Air fryer

An air fryer and chamber technology, which is applied in the direction of cooking utensil lids, inserts, kitchen utensils, etc., can solve the problems of uneven heating and baking of food surfaces, unable to solve the problem of food surface baking color, and insufficient baking of the bottom of food, etc. , to achieve the effect of improving thermal cycle efficiency, crispy and delicious food surface, and uniform heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

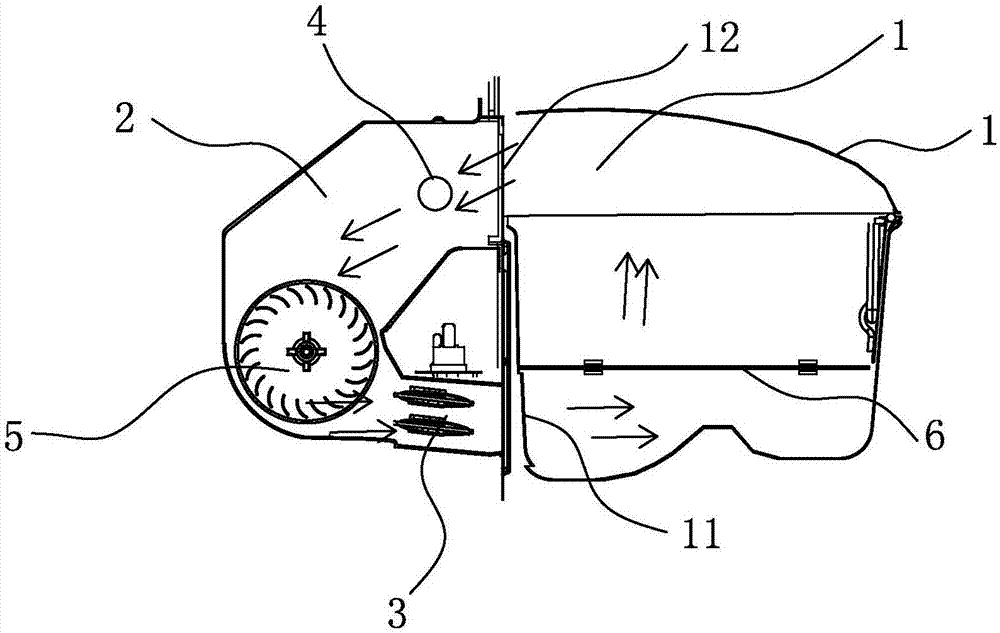

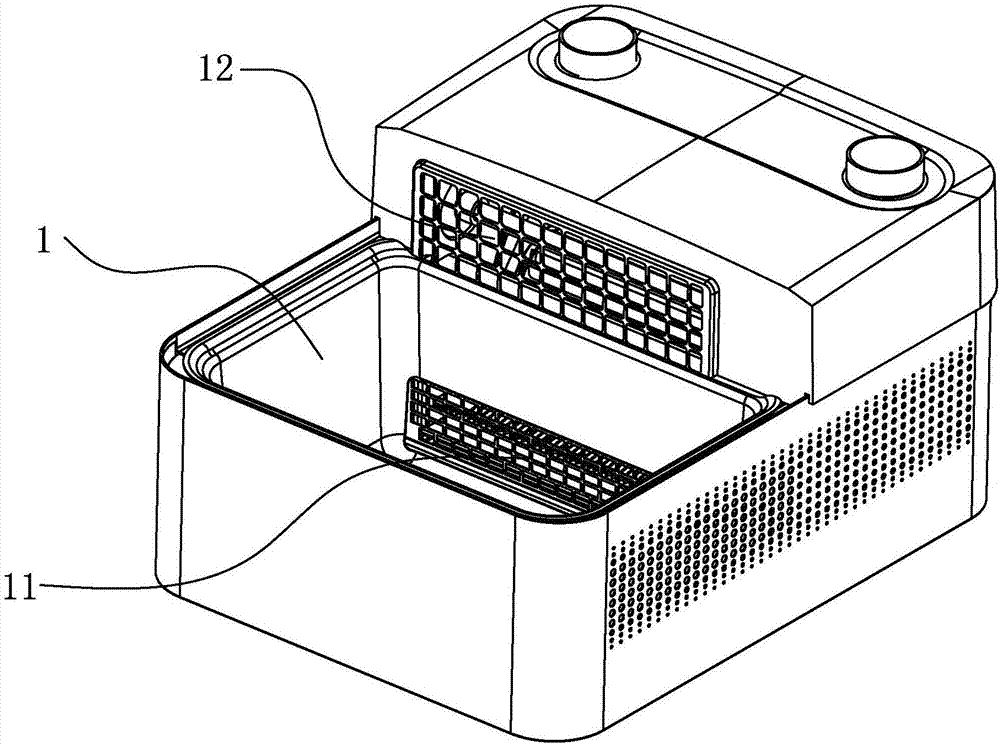

[0040] see figure 1, is a longitudinal sectional view of the air fryer provided in this embodiment. The air fryer includes a first chamber 1, a second chamber 2, a first heater 3, a second heater 4, a cross-flow fan 5, a storage partition 6, an oil receiving box (not shown), and an upper cover 7.

[0041] see figure 2 , is a schematic structural diagram of the air fryer provided in this embodiment. The bottom of the first chamber 1 is provided with an air outlet 11, and the top of the second chamber 2 is provided with an air inlet 12. The first chamber 1 and the second chamber 2 are connected through the air outlet 11 and the air inlet 12; The chamber 1 is used to accommodate food, the second chamber 2 is used to set the first heater 3, the second heater 4, and the cross-flow fan 5, and the air outlet 11 and the air inlet 12 are used to form a hot air circulation channel.

[0042] In this embodiment, the cross-flow fan 5 is arranged horizontally in the second chamber 2, a...

Embodiment 2

[0048] see Figure 4 , is the structure diagram of the air fryer provided in this embodiment. The air fryer includes: a first chamber 1, a second chamber 2, a heating device (not shown), a cross-flow fan (not shown), a rotating cage 3, a rotating mechanism 4, and an oil receiving box (not shown). ), cover 5. The difference between this embodiment and Embodiment 1 is that a tumbler 3 is used to replace the storage partition, and a rotating mechanism 4 that drives the tumbler to move is further provided.

[0049] In this embodiment, the tumbler 3 is detachably arranged in the first chamber 1, the tumbler 3 is cylindrical, the surface of the tumbler 3 and both ends in the axial direction are provided with ventilation holes, and each ventilation hole is arranged in an array. Cloth, the tumbler 3 is used for accommodating food, and the tumbler 3 is detachably arranged, so that it is convenient to take and clean when using the air fryer to cook food. In other embodiments, the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com