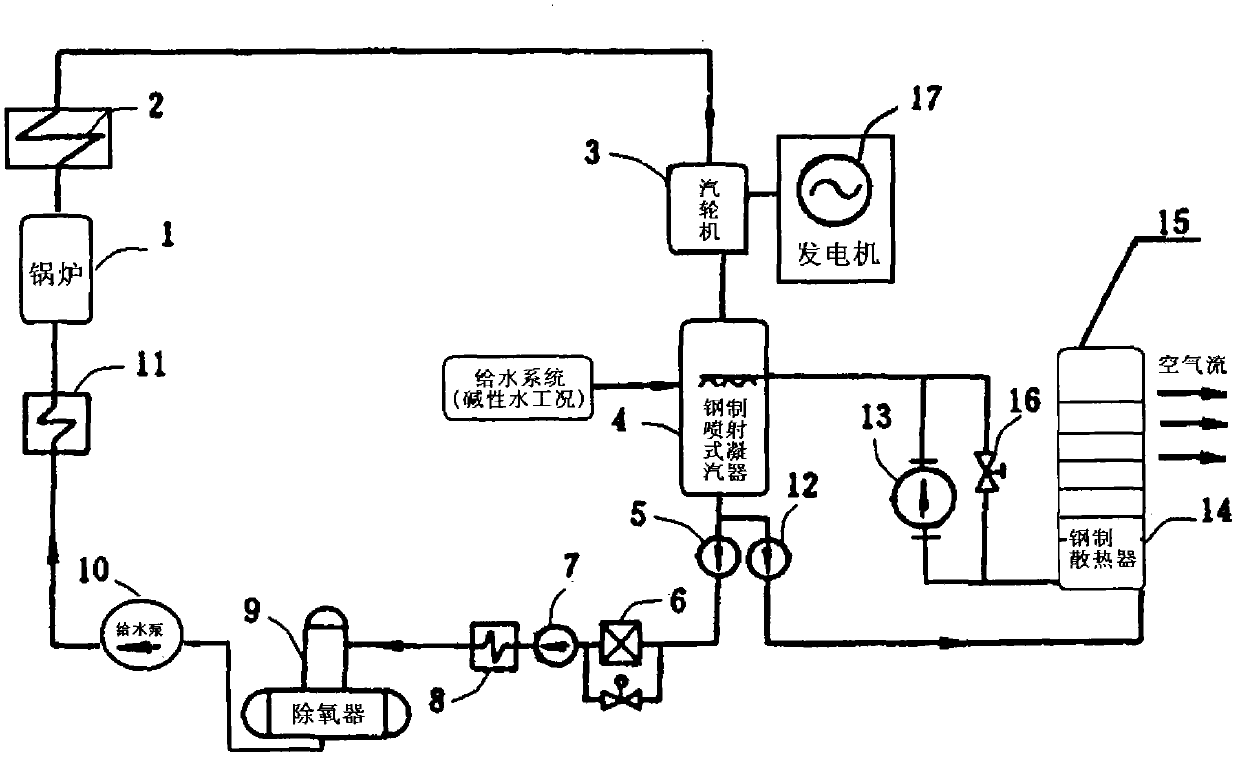

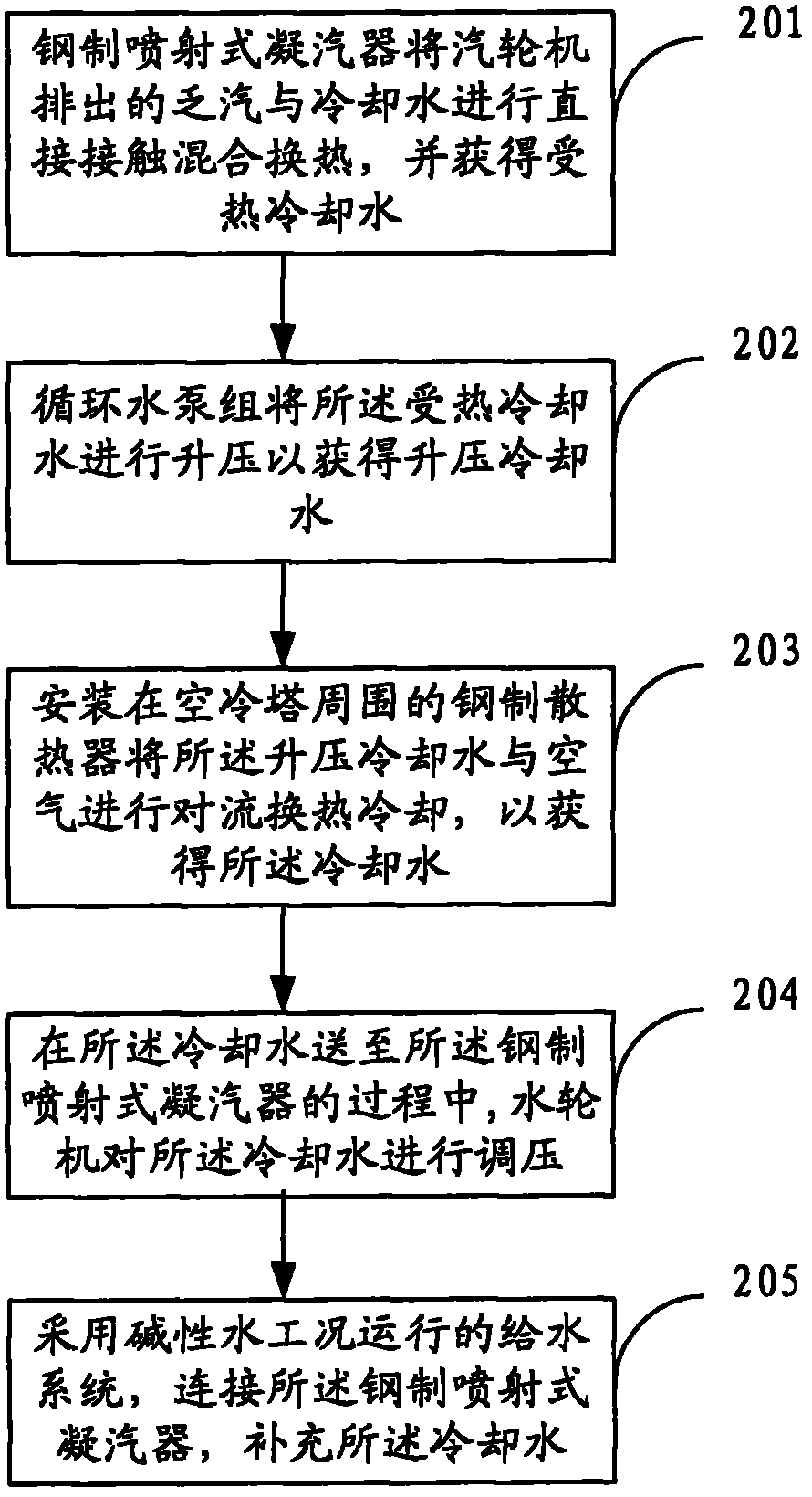

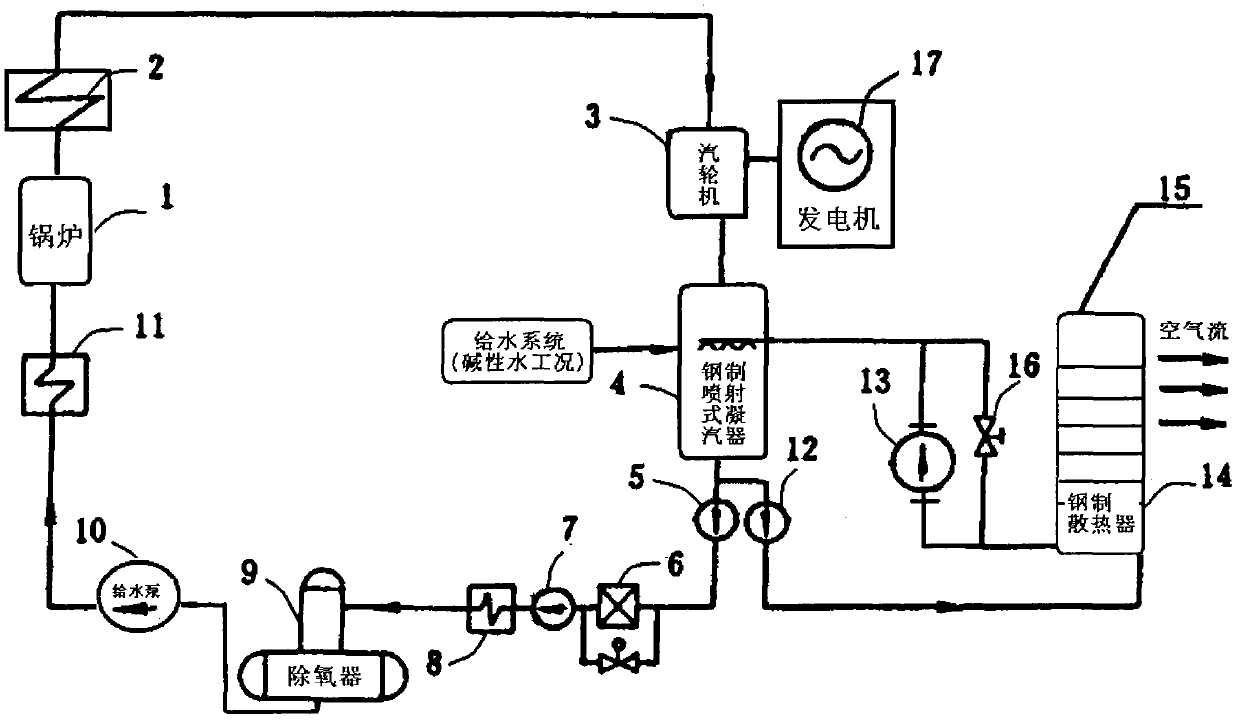

Indirect air cooling system and indirect air cooling method for supercritical machine set or ultra-supercritical machine set

ActiveCN102562183AWater quality control is simple and easyReduce processing costsStationary conduit assembliesEngine componentsAlkaline waterWater treatment system

The invention provides an indirect air cooling system and an indirect air cooling method for a supercritical machine set or an ultra-supercritical machine set. The indirect air cooling system comprises a steel injection type condenser for enabling waste steam and cooling water to perform direct contact