Motor vehicle door lock

A technology for motor vehicle door locks and rotating lock forks, which is applied in the application of vehicle locks, building locks, and locks, etc., can solve problems such as occurrence of problems, component parts are not correctly connected to each other, support sleeve inclination position, damage, etc., and achieve simplification. Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

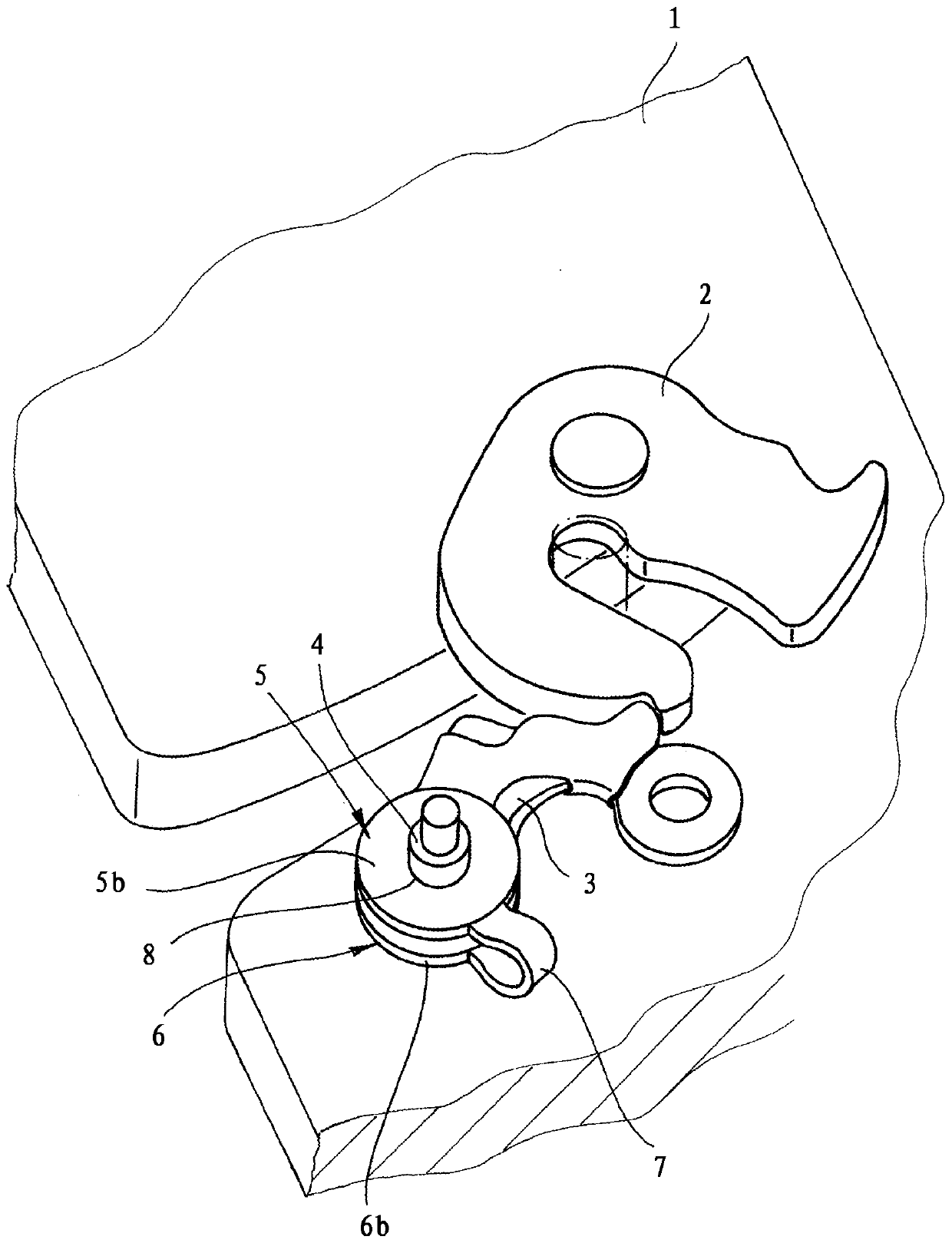

[0023] exist figure 1 A perspective view of a motor vehicle door lock is schematically shown in . The motor vehicle door lock has a housing 1 , which is currently designed as a metal lock box and in which, in the exemplary embodiment, a locking device 2 , 3 is mounted, which comprises a rotary locking fork 2 and a pawl 3 . In addition, further rods can also be mounted in the housing 1 , but this is not shown. Furthermore, instead of a metallic lock box as housing 1 , a housing cover made of plastic can also be used. This is likewise not shown. The lever, not shown, can be designed as a component of the actuating linkage and / or of the locking linkage.

