Mixed working medium for heat pump system

A heat pump and material technology, applied in the field of refrigerant mixtures, can solve the problem of high cost, achieve good environmental performance, reduce charging volume, and small temperature glide

Active Publication Date: 2013-08-28

王高元

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the refrigerating capacity of the replacement working medium is too different from R22, the compressor size must be redesigned, which is too expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment A1

[0045] Example A1: R125 and R152a were physically mixed in a liquid phase at a mass percentage of 5:95.

Embodiment A2

[0046] Example A2: R125 and R152a were physically mixed in a liquid phase at a mass percentage of 10:90.

Embodiment A3

[0047] Example A3: R125 and R152a were physically mixed in a liquid phase at a mass percentage of 14:86.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

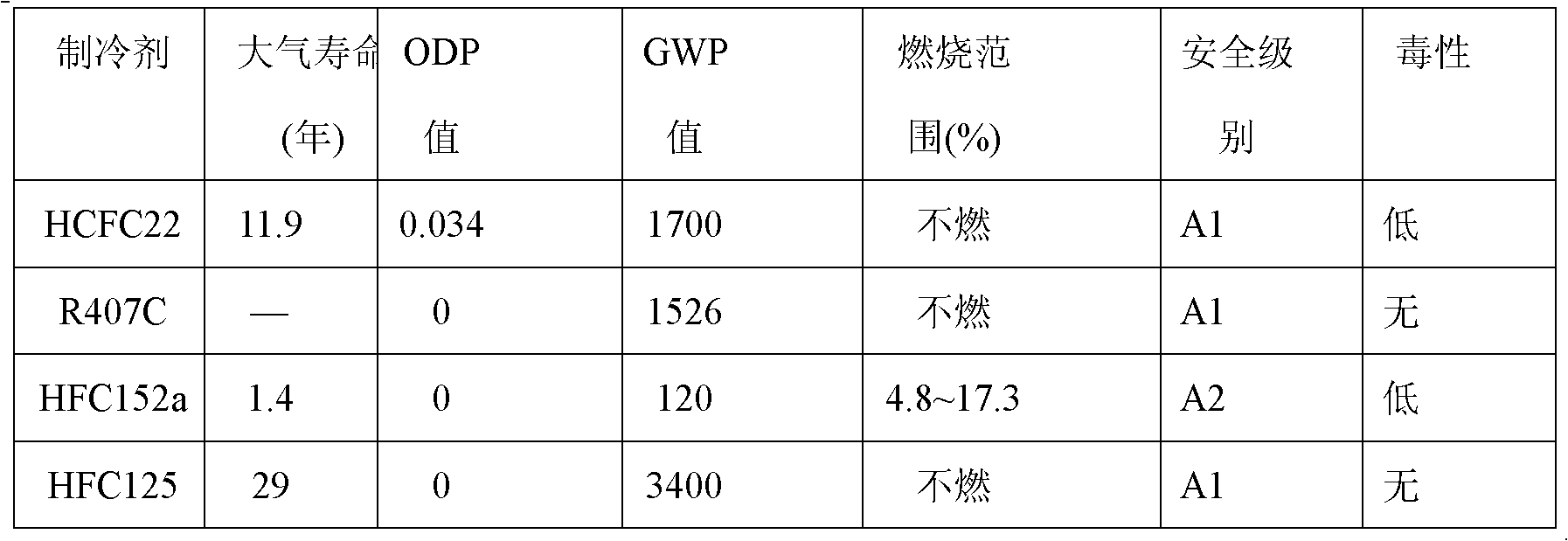

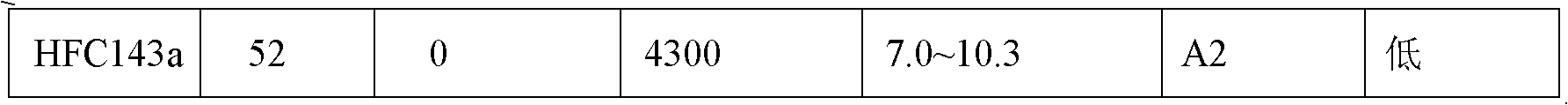

The invention relates to a refrigerant mixture combining three components, in particular to a ternary non-azeotropic refrigerant, which comprises the following components by weight percent: 2-50% of R125, 15-97% of R152a and 1-35% of R143a. The refrigerant mixture is formed by physical mixing at normal temperature according to the established mixture ratio, thereby getting a corresponding mixed working medium. The ODP (ozone depression potential) of the refrigerant is zero, an ozone layer is not damaged, and the impacts caused by greenhouse effect can be reduced, thereby being in line with requirements of environment friendliness; and thermal parameters are appropriate, and the circulation performance is good. The refrigerant mixture can replace the refrigerant mixture of dichlorodifluoromethane (CFC12) and difluorochloromethane (HCFC22) and be used in a heat pump system of the refrigerant mixture.

