Dyeing method of cheese yarn subjected to low-temperature pretreatment

A yarn dyeing and pretreatment technology, applied in the field of dyeing auxiliaries, can solve problems such as human health hazards, and achieve the effects of improving wettability, good dyeing rate and color fixing rate, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

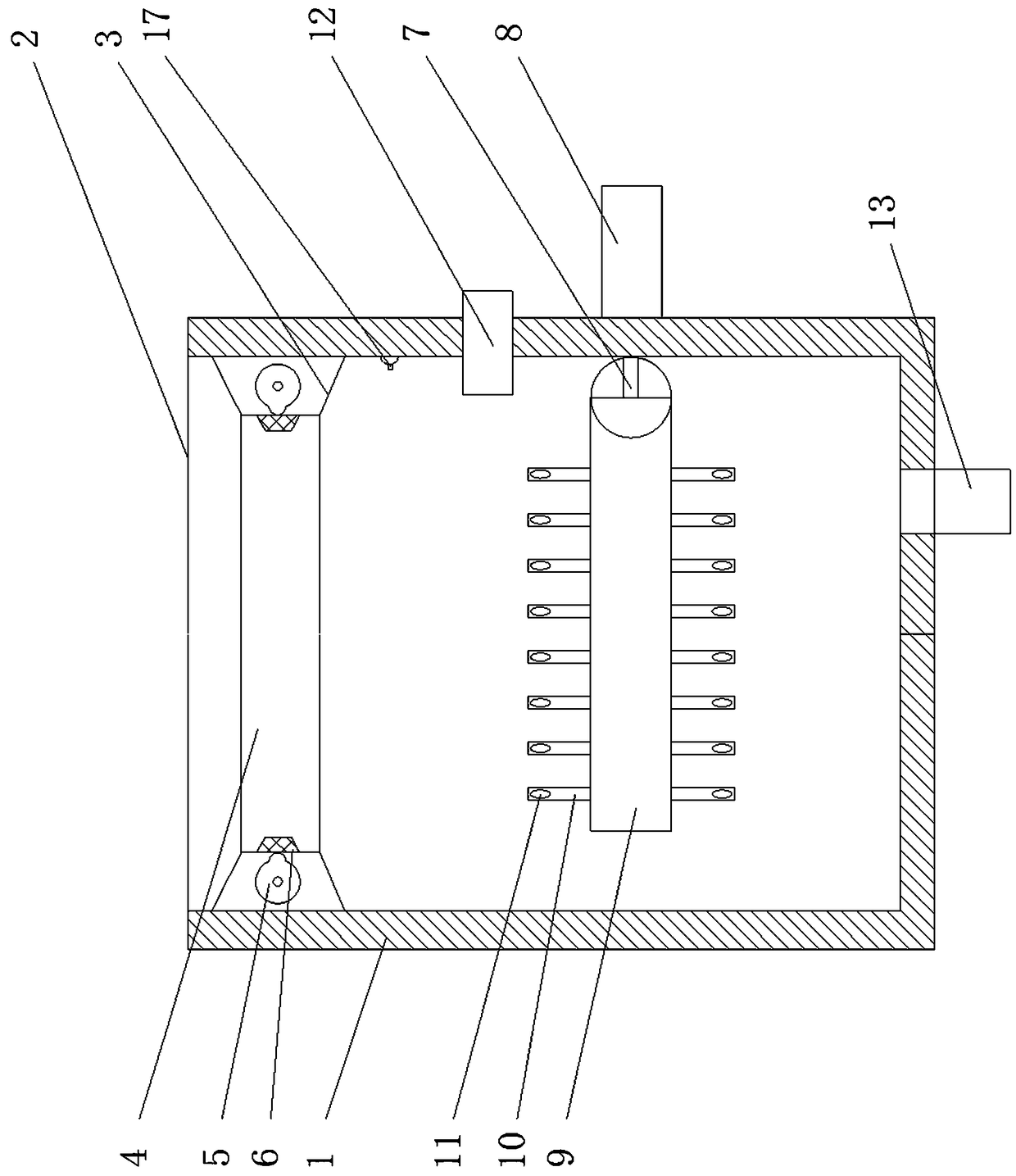

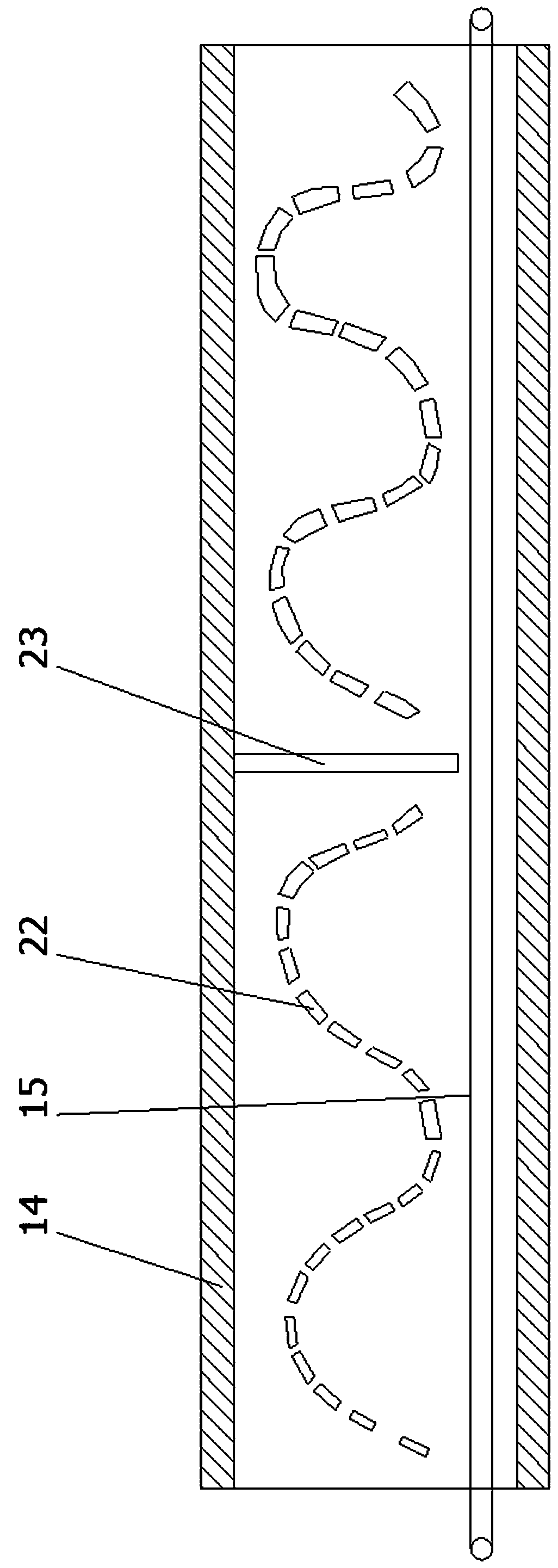

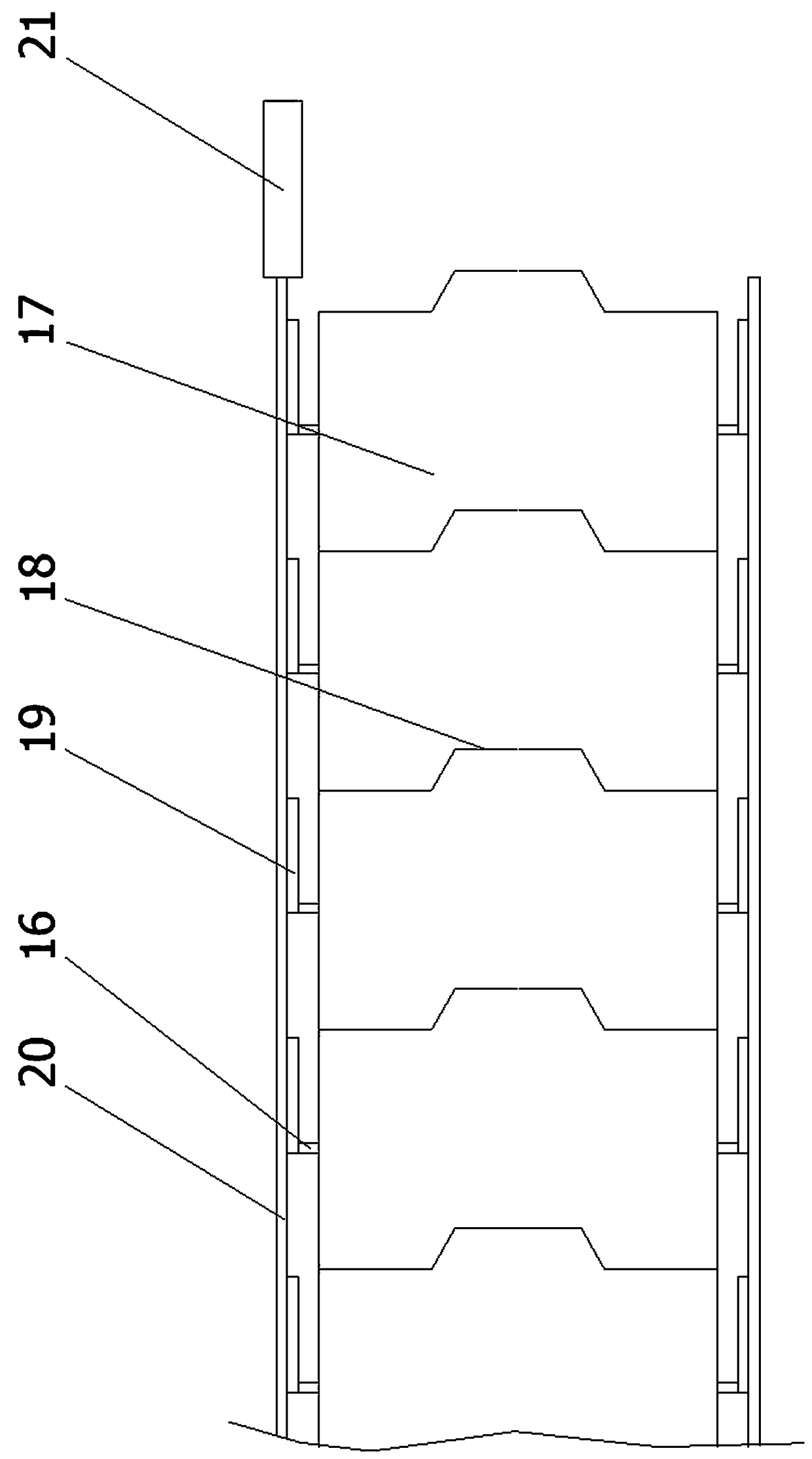

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of package yarn dyeing method after low temperature pretreatment:

