Preparation method of multi-core type phosphate compound positive electrode material with core-shell structure for lithium ion battery

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of slow ion transmission and low electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

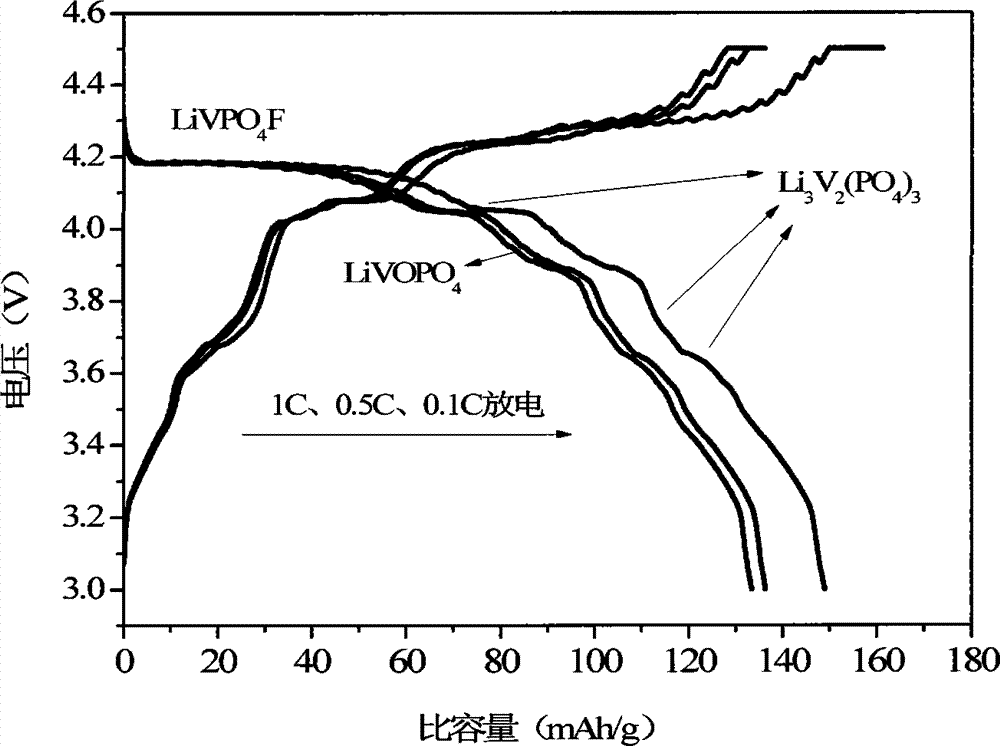

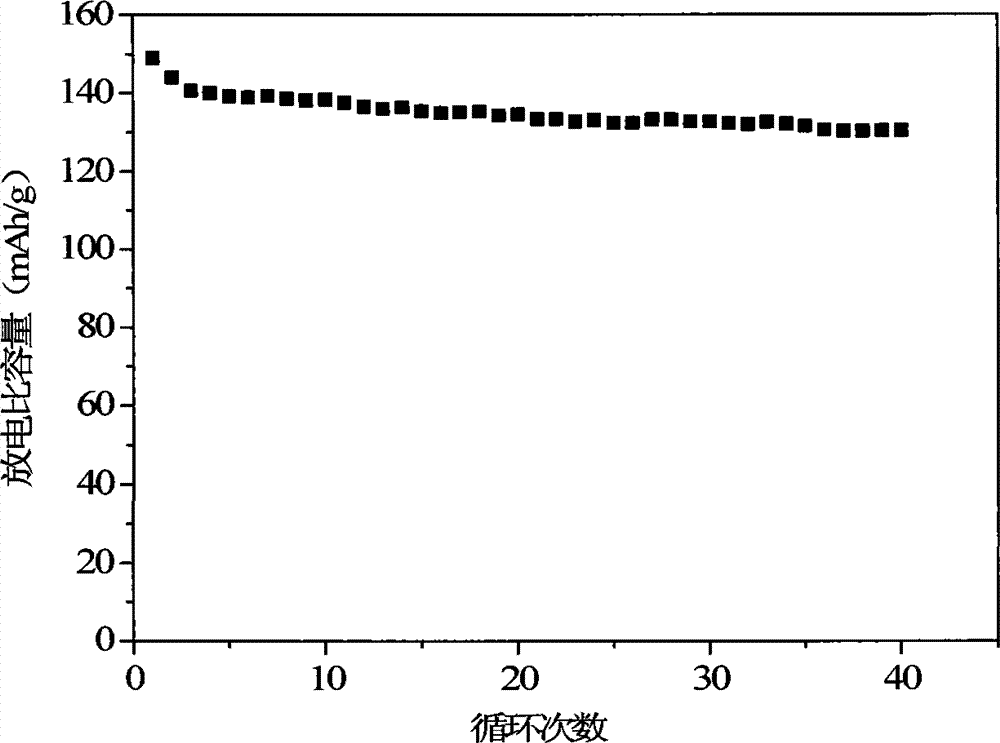

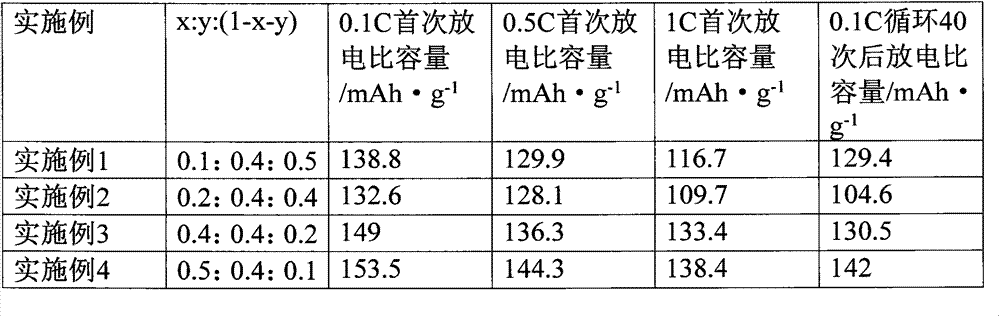

Embodiment 1

[0022] With lithium carbonate, vanadium pentoxide, diammonium hydrogen phosphate, and lithium fluoride as raw materials, LiVPO in the obtained composite positive electrode material 4 F. Li 3 V 2 (PO 4 ) 3 with LiVOPO 4 The molar ratio is 0.1:0.4:0.5, and mix evenly; then add the reducing agent oxalic acid to the mixed material, according to the molar ratio of oxalic acid and vanadium source is 3:1, add and mix, mechanical ball mill for 8 hours, and then turn it to vacuum drying The powder was dried in an oven, fully ground the powder in an agate mortar, pressed into tablets, heat-treated at 750°C for 6 hours in an argon atmosphere, then naturally cooled to 350°C and sintered in an air atmosphere for 1 hour, and finally cooled naturally to room temperature to obtain 0.1 LiVPO 4 F 0.4Li 3 V 2 (PO 4 ) 3 0.5LiVOPO 4 of composite materials. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. The ...

Embodiment 2

[0024] With lithium carbonate, vanadium pentoxide, diammonium hydrogen phosphate, and lithium fluoride as raw materials, LiVPO in the obtained composite positive electrode material 4 F. Li 3 V 2 (PO 4 ) 3 with LiVOPO 4 The molar ratio is 