Backpressure steam extraction small turbine thermal system which is coaxial with single reheating main turbine

A technology of small steam turbines and thermal systems, applied in steam engine devices, machines/engines, steam applications, etc., can solve problems such as high degree of superheat and affect thermal cycle efficiency, reduce system cost, improve thermal cycle efficiency, and reduce heat transfer area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

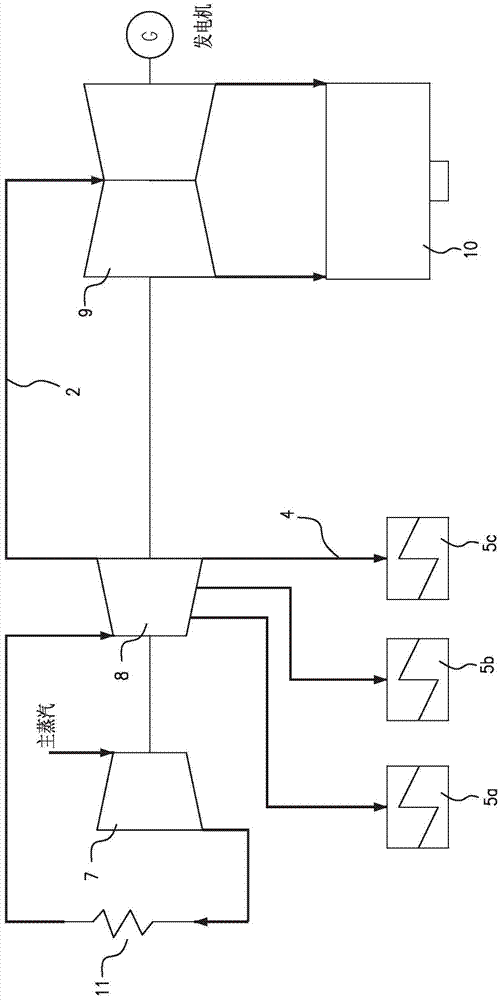

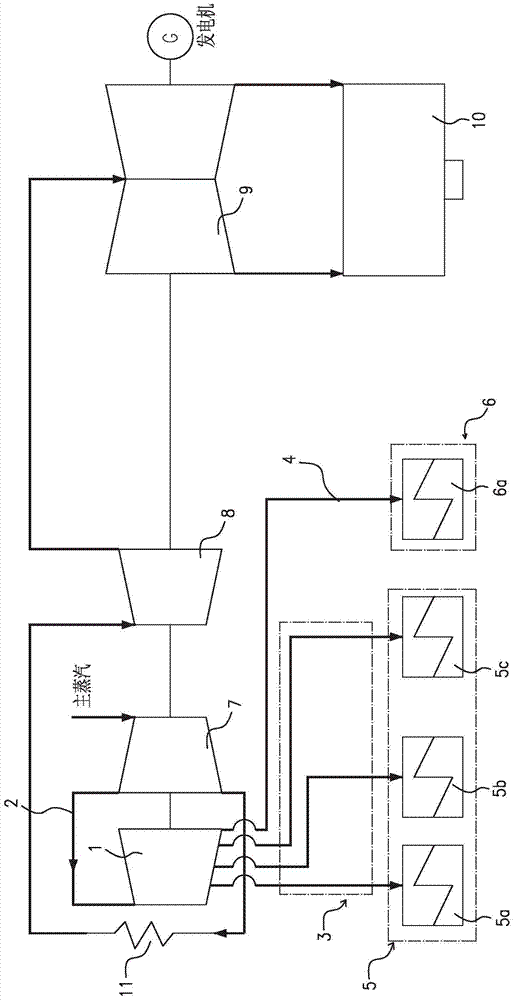

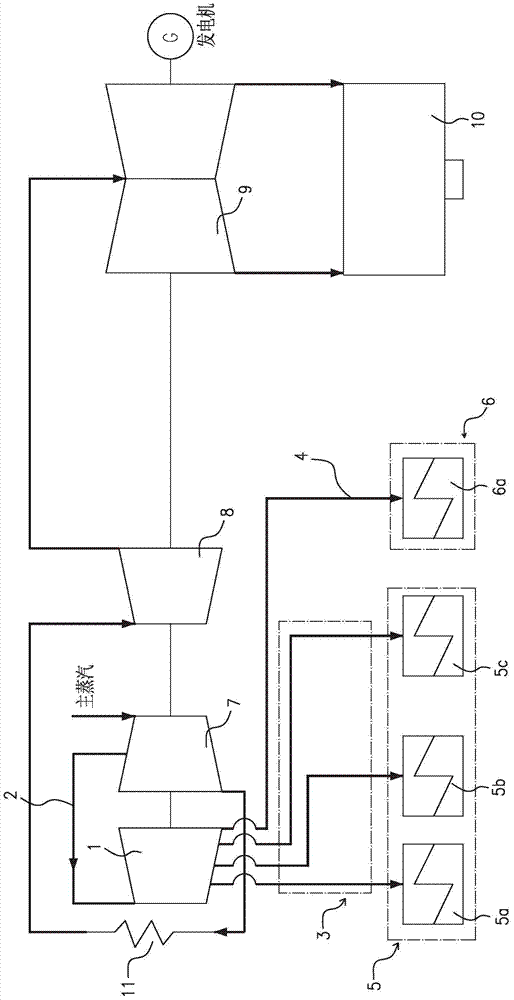

[0025] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0026] Terminology Explanation

[0027] Reheating: The steam that has done part of the work in the steam turbine is drawn out for reheating, and then led back to the steam turbine to continue to work. This method is called reheating. Through reasonable reheating, the exhaust humidity can be reduced and the thermal cycle efficiency can be improved.

[0028] Back-pressure steam turbine: A steam turbine that exhausts steam to a piping system or heat exchanger above atmospheric pressure is called a back-pressure steam turbine.

[0029] Condensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com