[0029] The preparation method of cationic starch is as follows: add 10g cornstarch and 200g distilled water into a three-necked flask, stir, and gelatinize at 80°C for 30min; then, add 10ml of 40% NaOH solution, 3-chloro-2-hydroxypropyltrimethyl chloride Ammonium chloride 10g, heated to 55°C, stirred and reacted for 6h; after the reaction, absolute ethanol was added to precipitate, filtered, the collected precipitate was washed several times with absolute ethanol, and dried in a vacuum oven at 50°C.

[0030] Cheese yarn dyeing method:

[0031] Step 1: Package yarn pretreatment, put package yarn into 40g / L sodium carbonate solution, heat up to 50℃ at a speed of 2℃ / min, and treat for 30min;

[0032] Step 2: Dyeing, configure 10g / L cationic starch solution according to the bath ratio of 1:30, add the pretreated cheese yarn, soak at room temperature for 20min; then add reactive dyes, n...

Embodiment 2

[0038] Embodiment 2, a method for dyeing cheese after low-temperature pretreatment: the reactive dye is domestic reactive yellow K-RN, and the rest are the same as in embodiment 1.

Embodiment 3

[0039] Embodiment 3, a method for dyeing cheese after low-temperature pretreatment: the reactive dye is domestic reactive blue X-BR, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com