mixing and heat exchange with each other, a circulating water pump group for boosting pressure of the heated cooling water so as to obtain pressure-boosting cooling water, a steel radiator, a water turbine and a water supply system running by adopting alkaline water working conditions, wherein the steel radiator is used for performing heat convection cooling to the pressure-boosting cooling water and the air so as to obtain the cooling water; the water turbine is used for performing pressure adjustment to the cooling water during the process of conveying the cooling water to the steel injection type condenser and is used for recycling energy simultaneously; and the water supply system is connected with the steel injection type condenser and is used for supplementing the cooling water. The indirect air cooling system and the indirect air cooling method enable the injection type condenser to adopt ordinary alkaline water, the technical problem that a Heller indirect air cooling system is difficult in application to the supercritical machine set of over 300MW is solved, a water quality control system is simple and practicable, and investment of a water treatment system is reduced.

Owner:CHINA POWER ENG CONSULTING GRP +1

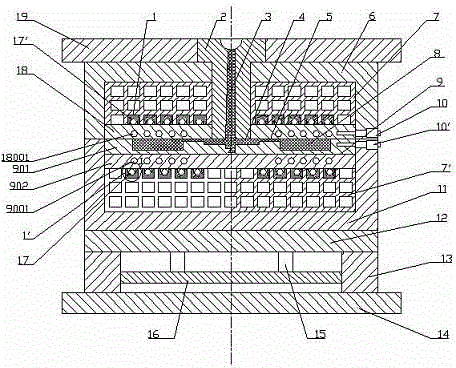

Electric heating type rapid heat cycle molding injection mold

InactiveCN104690890AReduce manufacturing costImprove thermal cycle efficiencySteel platesSheet steel

