Self-pressurization air inflation sealing butterfly valve

An inflatable sealing and self-pressurizing technology, which is applied in the field of sealing butterfly valves and self-pressurizing inflatable sealing butterfly valves, can solve problems such as operation and inability to operate remotely, and achieve the effects of prolonging service life, reliable shrinkage recovery, and uniform elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

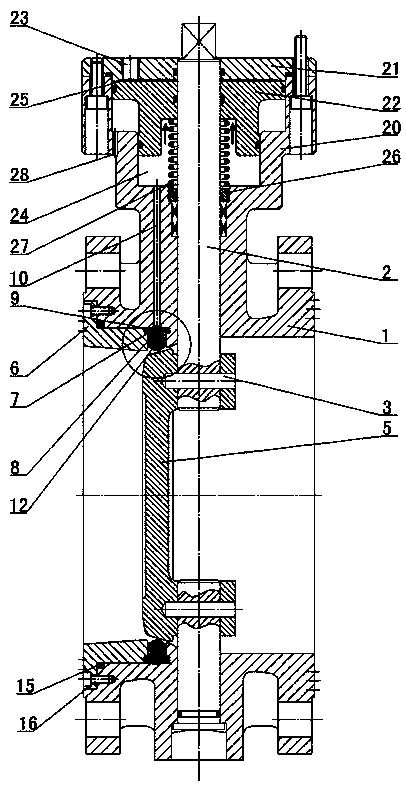

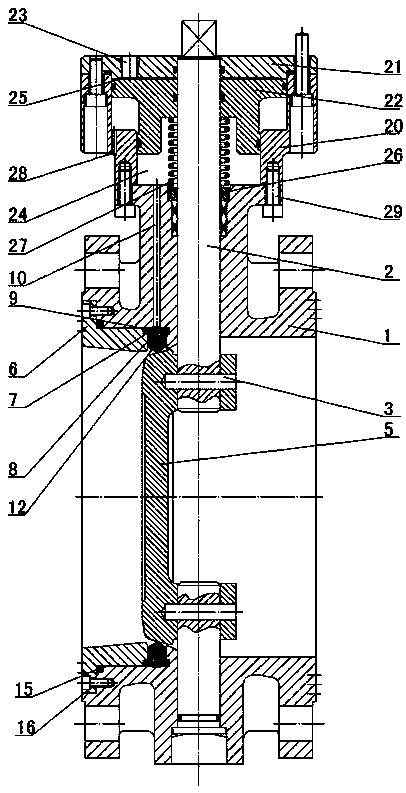

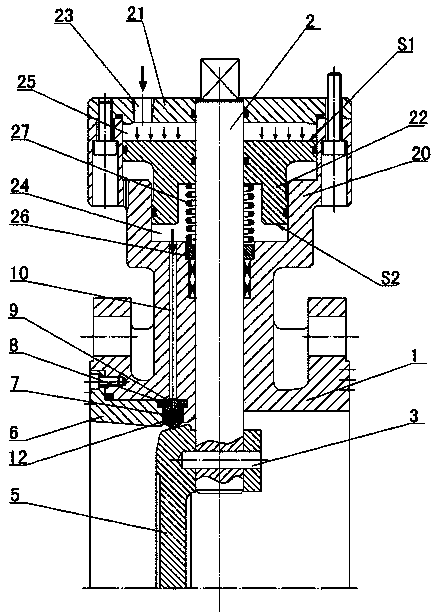

[0013] The invention relates to a self-pressurized air-tight sealing butterfly valve, such as figure 1 — Figure 5Said, including a valve body 1, valve shaft 2 is set in the valve body, the valve shaft is connected to the valve plate 5 through the pin 3, the inner port of the valve body 1 is provided with a sealing gland 6, and the sealing gland 6 is provided with a hollow The Ω-shaped pressure-charging rubber ring 7, the Ω-shaped pressure-charging rubber ring 7 is provided with a bar-shaped pressure-charging bracket 8, and a through-hole 9 is formed in the bar-shaped pressure-charging bracket, and the pressure-charging inner channel 10 is set in the wall of the valve body 1 , the pressurized inner channel 10 communicates with the through hole 9 to form a sealed cavity 4 in the Ω-shaped pressurized rubber ring 7, and the valve body 1 is provided with a self-pressurizing mechanism, and the self-pressurizing mechanism includes a valve shaft 2 as The center is provided with a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com