Patents

Literature

85 results about "Disperse orange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disperse Orange 1 (4-anilino-4'-nitroazobenzene) is an azo dye. Commercial samples contain approximately 25% dye by weight, with the remaining mass consisting of NaCl and other salts.

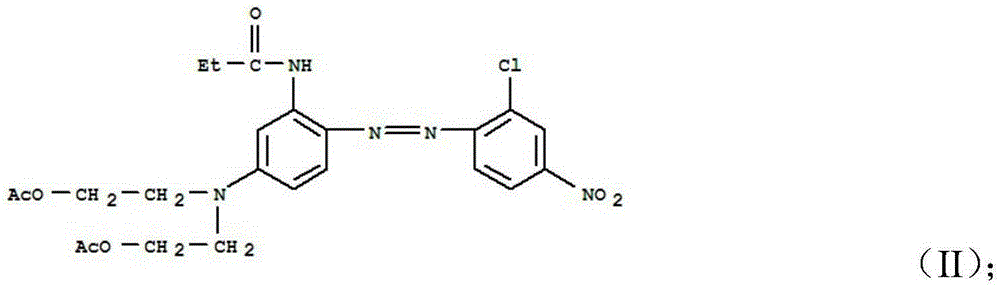

Dispersing orange dye composition and dispersing dye

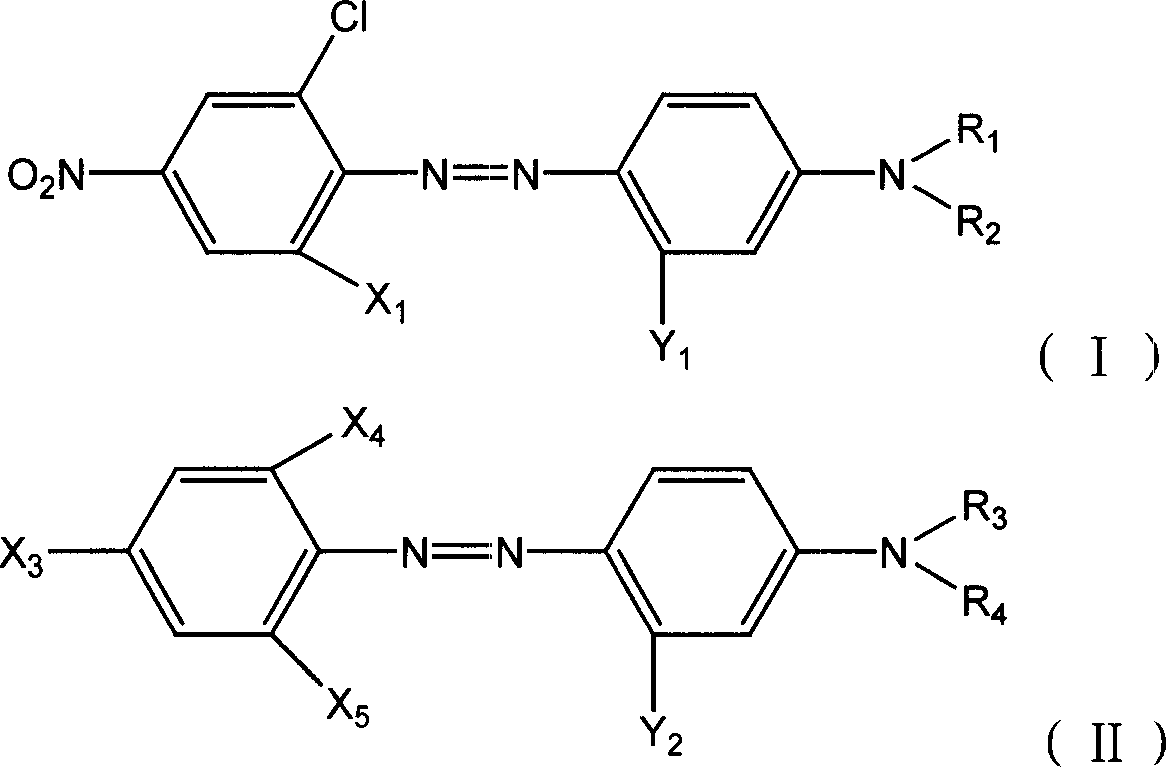

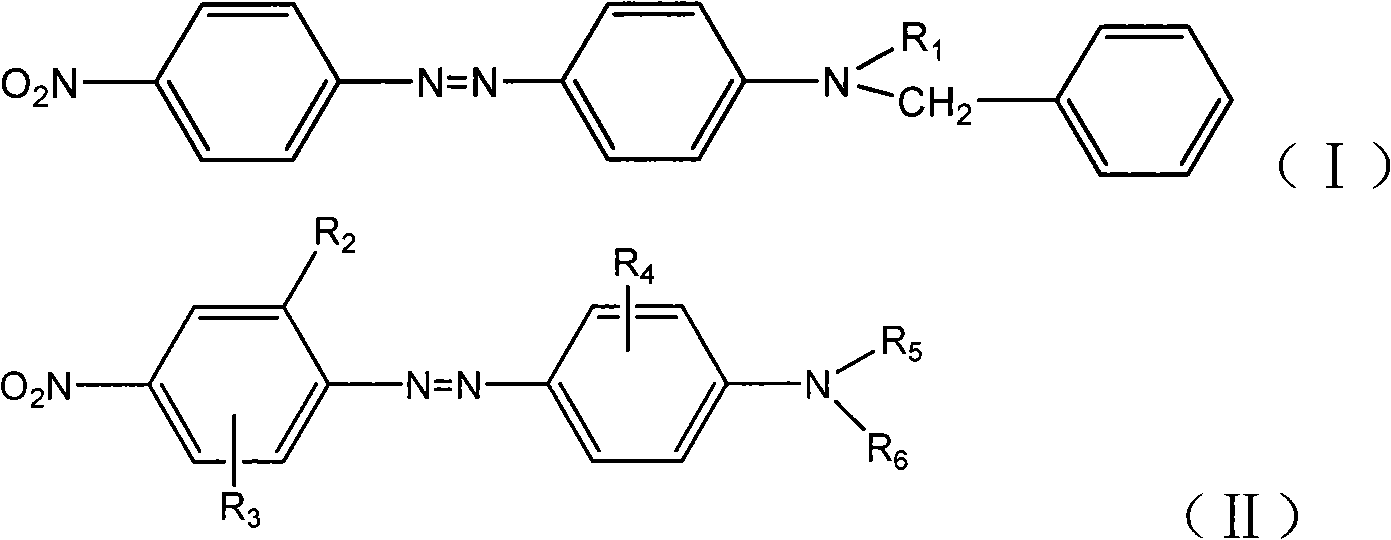

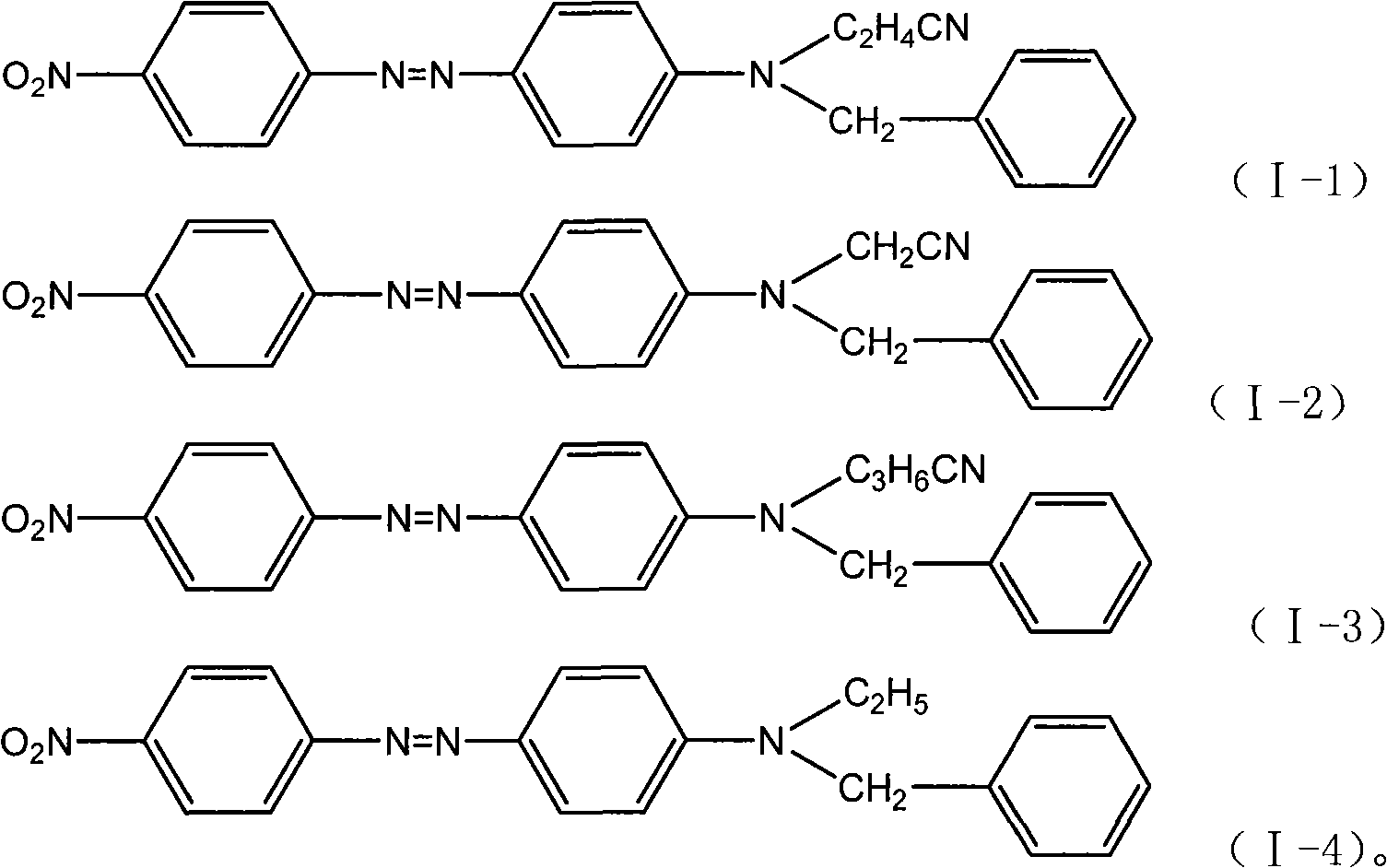

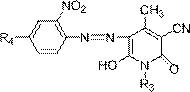

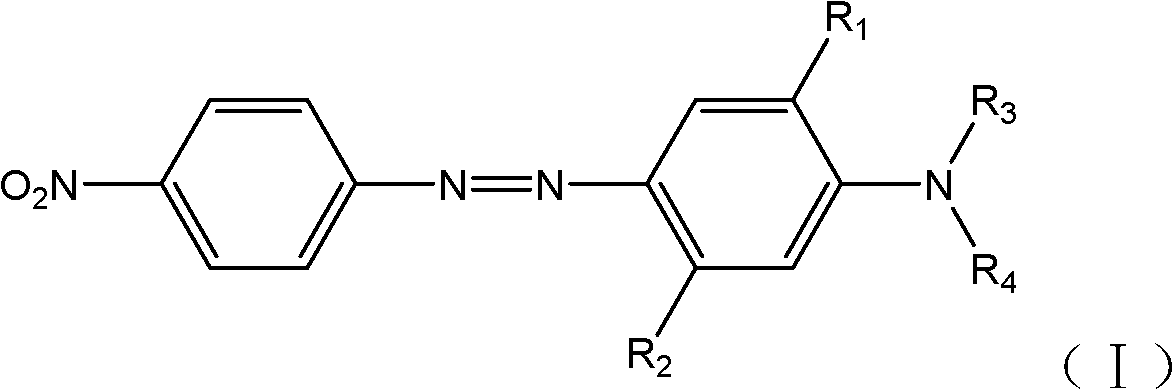

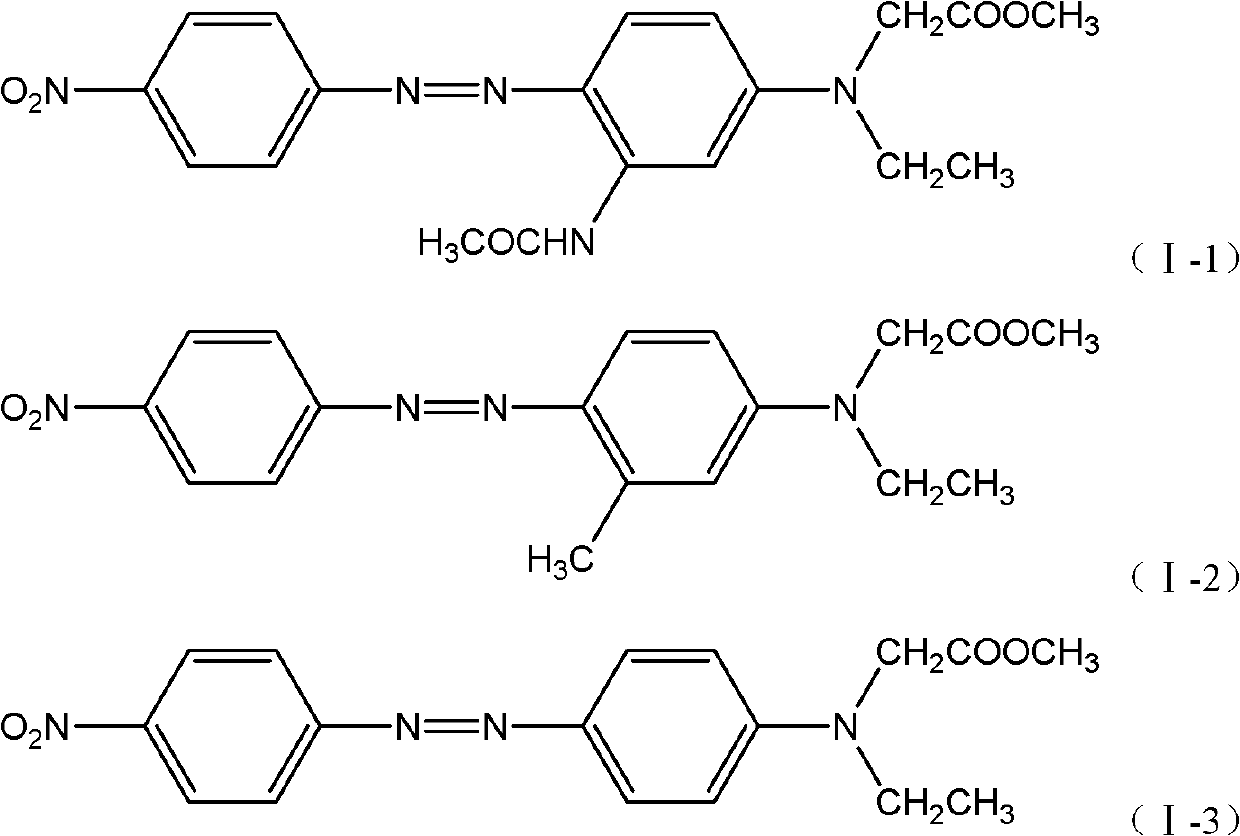

