Small turbine system in power plant and thermal cycle system in power plant containing same

A technology of thermal cycle system and small steam turbine, which is applied to steam engine installations, machines/engines, and preheating, etc., can solve the problems of reduced power supply efficiency, low cycle efficiency, and reduced plant power consumption in power plants, so as to improve plant power consumption. , The effect of reducing power consumption and improving power supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

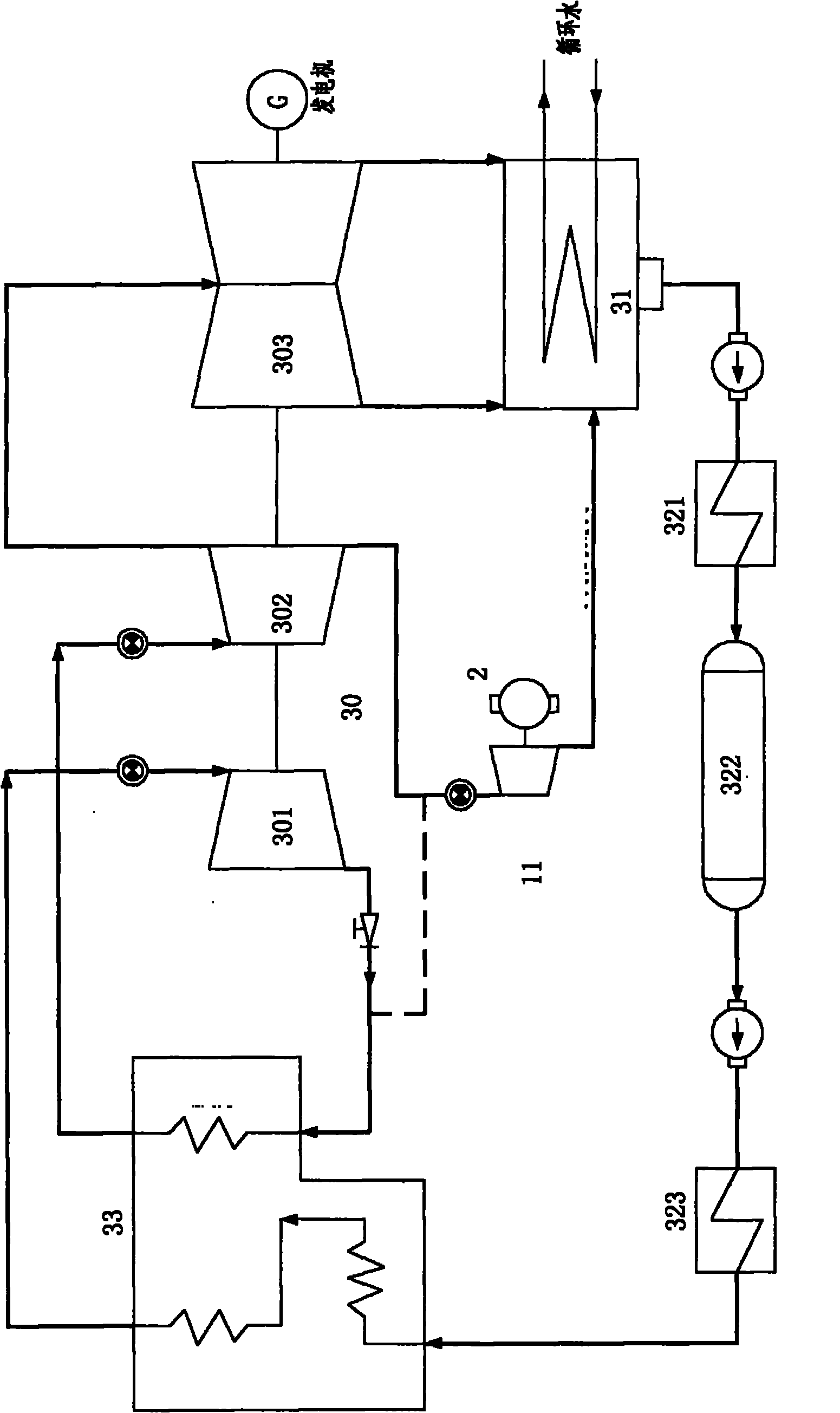