0.2:0.4:0.4, and mix evenly; then add the reducing agent oxalic acid to the mixed material, according to the molar ratio of oxalic acid and vanadium source is 3:1, add and mix, mechanical ball mill for 8 hours, and then turn it to vacuum drying The powder was dried in an oven, fully ground the powder in an agate mortar, pressed into tablets, heat-treated at 750°C for 4 hours in an argon atmosphere, then naturally cooled to 350°C and sintered in an air atmosphere for 2 hours, and finally cooled naturally to room temperature to obtain 0.2 LiVPO 4 F 0.4Li 3 V 2 (PO 4 ) 3 0.4LiVOPO 4 of composite materials. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. The...

Embodiment 3

[0026] With lithium carbonate, vanadium pentoxide, diammonium hydrogen phosphate, and lithium fluoride as raw materials, LiVPO in the obtained composite positive electrode material 4 F. Li 3 V 2 (PO 4 ) 3 with LiVOPO 4 The molar ratio is 0.4:0.4:0.2, and mix evenly; then add reducing agent oxalic acid to the mixed material, according to the molar ratio of oxalic acid and vanadium source is 3:1, add and mix, mechanical ball mill for 8 hours, and then turn it to vacuum drying The powder was dried in an oven, fully ground the powder in an agate mortar, pressed into tablets, heat-treated at 750°C for 2 hours in an argon atmosphere, then naturally cooled to 350°C and sintered in an air atmosphere for 4 hours, and finally cooled naturally to room temperature to obtain 0.4 LiVPO 4 F 0.4Li 3 V 2 (PO 4 ) 3 0.2LiVOPO4 of composite materials. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com