Method for operating a thermodynamic cycle, and thermodynamic cycle

A cyclic operation, thermal power technology, applied in machine/engine, steam engine installation, combined combustion mitigation, etc., can solve problems such as pressure pulsation, emergency cycle interruption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

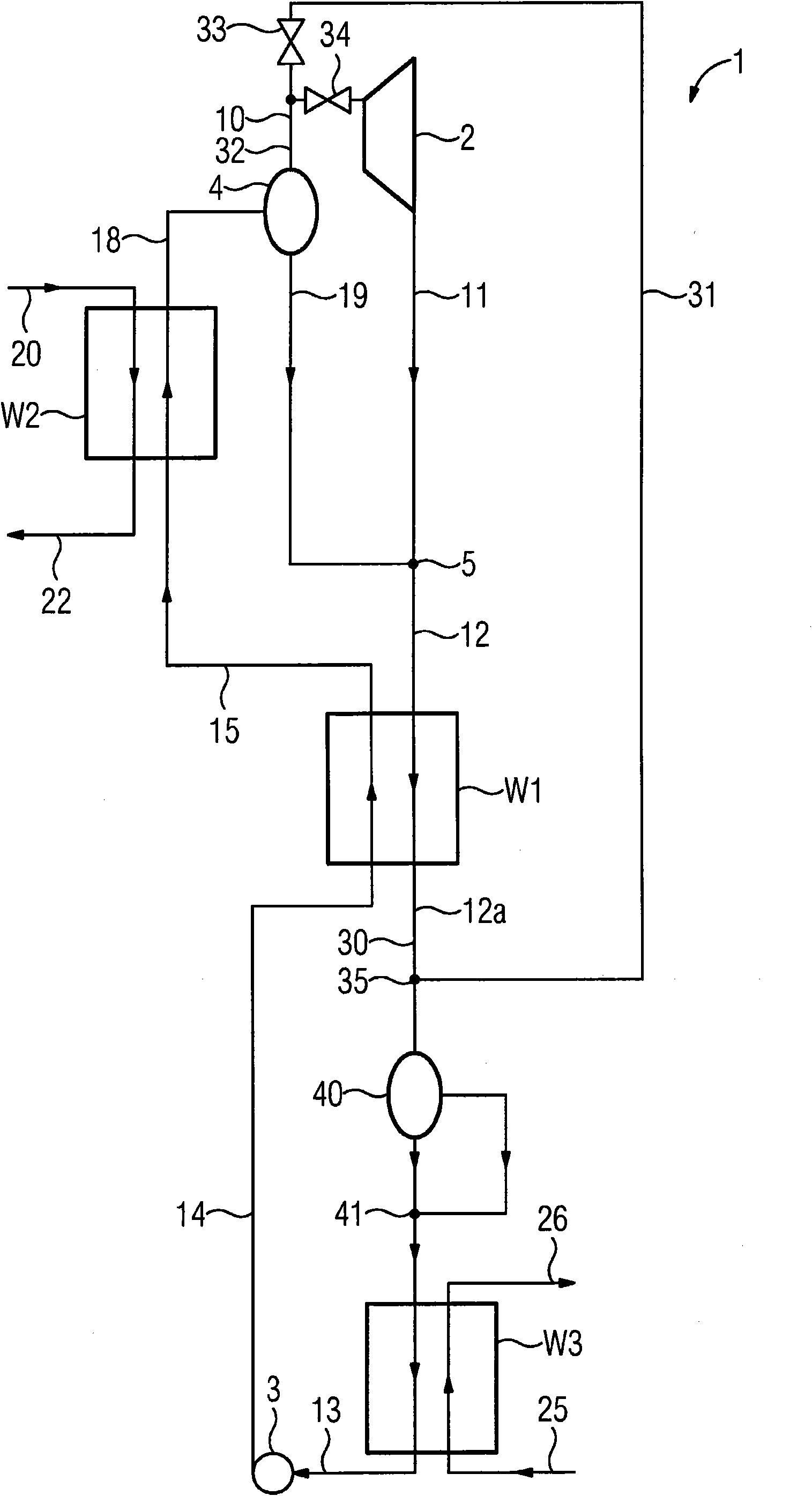

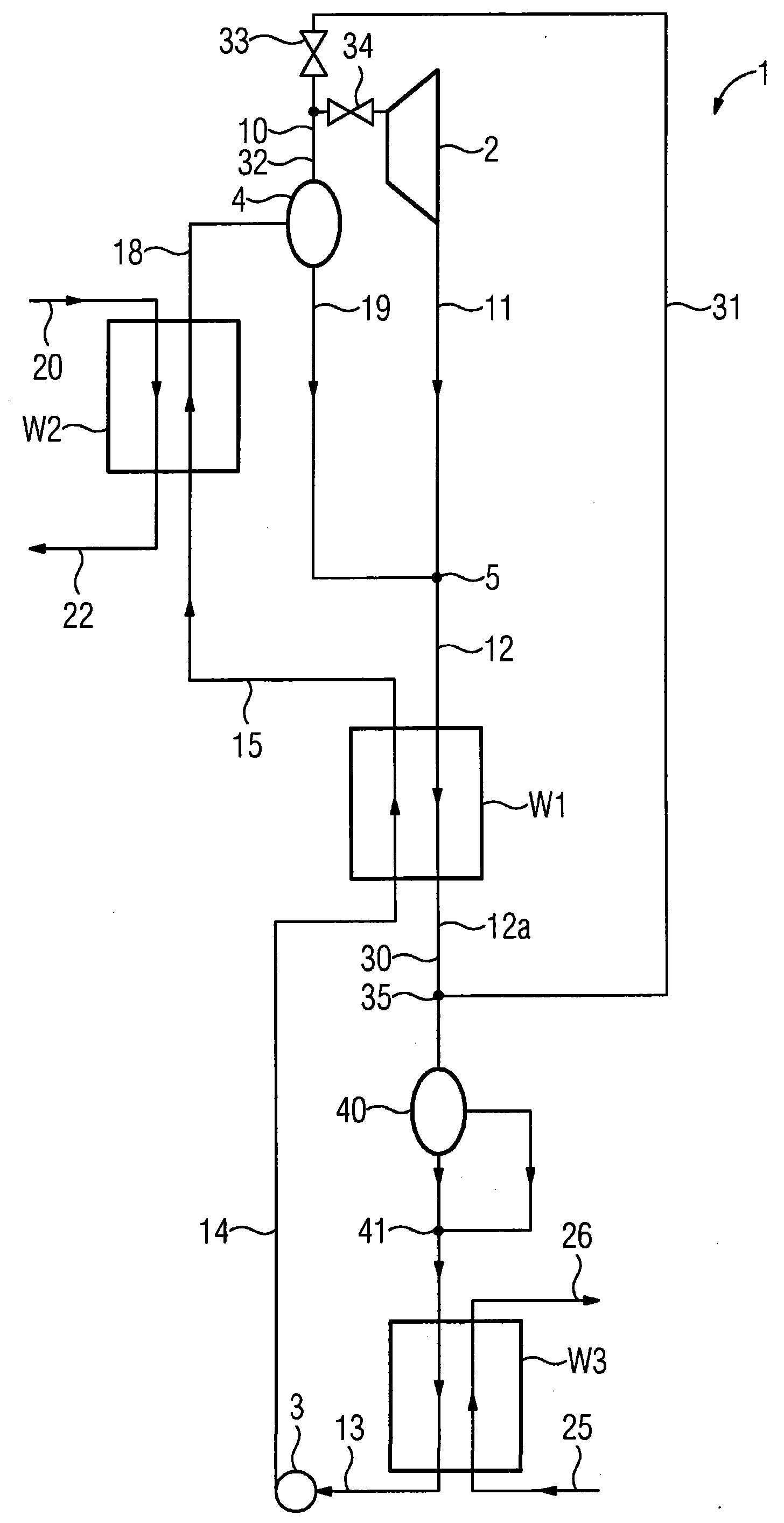

[0019] The thermodynamic cycle 1 shown in the drawings includes a first heat exchanger (preheater) W1, a second heat exchanger (evaporator) W2 and a third heat exchanger (condenser) W3.

[0020] The second heat exchanger W2 is in thermal contact with an external heat source on the primary side, in the illustrated embodiment the second heat exchanger is circulated on the primary side by hot water 20 from an earth heat source not shown in detail, and on the secondary side The stage side is connected on the one hand to the first heat exchanger W1 and on the other hand to the separator 4 . The separator 4 serves to separate the vapor phase of the partially evaporated working medium from the liquid phase. The evaporation side outlet of the separator 4 is connected to the turbine 2 as an expansion device. The turbine 2 is connected on the outlet side to a collecting device in the form of a mixer 5 . The mixer 5 is additionally connected to the liquid outlet of the separator 4 . O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com