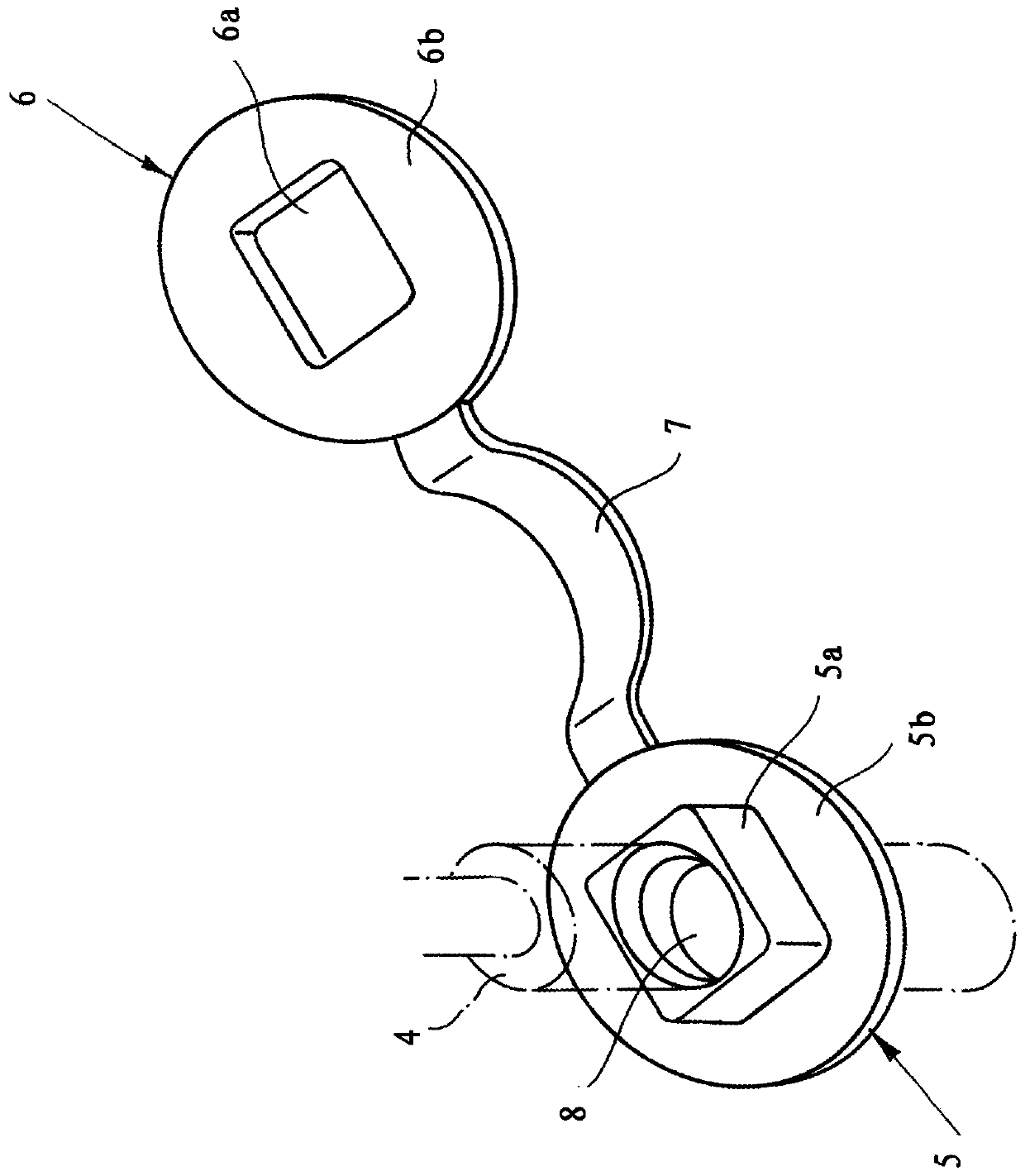

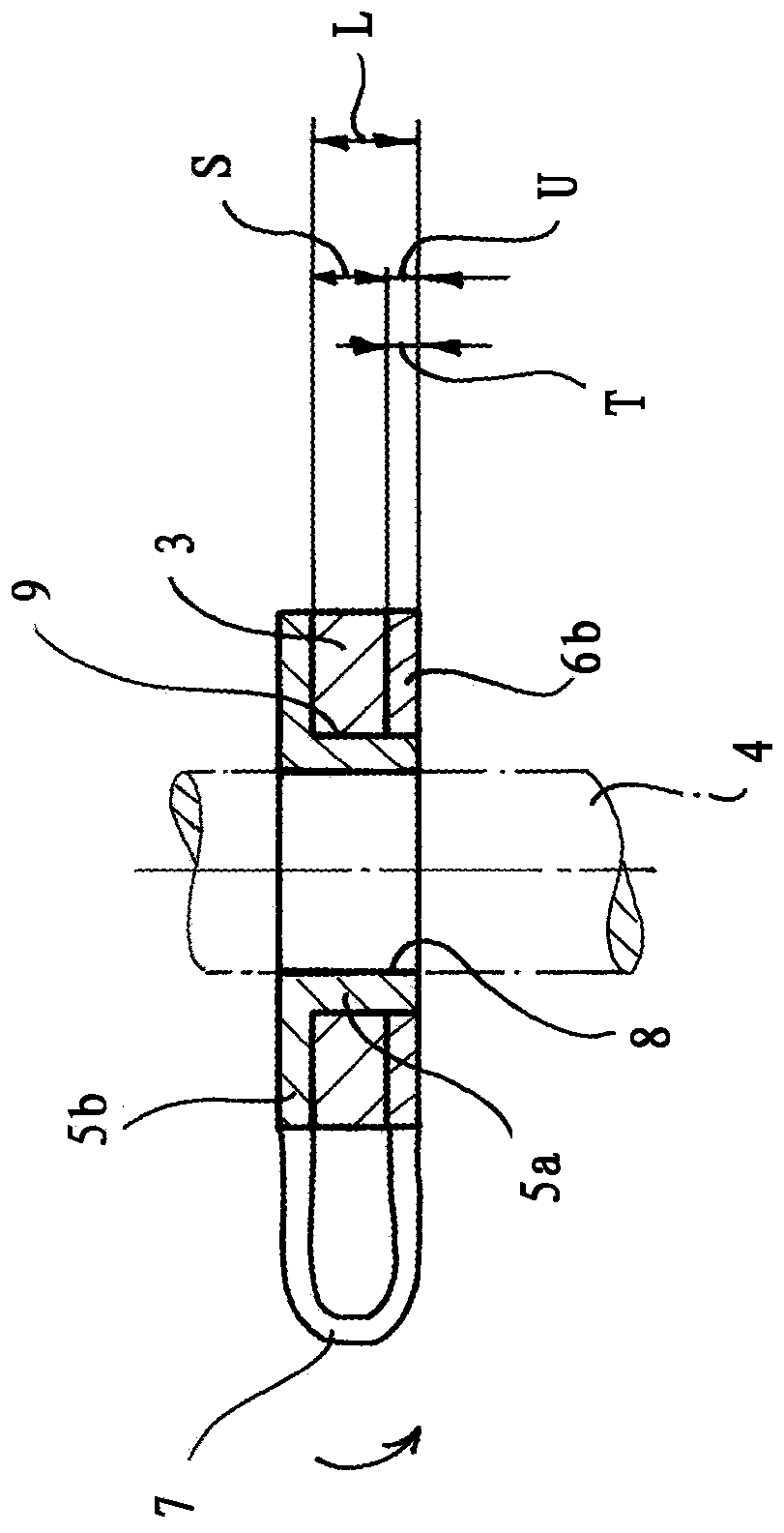

[0024] In this exemplary embodiment, a bearing pin 4 is provided for rotatably mounting the relevant locking device component 3 in the housing 1 . The locking device component 3 within the scope of the exemplary embodiment is the locking pawl 3 . In principle, it is also possible to mount the rotary locking fork 2 , which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com