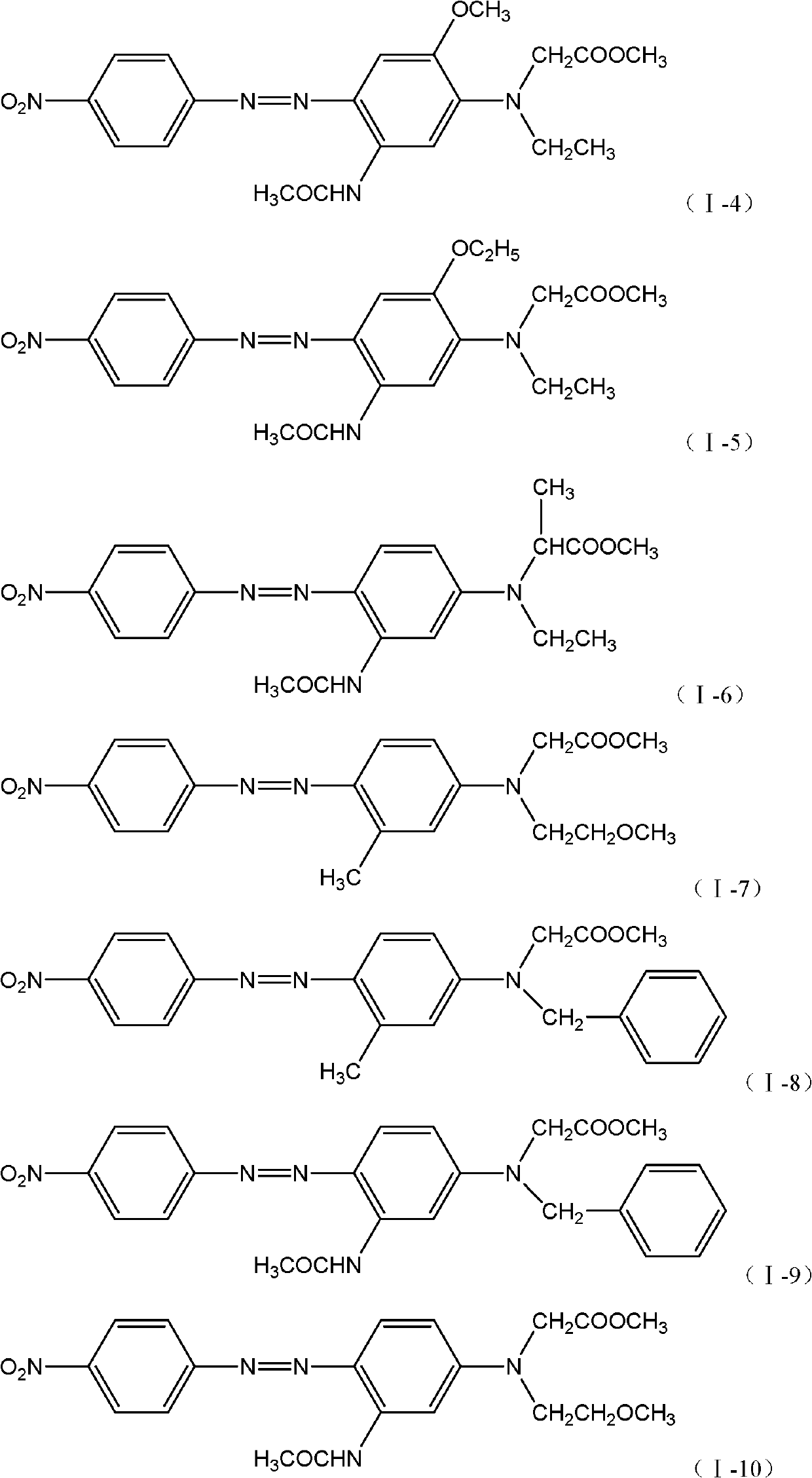

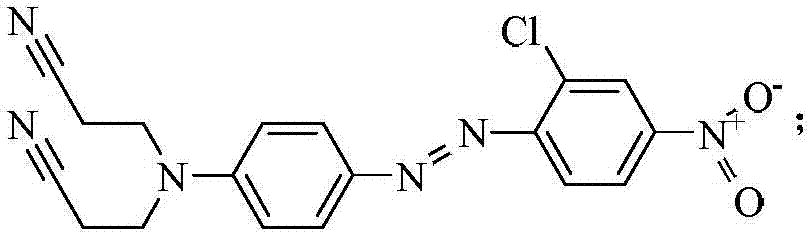

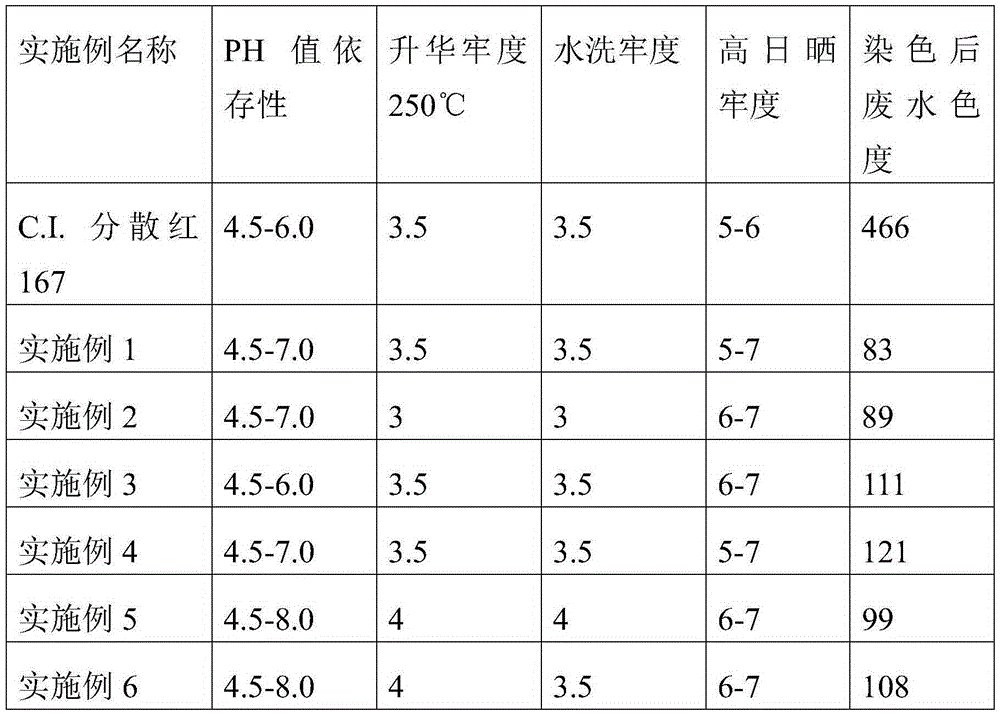

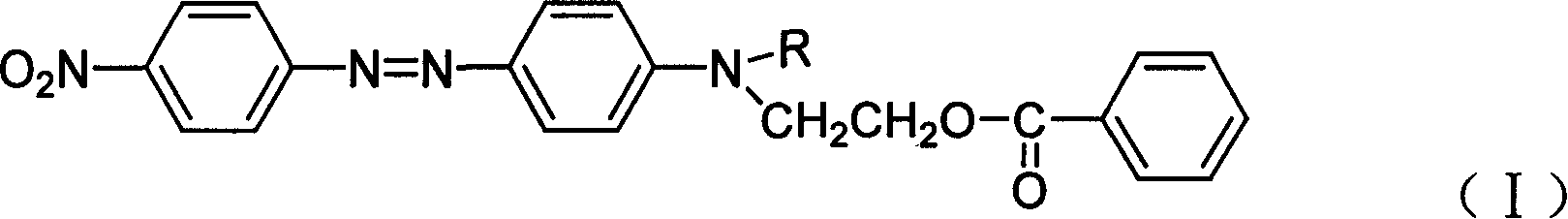

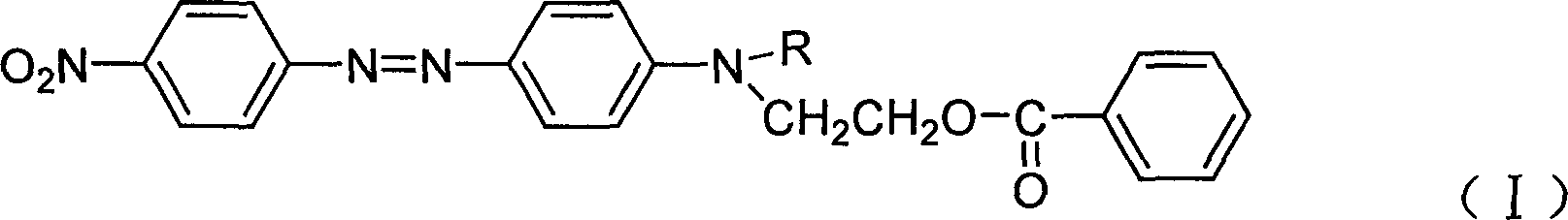

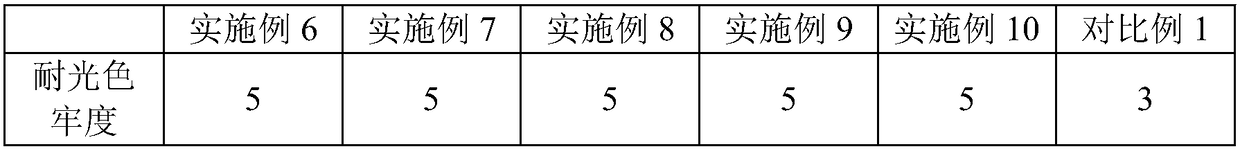

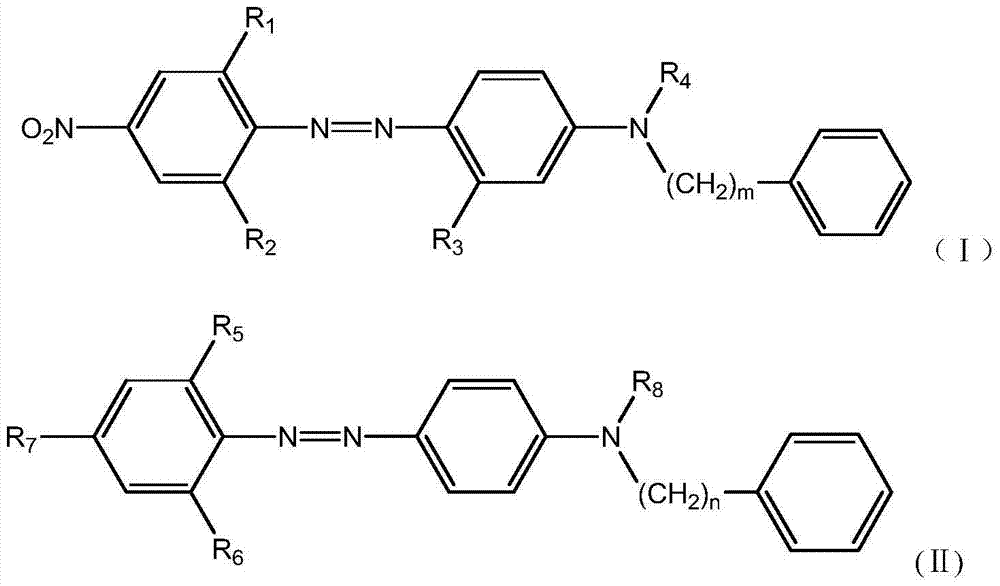

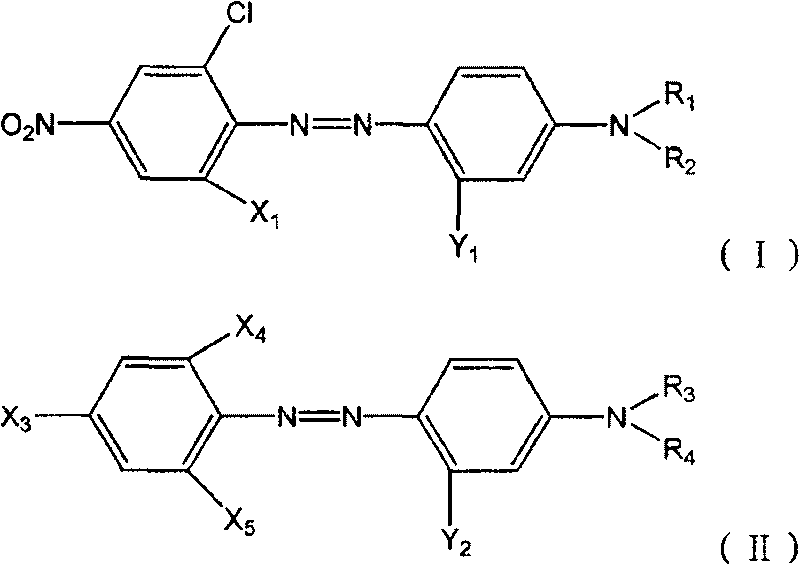

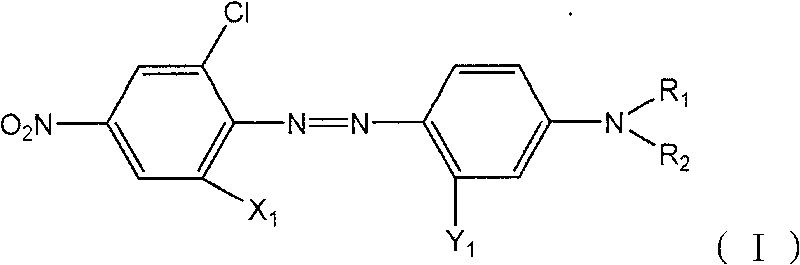

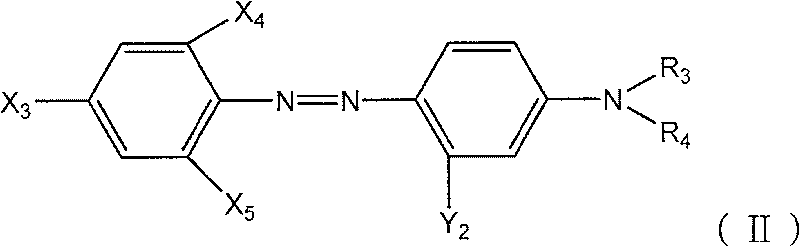

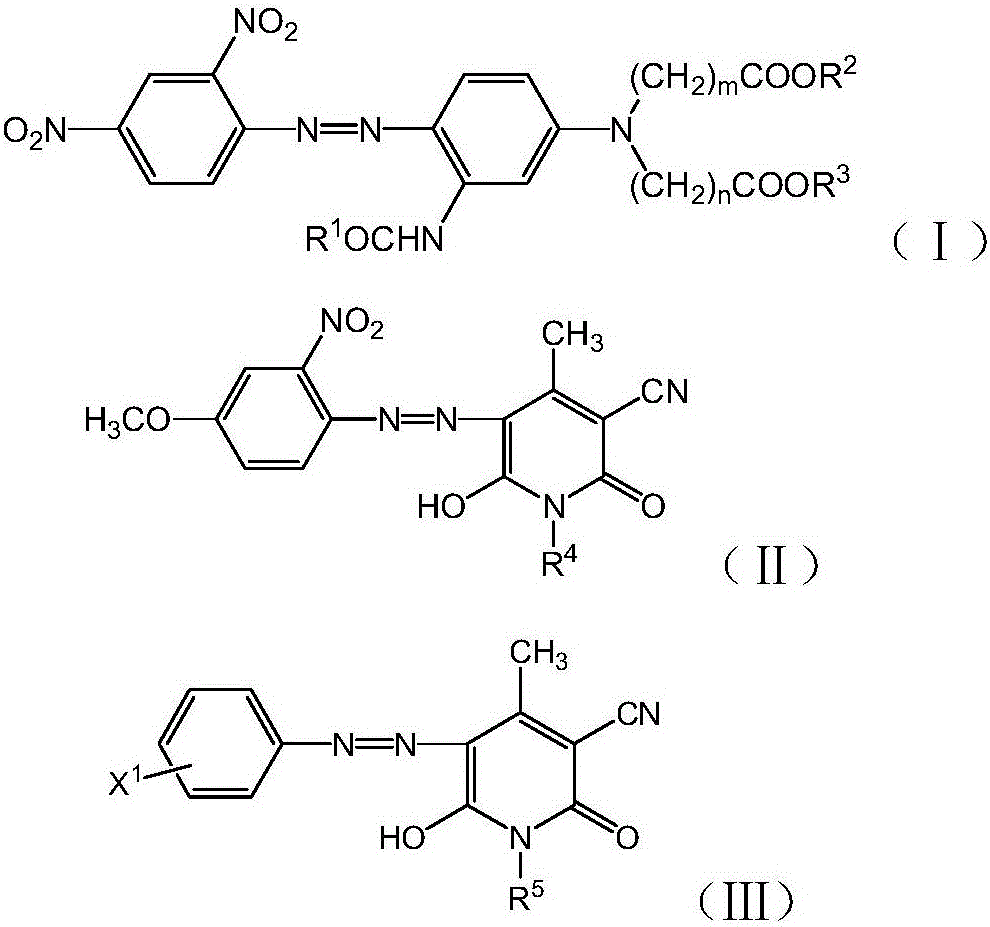

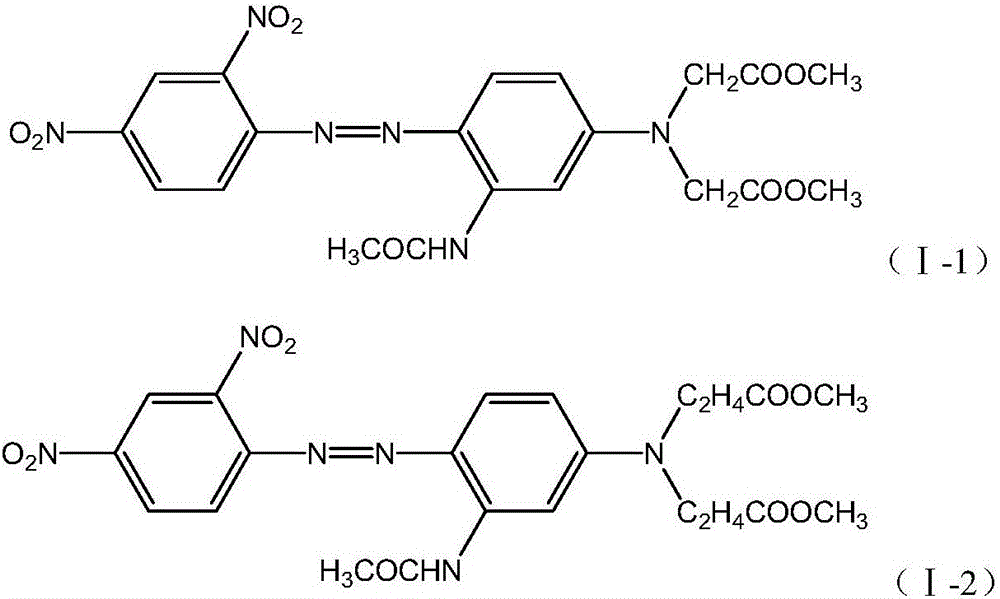

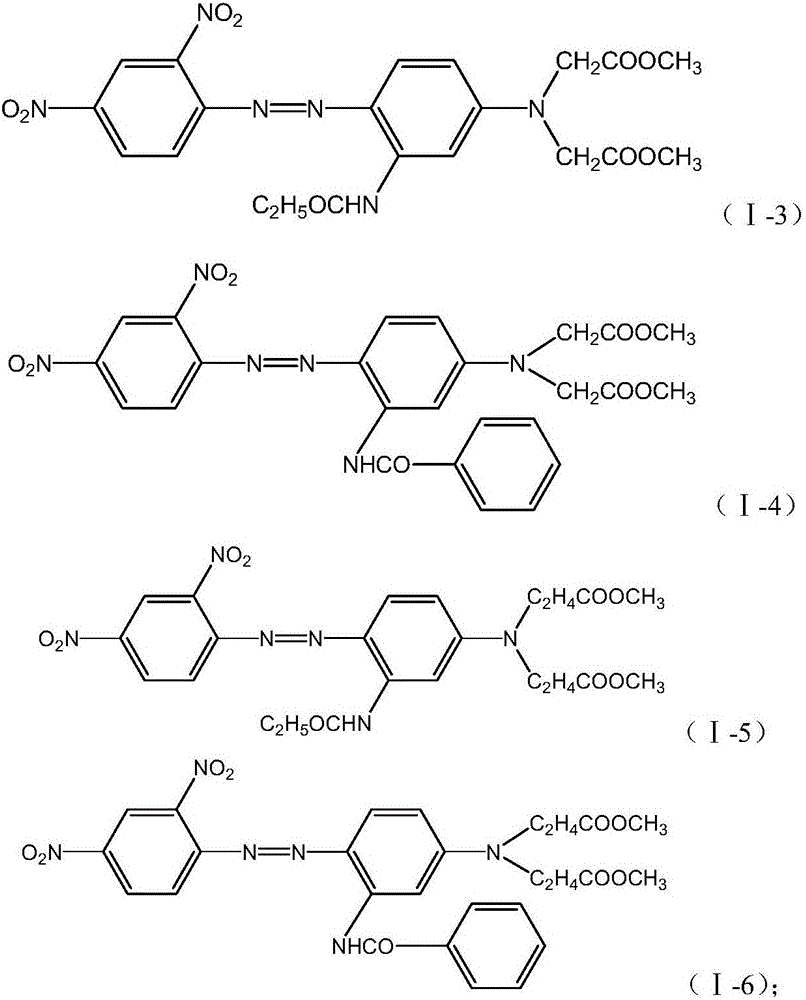

