High-temperature high-pressure natural circulation dry coke-quenching exhaust-heat boiler

A natural circulation and waste heat boiler technology, which is applied in coke ovens, coke cooling, petroleum industry, etc., can solve the problems of low thermal efficiency and small evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described,

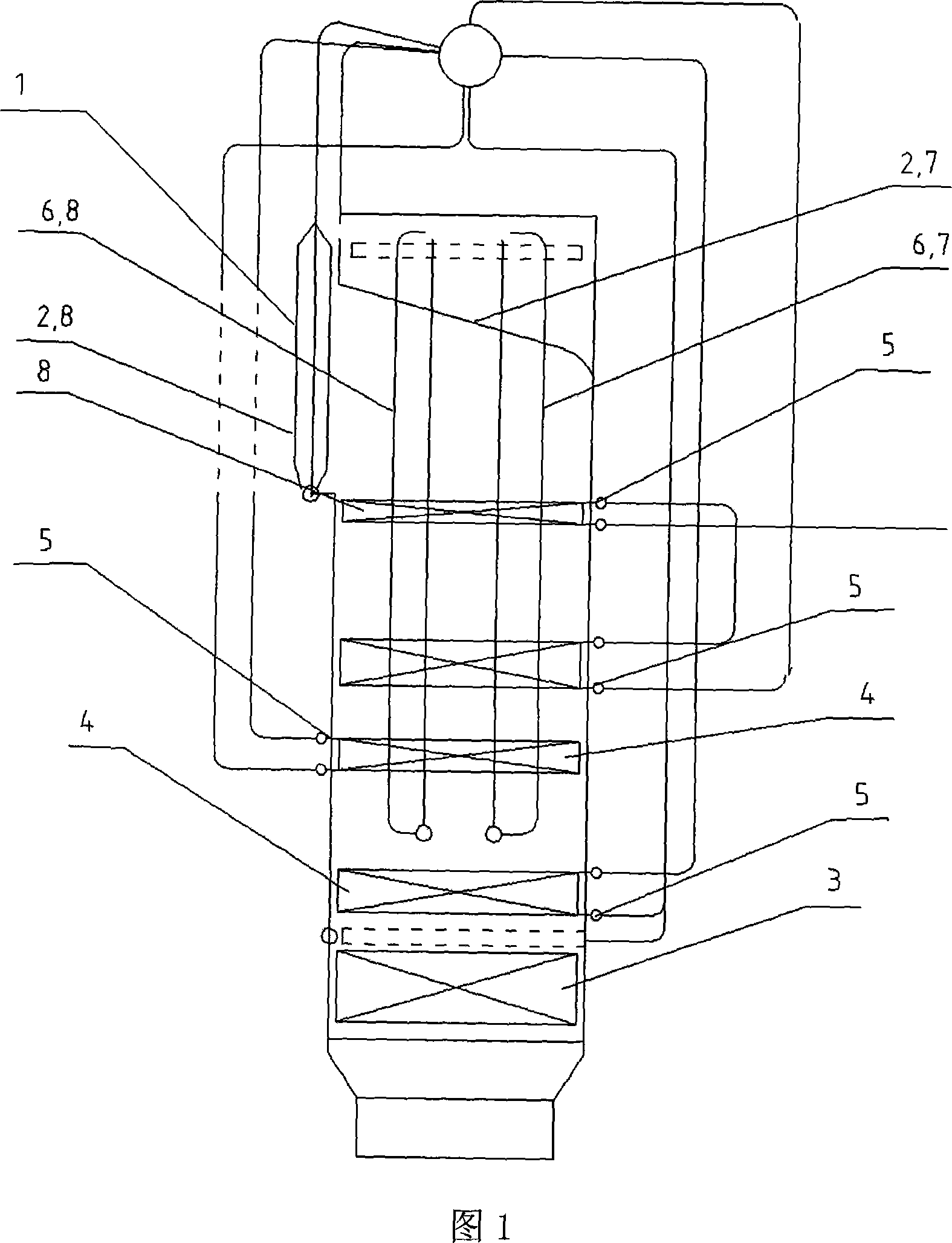

[0016] As shown in Figure 1, the high temperature and high pressure natural circulation CDQ waste heat boiler of the present invention includes a slag condensation tube 1, a membrane water wall 2, a boiling economizer 3, a horizontal tube evaporator 4, a wall tube 5, a suspension Hanging pipe 6, stainless steel baffle 7, metal spraying pipe 8, etc.

[0017] (1) The water wall of the front wall is provided with a slag tube 1 at the boiler inlet, which is used to increase the heat absorption of the water wall of the front wall and improve the safety of the water circulation of the water wall of the front wall;

[0018] (2) Membrane water cooling wall 2 is arranged in the boiler level and tail flue to improve the sealing performance of the boiler, and a suspension structure is adopted;

[0019] (3) A horizontally arranged finned economizer 1 with a high boiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com