Blowing multi-cabin cotton mixing machine

A multi-compartment cotton blending and blending machine technology, which is applied in the direction of fiber opening and cleaning machines, fiber mixing, opening and cleaning with toothed tools, etc., can solve the problem that cotton products of different densities cannot be mixed evenly, and achieve cotton blending high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the multi-compartment blowing and cotton blending machine provided in the embodiment of the present application will be described below in conjunction with the drawings in the description.

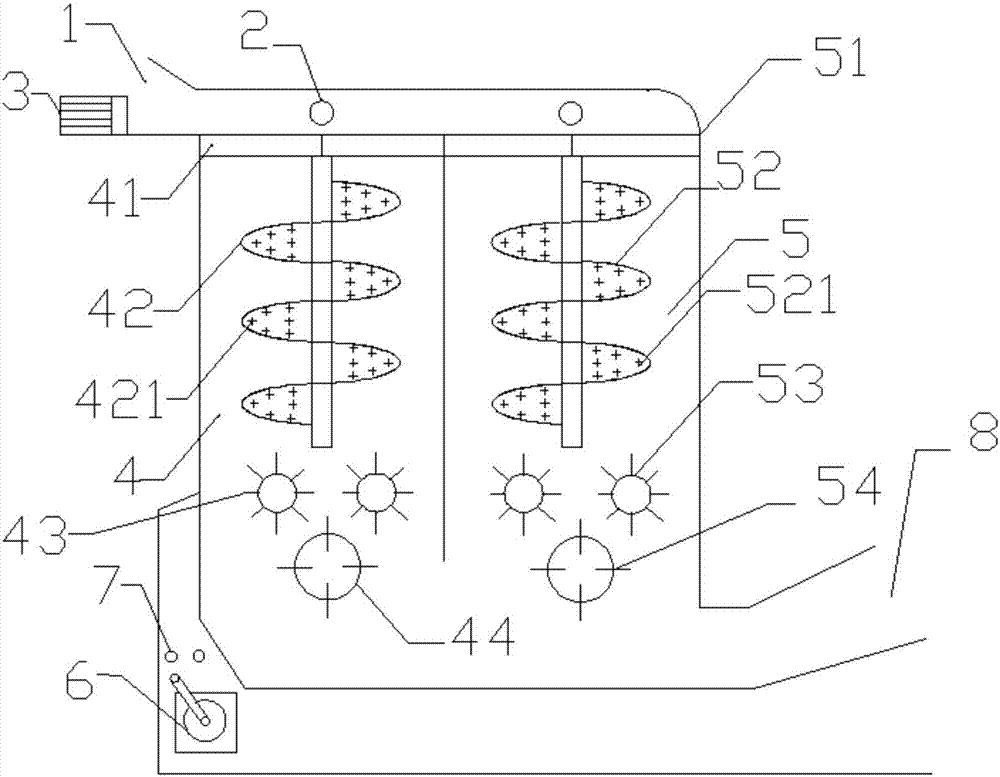

[0030] see figure 1 , a kind of blowing multi-compartment cotton blending machine provided in Embodiment 1 of the present application, comprising:

[0031] The cotton inlet channel 1, the cotton inlet roller 2 arranged in the cotton inlet channel 1, the cotton inlet fan 3 arranged at the entrance of the cotton inlet channel 1, the first cotton mixing chamber 4, and the first cotton mixing chamber The second cotton mixing bin 5 adjacent to the bin 4, the swing valve 6, the indicator light 7 and the cotton outlet channel 8;

[0032] The cotton feeding roller 2 is used to drive the cotton products into the cotton blending chamber, so that the cotton products enter at a uniform speed, ensure the amount of cotton feeding, and ensure the efficiency and qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com