Process and device for preparing continuous combined filament yarn

A technology of mixed fiber yarn and process, which is applied in the field of new material processing, can solve problems such as difficult to be widely promoted and applied, difficult to meet large-scale production, rigid and difficult to adjust yarn spreading effect, etc., to achieve optimal interface distribution, enhanced separation effect, The effect of improving fiber blending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

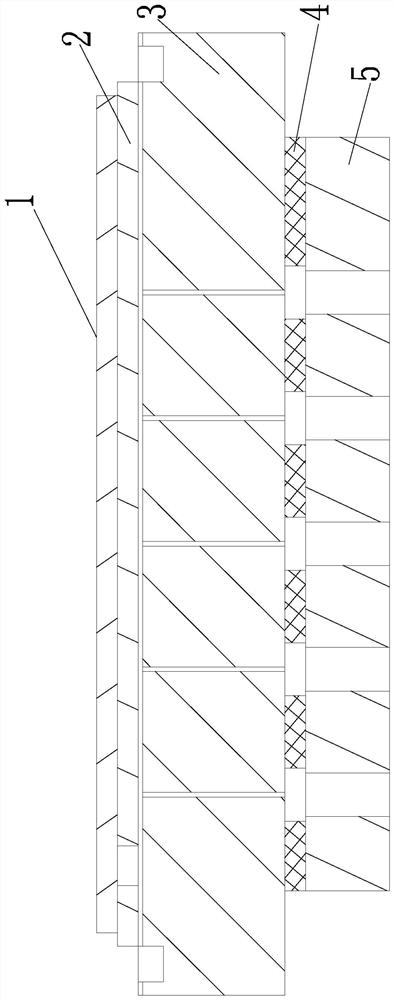

[0064] A process for spreading glass fiber tow, the specific steps are:

[0065] Place the glass fiber with a specification of 480Htex on the second creel, and pass the fiber through the third guide into the second release roller, then spread the fiber through the second air-jet diffusion device and enter the traction through the fourth guide Roll and enter the winding roll to obtain the glass fiber in the separated state;

[0066] The running speed of the unwinding roller adopted in this application is 2.1m / min, and the running speed of the traction roller is 2.0m / min;

[0067] What above-mentioned technique adopts is the device described in the equipment embodiment, and the parameter setting of further air jet diffusion device is:

[0068] The width of the outlet of the spreading channel is 15mm, the height is 1mm, the width of the entrance of the spreading channel is 3mm, and the height is 0.5mm, and the spreading channel expands synchronously in the horizontal and vertica...

Embodiment 2

[0072] A process for spreading nylon fiber tow, the specific steps are:

[0073] Place the nylon fiber tow with a specification of 1400Dtex on the first creel, and pass the fiber through the first guide into the first yarn-releasing roller, and then spread the fiber through the first air-jet diffusion device and pass through the second guide The device enters the traction roller and enters the winding roller to obtain nylon fibers in a separated state;

[0074] The running speed of the unwinding roller adopted in this application is 1.1m / min, and the running speed of the traction roller is 1.0m / min;

[0075] What above-mentioned technique adopts is the device described in the equipment embodiment, and the parameter setting of further air jet diffusion device is:

[0076] The width of the outlet of the spreading channel is 10mm, the height is 2mm, the width of the entrance of the spreading channel is 1mm, and the height is 1mm, and the spreading channel expands synchronously i...

Embodiment 3

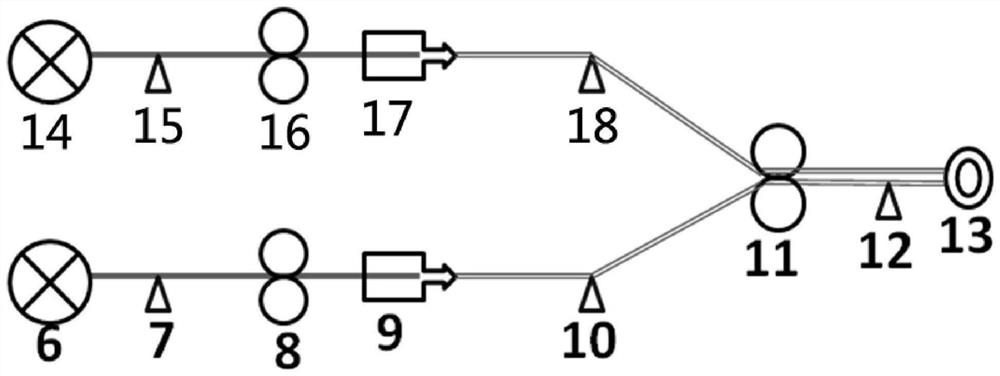

[0080] A kind of technology that is used to prepare glass fiber and nylon fiber mixed filament, concrete steps are:

[0081] Place the nylon fiber with a specification of 2135Dtex on the first creel, and pass the fiber through the first guide into the first yarn release roller, and then spread the thermoplastic resin fiber through the first air jet diffusion device and pass through the second guide The device enters the traction roller;

[0082]Place the glass fiber with a specification of 480Htex on the second creel, and pass the fiber through the third guide into the second release roller, then spread the reinforced fiber through the second air-jet diffusion device and enter through the fourth guide traction roller;

[0083] The fibers after the two kinds of spreading are mixed by the drawing roller and enter the winding roller through the fifth guide;

[0084] The running speed of the unwinding rollers adopted in this application is 1.6m / min, and the running speed of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com