The invention discloses a dispersed orange dye composition, which is composed of 1-99% one or several dye A with formula (I) and 1-99% one or several dye B with formula (II), wherein the composition can be microparticled into liquid pattern, cream pattern or powder and particle pattern, which makes polyester fiber material display yellow to orange to red.

Owner:ZHEJIANG LONGSHENG GROUP

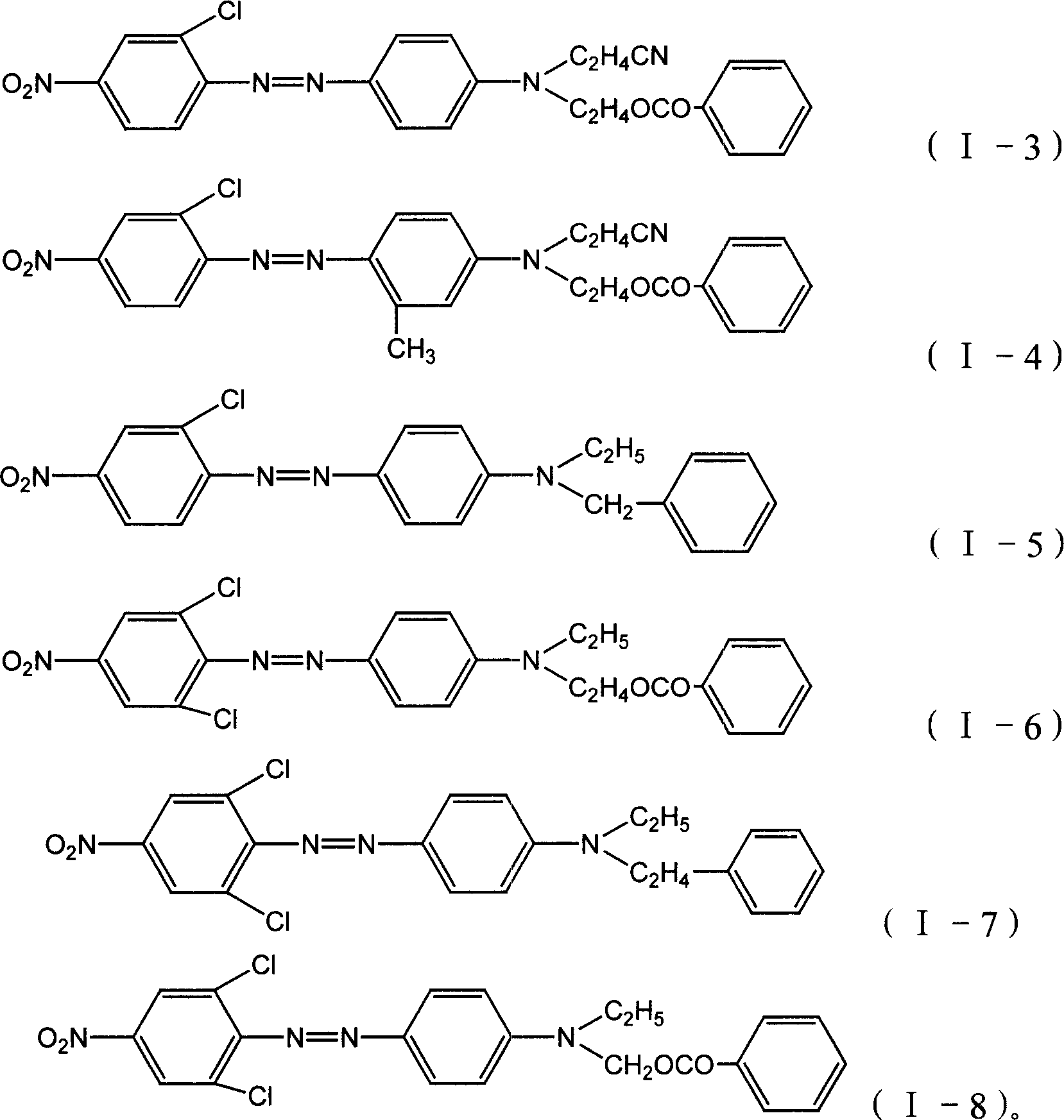

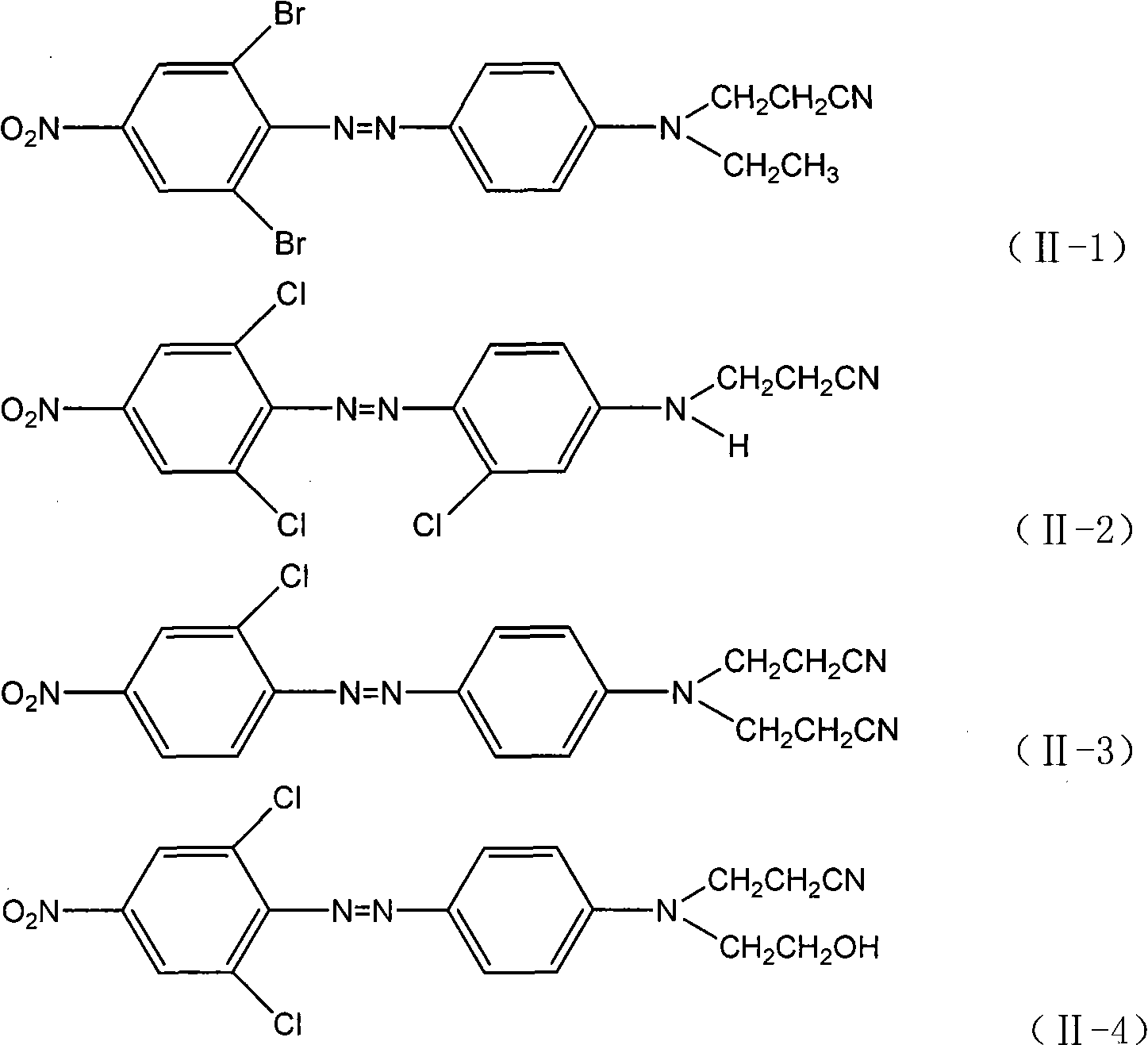

Environment-friendly type and alkali-resistant disperse orange dyes mixture

ActiveCN101225243ASolve the problem of detection exceeding the standardOvercome the disadvantages of alkali resistanceOrganic dyesDyeing processHydrogenPhenyl group