The invention relates to an electric heating type rapid heat cycle molding injection mold. The mold comprises a core plate and a cavity plate, wherein the core plate and the cavity plate are respectively connected with support plates; the support plates are characterized by connecting a plurality of ordinary steel plates with poor heat-conducting properties in a criss-cross manner to form a latticed structure; part of meshes in closed holes formed by matching the support plates with the core plate and the cavity plate are preferably selected and heating elements are installed inside the meshes by utilizing special heat insulation devices to achieve rapid heating of the molding surface of the mold; the cavity plate is formed by a molding layer and a base layer; the base layer is prepared with ordinary hot work mold steel by adopting a conventional process; the molding layer is prepared by superposing high-quality mold steel with good heat fatigue resistance and terrific polishing property on the surface of the base layer by adopting an overlay welding method; cooling pipelines are arranged on the core plate and the base layer of the cavity plate to achieve rapid cooling of the molding surface of the mold. The electric heating type rapid heat cycle molding injection mold has the beneficial effect that innovative designs of the material, the structure, and the like are put forward.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Method and system for enhancing power output of renewable thermal cycle power plants

InactiveUS8631658B2Improve thermal cycle efficiencyHigh power outputSteam useGas turbine plantsAtmospheric emissionsWorking fluid

A steam reheat process is provided to enhance a thermal power cycle, and particularly a renewable steam thermal cycle. An oxyfuel combustion gas generator is provided which combusts a hydrogen and / or carbon containing fuel with an oxidizer of primarily oxygen to generate products of combustion including steam and / or carbon dioxide. Water from the thermal cycle is directed to the reheater for mixing with the products of combustion within the reheater to generate a working fluid containing steam. This steam is routed through a turbine or other expander and power is outputted from the system. The water is optionally thereafter condensed and at least partially routed back to the thermal cycle. Any carbon dioxide within the working fluid can be separated in a condenser downstream of the expander for capture of the carbon dioxide, such that increased power output for the thermal power cycle is achieved without atmospheric emissions.

