Rotary oil-jetting mixer

A technology of rotary injection and blender, which is applied in fluid mixers, mixers, chemical instruments and methods, etc. It can solve the problems of easily damaged inner floating discs, difficult equipment maintenance, long blending time, etc., and achieve material loss less, improve the turnover utilization rate, and improve the effect of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

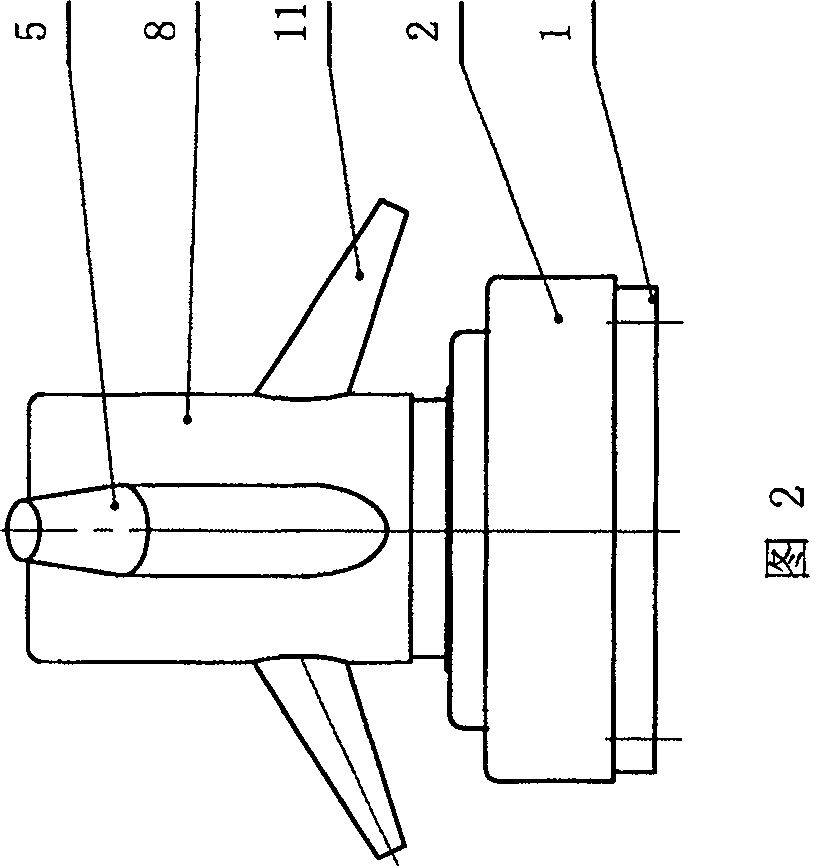

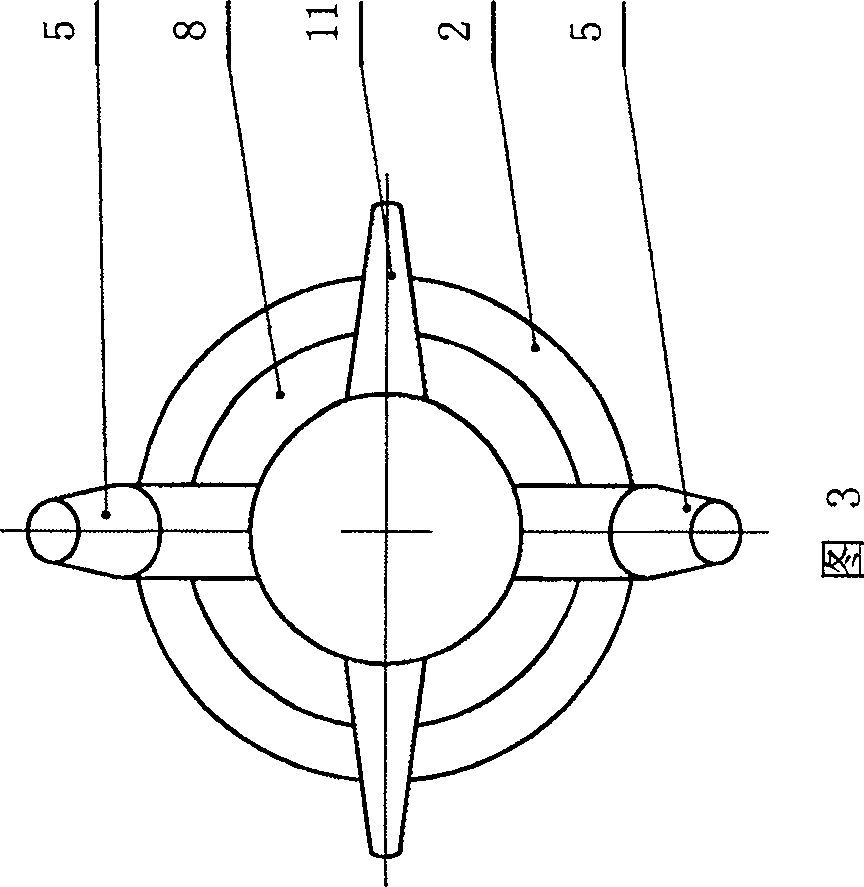

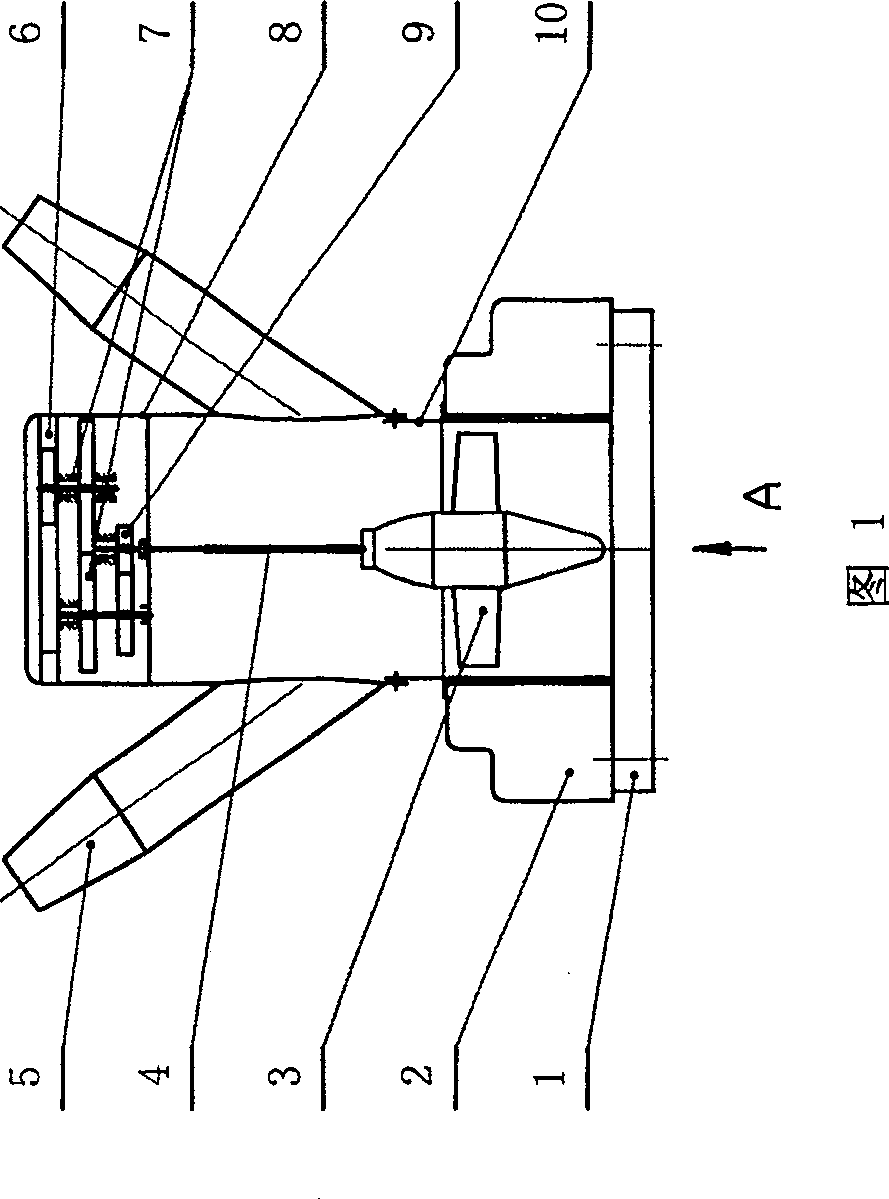

[0018] Embodiment 1 is shown in Figures 1 to 4: a rotary jet blender for oil products, a rotatable inner sleeve 10 is installed on the base 2, and the drum 8 is fastened to the inner sleeve 10; A reduction box 7 is installed, and the inner ring gear 6 of the reduction box 7 is fastened on the top of the inner wall of the drum 8 and meshed with the final external gear of the reduction box 7; the primary gear 9 of the reduction box 7 is installed on the upper end of the main shaft 4, The lower end of the main shaft 4 is equipped with an axial flow turbine 3 . A pair of upper nozzles 5 and a pair of lower nozzles 11 communicated with the inner cavity and arranged symmetrically are arranged on the outer wall of the drum 8, and the center planes of the upper nozzles 5 and the lower nozzles 11 are perpendicular to each other. There is a flange 1 on the outside of the base 2, the flange 1 is connected to the delivery pipe, and the liquid flow drives the axial flow turbine 3 through t...

Embodiment 2

[0019] Embodiment 2: Configure the nozzles with appropriate angles and the rotational speed of the nozzles, so that the jets of the nozzles are concentrated and impact the sludge accumulated in the tank to dissipate it. In this way, the present invention is used to clean the oil storage tank, remove the deposition of materials in the tank, increase the effective volume of the storage tank, thereby greatly improving the utilization rate of the storage tank; it replaces the manual cleaning of the tank, and avoids the problems caused by manual cleaning of the tank. It reduces personal injury, reduces the waste of people, energy, and materials, and fully meets the market and environmental requirements for high-quality cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com