A kind of preparation method of polynuclear core-shell structure phosphate series composite positive electrode material for lithium ion battery

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of slow ion transmission, low electronic conductivity, etc., and achieve the improvement of kinetic factors and kinetic factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

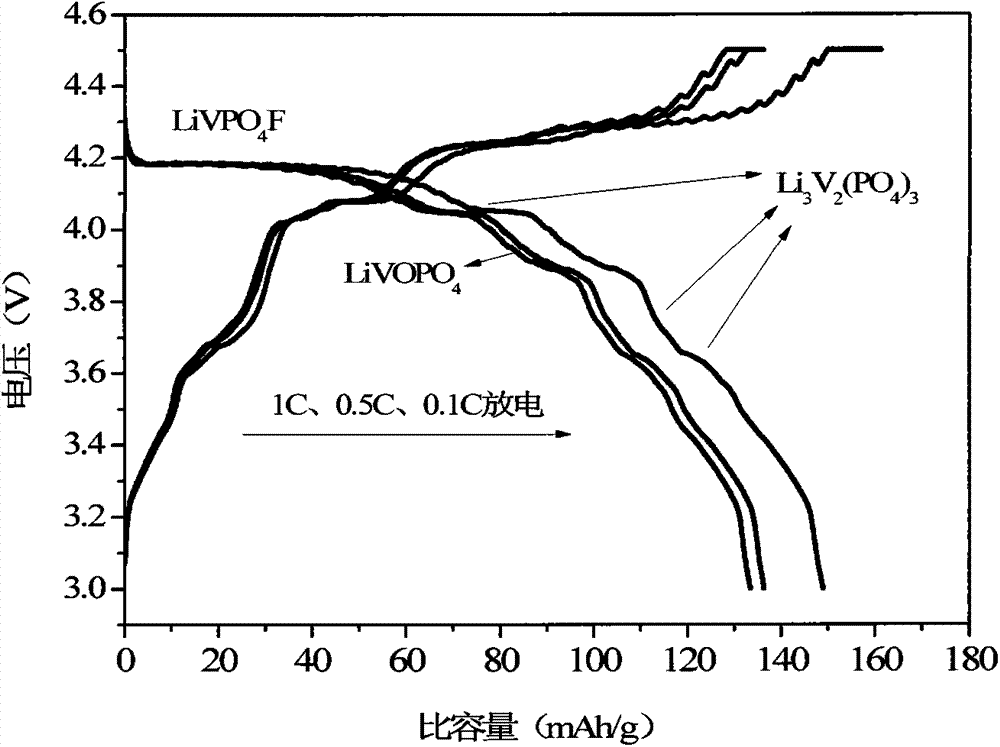

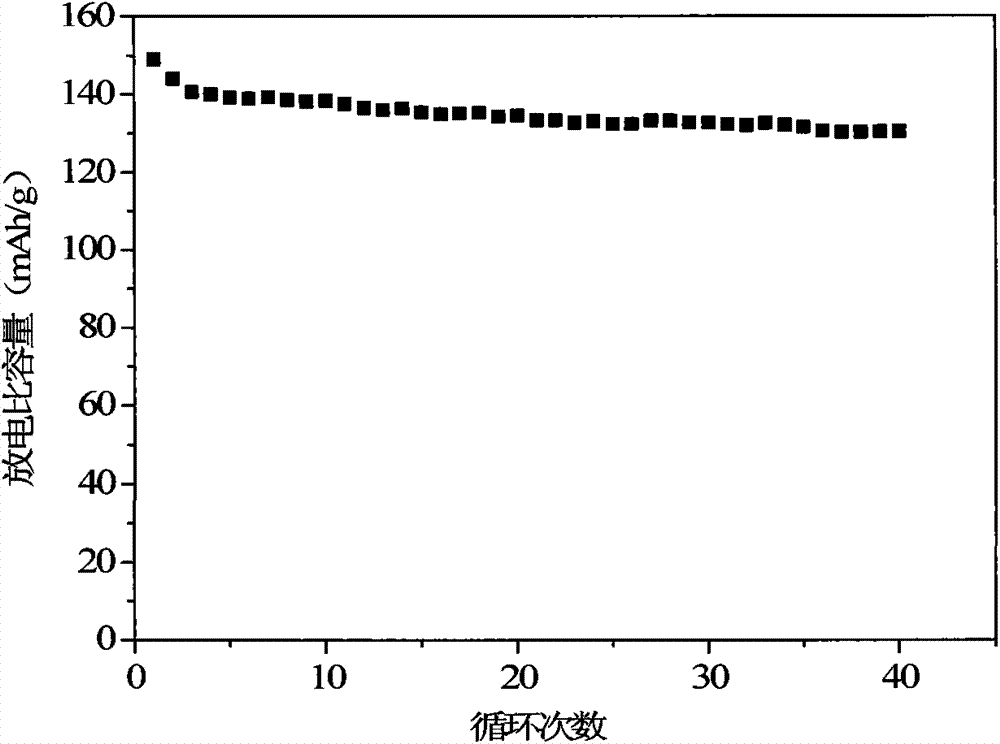

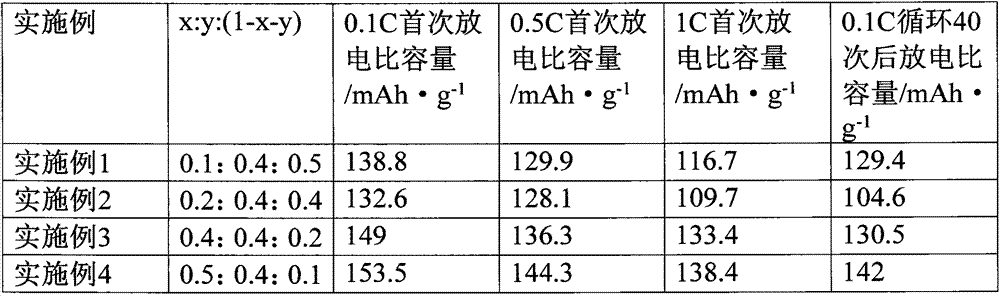

Embodiment 1

[0022] With lithium carbonate, vanadium pentoxide, diammonium hydrogen phosphate, and lithium fluoride as raw materials, LiVPO in the obtained composite positive electrode material 4 F. Li 3 V 2 (PO 4 ) 3 with LiVOPO 4 The molar ratio is 0.1:0.4:0.5, and mix evenly; then add the reducing agent oxalic acid to the mixed material, according to the molar ratio of oxalic acid and vanadium source is 3:1, add and mix, mechanical ball mill for 8 hours, and then turn it to vacuum drying The powder was dried in an oven, fully ground the powder in an agate mortar, pressed into tablets, heat-treated at 750°C for 6 hours in an argon atmosphere, then naturally cooled to 350°C and sintered in an air atmosphere for 1 hour, and finally cooled naturally to room temperature to obtain 0.1 LiVPO 4 F 0.4Li 3 V 2 (PO 4 ) 3 0.5LiVOPO 4 of composite materials. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. The ...

Embodiment 2

[0024] With lithium carbonate, vanadium pentoxide, diammonium hydrogen phosphate, and lithium fluoride as raw materials, LiVPO in the obtained composite positive electrode material 4 F. Li 3 V 2 (PO 4 ) 3 with LiVOPO 4 The molar ratio is 0.2:0.4:0.4, and