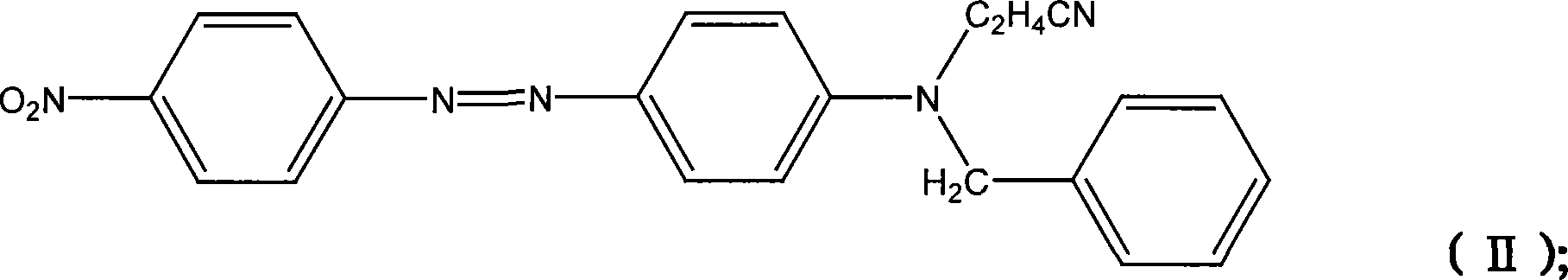

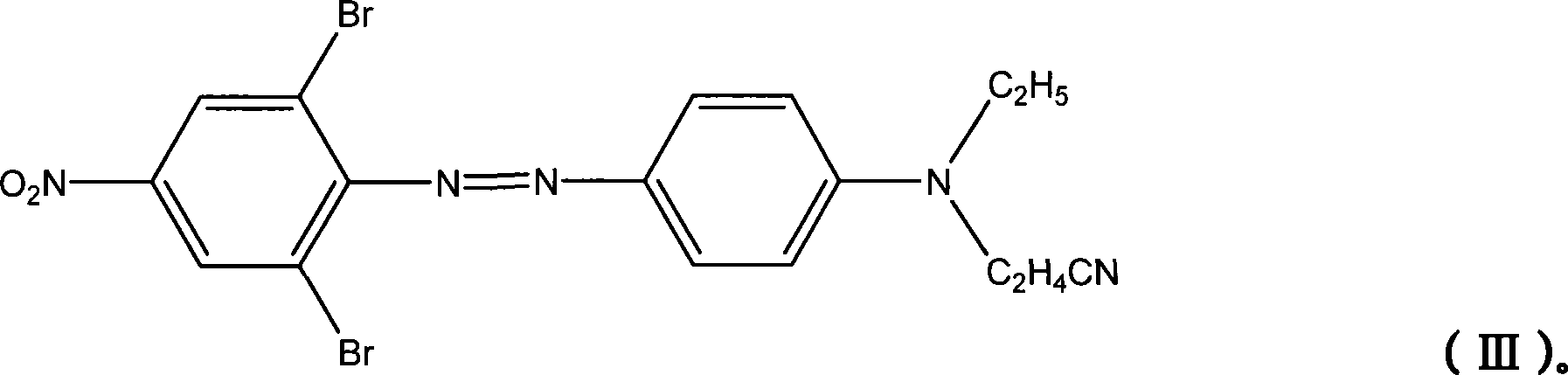

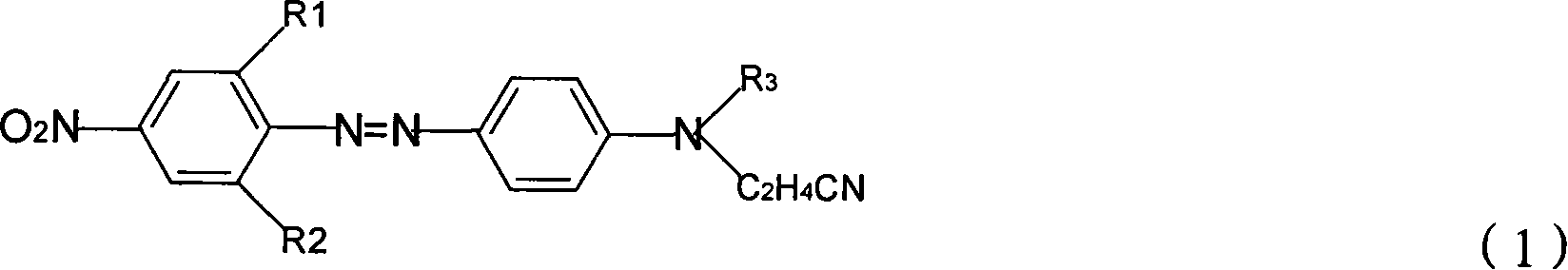

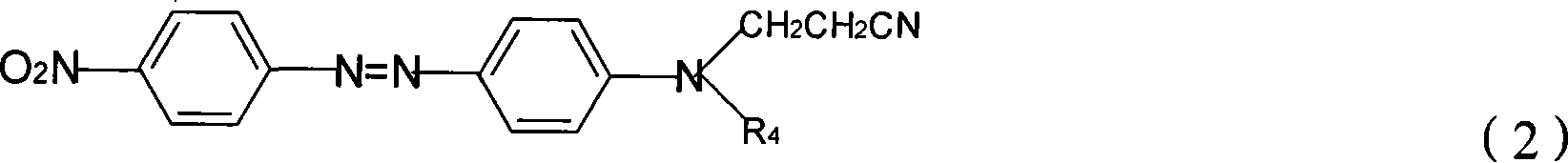

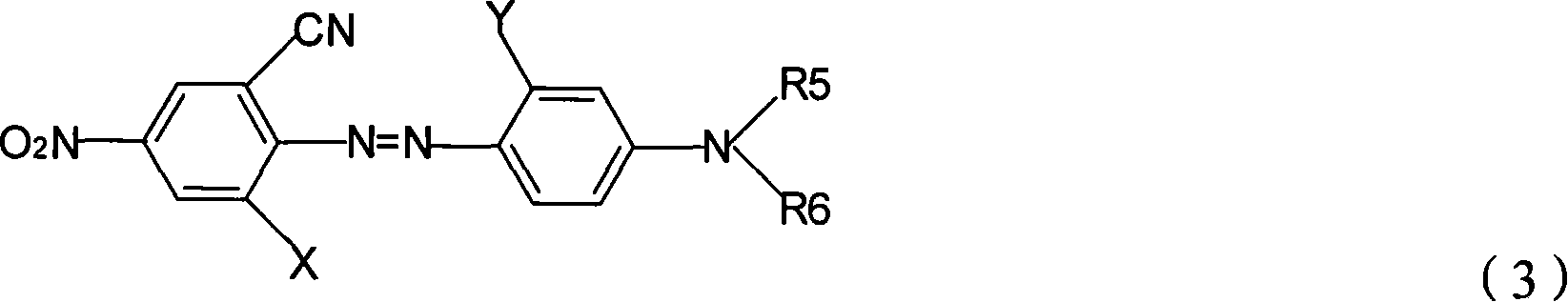

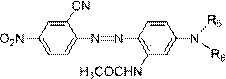

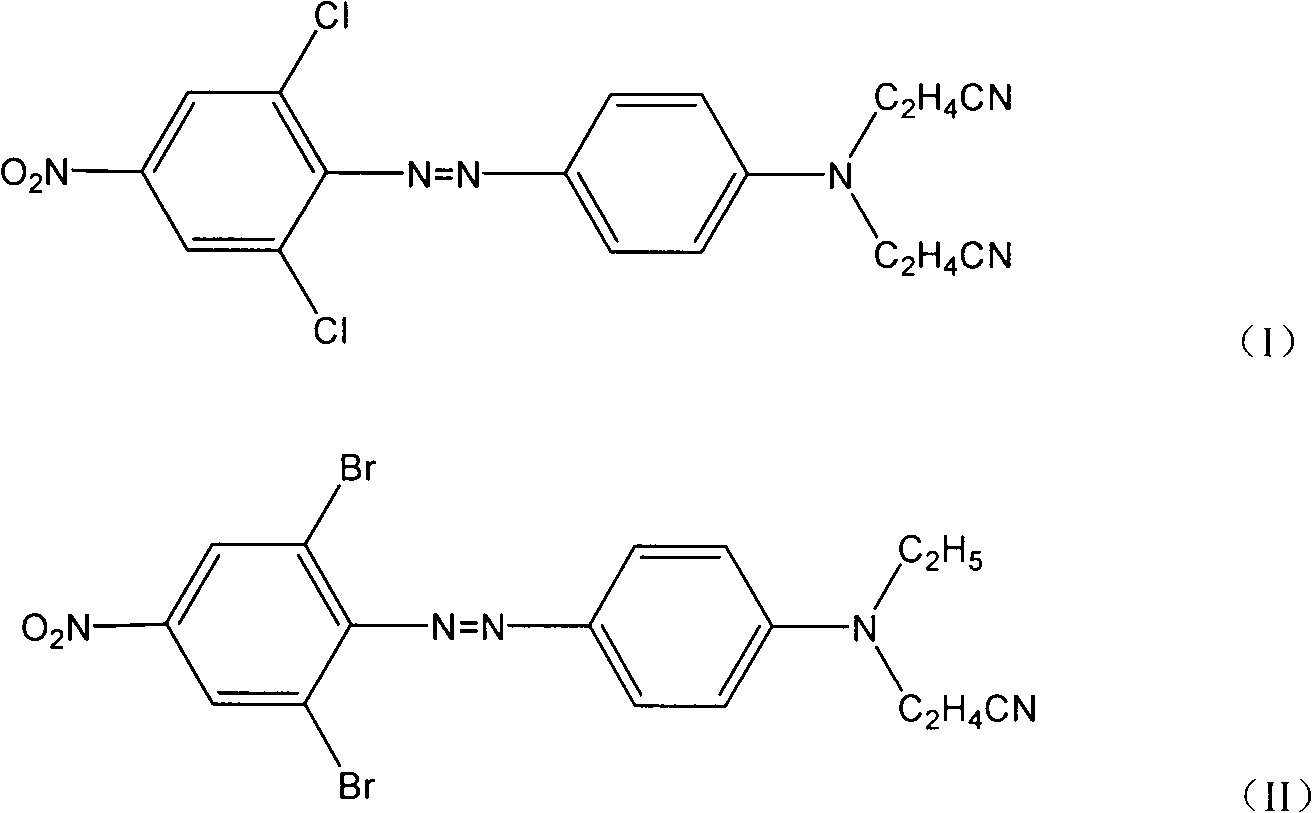

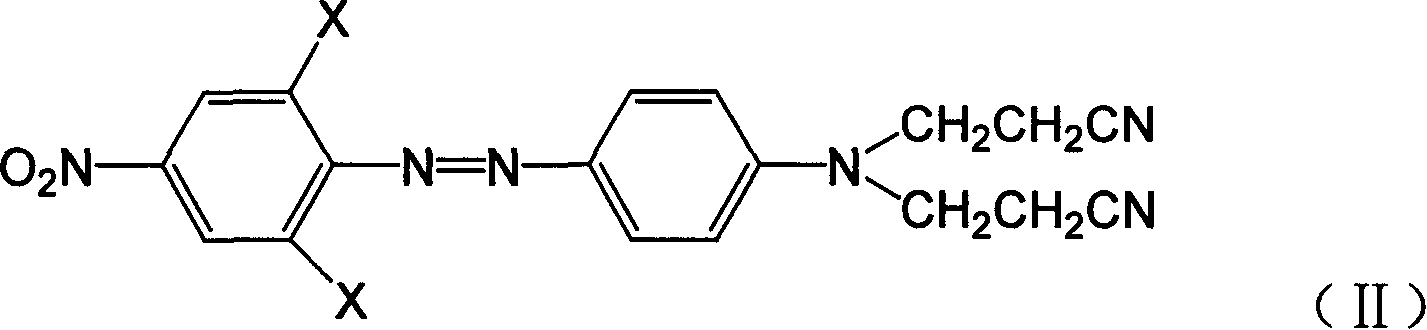

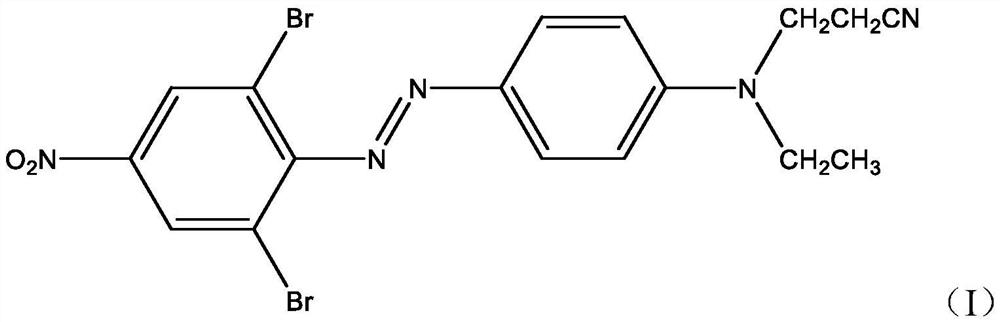

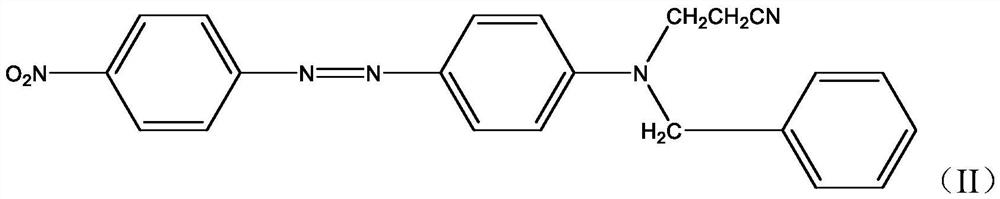

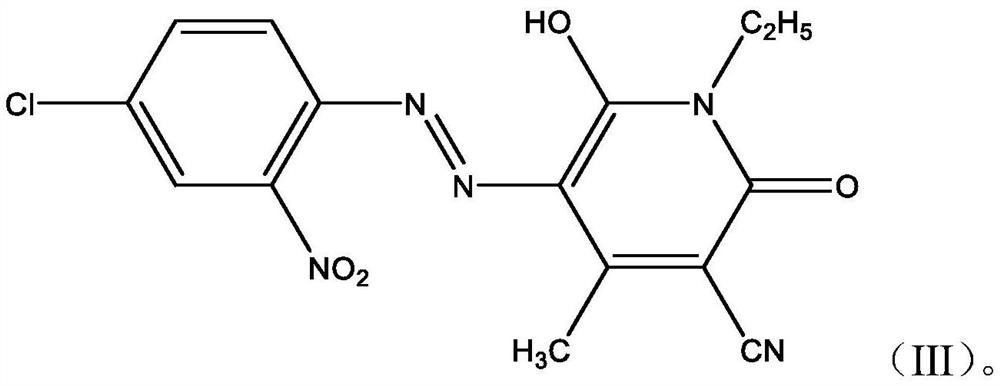

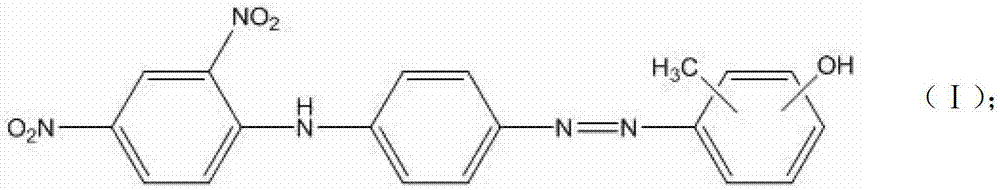

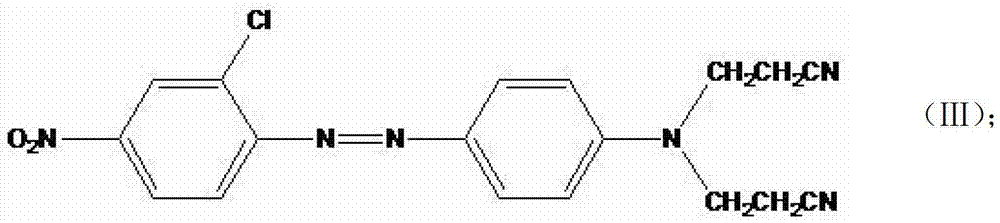

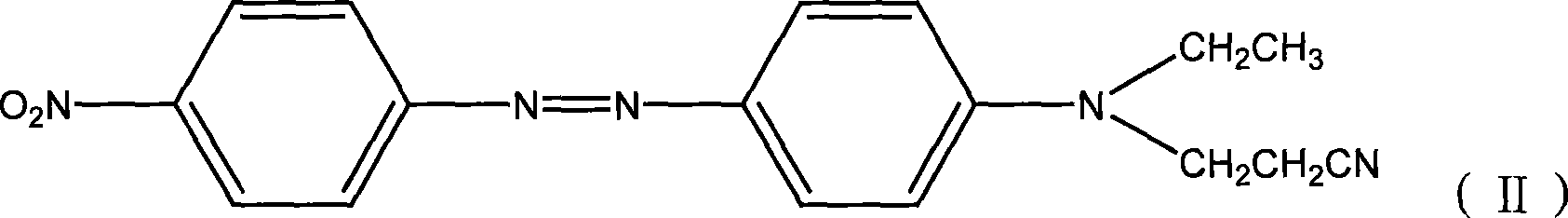

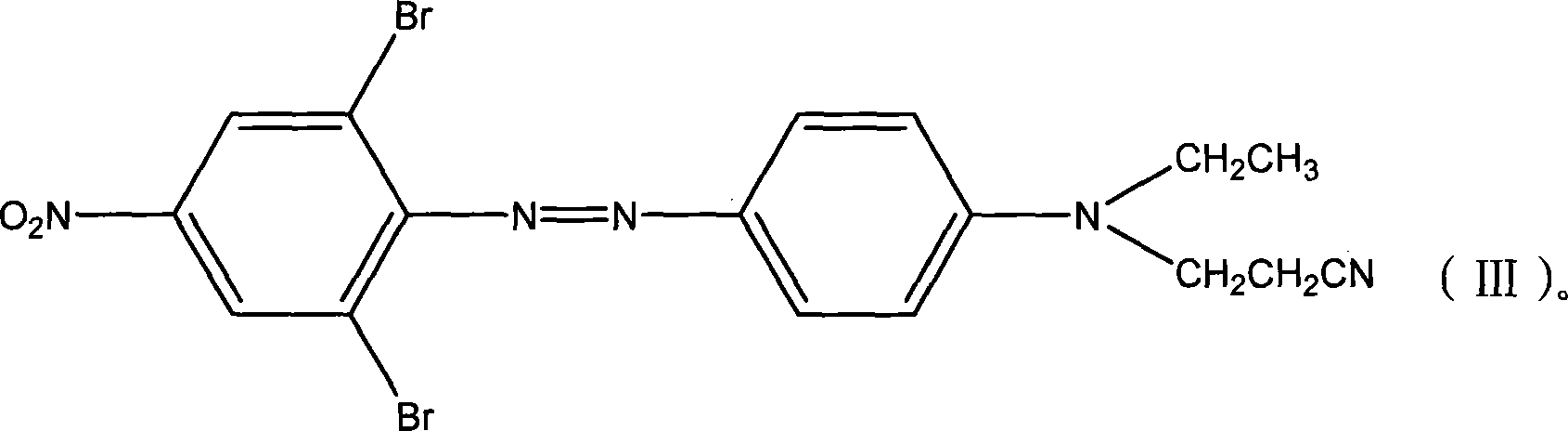

The invention relates to a mixture of environment-friendly and alkali resistant type dispersed orange dye, comprising dye and addition agent, which is characterized in that the dye part comprises the following three dyes: dye agreed with the general chemical formula (I), the weight of which is 2.5 to 95 percent of the gross weight of the dye part, wherein, the R in the formula is hydrogen group, alkyl or phenyl; dye agreed with the general chemical formula (II), the weight of which is 2.5 to 95 percent of the gross weight of the dye part; and dye agreed with the general chemical formula (III), the weight of which is 2.5 to 95 percent of the gross weight of the dye part. The mixture of environment-friendly and alkali resistant type dispersed orange dye is similar to the current C.I. dispersed orange 30 dye in color light strength and dyeing property but overcomes the drawbacks of the current dye of poor alkali resistance and poor environment protection, so can replace the current C.I. dispersed orange 30 dye.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

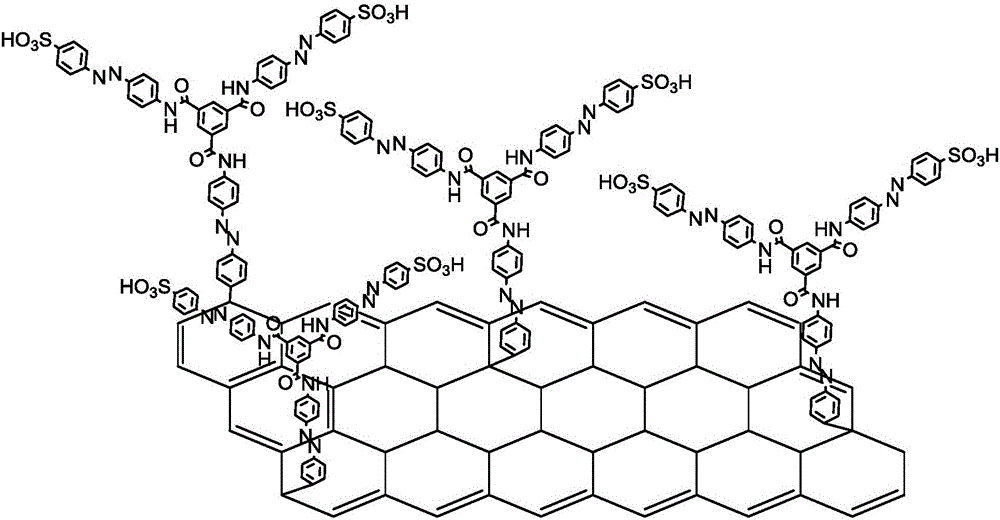

Tri-branched azobenzene/graphene composite energy storage material and preparation method thereof

The invention relates to a tri-branched azobenzene / graphene composite energy storage material and a preparation method thereof. According to the invention, tri-branched azobenzene is grafted on single-layer graphene. The method comprises a nucleophilic substitution reaction and a diazonium salt method. First, disperse orange and p-aminoazophenyl-4-sulfonic acid react with trimethyl-1,3,5-benzenetricarboxylic acid, such that tri-branched azobenzene is synthesized; and the tri-branched azobenzene is compounded with pretreated reduced graphene oxide. Compared to azobenzene small molecules, the obtained tri-branched azobenzene / graphene composite material is greatly improved in energy value and half-life period, and facilitates solar energy heat storage. Through DSC detection, the energy density of the prepared tri-branched azobenzene / graphene composite material is 150-250Wh / kg. The material has an important application prospect in solar energy storage in the future.

