Separated thermal cycle sludge dry method and device thereof

A technology of sludge drying and thermal circulation, which is applied in the direction of sludge treatment through temperature control, dehydration/drying/concentrated sludge treatment, etc. problems, to achieve the effect of reducing energy consumption and improving thermal cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of isolated thermal cycle sludge drying method, the processing steps of this method are:

[0046] (1) Inject the wet sludge into the drying device for drying;

[0047] (2) The steam and non-condensable gas produced by drying the wet sludge in the drying device are pumped to the heat exchanger through the fan, and exchange heat with the working medium water with a lower temperature outside the heat exchanger tubes;

[0048] (3) The steam is condensed into water droplets in the heat exchanger and enters the wet material preheating conveyor through the water vapor separation device with the non-condensable gas. The water condensed by the steam preheats the wet sludge injected into the wet material preheating conveyor. Hot, non-condensable gas enters the heat exchange combustion furnace through the gas outlet of the water vapor separation device to be burned, and the heat generated by the combustion of the non-condensable gas is transported to the heat ...

Embodiment 2

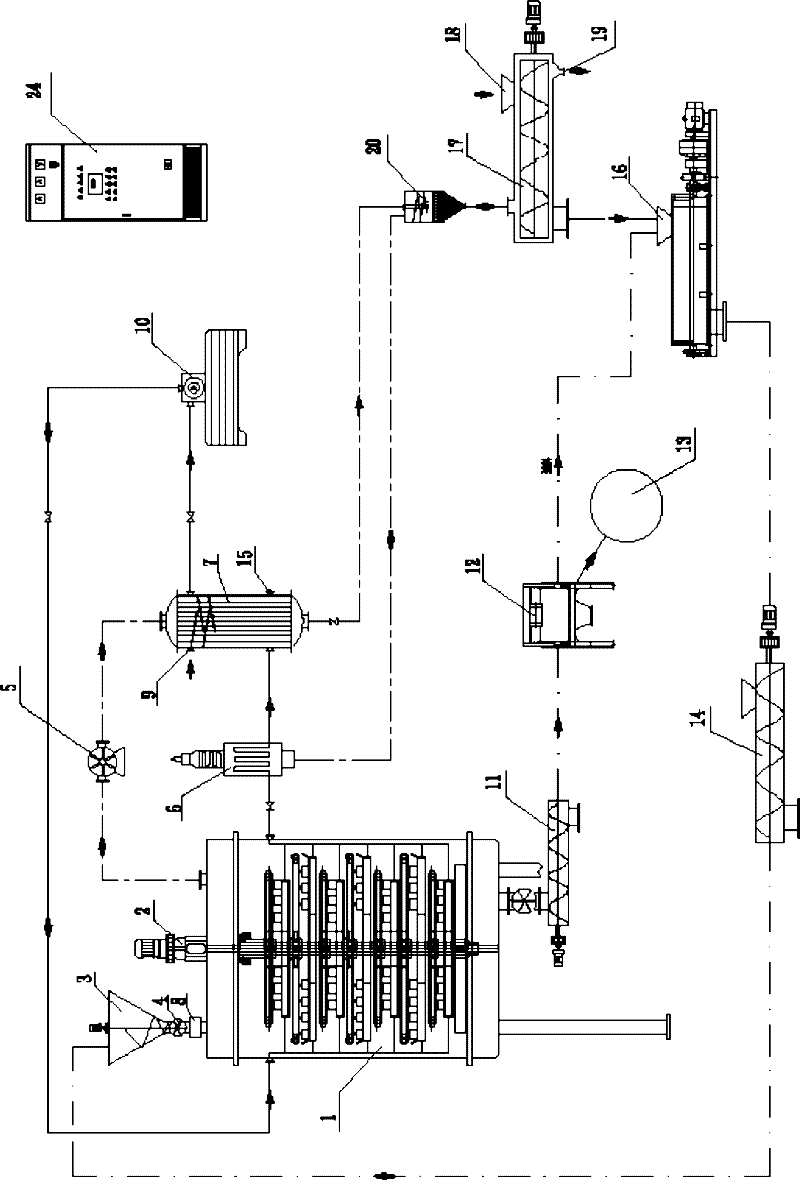

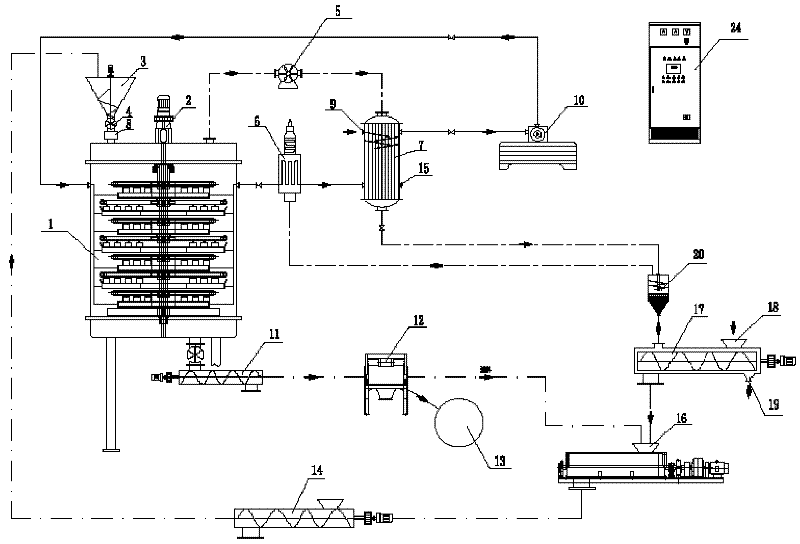

[0052] Embodiment 2: as figure 1 As shown, an isolated thermal cycle sludge drying device includes a disc-type continuous drying tank 1 driven by a frequency conversion speed regulating motor 2 to rotate the tray, a heat exchange combustion furnace 6, a heat exchange evaporator 7, a vapor compression machine 10, wet