mix evenly; then add the reducing agent oxalic acid to the mixed material, according to the molar ratio of oxalic acid and vanadium source is 3:1, add and mix, mechanical ball mill for 8 hours, and then turn it to vacuum drying The powder was dried in an oven, fully ground the powder in an agate mortar, pressed into tablets, heat-treated at 750°C for 4 hours in an argon atmosphere, then naturally cooled to 350°C and sintered in an air atmosphere for 2 hours, and finally cooled naturally to room temperature to obtain 0.2 LiVPO 4 F 0.4Li 3 V 2 (PO 4 ) 3 0.4LiVOPO 4 of composite materials. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. The...

Embodiment 3

[0026] With lithium carbonate, vanadium pentoxide, diammonium hydrogen phosphate, and lithium fluoride as raw materials, LiVPO in the obtained composite positive electrode material 4 F. Li 3 V 2 (PO 4 ) 3 with LiVOPO 4 The molar ratio is 0.4:0.4:0.2, and mix evenly; then add reducing agent oxalic acid to the mixed material, according to the molar ratio of oxalic acid and vanadium source is 3:1, add and mix, mechanical ball mill for 8 hours, and then turn it to vacuum drying The powder was dried in an oven, fully ground the powder in an agate mortar, pressed into tablets, heat-treated at 750°C for 2 hours in an argon atmosphere, then naturally cooled to 350°C and sintered in an air atmosphere for 4 hours, and finally cooled naturally to room temperature to obtain 0.4 LiVPO 4 F 0.4Li 3 V 2 (PO 4 ) 3 0.2LiVOPO4 of composite materials. The resulting product was formed into a button battery to measure its charge-discharge specific capacity and cycle performance. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com