Owner:TIANJIN UNIV

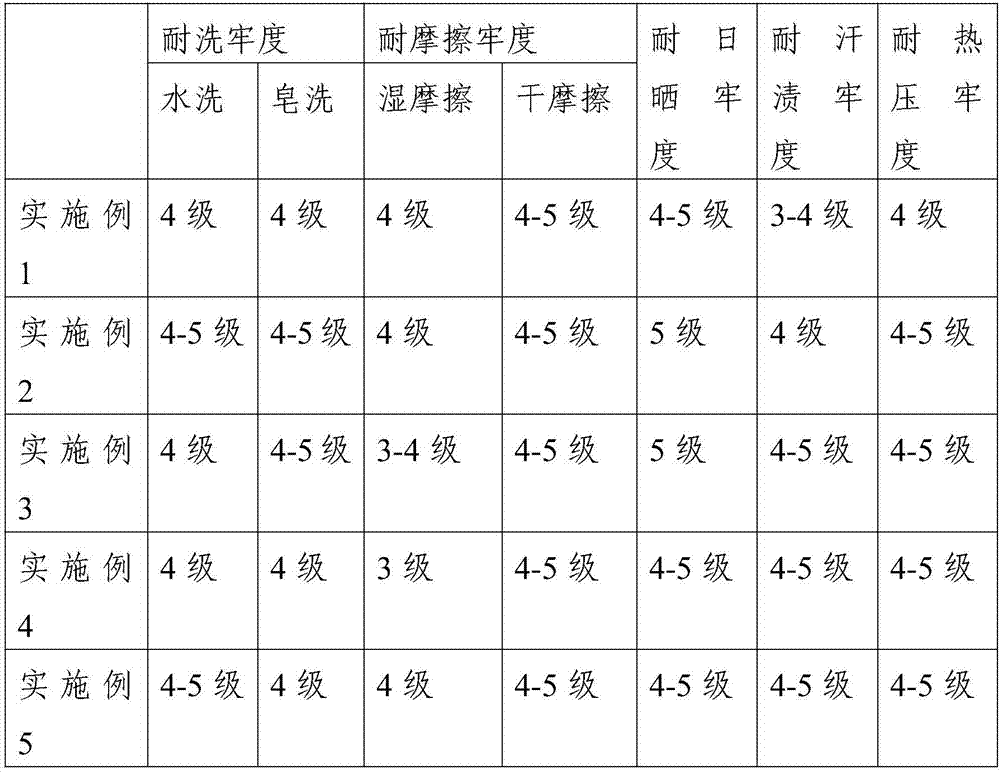

Disperse orange dye composition

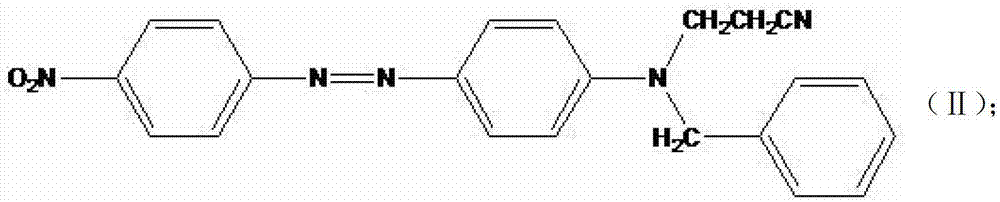

The invention provides a dispersing orange dye composition, which consists essentially of one or more components A with the structure shown as formula (I) and one or components B with the structure shown as formula (II); the weight portion of components A is 1 to 99 percent, and the weight portion of components B is 1 to 99 percent. The dispersing orange dye composition of the invention is suitable for dyeing wool and wool blends, silk, polyamide, protein fiber and protein fiber blends, and polyamide fiber and polyamide fiber blends; the dispersing orange dye composition of the invention has the advantages of good washing resistance, abrasion resistance, perspiration resistance and sunlight fastness, and can provide orange color with uniformity and good fastness performance for textile.

Owner:SHANGYU JINGUAN CHEM IND +2

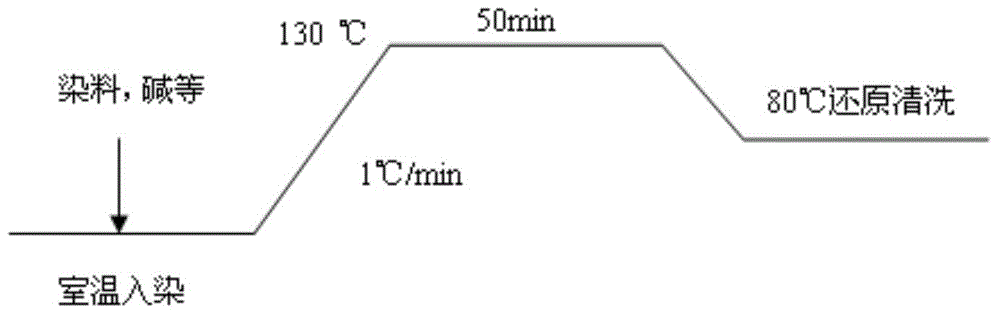

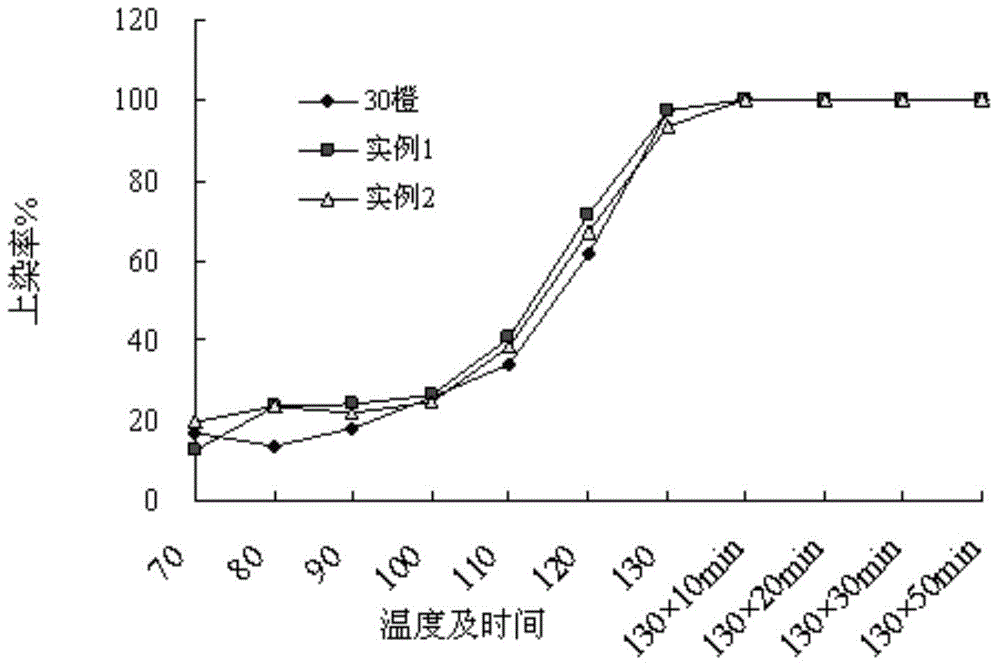

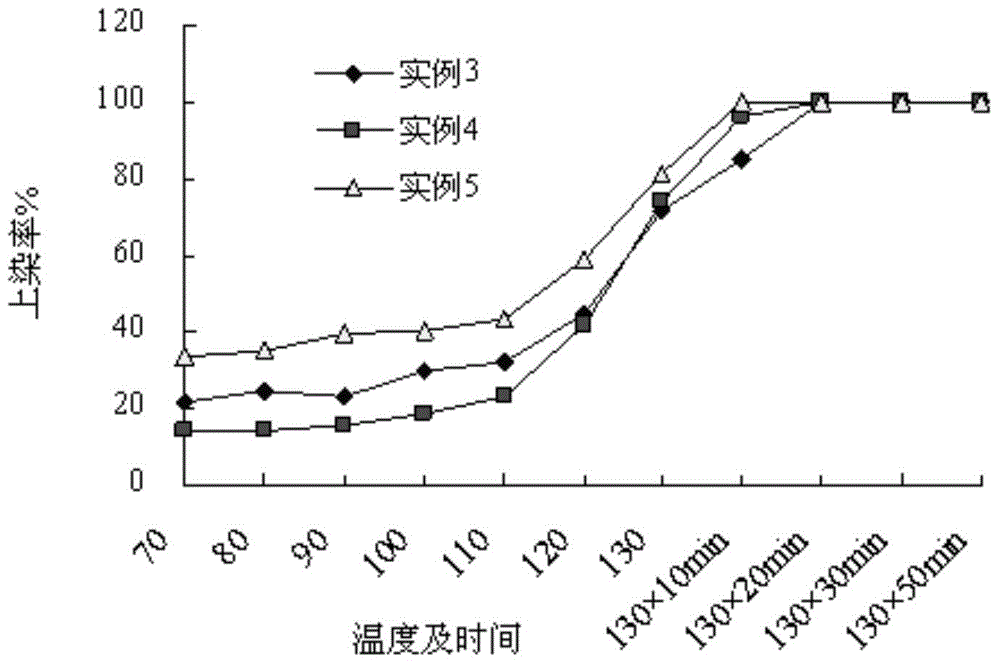

Medium-temperature-type environmental protection dispersion orange dyes

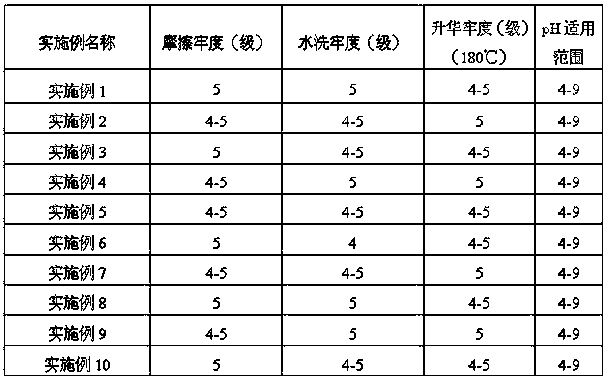

The invention discloses a moderate-temperature environment-friendly disperse orange dye, which comprises a dye monomer A as shown by the formula (1) and accounting for 10 to 50 percent; a dye monomer B as shown by the formula (2) and accounting for 8 to 45 percent; and an accessory ingredient accounting for the rest. The disperse orange dye can further comprise a dye monomer C as shown by formula (3) and accounting for 0.01 to 2 percent. The environment-friendly dye disclosed by the invention can substitute for the mixing color of No.30 C.I.DISP.ORANGE in black and blue of 300 percent, and can be applied in wide PH values when used for dyeing with high build-up, high color yield, excellent level-dyeing property and overall firmness.

Owner:ZHEJIANG RUNTU

Environment-friendly orange disperse dye mixture

ActiveCN103450708AInsufficient improvementGood compatibilityOrganic dyesDyeing processDisperse dyeEnvironmental engineering

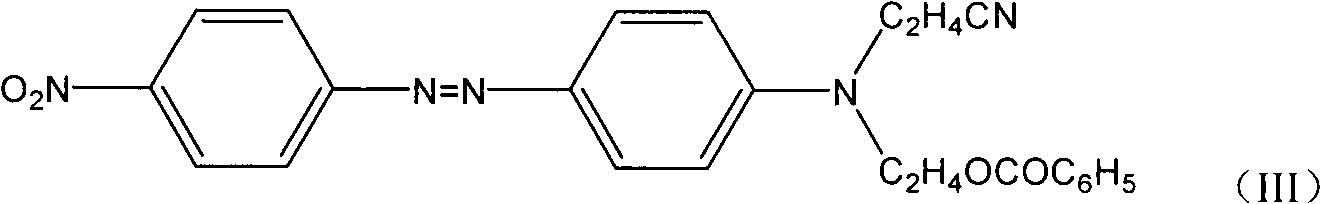

The invention relates to an environment-friendly orange disperse dye mixture which comprises the following components in percentage by weight: 1%-50% of dye monomers A shown in a formula (I), 1%-70% of dye monomers B shown in a formula (II), 1%-30% of dye monomers C shown in a formula (III) and the balance being additives. According to the environment-friendly orange disperse dye mixture, the defects of C.I. disperse oranges 29 and 30 are effectively overcome, the production cost can be reduced, sewage caused by dyeing is reduced, the dye mixture is ecological and green dye meeting the European Union Reach regulatory requirements and the Oeko-Tex Standard 100 environmental certification, the disperse oranges 29 and 30 can be successfully replaced by the dye mixture, the dye mixture is good in compatibility, wide in pH value range during a dyeing process, high in dye yield, good in leveling property and more outstanding in sublimation fastness and washing fastness especially, and the dye mixture is environment-friendly orange disperse dye superior in various performance.

Owner:JIANGSU YABANG DYE

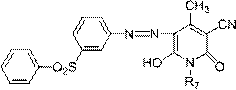

High washing fastness dispersed yellow and brown dye composition

The invention relates to a high washing fastness dispersed yellow and brown dye composition. The high washing fastness dispersed yellow and brown dye composition aims at overcoming the defects that a dye composition is poor in color fastness in the prior art. The high washing fastness dispersed yellow and brown dye composition is composed of, by weight, 20 % to 40 % of dispersed orange, 25 % to 50 % of dispersed golden yellow, 10 % to 20 % of dispersed red dye and 10 % to 20 % of dispersed yellow in a mixing mode, and the balances auxiliaries. The dispersed orange is the combination of one or more compounds shown in a formula (1); the dispersed golden yellow is the combination of one or more compounds shown in a formula (2); the dispersed red dye is the combination of one or more compounds shown in a formula (3); the dispersed yellow is the combination of one or more compounds shown in a formula (4); R7 in the formula (4) is -CH3 or -CH2CH3. When the high washing fastness dispersed yellow and brown dye composition is used for dyeing of spandex fabrics, the dyeing effect is good, the color fastness is good, and the quality of the spandex fabrics can be greatly improved.

