Piston ram self-ignition pulse-jet engine

A jet engine and engine technology, applied in ramjet engines, mechanical equipment, intermittent injection devices, etc., can solve the problems of air pollution, low power density, low fuel efficiency, etc., and meet the requirements of large thrust-to-weight ratio and gas compression ratio Lower, start and stop simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

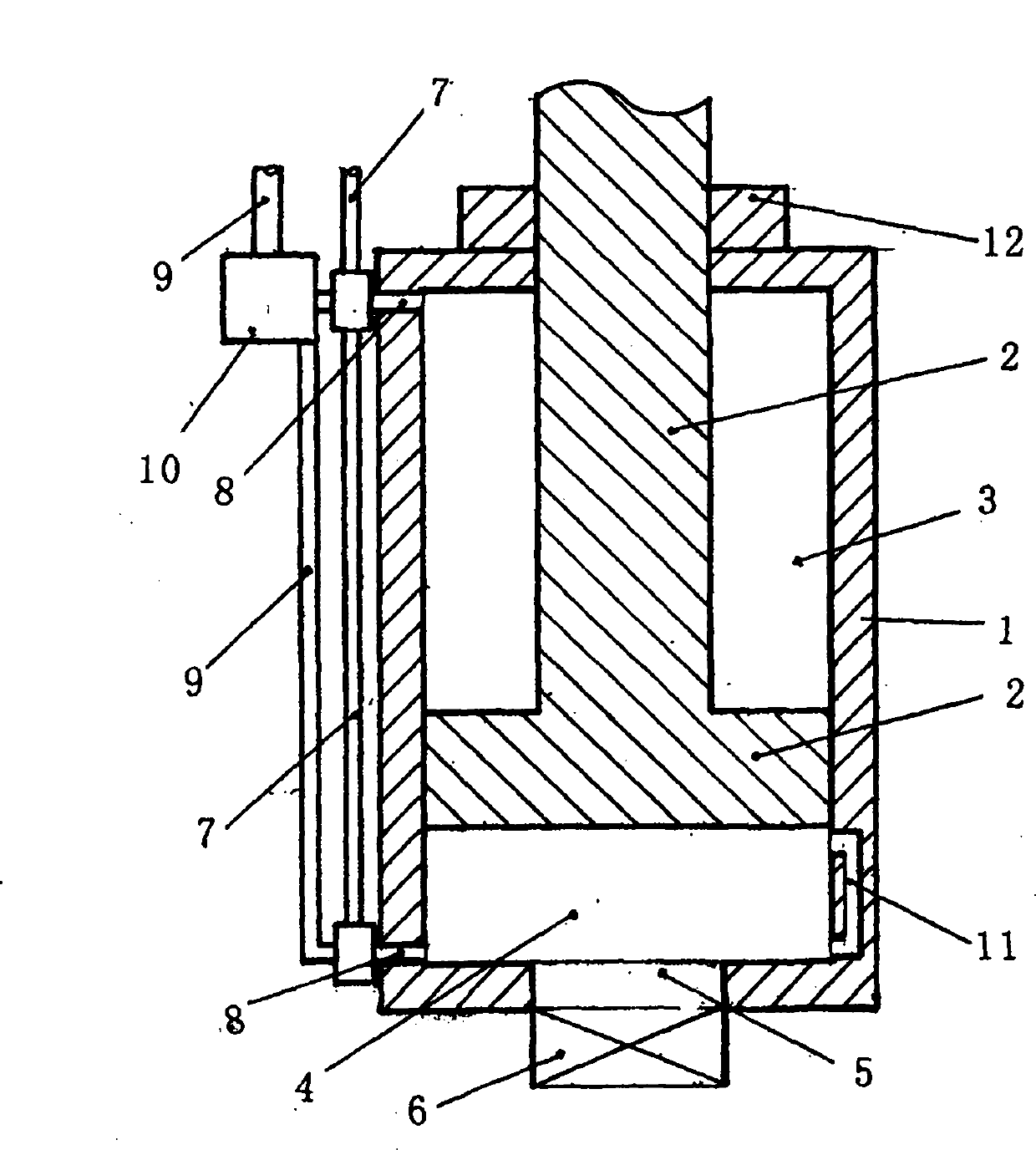

[0013] figure 1 As shown: the engine is equipped with a stepped free piston 2 in the body 1, so that the body 1 constitutes a pre-combustion combustion chamber 3 and a main combustion chamber 4, and a pressure control chamber is installed on the cylinder body 1 at the front end of the main combustion chamber 4. The nozzle 5 of the switch 6, the fuel pipe 7 and the low-pressure air pipe 8 on the side of the cylinder block 1 are respectively connected with the pre-combustion combustion chamber 3 and the main combustion chamber 4 through the air inlet 8, and a ventilator is provided on the inside of the front end of the cylinder block 1. Road 11. A gas distribution controller 10 is provided at the front end of the low-pressure air pipe 9 . A magnetic control block 12 is sleeved on the stepped free piston 2 outside the cylinder body 1 .

[0014] Under the working state situation of the present invention: be full of a certain amount of oil-gas mixture to the pre-combustion chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com