Air-cooled steam condensing system with natural ventilation and direct water film evaporation

A natural ventilation, air-cooled condenser technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as system complexity and initial investment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. But the present invention is not limited to the embodiments, technical solutions formed by those skilled in the art making some non-essential modifications to the present invention are all within the protection scope of the present invention.

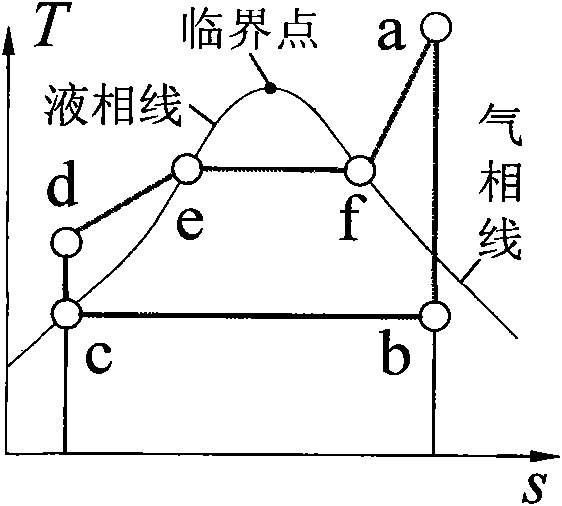

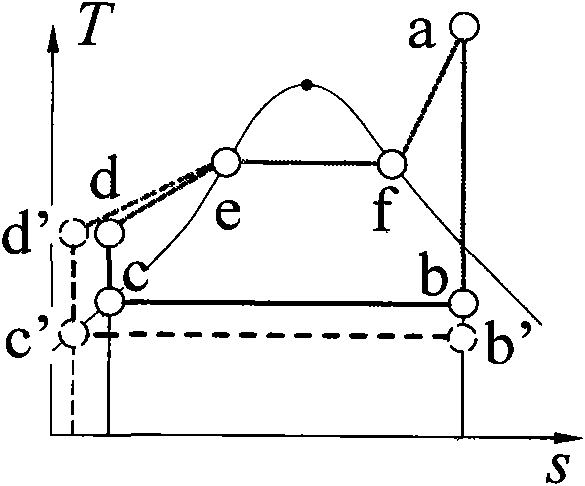

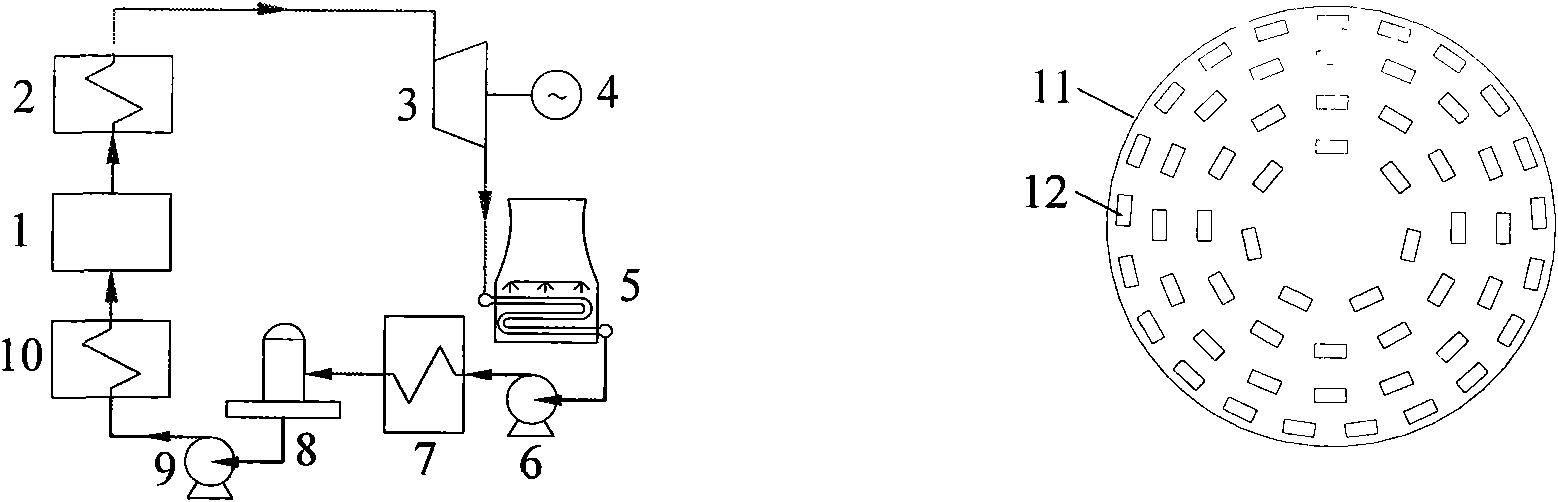

[0073] refer to image 3 , the natural ventilation direct water film evaporation air cooling system of the present invention is mainly used for exhaust steam condensation of steam turbine generator sets such as thermal power or nuclear power. The system is mainly composed of direct water film evaporation air-cooled group condensers and natural draft cooling towers, and is characterized in that multiple direct water film evaporation air-cooled The lower part, above the cooling tower pool. Therefore, this system can also be referred to as "condensation air cooling tower". image 3 Totally ten kinds of equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com