Re-liquefying method for shipping liquefaction ethylene/ethane vaporized gas

A technology for evaporating gas and liquefying ethylene, applied in liquefaction, refrigeration, liquefaction, solidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

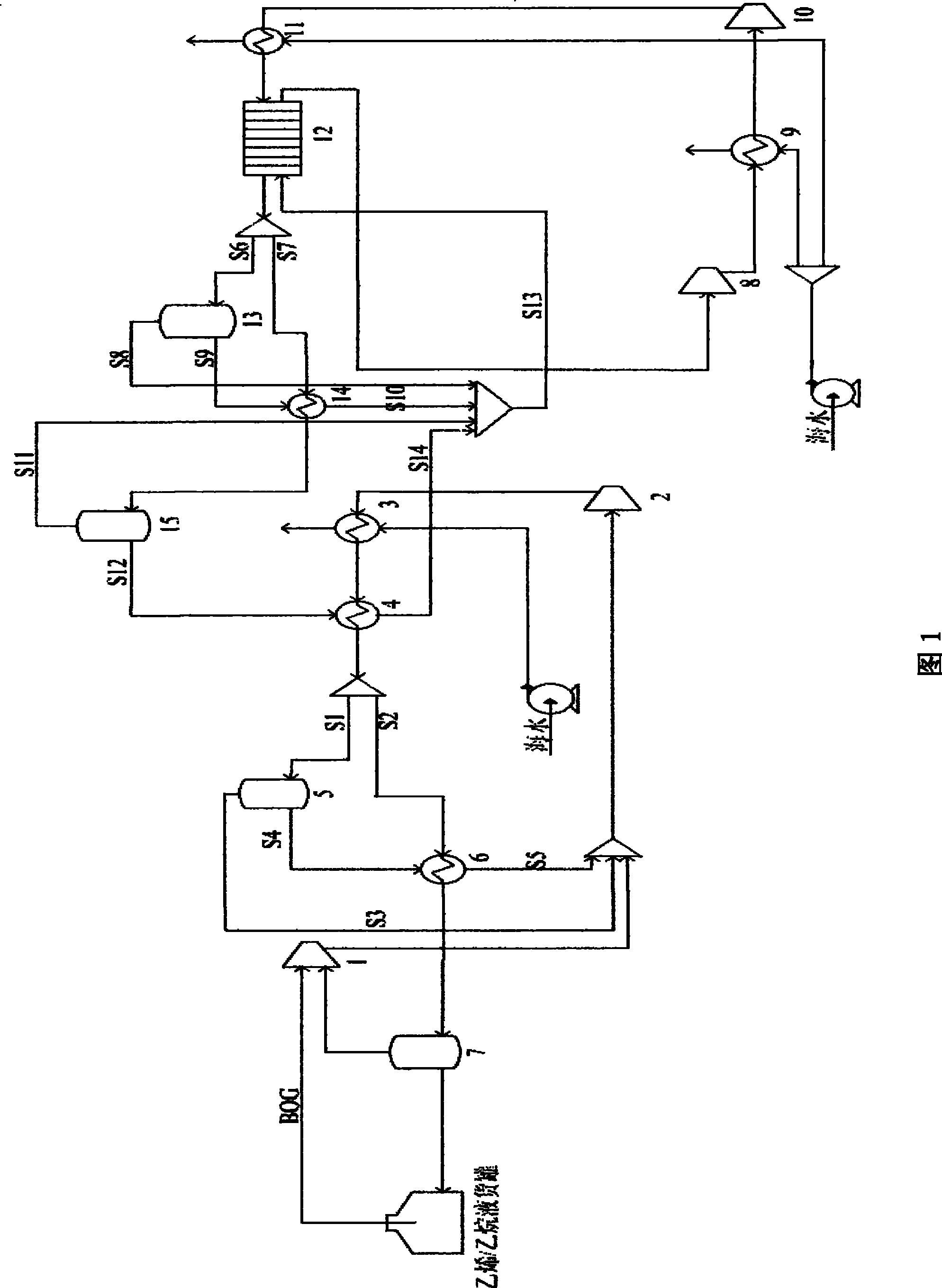

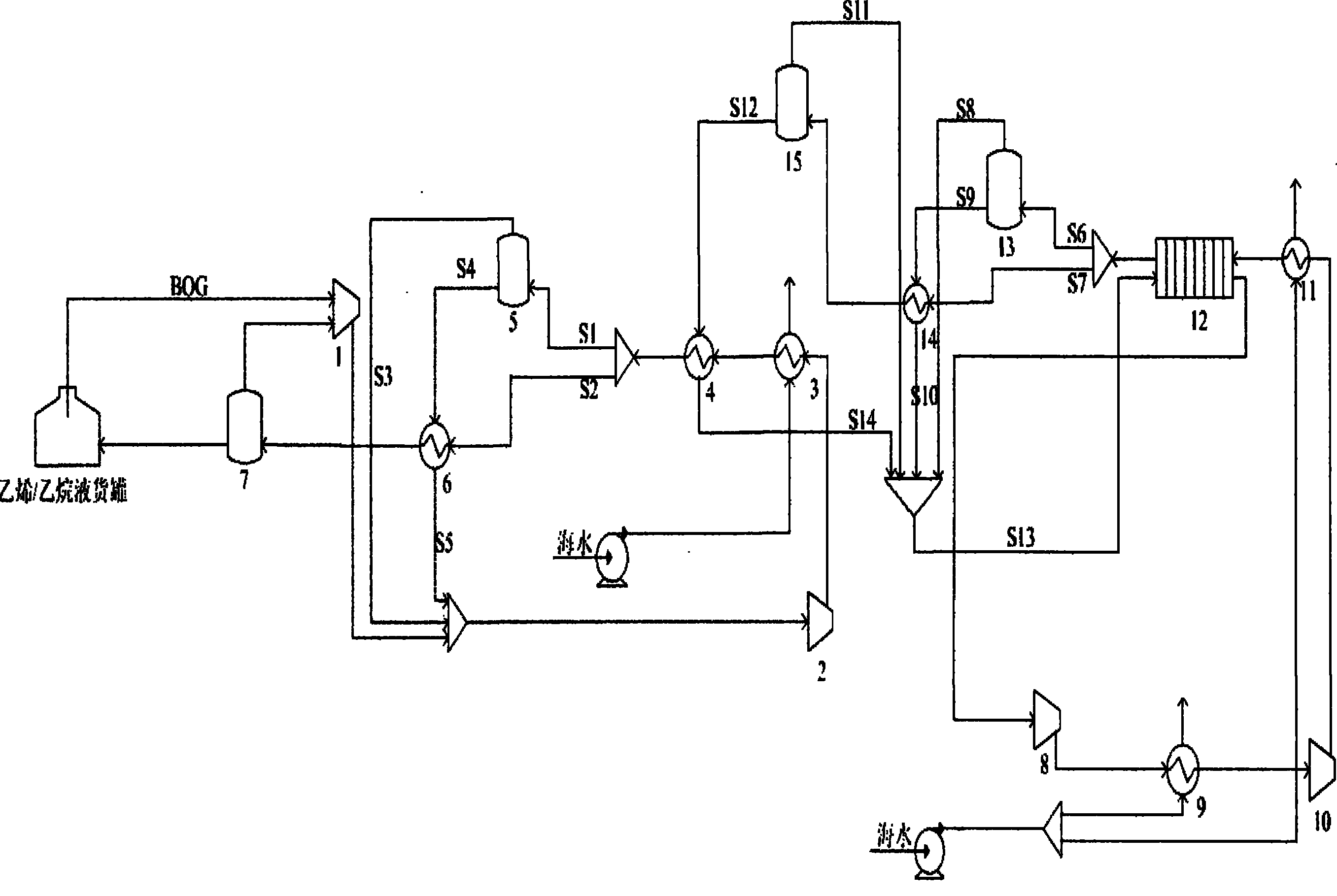

[0043] Embodiment one: reliquefaction of liquid ethylene BOG

[0044] Two-stage compression of ethylene BOG in the first step

[0045] The 1500Kg / hr, -102.0°C, 0.11MPa ethylene BOG gas evaporated from the ship's ethylene liquid cargo tank enters the primary compressor 1 and is compressed to 0.52MPa, and the temperature rises from -102°C to -0.7°C. The ethylene BOG from the outlet of the first-stage compressor is mixed with the return gas S3 and S5 of the subsequent process, cooled to -13.1°C, and entered into the second-stage compressor 2 for compression, the pressure rises to 1.72MPa, and the temperature is 83.9°C.

[0046] The second step is the cooling of ethylene BOG

[0047] The cooling device includes a seawater heat exchanger 3 and an ethylene condenser 4; the high-temperature and high-pressure ethylene gas compressed in two stages first enters the seawater heat exchanger 3 and exchanges heat with seawater. The temperature drops from 83.9°C to 38°C, and the pressure dr...

Embodiment 2

[0061] Embodiment two: reliquefaction of liquid ethane BOG

[0062] Step 1 Two-stage compression of ethane gas

[0063] The 1480Kg / hr, -85.0°C, 0.12MPa ethane BOG evaporated from the ship's ethane liquid cargo tank enters the primary compressor 1 and is compressed to 0.56MPa, and the temperature rises from -85.0°C to 2.8°C. The ethane BOG from the outlet of the primary compressor is mixed with the return gas S3 and S5 of the subsequent process, cooled to -6.1°C, and enters the secondary compressor 2, the pressure rises to 1.86MPa, and the temperature is 75.4°C.

[0064] Step 2 Cooling of Ethane BOG

[0065] The cooling device includes a seawater heat exchanger 3 and an ethane condenser 4; the high-temperature and high-pressure ethane gas compressed in two stages first enters the seawater heat exchanger 3 and exchanges heat with seawater. The temperature drops from 75.4°C to 40°C, and the pressure drop It is 1.82MPa. Then enter the ethane condenser 4 to exchange heat with re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com