material preheating conveyor 17, water vapor separation device 20, material mixing mixer 16, screening proportioner 12, screw conveyor, the bottom outlet of quantitative feeder 3 passes through the first continuous locker 4 on the same plate The top of the disc-type continuous drying tank 1 is connected to the feed inlet of the electromagnetic valve 8; the steam outlet of the disc-type continuous drying tank 1 is connected to the steam inlet of the heat-exchanging tube in the inner cavity of the heat-exchanging evaporator 7 through the induced draft fan 5, The condensed water outlet of the heat-exchanged evaporator 7 is connected to the condensed water inlet at one...

Embodiment 3

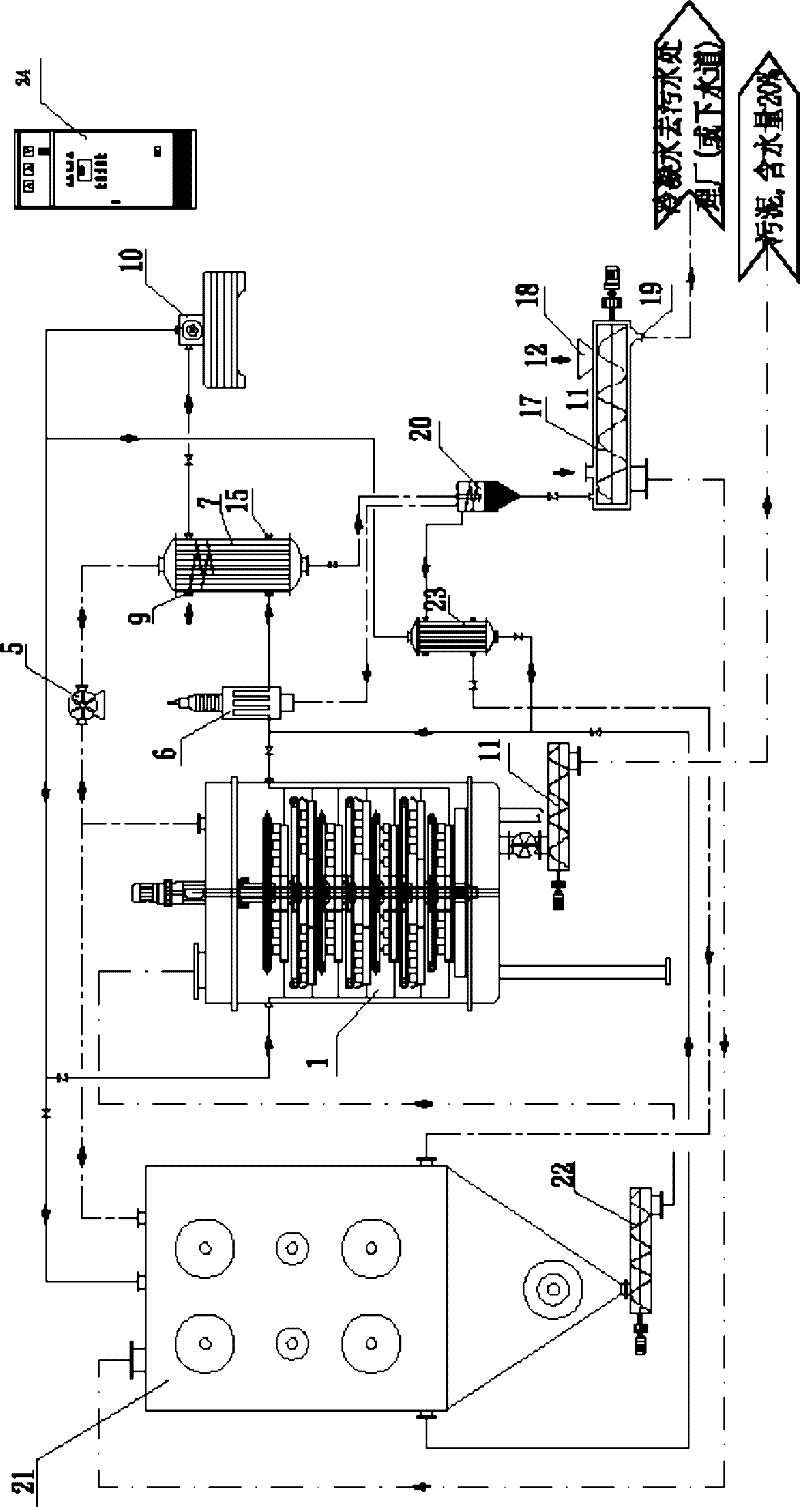

[0065] Embodiment 3: as figure 2As shown, an isolated thermal cycle sludge drying device includes a soft granulation drying machine 21, a disc-type continuous drying tank 1 driven by a frequency conversion speed regulating motor 2 to rotate the tray, a heat exchange combustion furnace 6, and a heat transfer furnace 6. Thermal evaporator 7, steam compressor 10, air preheating device 23, wet material preheating conveyor 17, water vapor separation device 20, screening proportioner 12, screw conveyor; : steam from soft granulation drying machine 21 The outlet and the steam outlet of the disc-type continuous drying tank 1 are respectively connected to the steam inlet of the heat exchange tube in the inner cavity of the heat exchange evaporator 7 through the induced draft fan 5, and the condensed water outlet of the heat exchange evaporator 7 heat exchange tube is passed through The water vapor separation device is connected with the condensed water inlet at one end of the outer pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com