Owner:HANGZHOU FLARIANT SPECIALTY

Disperse orange dye mixture

ActiveCN102516815ALow priceConforms to ecological product indicatorsOrganic dyesDyeing processOrganic chemistryDisperse orange

A disperse orange dye mixture comprises a dye part and an auxiliary part which are mixed with each other, and is characterized in that the dye part is formed by mixing at least four dyes adopting the structures as follows: one of the three dyes is a dye adopting the chemical structural formula I, and is 2 to 80 percent of the dye part by weight; the second of the three dyes is a dye adopting the chemical structural formula II, and is 2 to 80 percent of the dye part by weight; and the last dye is a dye adopting the chemical structural formula III, and is 2 to 80 percent of the dye part by weight.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

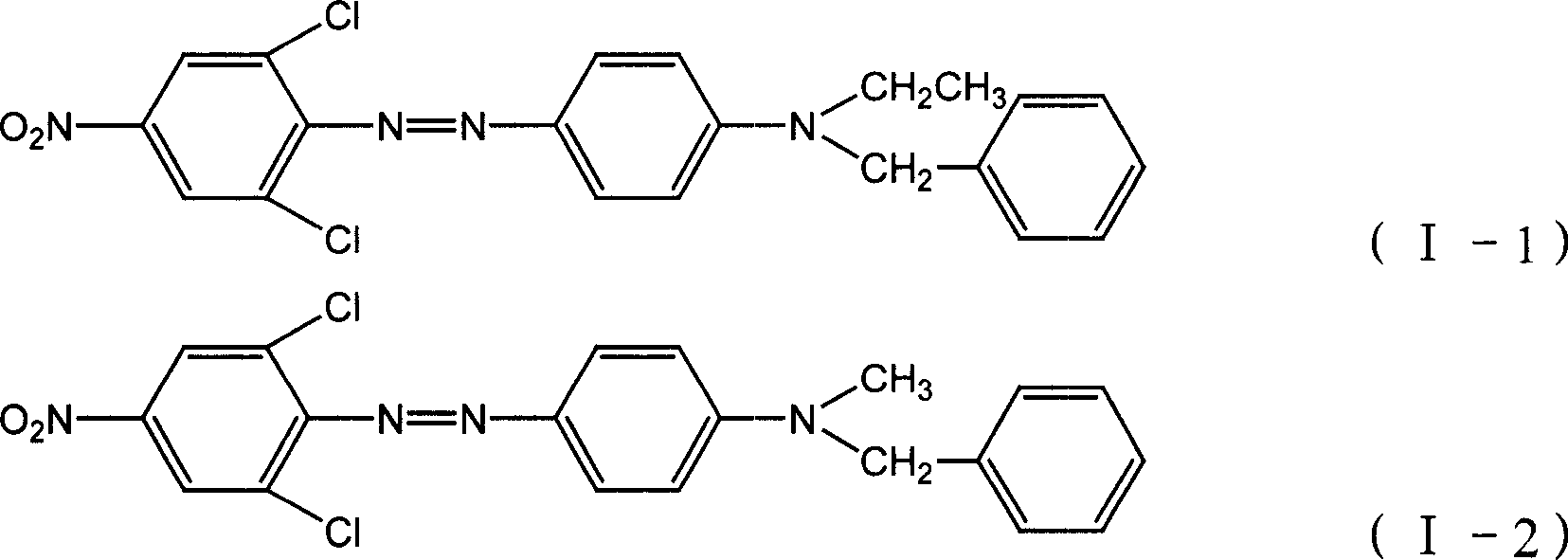

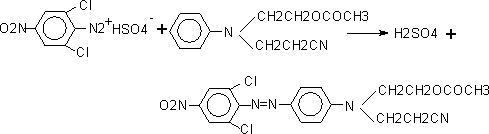

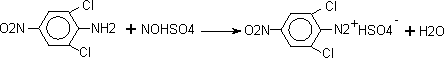

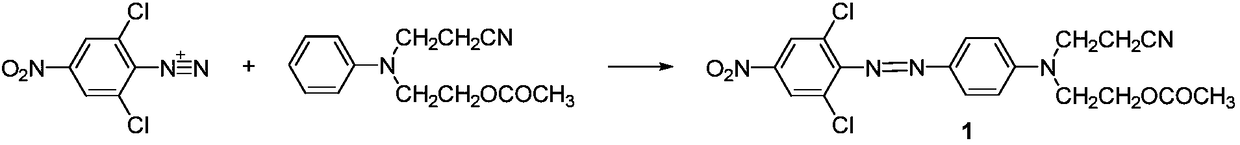

Preparation method for 2-[N-(2-cyanoethyl)-4-[(2,6-dichloro-4-nitrobenzophenone)azo]anilino]ethyl acetate

The invention relates to a preparation method for disperse orange 30. The preparation method comprises the following steps of: (1) undergoing a diazotization reaction: undergoing a diazotization reaction on 2,6-dichloroparanitroaniline and nitrosyl sulfuric acid in a sulfuric acid medium to obtain a diazonium product solution; and (2) undergoing a coupling reaction: undergoing a coupling reactionon the diazonium product solution obtained in the step (1) and N-cyanoethyl-N-acetoxyethyl to generate disperse orange 30. Particularly, the chromatograph content of 2,6-dichloro paranitroaniline serving as a raw material used in the step (1) is over 99.8 percent by weight, the content of polychlorinated biphenyl amine is lower than 5 ppm, and the diazotization reaction is undergone at the temperature of 0-5 DEG C in the step (1). A product prepared with the method does not contain any international forbidden byproduct, i.e., polychlorinated biphenyl amine, and a basis is laid for the development of the international market; and moreover, the product prepared with method has high yield, high purity and gorgeous chromatic light.

Owner:苏州市罗森助剂有限公司

Preparation method for producing disperse orange by salt-free diazotization method and high-temperature coupling method

The invention relates to a preparation method for producing disperse orange by a salt-free diazotization method and a high-temperature coupling method, which includes the steps of diazotization, coupling and the like. In the step of diazotization, nitrosylsulfuric acid is utilized, and the salt-free diazotization method and a high-temperature diazotization method are adopted; in the step of coupling, mother liquor with certain acidity is adopted as diazo thinner, the solid content is increased by esterifying liquid, acetic acid is recovered, a stage-by-stage dripping method is adopted, washing water is utilized for material precipitation, and after filter pressing, washing and drying, the finished disperse orange is obtained. The process of the method is more reasonable, the mother liquor can be recycled, the product yield is effectively increased, the production cost is reduced, and the discharge of waste water (COD) is reduced.

Owner:JIANGSU YUANZHENG CHEM

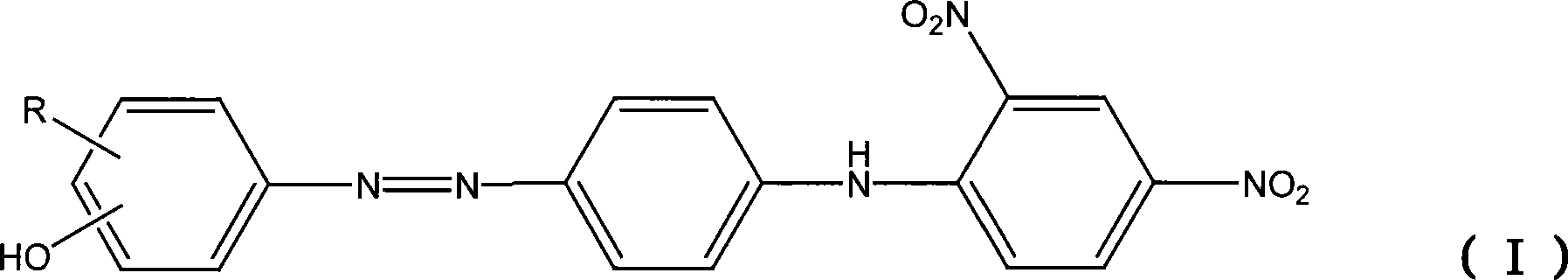

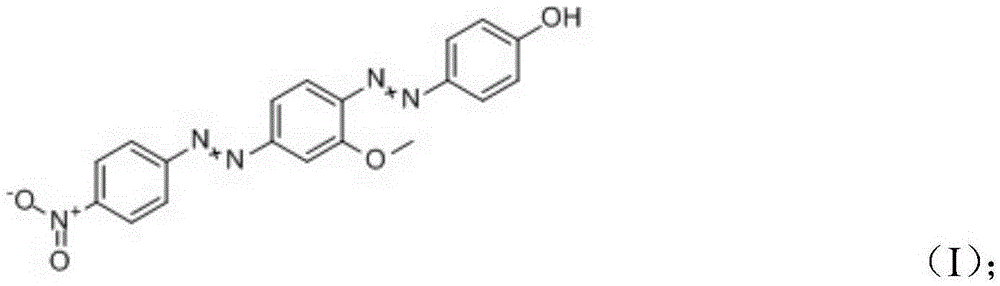

Monoazo dye compound and orange to red dye composition

The invention provides a monoazo dye compound with a structure shown as a formula (I) and application thereof, and an orange to red dye composition containing the monoazo dye compound. The disperse orange to red monoazo dye and the dye composition thereof are commercialized to be supplied for dyeing in a liquid state and an emulsifiable paste state after being micro-granulated, or in a powder state and a particle state after being dried through a spray drying method and the like; can be applied to dyeing of dacron, acetate, acrylic fibers, polyester, mixture yarn and other hydrophobic fiber materials so as to obtain dyeing products with bright color, and excellent washing fastness, light resistant, color fastness to sublimation; have low cost and excellent application effect; and are rare products with huge application prospect. The formula (I) is shown in the description.

Owner:浙江龙盛染料化工有限公司

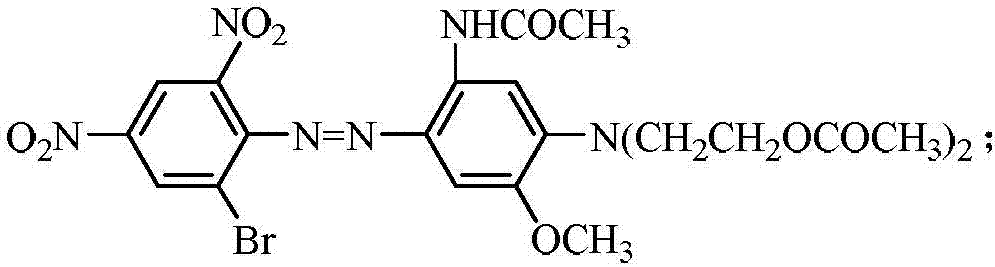

Environment-friendly alkaline-resistant high-washing-dispersity orange dye composition and application thereof

ActiveCN104151865AStructural environmental protectionGood alkali resistanceOrganic dyesDyeing processDispersityStructural formula

The invention relates to an environment-friendly alkaline-resistant high-washing-dispersity orange dye composition and an application thereof. The dye composition comprises dyes and auxiliaries, wherein the dyes include a dye A and a dye B; the structural formula of the dye A is as shown in the specification, while the structural formula of the dye B is as shown in the specification; the environment-friendly alkaline-resistant high-washing-dispersity orange dye composition is applied to textile dyeing. The environment-friendly alkaline-resistant high-washing-dispersity orange dye composition is good in all build-up, fixation rate, levelling property, compatibility and alkali resistance, and especially quite excellent in washing fastness. Specially, the dye composition is similar to the existing C.I. disperse orange 30 dye in chromatic light intensity and dyeing property, overcomes the defects of no resistance to alkali and non-environmental friendliness of the existing dye, and thus can be used for substituting for the existing C.I. disperse orange 30 dye.

Owner:ZHEJIANG WANFENG CHEM

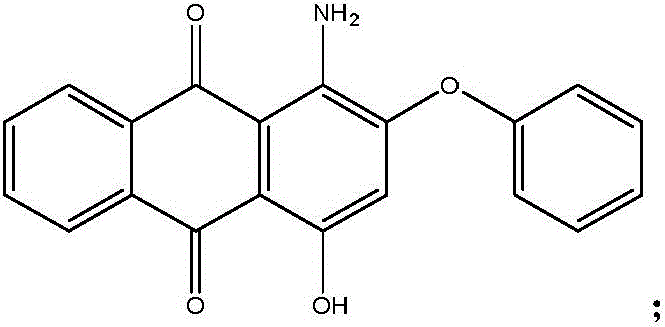

Printing black dye and blending technology thereof

The invention discloses a printing black dye. The printing black dye comprises, by weight, 40 to 60 parts of a C. I. disperse blue 79 dye, 30 to 50 parts of a C. I. disperse orange 44 dye, 5 to 20 parts of a C. I. disperse purple 93 dye, 10 to 27 parts of sodium lignin sulfonate, 5.25 to 28 parts of lignin and 60 to 75 parts of water. The C. I. disperse blue 79 dye has a structural formula shown in the description. The C. I. disperse orange 44 dye has a structural formula shown in the description. The C. I. disperse purple 93 dye has a structural formula shown in the description. Lignin contains an active group, has a long chain structure on the side chain and has a structure similar to that of sodium lignin sulfonate. Based on the principle of dissolution in the similar material structures, sodium lignin sulfonate connection is formed and full contact and binding of sodium lignin sulfonate and lignin to the mixed dye is realized through electron donating and electron withdrawing groups. Through a large amount of hydroxyl groups, the mixed dye bonded to the sodium lignin sulfonate and lignin can be firmly bonded to fabric fibers so that the dye is firmly fixes to the fabric fibers and the fabric has excellent color fastness.

Owner:绍兴柯桥滨海飞翔化工有限公司

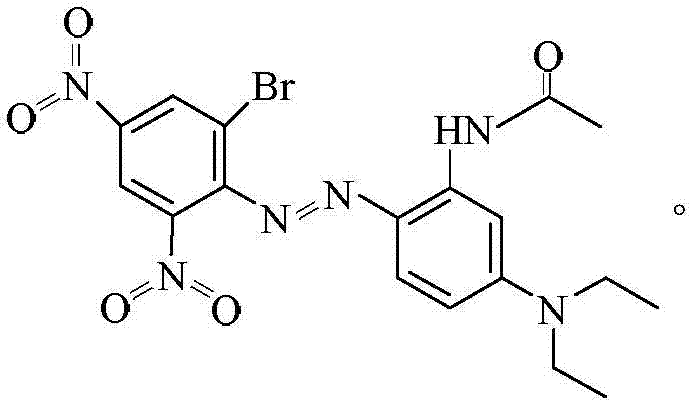

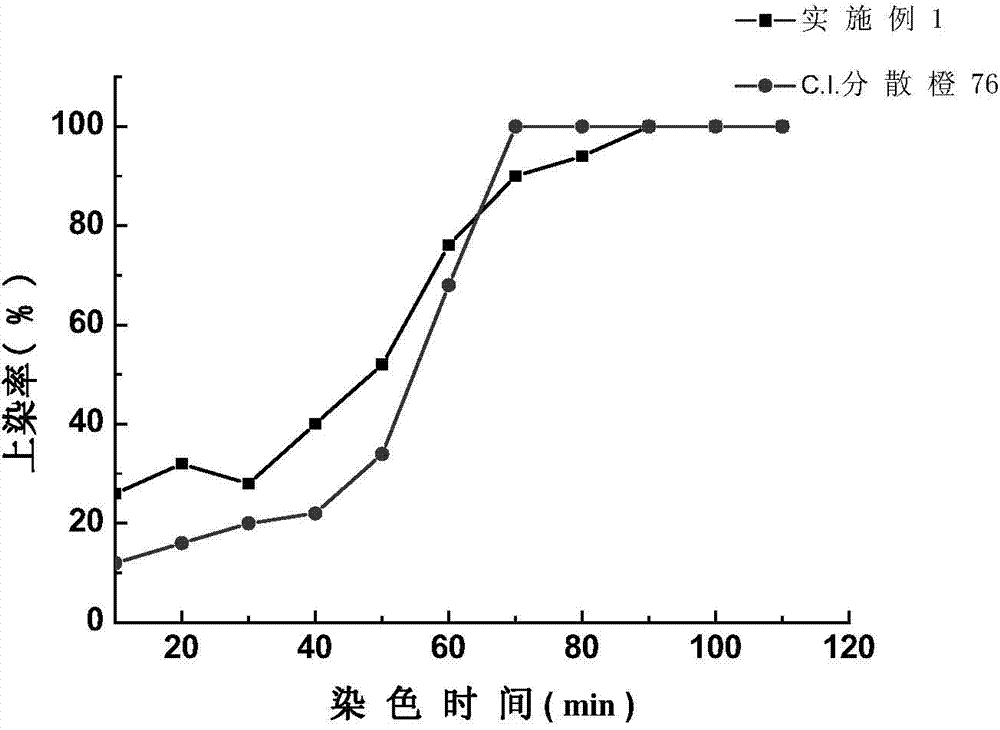

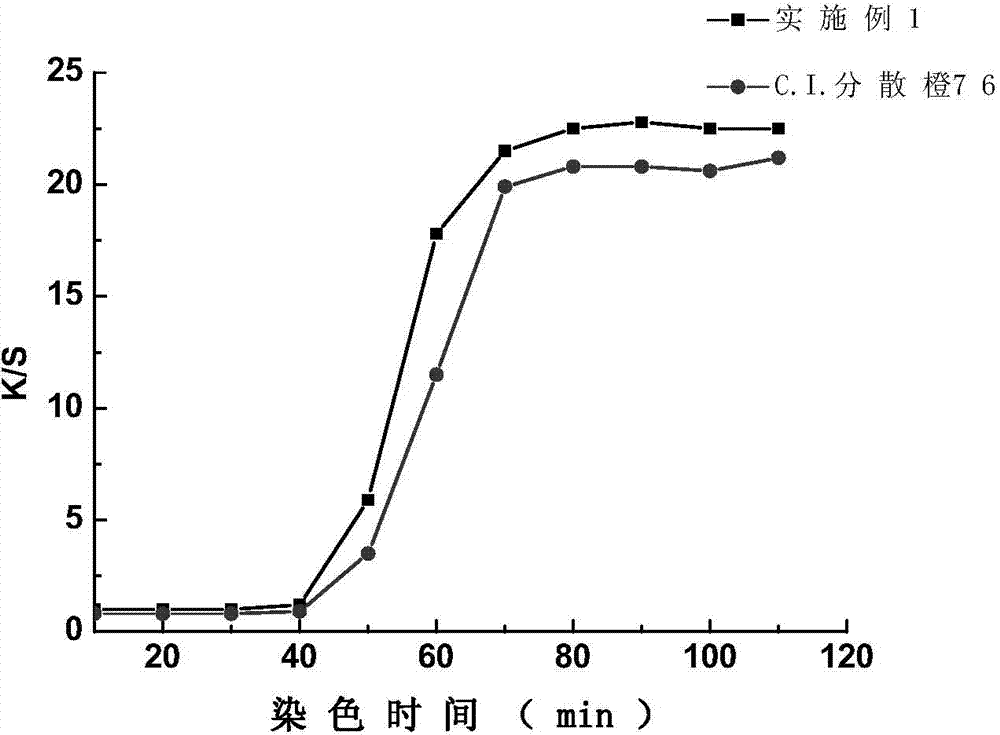

Environment-friendly type high-efficiency washing disperse orange dye composition and application thereof

ActiveCN104119695AStructural environmental protectionGood alkali resistanceOrganic dyesDyeing processColor intensityStructural formula

The invention relates to an environment-friendly type high-efficiency washing disperse orange dye composition and an application thereof. The dye composition comprises dyes and auxiliaries, wherein the dyes consist of a dye A, a dye B and a dye C; a structural formula of the dye A is as shown in the specification; the structural formula of the dye B is as shown in the specification; the structural formula of the dye C is as shown in the specification. The environment-friendly type high-efficiency washing disperse orange dye composition disclosed by the invention is applied to fabric dyeing. The dye disclosed by the invention is good in lifting power, fixation rate, leveling property, compatibility and alkali resistance, and especially extremely excellent in washing fastness. Especially, compared with the existing C.I. disperse orange 76 dye, the dye composition disclosed by the invention has similar color intensity and dyeing performance, overcomes the defect that the existing dye is not environment-friendly, and can be used for substituting the existing C.I. disperse orange 76 dye.

