Method for removing acidic gas from natural gas

A sour gas and natural gas technology, applied in liquefaction, solidification, lighting and heating equipment, etc., can solve the problems of increased recycling costs and side effects of hydrocarbons, and achieve the effects of improving market competitiveness, no three wastes, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

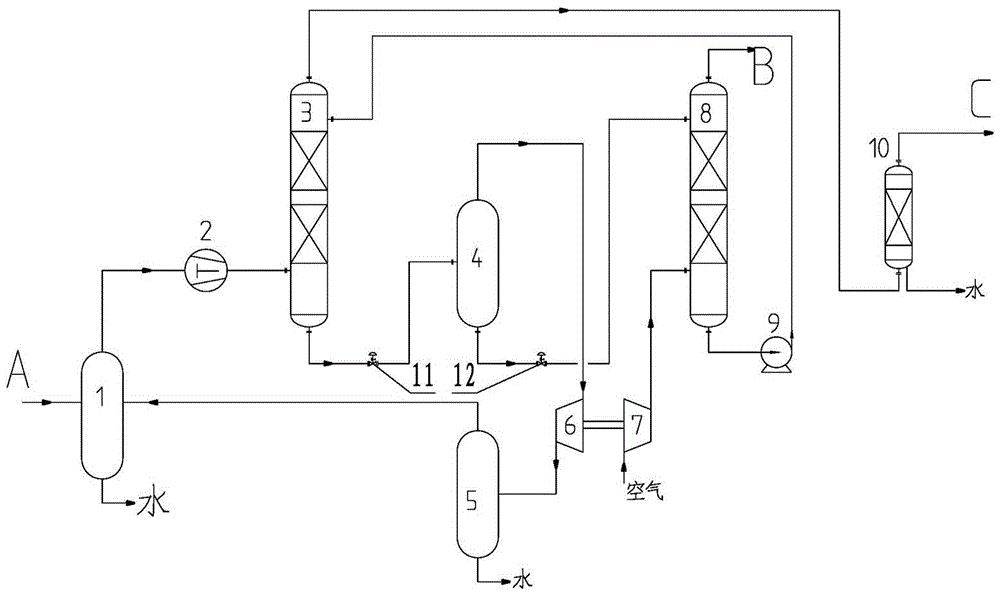

[0017] Depend on figure 1 As shown, 1 in the figure is the raw material gas separation tank before the compressor, 2 is the raw material gas compressor, 3 is the absorption tower, and 4 is the flash tank; in the flash tank 4, the gas outlet pipe and the feed pipe of the expander 6 Connected, the discharge pipe of the expander 6 is connected with the feed pipe of the separation tank 5 after the expander, the discharge pipe of the braking fan 7 of the expander is connected with the carrier gas port of the stripping tower 8, and the expansion The feed pipe of the braking fan 7 of the machine is connected with the atmosphere; the raw natural gas ( figure 1 The feed pipe in A) and the outlet pipe of the separation tank 5 after the expander are respectively connected to the feed pipe of the separation tank 1 before the compressor, and the outlet pipe of the raw gas separation tank 1 before the compressor is connected to the compressor unit 2 The feed pipe connection of the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com