Thermodynamic system for combined heat recovery of power plant

A technology of thermal system and thermal cycle system, applied in the field of recycling to regenerative system, can solve the problems of heat loss, single function of heat recovery of flue gas, large pressure fluctuation of deaerator, etc., to reduce coal consumption, improve thermal cycle efficiency, The effect of reducing the loss of cold source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

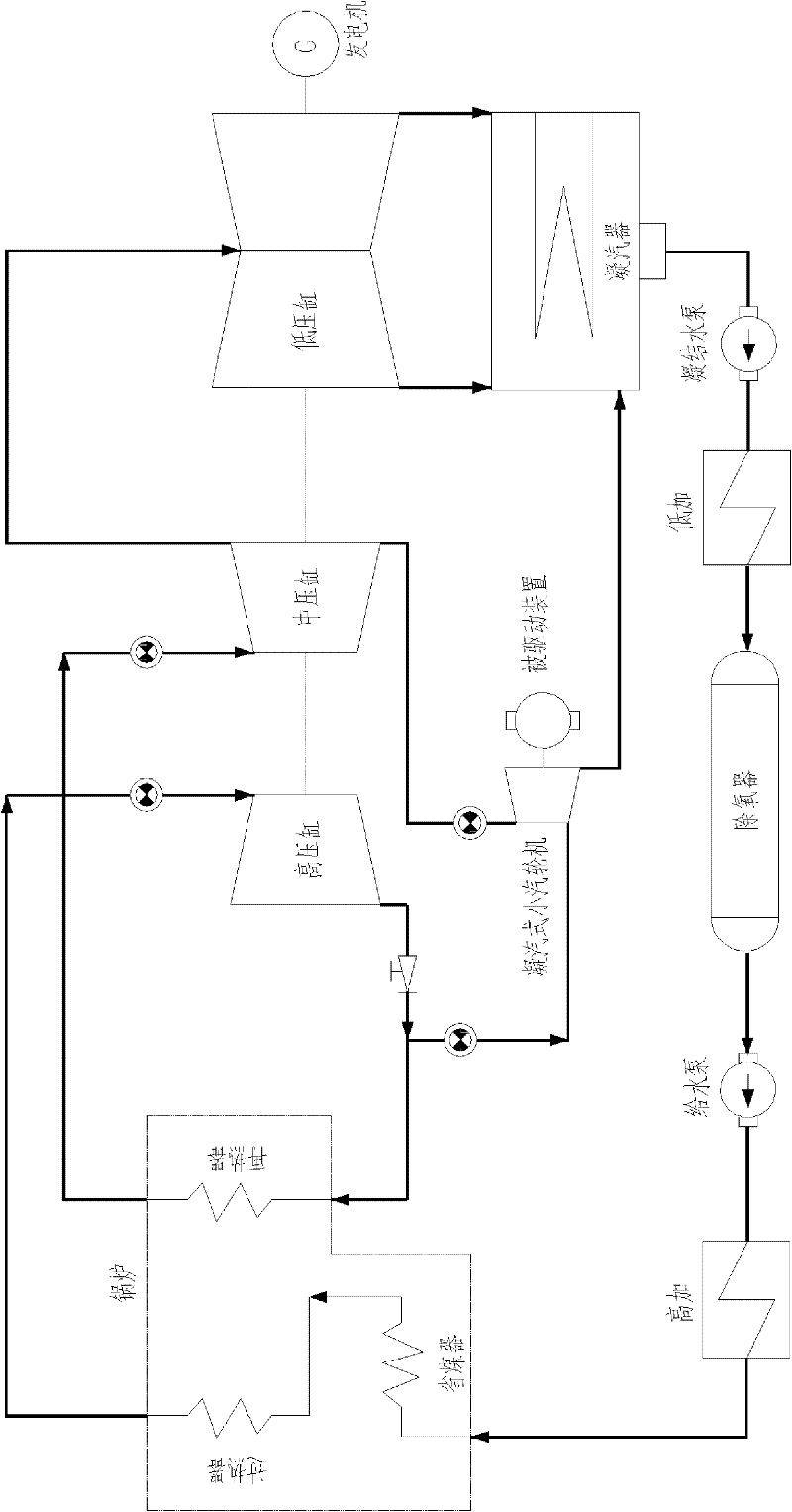

[0033] Figure 4 It shows the structure of the first embodiment of the combined heat recovery thermal system of the power plant of the present invention. See Figure 4 , The system of this embodiment includes a fan exhaust steam waste heat recovery heater 10, a regenerative driving steam turbine 11, a drain pump 12, a flue gas waste heat recovery device 13, and an atmospheric expansion vessel 14 for exhaust steam. The flue gas waste heat recovery device 13 provides a separate external heat source for the thermal cycle system of the power plant, and the fan exhaust waste heat recovery heater on the fan side is connected in series or parallel to the thermal cycle system of the unit.

