Thermal power plant combined heat system and thermal power plant

A thermal system and thermal power plant technology, applied in the field of electric power equipment, can solve the problems of small power generation capacity, loss of working capacity, and waste of back pressure units, so as to improve thermal cycle efficiency, improve operational flexibility, and reduce pollutant emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

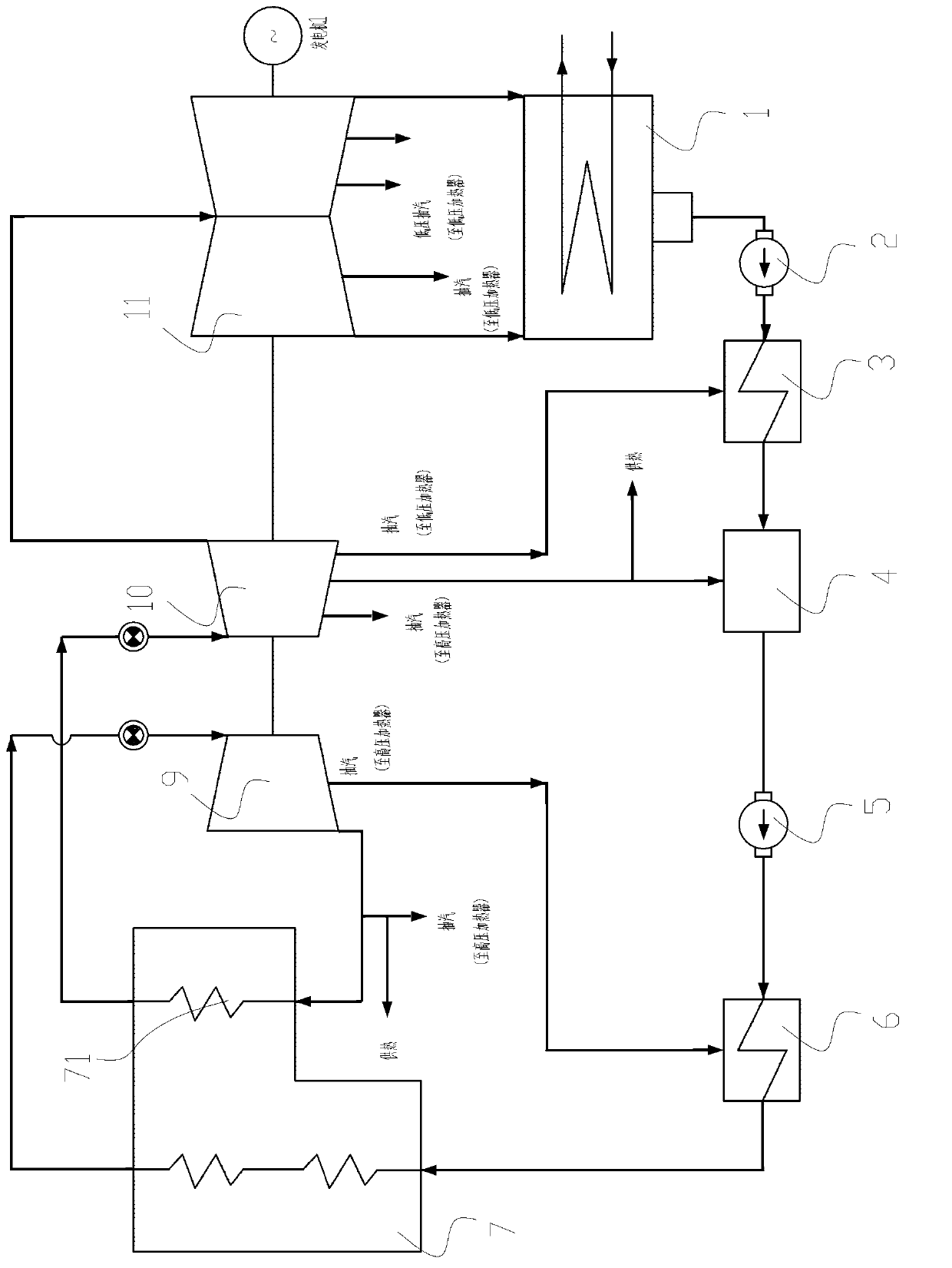

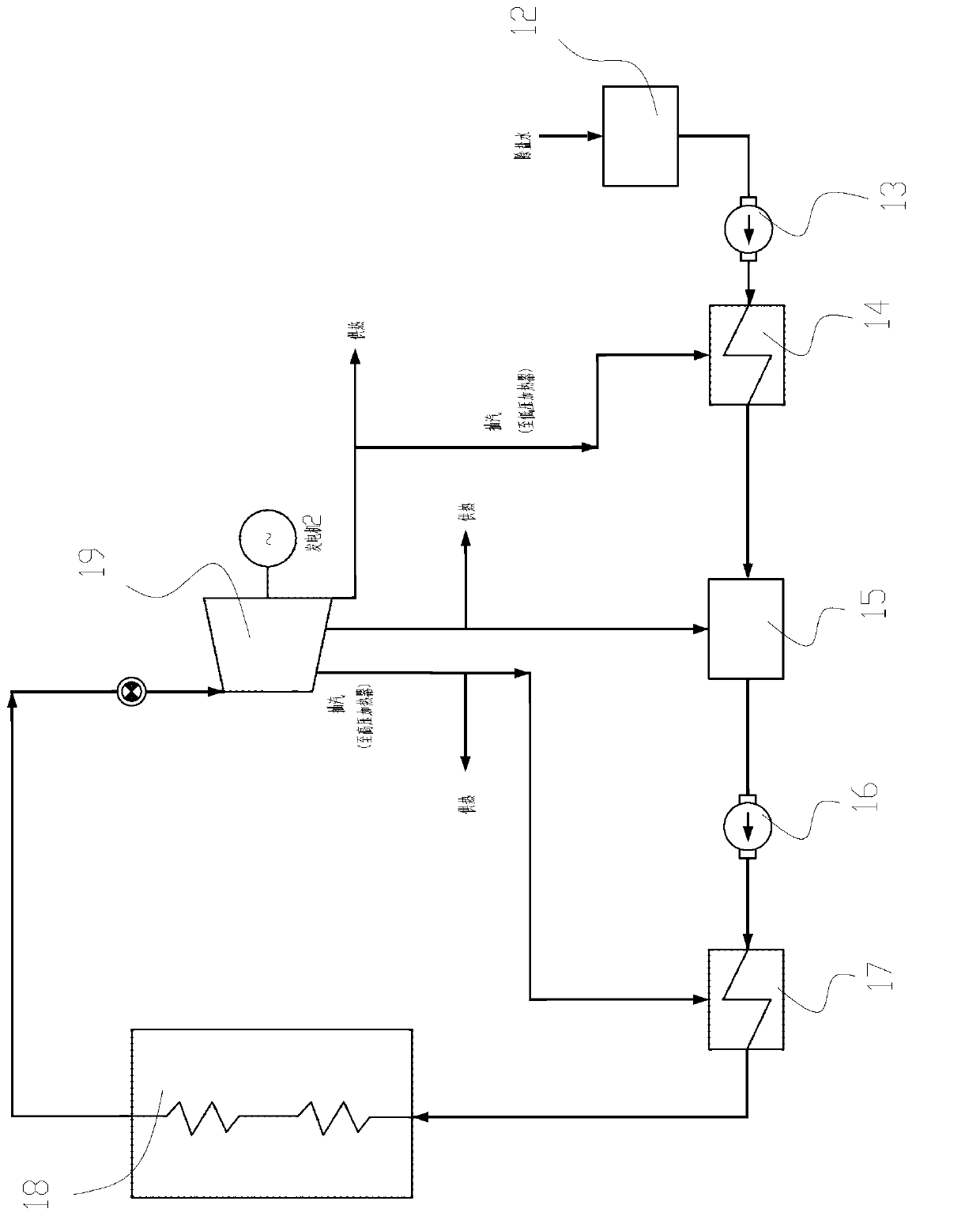

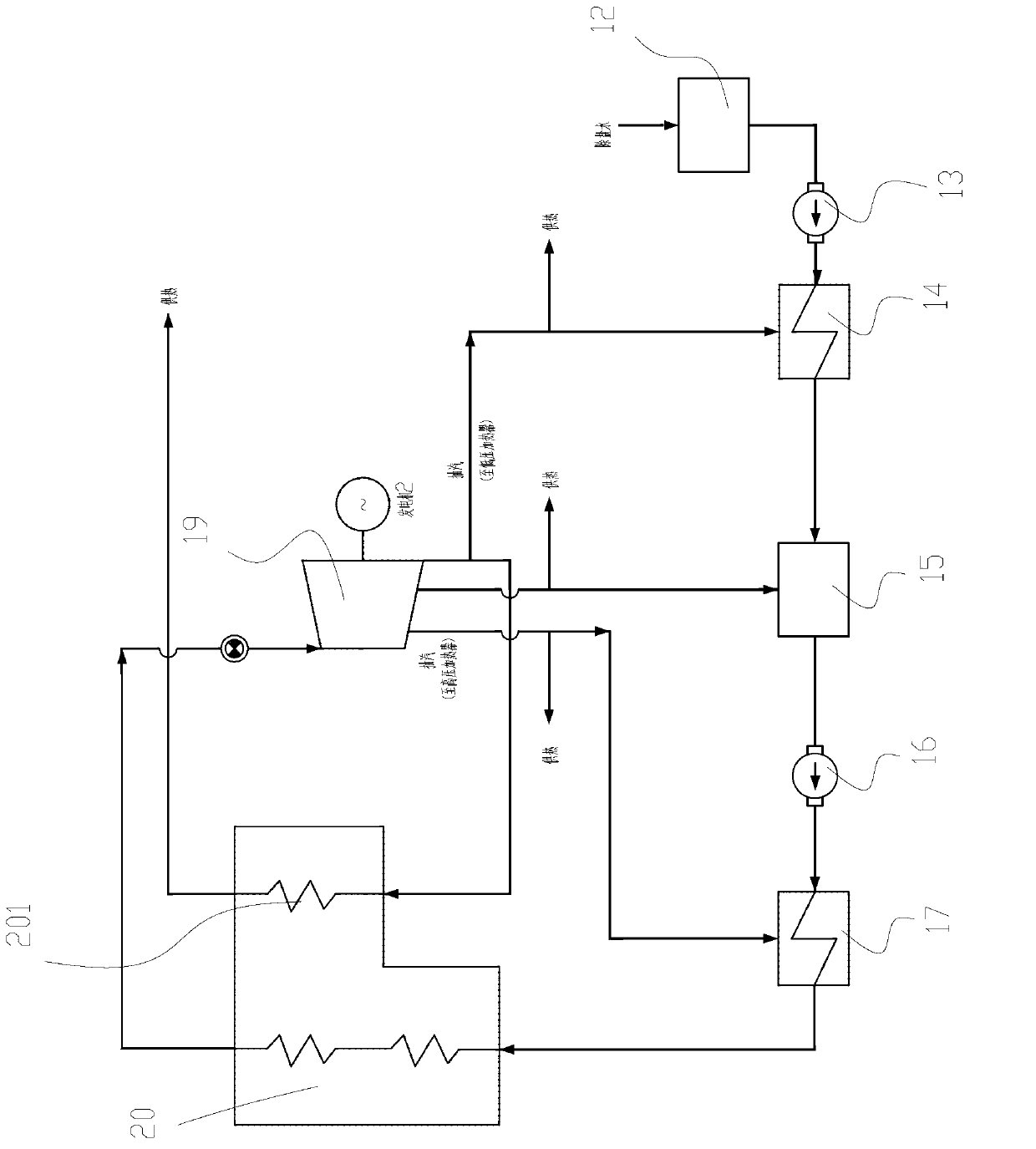

[0030] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention. In the present invention, the same or similar components in each embodiment are given the same reference numerals.

[0031] Hereinafter, main technical terms of the present invention will be described.

[0032] In this paper, heat recovery refers to recovering the latent heat of vaporization of steam to improve the efficiency of thermal cycle.

[0033] In this paper, primary reheating refers to the fact that the steam enters the boiler again during the work of the steam turbine, and returns to the steam turbine to continue to work after heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com