Grease food packaging bag convenient for secondary sealing

A technology for oily food and secondary sealing, which is applied in the direction of sealing devices, etc., and can solve problems such as difficult unpacking and over-tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

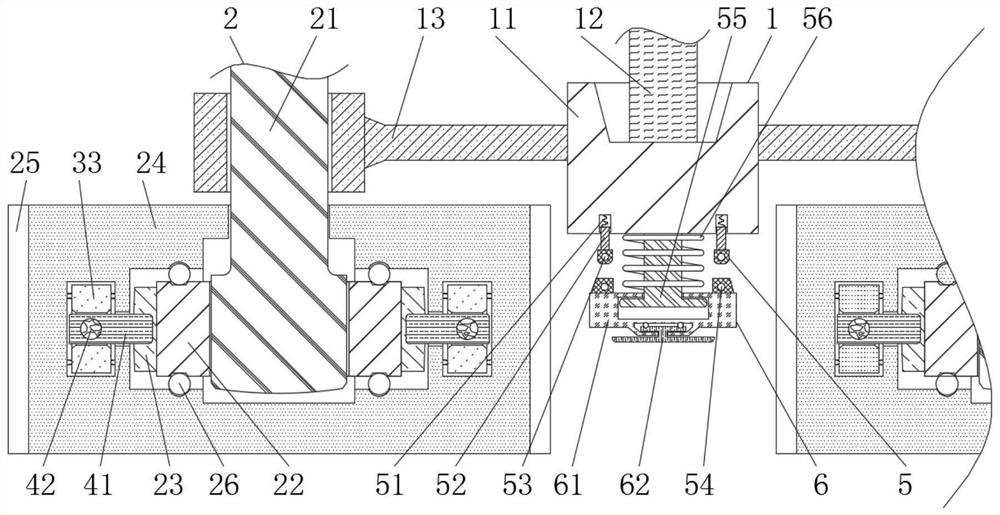

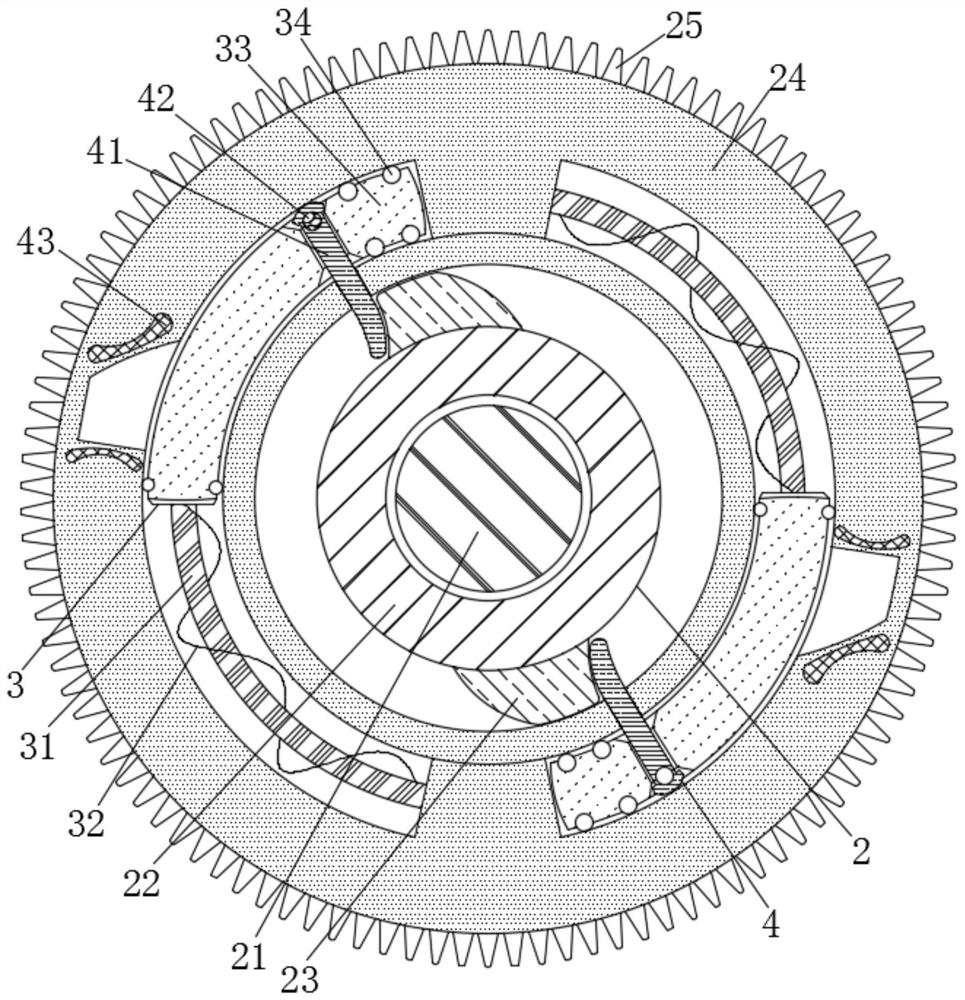

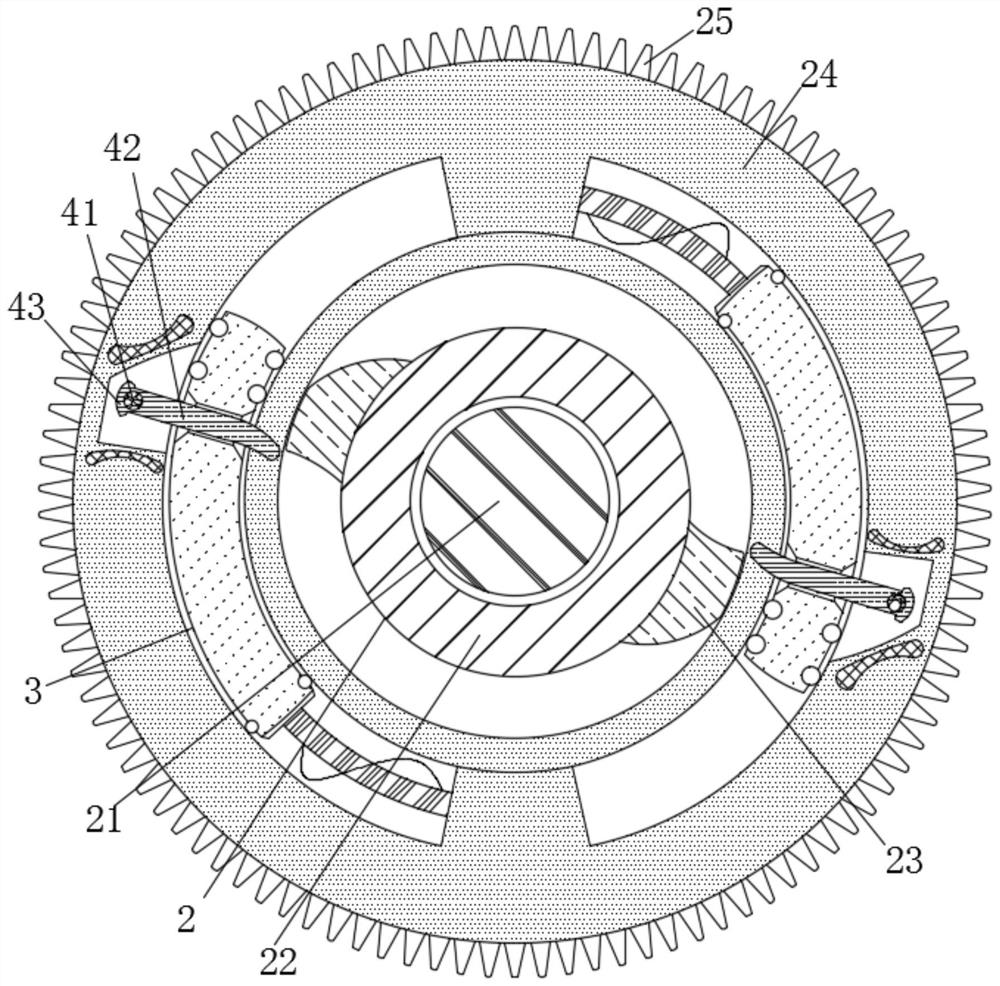

[0026] see Figure 1-2 , a convenient secondary sealing oil food packaging bag, including a fixing mechanism 1, a rotating mechanism 2, a force transmission mechanism 3, a control mechanism 4, a judging mechanism 5, a matching mechanism 6, the fixing mechanism 1 includes a fixed block 11, a moving rod 12. The fixed arm 13, the moving rod 12 is fixedly connected to the top of the fixed block 11, the fixed arm 13 is fixedly connected to the outside of the fixed block 11, the fixed block 11 is made of metal material, the moving rod 12 includes a push rod, a motor and a control assembly, and the moving rod 12 can drive the product to move down as a whole. The fixed arm 13 is made of metal material. The inside of the fixed arm 13 is provided with a through hole that matches the main shaft 21. Both sides of the fixed mechanism 1 are movably connected with a rotating mechanism 2. The rotating mechanism 2 Including the main shaft 21, the mating wheel 22, the force transmission block 2...

Embodiment 2

[0031] see Figure 1-4 , a convenient secondary sealing oil food packaging bag, including a fixing mechanism 1, a rotating mechanism 2, a force transmission mechanism 3, a control mechanism 4, a judging mechanism 5, a matching mechanism 6, the fixing mechanism 1 includes a fixed block 11, a moving rod 12. The fixed arm 13, the moving rod 12 is fixedly connected to the top of the fixed block 11, the fixed arm 13 is fixedly connected to the outside of the fixed block 11, the fixed block 11 is made of metal material, the moving rod 12 includes a push rod, a motor and a control assembly, and the moving rod 12 can drive the product to move down as a whole. The fixed arm 13 is made of metal material. The inside of the fixed arm 13 is provided with a through hole that matches the main shaft 21. Both sides of the fixed mechanism 1 are movably connected with a rotating mechanism 2. The rotating mechanism 2 Including the main shaft 21, the mating wheel 22, the force transmission block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com