Owner:ZHEJIANG WANFENG CHEM

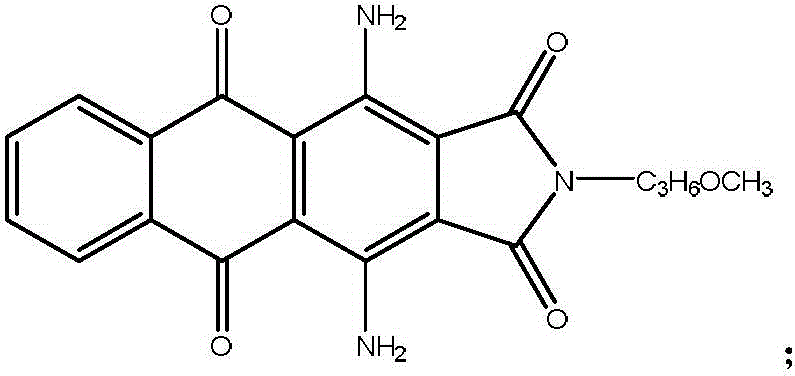

Orange mix

The invention discloses orange mix and production method thereof. The orange mix is mainly produced by mixing disperse yellow 163 shown in a structural formula (I), disperse orange 61 shown in a structural formula (II) and disperse orange 73 shown in a structural formula (III). When the organ dye is used to print and dye superfine fiber materials, dyed fabrics with good properties such as bright color, vivid print profile, fine pattern washing fastness, sun-drying resistance, sweat resistance and the like can be obtained by adjusting proportions of the different components.

Owner:JIANGSU ZHIJIANG CHEM

Superfine fiber dye with high light fastness and preparation method thereof

The invention belongs to the technical field of dyes and relates to disperse dye composition, in particular to a superfine fiber dye with high light fastness and a preparation method thereof. The superfine fiber dye with the high light fastness comprises components in percentage by mass as follows: 30%-34% of disperse orange 29# serving as a component A, 10%-15% of disperse red 167# serving as a component B, 14%-18% of disperse blue 60# serving as a component C, 38%-42% of disperse blue 56# serving as a component D and the balance of a dispersing agent. Compared with the prior art, the superfine fiber dye with the high light fastness has the advantages as follows: the dye composition is prepared in the specific mixing ratio, each component has higher fastness, so that the performance of the components after combination is not changed, the comprehensive performance is improved, data such as sublimation fastness, washing fastness and the like are correspondingly improved, besides, an idiomatic mode of the industry is adopted for dyeing, dyed fabric with full hue can be obtained, further, the consumed time is shorter, and the production cost is reduced.

Owner:杭州福莱蒽特科技有限公司

Complex disperse orange dye

InactiveCN107974102AImprove dyeing effectImprove color fastness to washingOrganic dyesPerspirationRubbing

The invention provides a complex disperse orange dye. The complex disperse orange dye comprises the following raw materials in percentage by weight: 15-23% of disperse orange 73, 6-10% of disperse orange 5, 12-14% of disperse orange 25, 0-11% of disperse orange 37, 0-6% of disperse orange 44 and the balance of an auxiliary agent. According to the invention, through reasonable compound of the raw materials, the dyeing property of the dye is effectively improved, the color fastness to washing, the color fastness to perspiration, the color fastness to rubbing, and the color fastness to hot pressing are all improved obviously, and the dye uptake is greater than 85%.

Owner:安徽融创化工科技股份有限公司

Composite disperse orange dye

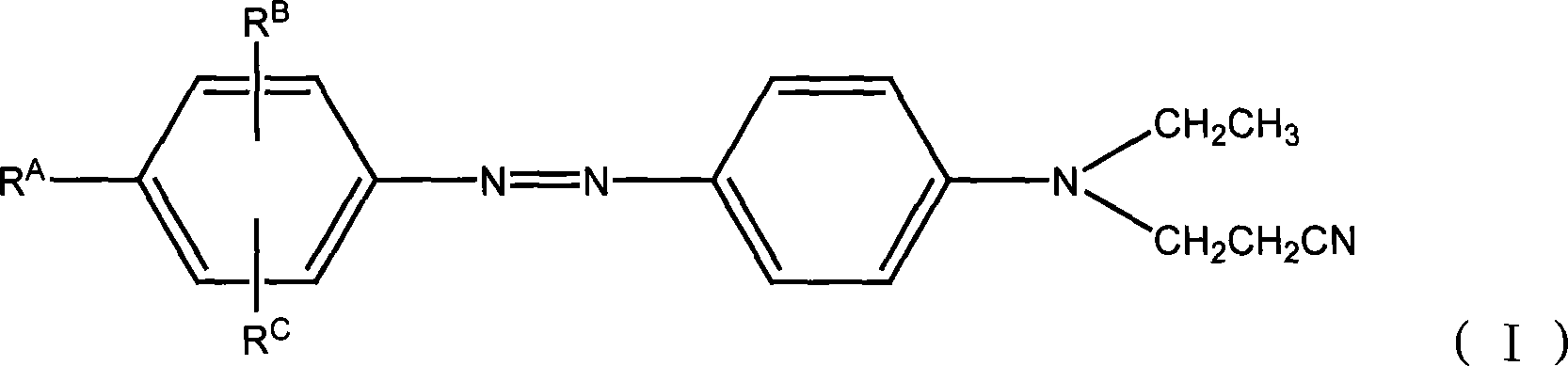

The invention relates to a combiner of compound azo color, mainly be comprised of monomer of color A shown as (I) (5-35%) and monomer of color B shown as (II) (5-35%) and others as assistant . The compound dispersed orange color is especially suitable for coloring polyester materials, yarn and dye printing, with outstanding coloring performance in high temperature and stability such as resistance to sunshine, sublimation and washing.

Owner:ZHEJIANG LONGSHENG GROUP

Dispersed black dye for memorability fiber

InactiveCN101724297ANo reduction in form retentionAchieve color fastnessOrganic dyesDyeing processDisperse dyeColor index

The invention relates to a dispersed black dye for memorability fiber, which is composed of the following ingredients by weight percentage: 5-15 percent of Color Index C.I. disperse orange 73, 5-20 percent of C.I. disperse orange 61, 4-10 percent of C.I. disperse violet 77,5-15 percent of C.I. disperse violet 33, 8-15 percent of C.I. disperse blue 291, 6-15 percent of C.I. disperse blue 165, 50-59 percent of dispersing agent, 1-2 percent of dust laying oil and 0.2-0.3 percent of disperse complexing agent; the dispersed black dye has the beneficial effects that: the memorability fiber can be dyed at low temperature, so as not to reduce the fiber shape holding facility and achieve the dying firmness of conventional high-temperature disperse dye.

Owner:SHANGHAI ANOKY GRP

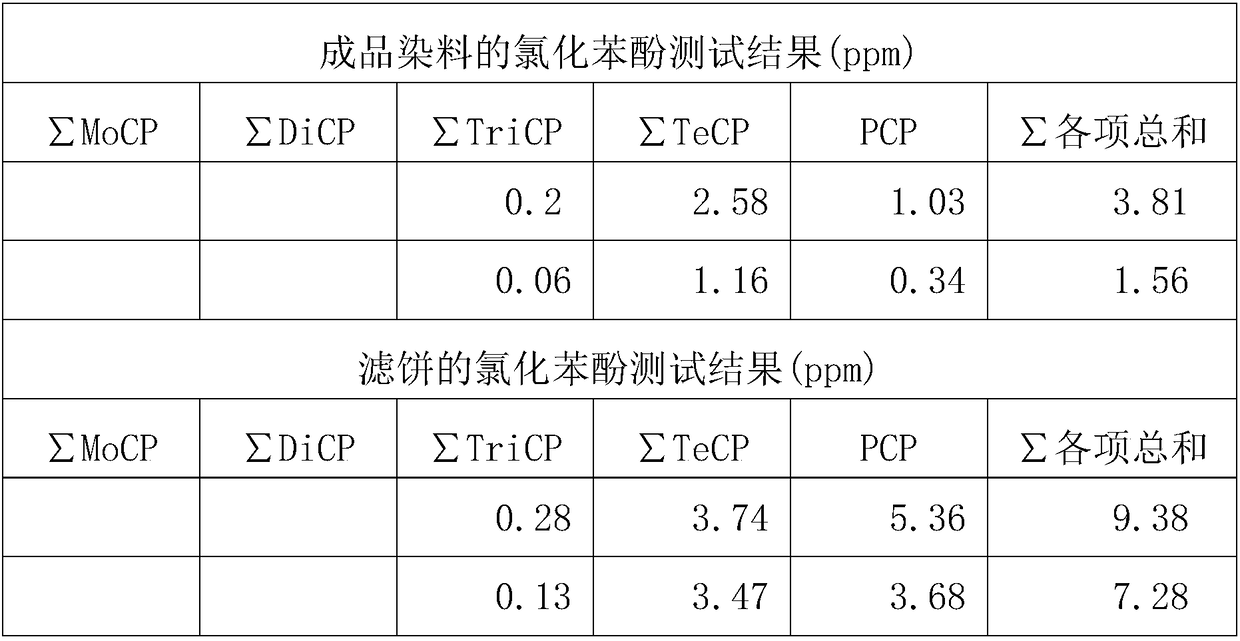

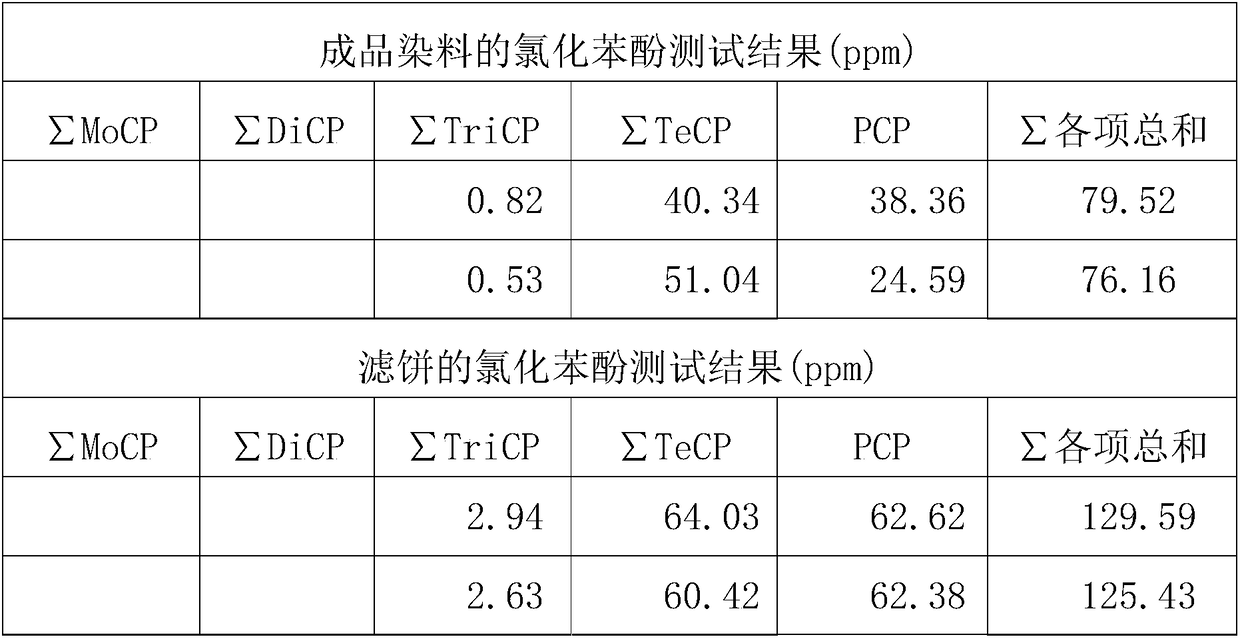

Orange disperse dye composition, orange disperse dye and preparation method and application of orange disperse dye

The invention provides an orange disperse dye composition, an orange disperse dye and a preparation method and application of the orange disperse dye. The orange disperse dye composition comprises: acomponent A as shown in a formula (I), a component B as shown in a formula (II) and a component C as shown in a formula (III). The contents of chlorobenzene, toluene chloride and chlorinated phenols in the orange disperse dye composition disclosed by the invention all meet the requirements of Oeko-Tex Standard 100 and the requirements of European Union Reach regulations, and the orange disperse dye composition is an ecological and environment-friendly disperse dye composition. The orange disperse dye composition can reduce the production cost, reduce the dyeing sewage and effectively make up for the deficiency of disperse orange 30 in the market.

Owner:约克夏(浙江)染化有限公司

Dye for milk silk-nonwoven fabric lace and dyeing technology thereof

ActiveCN108442134AReduce solubilityReduce hydrolysisBiochemical fibre treatmentDyeing processAcetic acidNonwoven fabric

