Electric control cabinet heat dissipation system and electric control cabinet

A technology of heat dissipation system and electric control cabinet, applied in the direction of electrical equipment shell/cabinet/drawer, static electricity, electrical components, etc. problem, to achieve better cooling effect, automatic control function, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

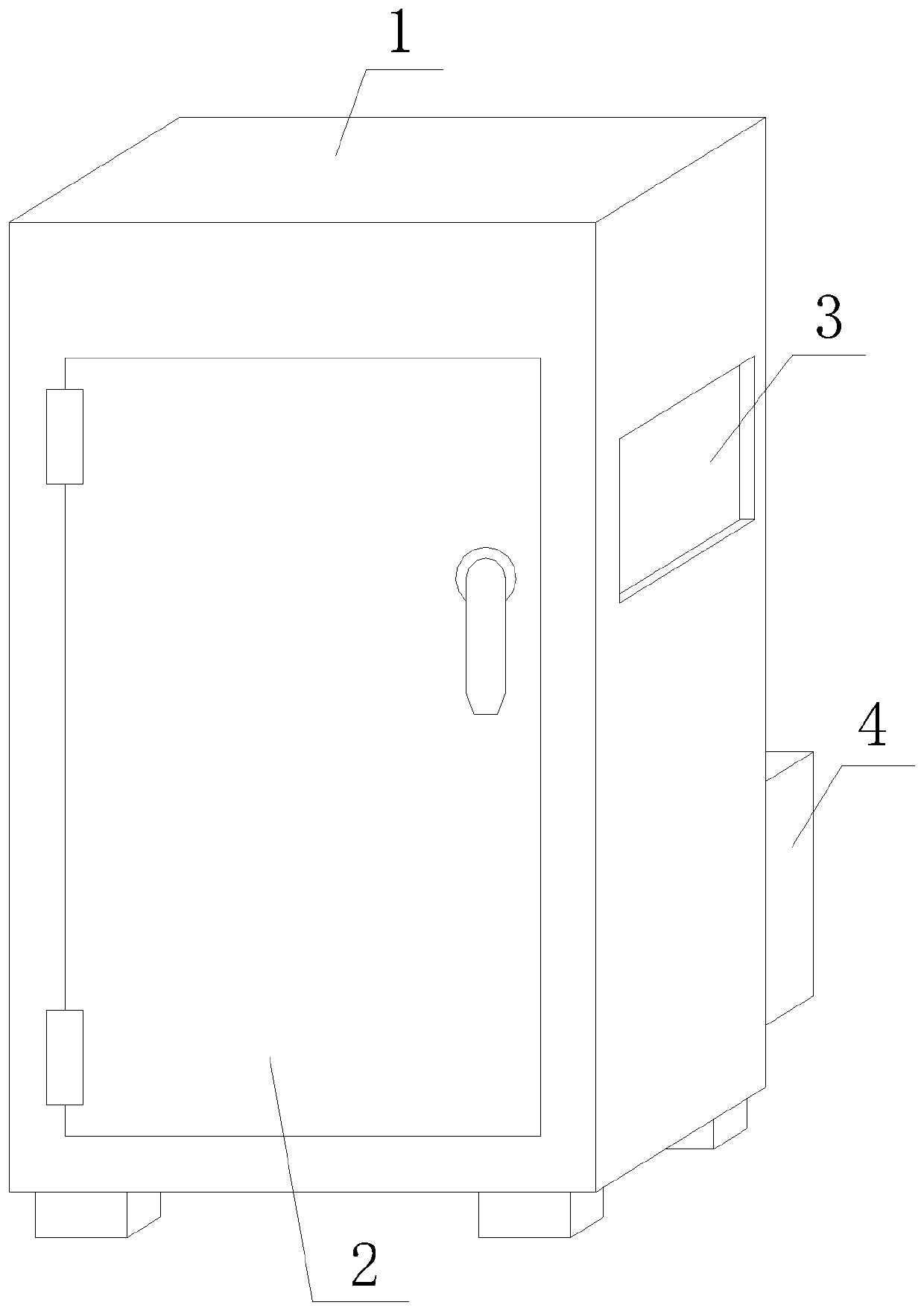

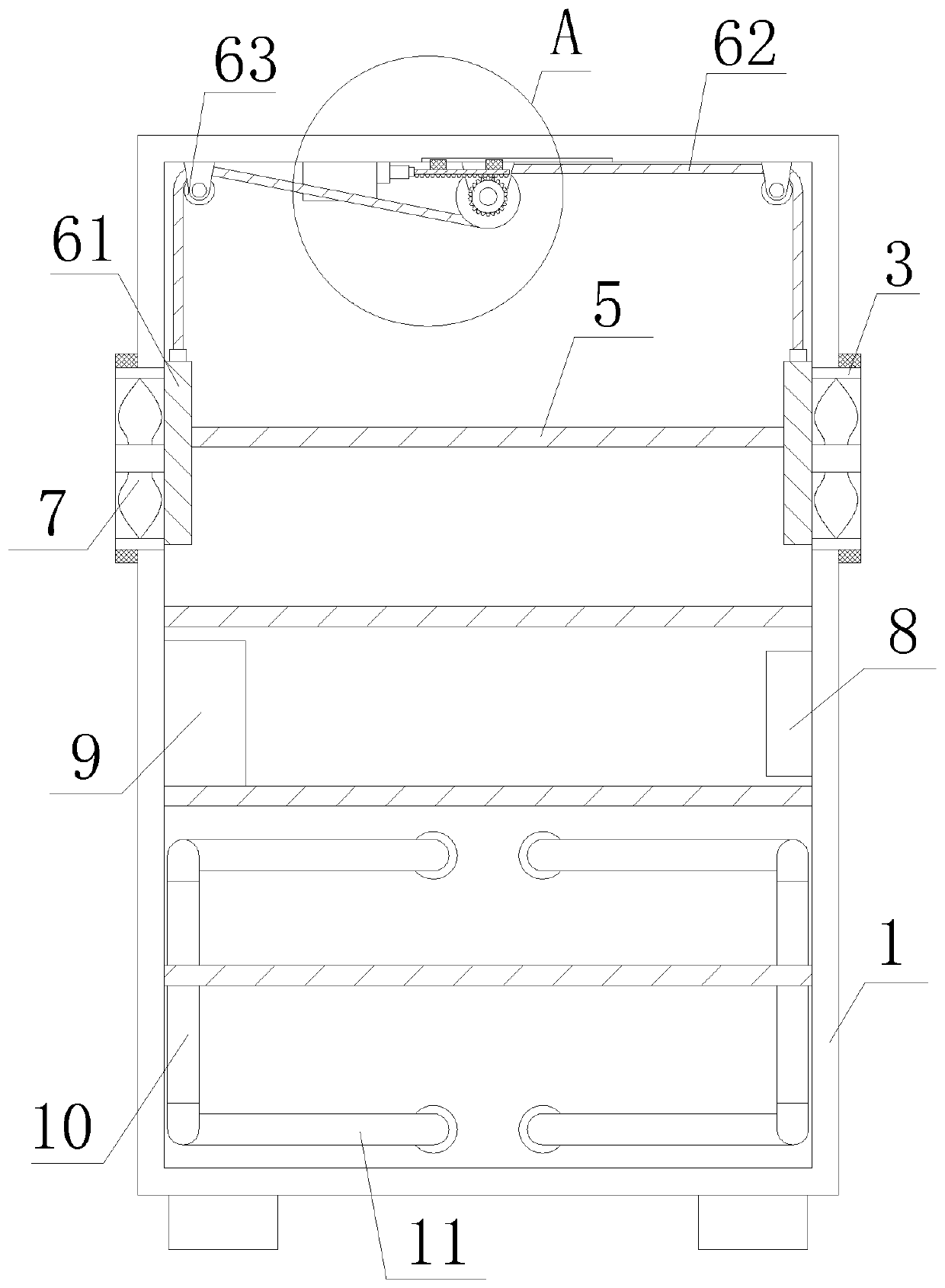

[0028] Attached below Figure 1-5 The present invention is further described with embodiment:

[0029] A heat dissipation system for an electric control cabinet, comprising an air-cooled heat dissipation system 6 and a temperature control trigger assembly 9 arranged in the inner cavity of the main body 1 of the electric control cabinet;