Owner:CLEAN ENERGY SYST

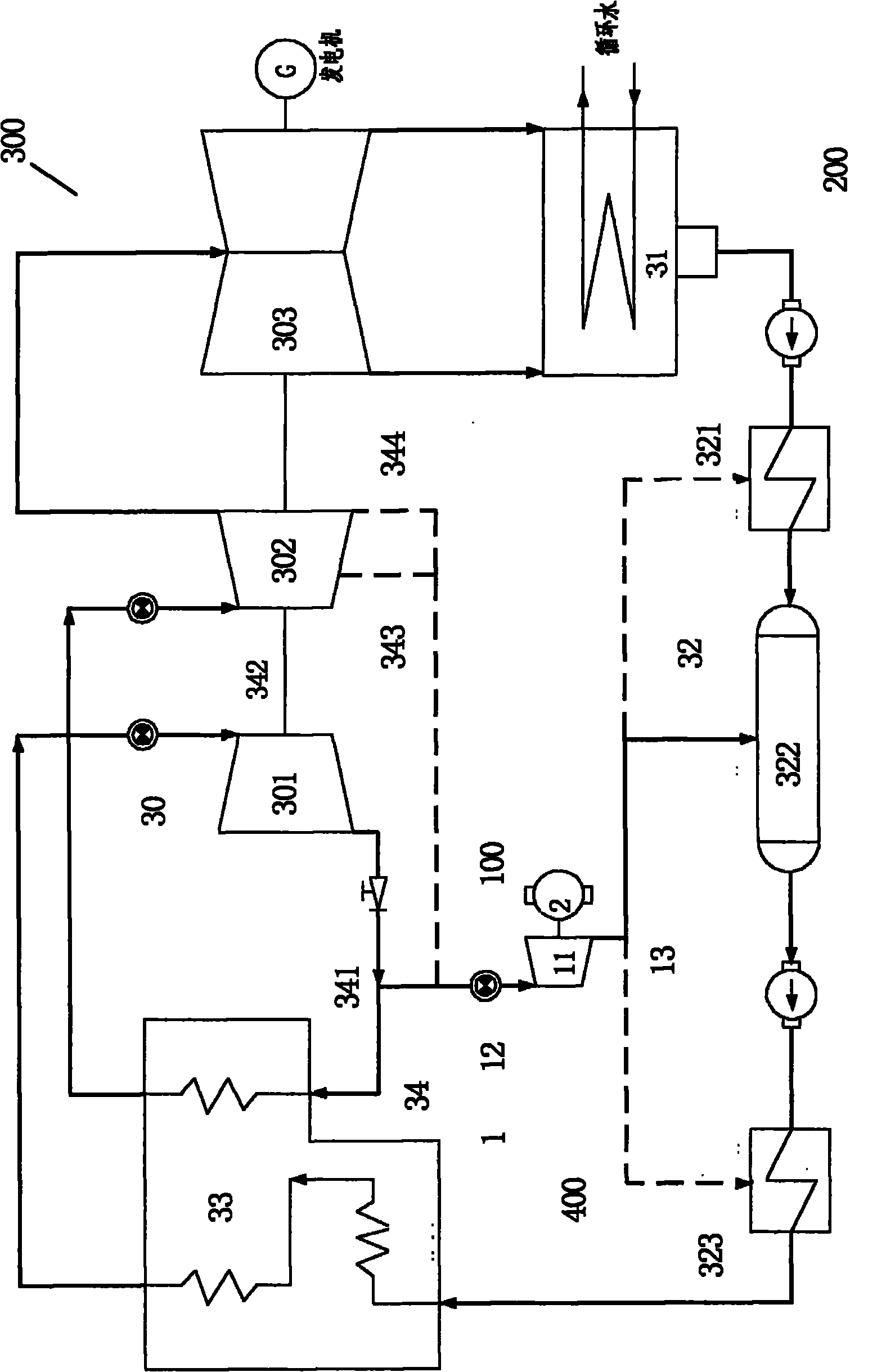

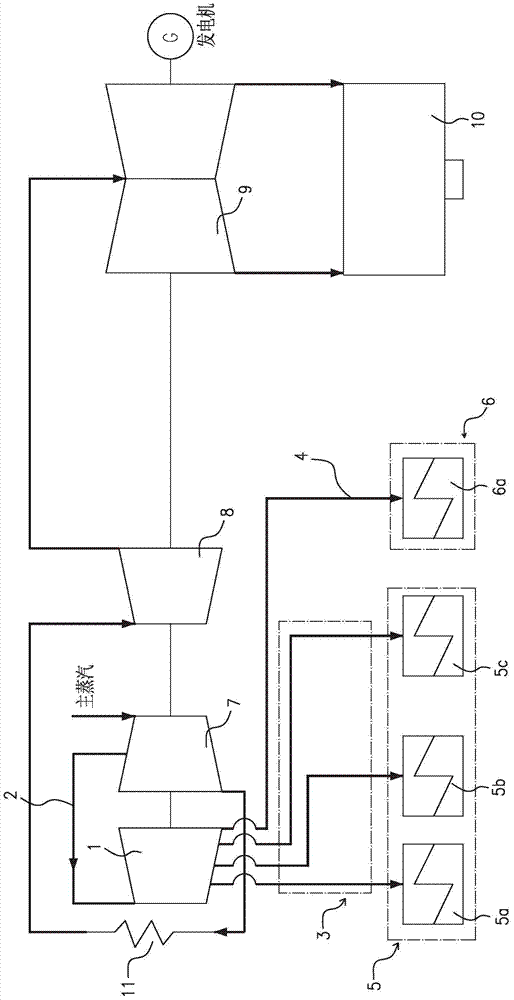

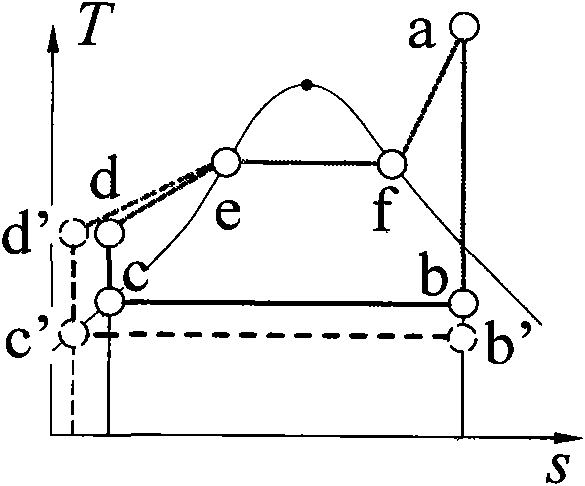

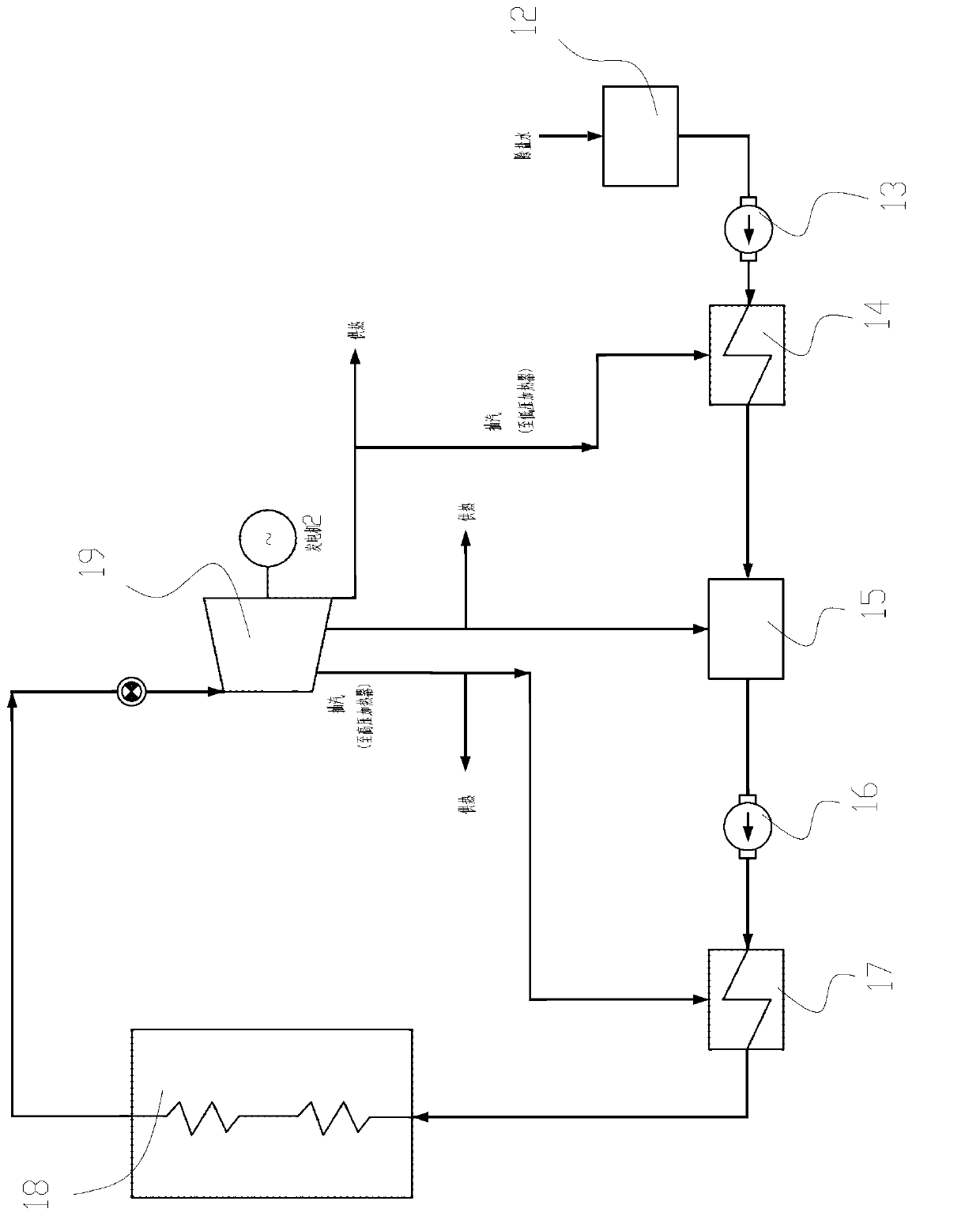

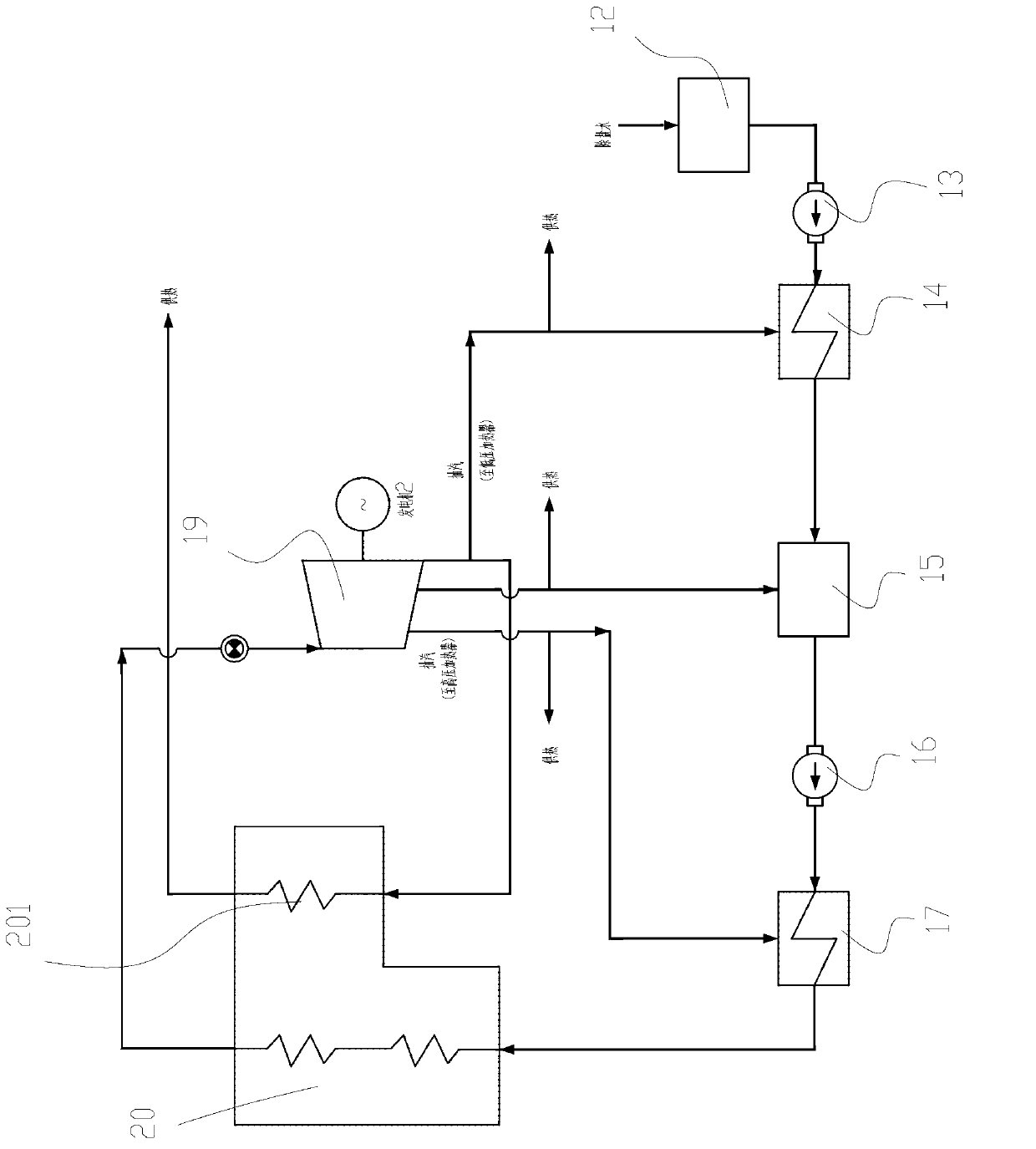

Thermal power plant combined heat system and thermal power plant

ActiveCN102828792AImprove thermal cycle efficiencyLower fuel consumptionSteam useCombined combustion mitigationEngineeringThermal cycle

The invention discloses a thermal power plant combined heat system and a thermal power plant. The thermal power plant comprises a primary reheat condensing steam unit and a backpressure unit; and the combined heat system comprises a heat system of the primary reheat condensing steam unit and a heat system of the backpressure unit, wherein the heat system of the primary reheat condensing steam unit and the heat system of the backpressure unit share a heat recovery system from a condenser to a deaerator; condensation water of the primary reheat condensing steam unit and the supplement demineralized water of the backpressure unit are divided into two paths through the shared heat recovery system; and one path enters the primary reheat condensing steam unit, and the