Mix refrigerant, preparing method and uses thereof

A technology for mixing refrigerants and refrigerants, which is used in the preparation of the mixed refrigerants, the mixed refrigerants, and the field of the mixed refrigerants, can solve problems such as the inability to form mixtures, and achieve stable evaporation working conditions, increased refrigeration capacity, The effect of increasing the pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

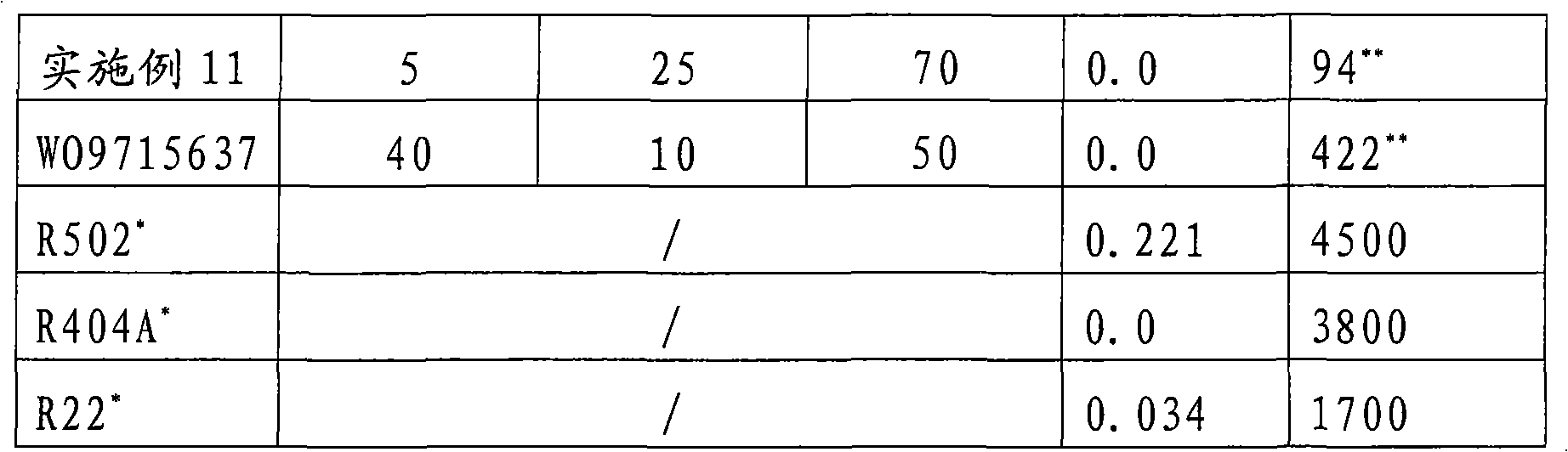

[0025] Example 1: 1,1,2,2-tetrafluoroethane with a mass concentration of 1%, 1,1-difluoroethane with a mass concentration of 50%, and propane with a mass concentration of 49% are physically mixed at room temperature , to obtain a mixed refrigerant that can be applied to a single-stage compression refrigeration system.

Embodiment 2

[0026] Example 2: 1,1,2,2-tetrafluoroethane with a mass concentration of 20%, 1,1-difluoroethane with a mass concentration of 50%, and propane with a mass concentration of 30% are physically mixed at room temperature , to obtain a mixed refrigerant that can be applied to a single-stage compression refrigeration system.

Embodiment 3

[0027]Example 3: 1,1,2,2-tetrafluoroethane with a mass concentration of 9%, 1,1-difluoroethane with a mass concentration of 1%, and propane with a mass concentration of 90% are physically mixed at room temperature , to obtain a mixed refrigerant that can be applied to a single-stage compression refrigeration system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com