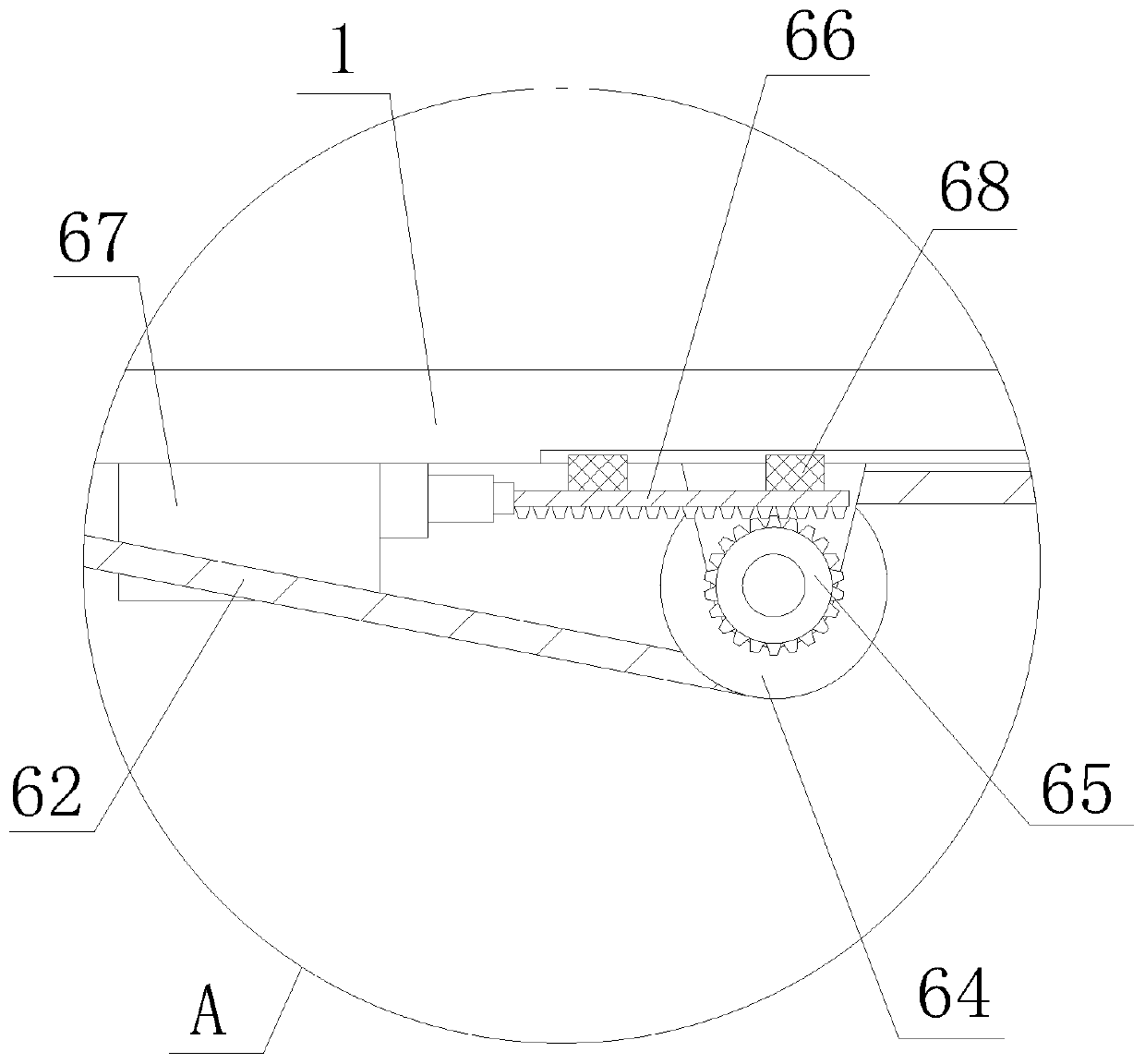

[0030] In this example, if figure 2 and 3 As shown, the air-cooled heat dissipation system 6 includes two cooling vents 3 provided on the upper symmetrical side wall of the main body of the electric control cabinet 1. A cooling fan 69 is installed on the cooling vents 3. The opposite sides of the two cooling vents 3 are All are provided with heat dissipation opening sealing plate 61, and described heat dissipation opening sealing plate 61 is slidably installed on the inner wall of electric control cabinet main body 1, and the upper end of described heat dissipation opening sealing plate 61 is equipped with traction rope 62, and the two tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com