other path enters the backpressure unit. According to the combined heat system, the requirements of industrial high capacity and high parameter heat supply can be simultaneously met, the thermal cycle efficiency is greatly improved, the fuel consumption is reduced, and the pollutant discharge is reduced; and meanwhile, the power plant investment can be greatly reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

Piston ram self-ignition pulse-jet engine

InactiveCN103967652AGuaranteed initial pressureAct as a superchargerIntermittent jet plantsRam jet enginesMultifuelCombustion chamber

The invention provides a piston ram self-ignition pulse-jet engine. A stepped free piston is mounted in an engine bod, and a pre-combustion chamber and a main combustion chamber are formed. The front end of the main combustion chamber is provided with a spout provided with a pressure control switch; a fuel pipe on one side and a low-pressure gas pipe are both communicated with the pre-combustion chamber and the main combustion chamber through air inlets; the inner front end of a cylinder block is provided with a vent way. The cylinder block is divided into the two combustion chambers, ignition is achieved by gas pressure, mechanical means or a spark plug, the pre-combustion chamber is controlled to combust first by one or any of the means such as photoelectricity and electromagnetic wave, the main combustion chamber is blast through the free piston, high-temperature high-pressure gas is formed and thrusts the spout open, thrust is generated, and no power turbine is required. The piston ram self-ignition pulse-jet engine can be switched to a rocket operation mode and is a dual-mode efficient engine ideal for aerospace, aviation, rockets and the like. Multiple fuels are available to the piston ram self-ignition pulse-jet engine, the structure is simplified, and the piston ram self-ignition pulse-jet engine can be combined with the existing engine to form novel engines.

Owner:钱金虎 +1

Adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization

InactiveCN105091020AIncrease independenceBest Cascade UtilizationCombustion processSteam useEngineeringRecuperator

The invention belongs to the fields of thermal power generation and the like and particularly relates to an adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization. According to the adjustable boiler air preheating system and method, air preheating, waste heat utilization and regenerative heat cycling are made to be combined organically; heat-transmission cycling condensate water is divided into a large open cycle in which a bypass low-pressure heater extrudes a steam turbine to perform high-parameter steam extraction and a small closed cycle in which the low-pressure heater (or an added heat exchanger) is used for absorbing heat to increase low-parameter steam extraction; heat flow is divided according to the temperature level difference, heat source and cold source resources are dynamically and sufficiently used, optimal gradient utilization of heat energy in the power generation thermodynamic cycle is achieved, the energy use quality is improved, and energy losses are reduced. According to the adjustable boiler air preheating system and method, the operation mode of the system can be optimized and adjusted automatically according to the change of the operation condition so that gradient utilization of energy of different qualities can be achieved and energy losses can be reduced, and the thermodynamic cycle efficiency and the system economy are maximized.

Owner:郝江平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com