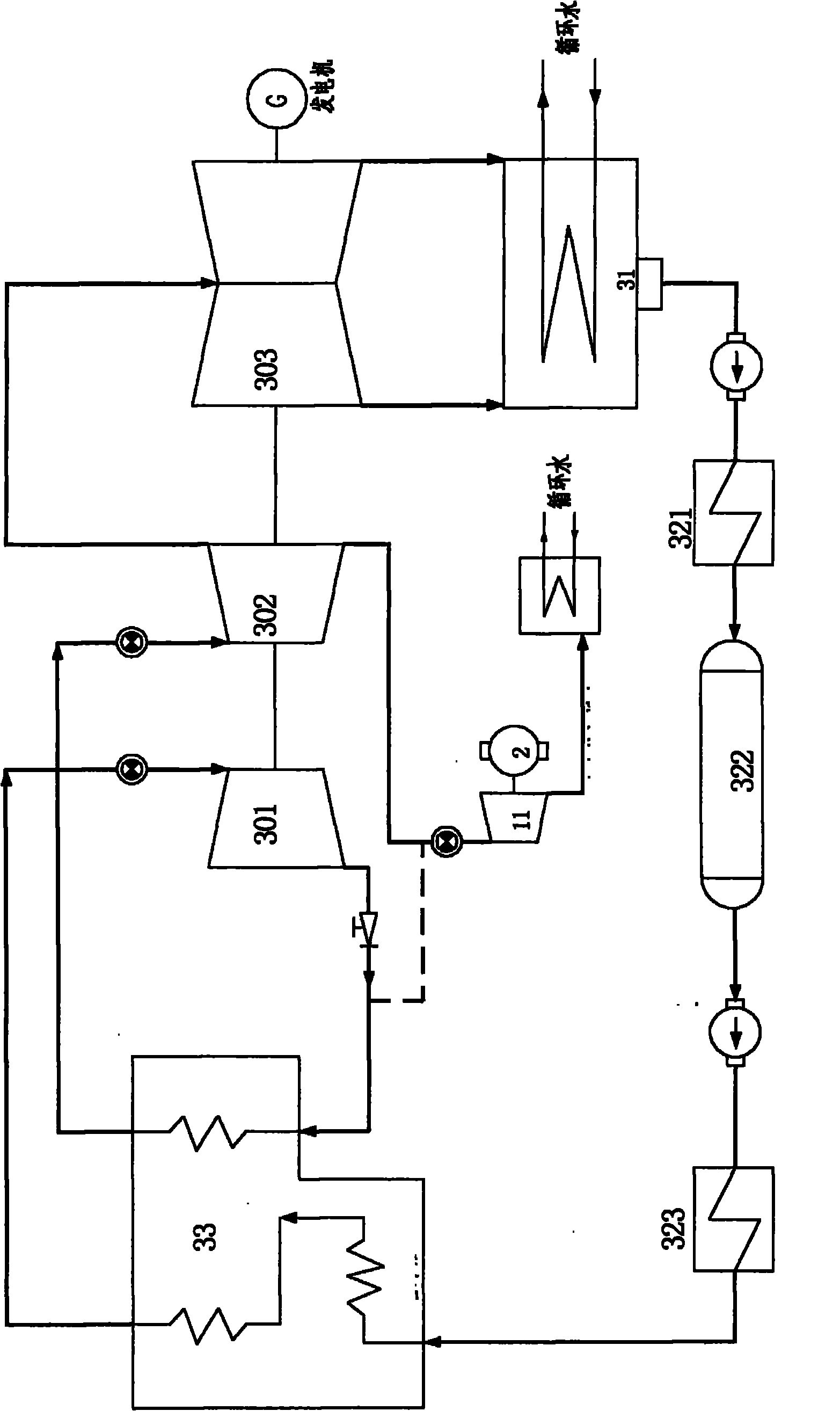

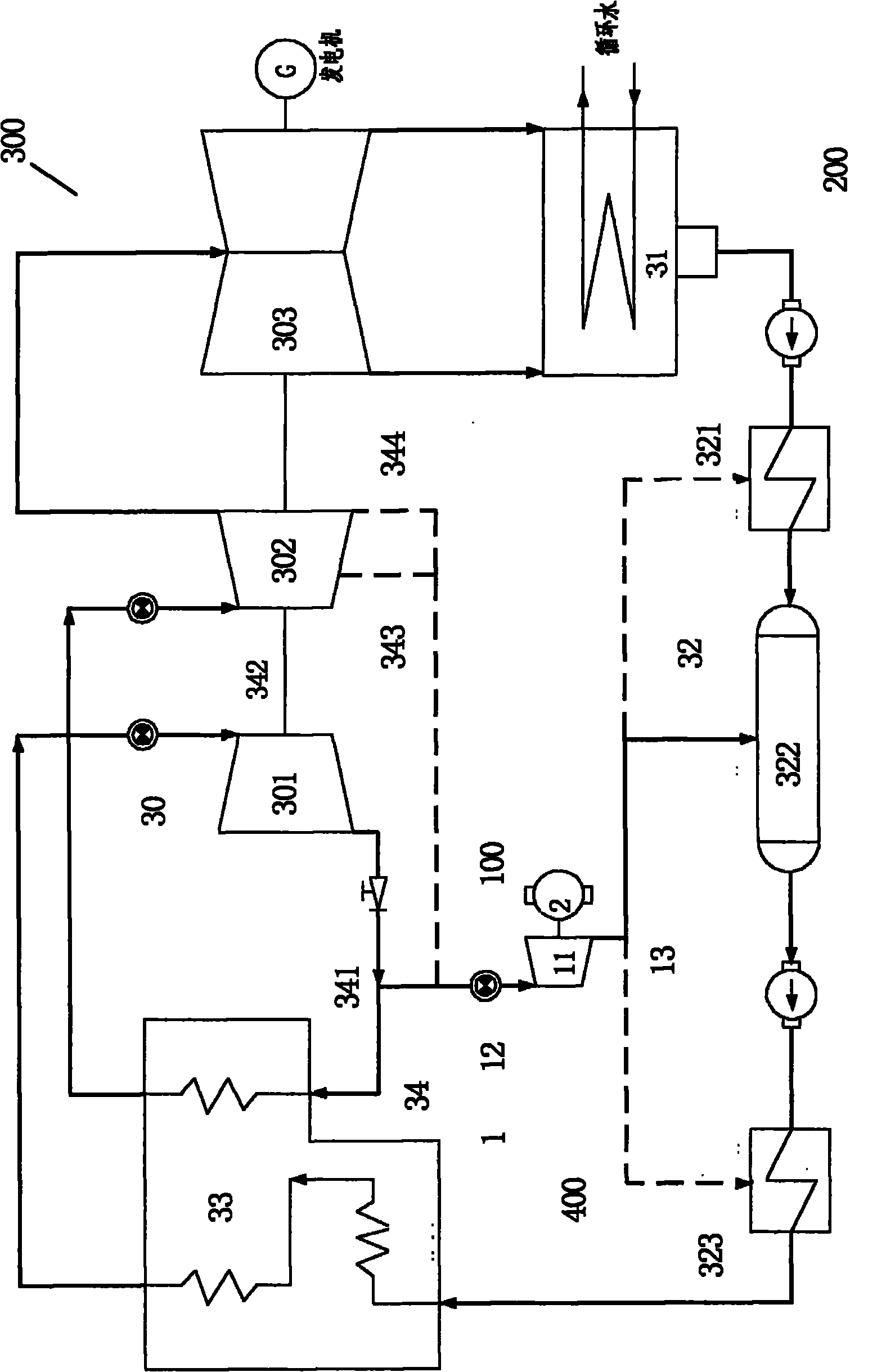

[0101] like image 3 As shown, a specific embodiment of the regenerative small steam turbine system of the power plant of the present invention is shown. Only typical steam sources and heat recovery equipment are connected in the figure, not all possibilities are shown, so image 3 It is used as an illustration only and not as a limitation of the invention.

[0102] image 3 Shown is a power plant regenerative small steam turbine system 100 of the present invention, which is used to recover the heat of the exhaust steam of the small steam turbine 11 to the power plant thermal cycle system 300, which includes: a regenerative small steam turbine unit 1; The regenerative small steam turbine unit 1 includes: a small steam turbine 11; a small steam turbine inlet piping system 12 located at the upstream of the small steam turbine 11, wherein the small steam turbine inlet piping system 12 receives heat from the power plant thermal cycle system 300 steam source 34; and the small st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com