[0034] The fan exhaust waste heat recovery heater 10 is located at the fan side, that is, a first-stage fan exhaust waste heat recovery heater 10 is added to the original thermal cycle heat recovery system. The steam in the thermal cycle system of the power plant is connected to the regenerative ...

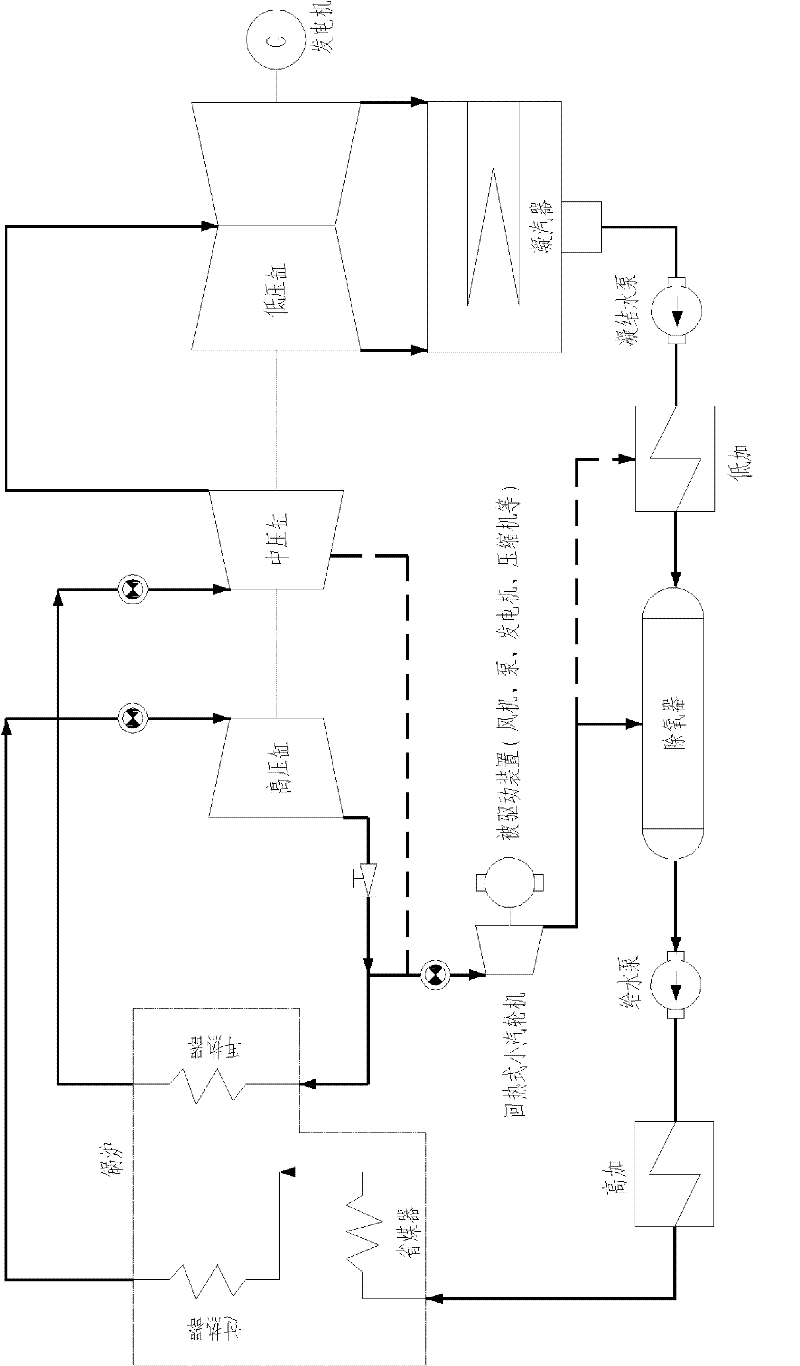

no. 3 example

[0055] Figure 6 It shows the structure of the third embodiment of the combined heat recovery thermal system of the power plant of the present invention. See Figure 6 , The system of this embodiment includes a fan exhaust steam waste heat recovery heater 30, a regenerative drive steam turbine 31, a drain pump 32, a flue gas waste heat recovery device 33, and an expansion vessel 34 for exhaust steam. The flue gas waste heat recovery device 33 provides a separate external heat source for the thermal cycle system of the power plant, and the fan exhaust waste heat recovery heater on the fan side is connected in series or parallel to the thermal cycle system of the unit.

[0056] The fan exhaust waste heat recovery heater 30 is located at the fan side, that is, a first-stage fan exhaust waste heat recovery heater 30 is added to the original thermal cycle heat recovery system. The steam in the thermal cycle system of the power plant is connected to the regenerative drive steam tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com