Air-cooling reheating unit system arranged in small back-pressure type steam turbine and used for driving feed pump

A technology of steam-driven feed water pump and air cooling system, which is applied to machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of low thermal cycle efficiency, reduced thermal cycle efficiency, and reduced use efficiency of small steam turbines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

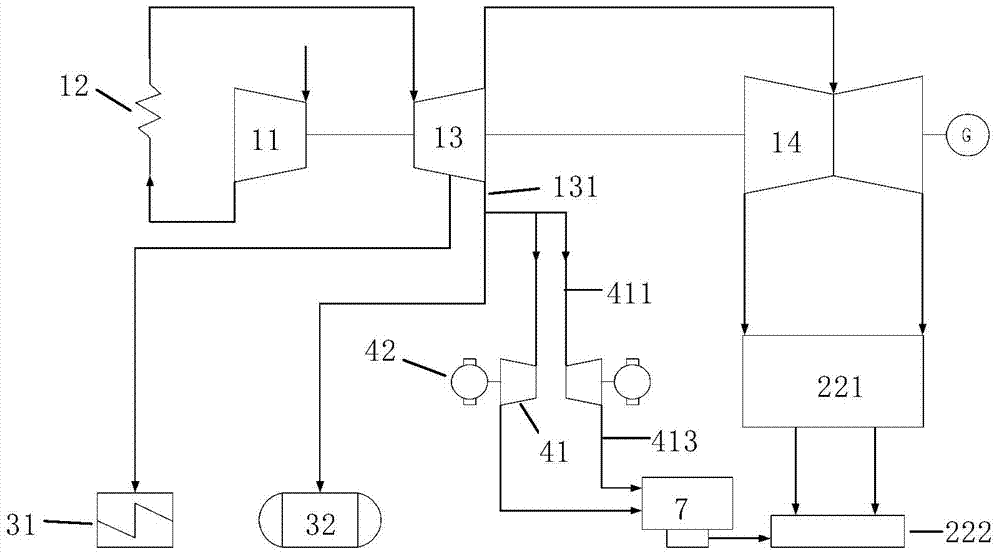

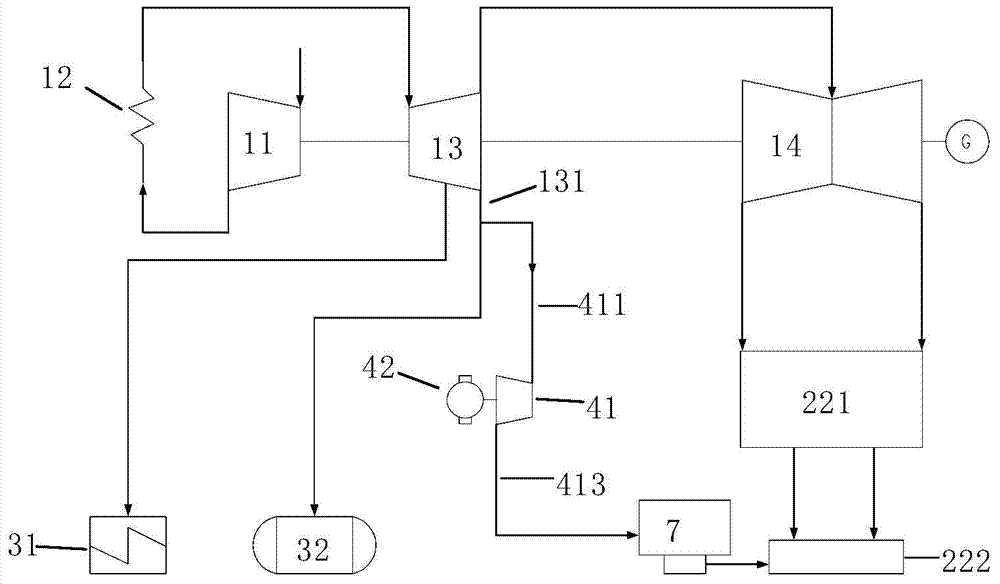

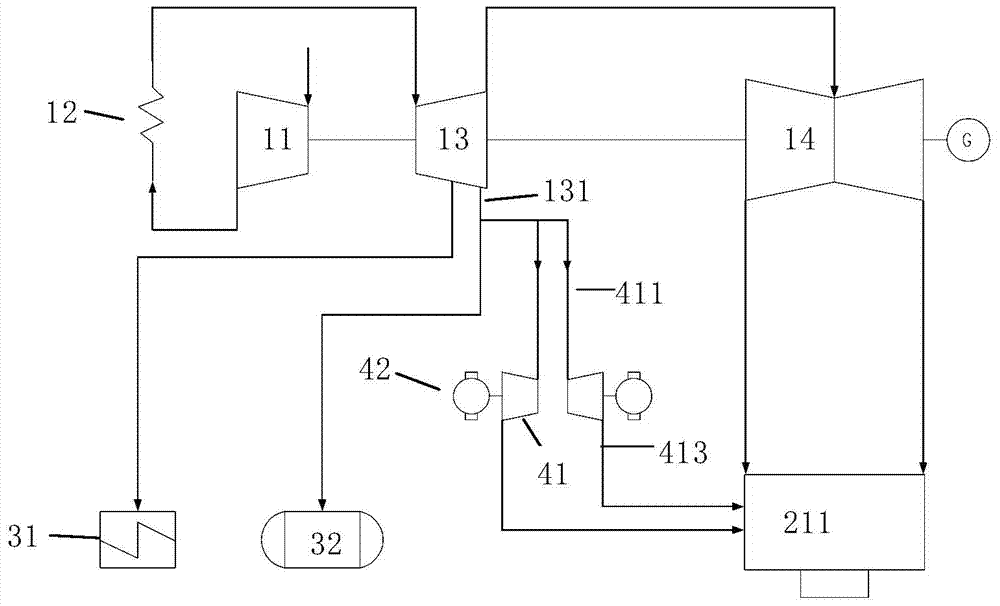

[0042] Figure 9-16 They are the system flow diagrams of 8 embodiments of the air-cooled reheating unit system driven by the back pressure small steam turbine of the present invention.

[0043] The air-cooled reheat unit system of the back-pressure small turbine-driven feedwater pump includes: reheat system, air-cooled system, back-pressure steam-driven feedwater pump system, heat recovery system, exhaust steam flow balance piping system and start-up exhaust steam piping system, among which , the reheat system can be a primary reheat system (including steam turbine high-pressure cylinder 11, reheater 12, steam turbine medium-pressure cylinder 13 and steam turbine low-pressure cylinder 14), or a secondary reheat system (including steam turbine ultra-high pressure cylinder 15, Primary reheater 121, steam turbine high pressure cylinder 11, secondary reheater 122, steam turbine medium pressure cylinder 13 and steam turbine low pressure cylinder 14).

[0044] The air cooling system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com