Description

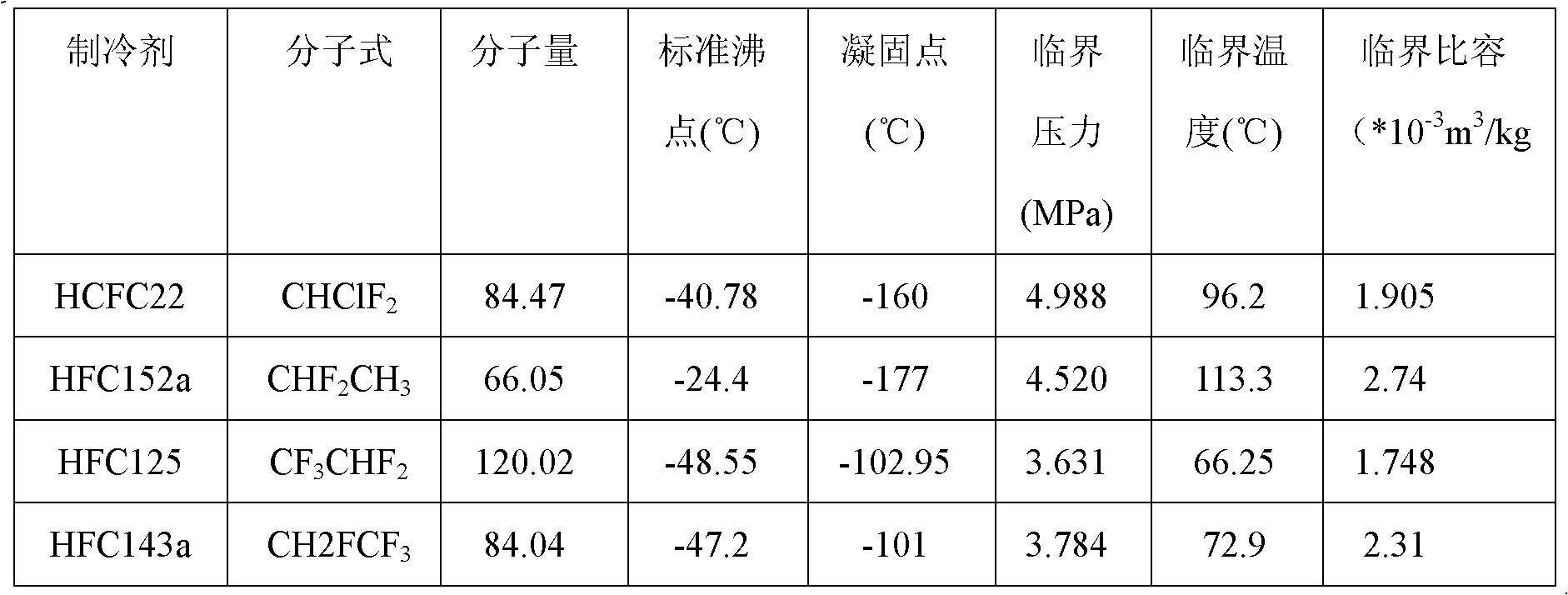

technical field [0001] The invention relates to a refrigerant mixture, especially a refrigerant mixture used in a heat pump system, which is used to replace the heat pump system containing CFCl2 or HCFC22 and used in the refrigerant mixture. Background technique [0002] Since 1987, global actions to protect the ozone layer, phase out ozone-depleting substances, and reduce the greenhouse effect are being carried out in countries around the world in accordance with the Montreal Protocol. Our country has begun to actively carry out substitution work, and finding safe, efficient and environmentally friendly alternative refrigerants has become an urgent and important task. [0003] Due to the high ozone depletion potential (ODP) of CFC refrigerants, they are strictly controlled in Montreal and subsequent revisions. HCFC refrigerants, unlike CFC, HCFC only partially replaces the hydrogen atoms with halogen atoms, and the remaining hydrogen atoms help the chemical to partially de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K5/04

Inventor 王高元

Owner 王高元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com