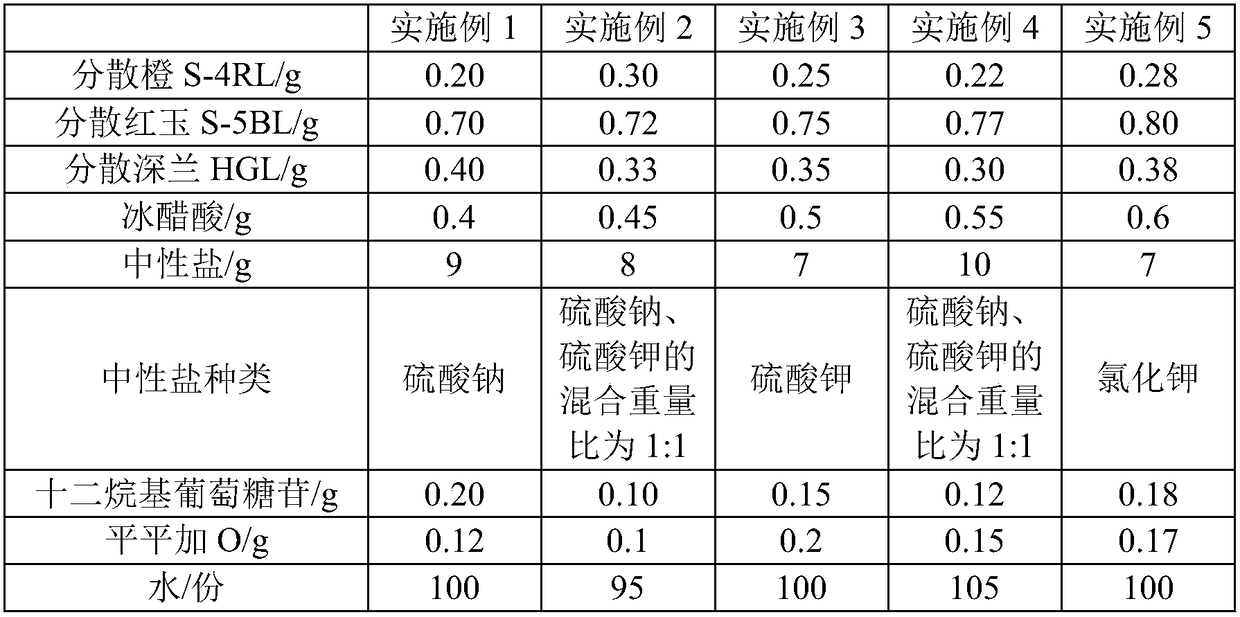

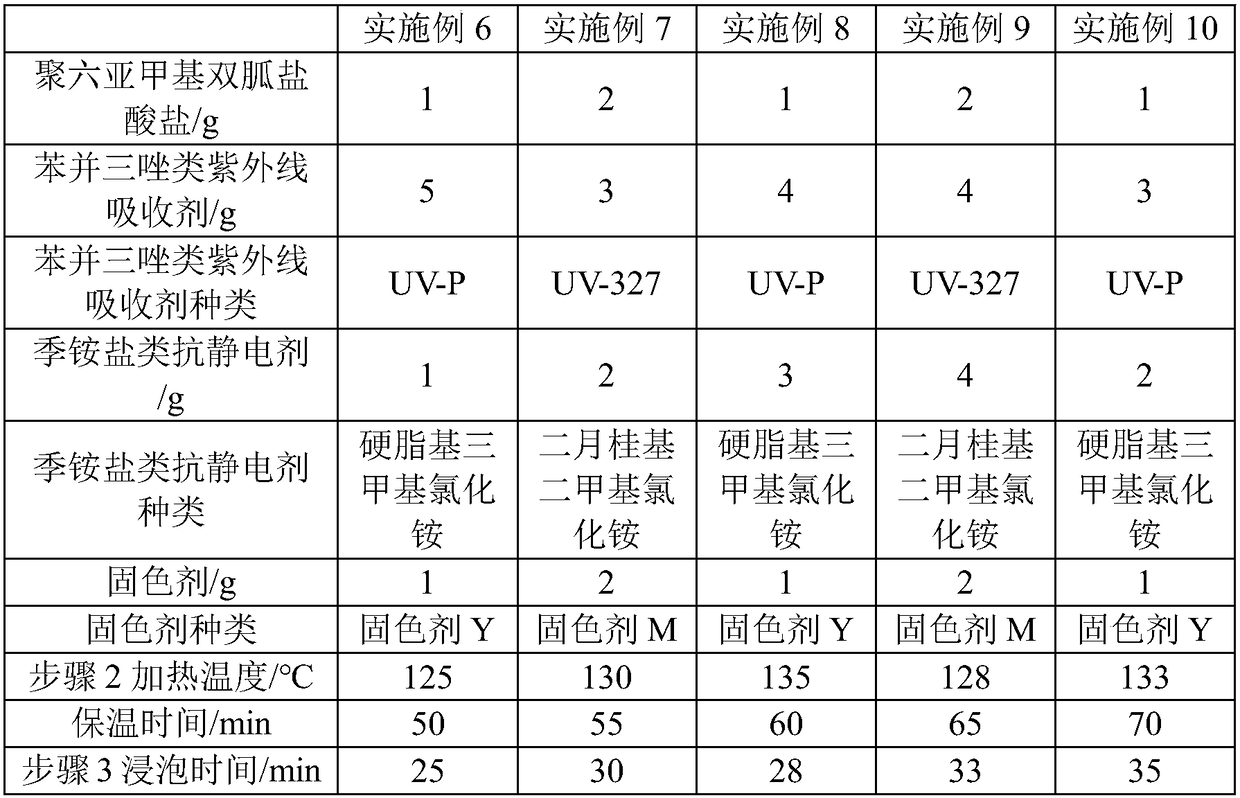

The invention discloses a dye for a milk silk-nonwoven fabric lace and a dyeing technology thereof. The dye for the milk silk-nonwoven fabric lace comprises the following components in parts by weight: 0.2-0.3 part of disperse orange S-4RL, 0.7-0.8 part of disperse rubine S-5BL, 0.3-0.4 part of disperse dark blue HGL, 0.4-0.6 part of glacial acetic acid, 7-10 parts of neutral salt, 0.1-0.2 part ofdodecyl glucoside, 0.1-0.2 part of peregal O and 95-105 part of water. The dye for the milk silk-nonwoven fabric lace has the beneficial effects as follows: the milk silk-nonwoven fabric lace dyed bythe dye for the milk silk-nonwoven fabric lace has good light fastness.

Owner:纪梵喜服饰有限公司

Brightening agent for weaving

The invention discloses a brightening agent for weaving, which comprises the following steps by weight: 6-10 parts of fluorescent whitening agent, 0.01-0.02 parts of disperse purple, 0.005-0.01 parts of disperse blue, 0.2-0.3 parts of disperse orange and 89.67-93.785 parts of water. The brightening agent for weaving has the beneficial effects that the brightening agent has wide application scope, compared with similar products, and the whitening effects can reach 1-3 times.

Owner:联业织染(珠海)有限公司

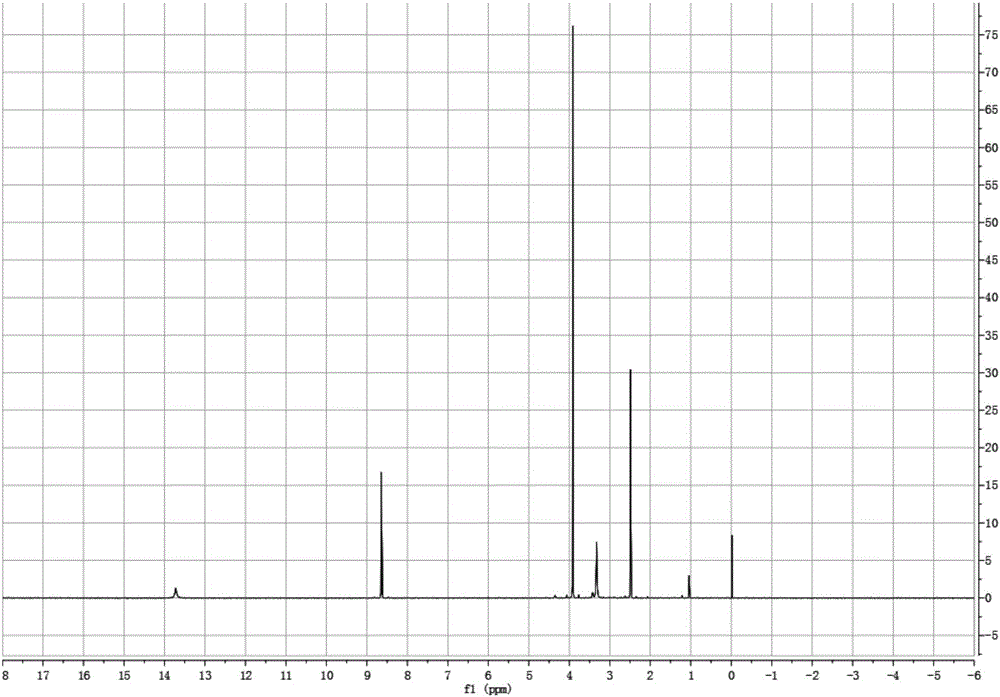

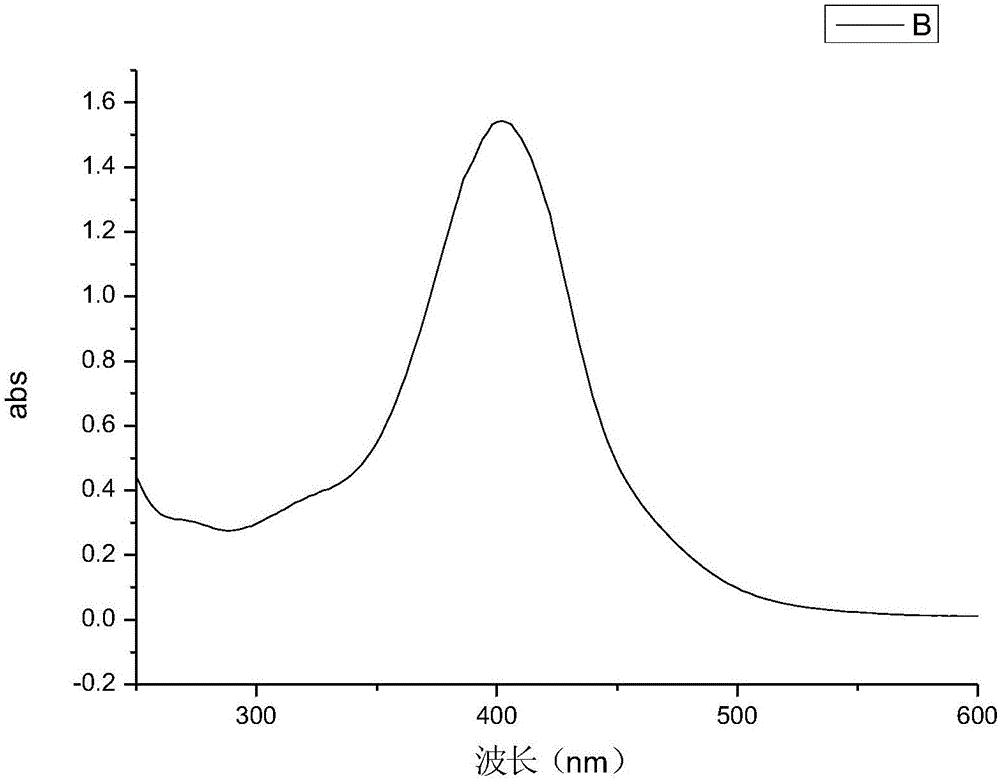

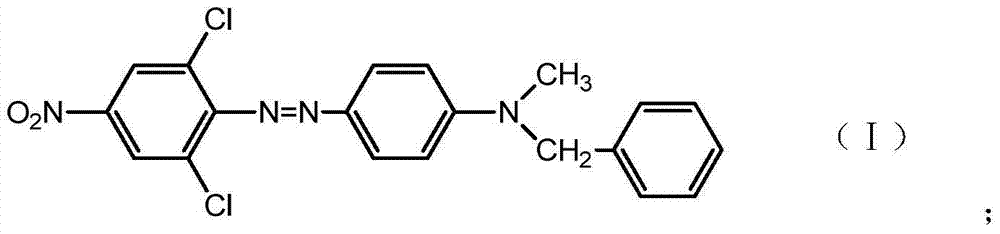

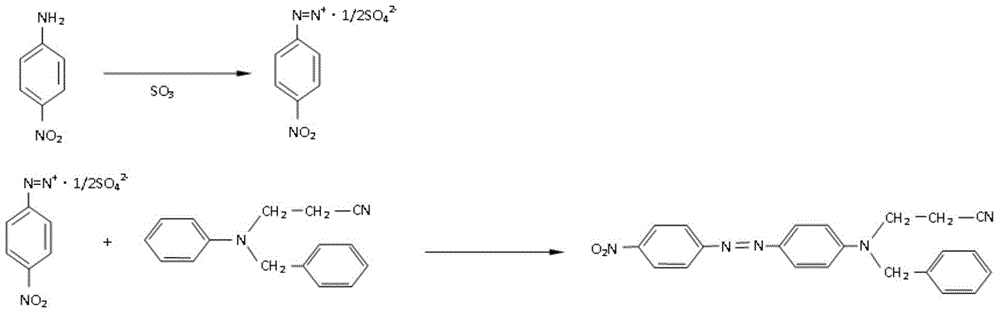

One-pot-method synthesis process for disperse orange 288

The invention relates to a one-pot-method synthesis process for disperse orange 288. The synthesis process comprises the following specific steps: (1) carrying out diazotization: adding p-nitroaniline into a proper volume of water, introducing a certain volume of sulfur trioxide gas into the water, carrying out pulping, adding a proper volume of ice into the pulp so as to cool the pulp to a temperature below 0 DEG C, rapidly adding a proper volume of 30% (mass percent) sodium nitrite solution into the cooled pulp, carrying out heat preservation, carrying out a test by adopting potassium iodide test paper (a reaction ends when the test paper becomes blue), adding a proper volume of aminosulfonic acid into the reacted solution so as to remove superfluous sodium nitrite, and adding a certain volume of OP-10 and Peregal O into the reacted solution; and (2) carrying out coupling. The synthesis process has the beneficial effects that the product, i.e., the disperse orange 288 is prepared through taking p-nitroaniline as a raw material, subjecting sulfur trioxide and sodium nitrite to a diazotization reaction and carrying out one-pot-method coupling with N-cyanoethyl-N-benzylaniline, the process operation is simple and convenient, the product is high in yield and high in purity, and the volume of waste gases, waste water and waste residues is small, so that environment-friendly and clean production is achieved.

Owner:浙江永合新材料科技有限公司

Disperse orange dye mixture

ActiveCN102516815BGood dyeing compatibilityGood alkali resistanceOrganic dyesDyeing processPhysical chemistryOrganic chemistry

Disclosed is a dispersed orange dye mixture, composed of two parts, a dye and an auxiliary, and characterized in that the dye part is at least composed of the dyes of the following three structures: the first one being a dye corresponding to the chemical structural formula (I), and having a content of 2-80% of the total weight of the dye part; the second one being a dye corresponding to the chemical structural formula (II), and having a content of 2-80% of the total weight of the dye part; and the third one being a dye corresponding to the chemical structural formula (III), and having a content of 2-80% of the total weight of the dye part.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

Disperse yellow and disperse orange dye composition

ActiveCN104327548AGood pH dependence of dyeingGood lifting effectOrganic dyesDyeing processHydrogenDisperse yellow

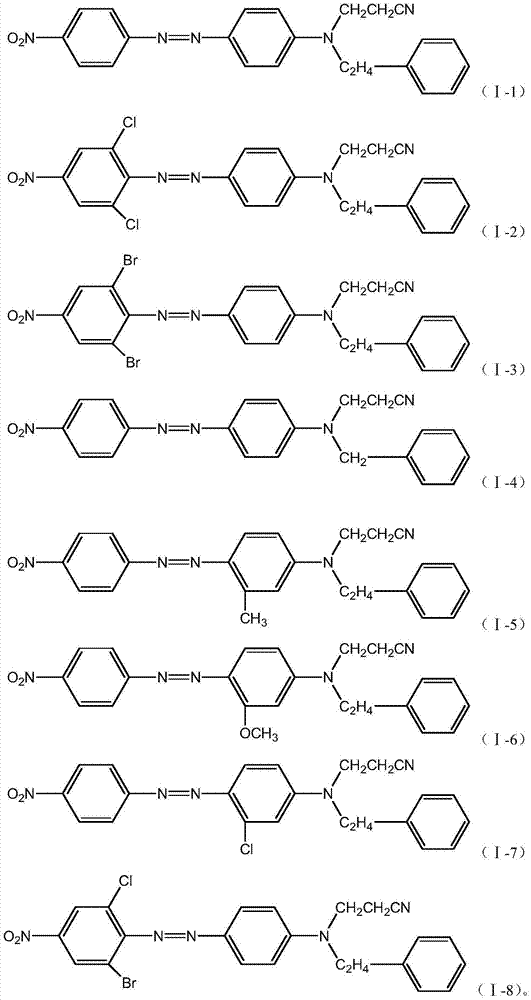

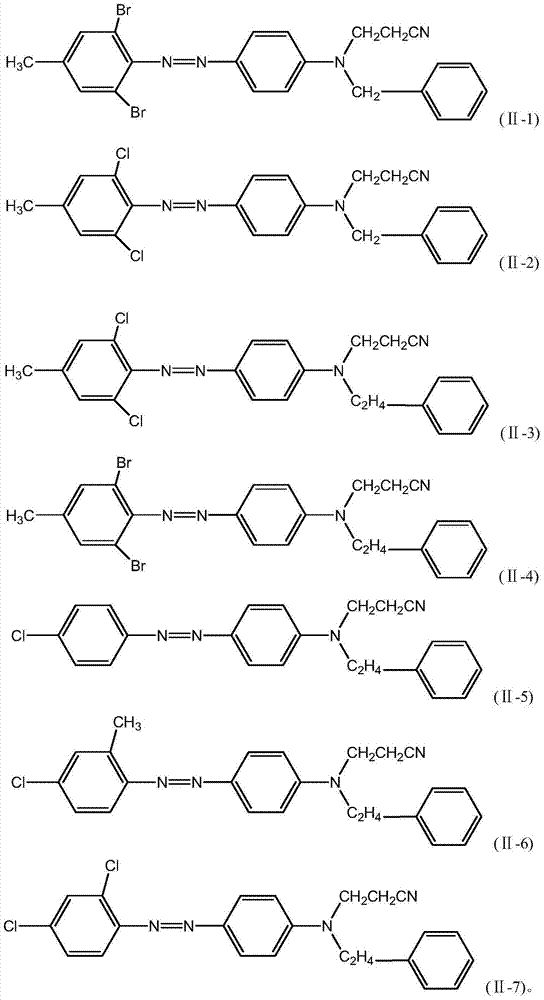

The invention relates to a disperse yellow and disperse orange dye composition, which is prepared by mixing and blending raw dyes and assistant agents, wherein the raw dyes comprise 1-99 wt% of a component A and 1-99 wt% of a component B, the component A is one or a plurality of materials selected from compounds represented by a formula (I), and the component B is one or a plurality of materials selected from compounds represented by a formula (II), wherein in the formula (I), R1 and R2 are simultaneously hydrogen or are independently Cl or Br, R3 is hydrogen, C1-C4 alkyl, C1-C4 alkoxy or Cl, R4 is cyanoethyl or C1-C4 alkyl, m is 1 or 2, and R1 and R2 are simultaneously H when m is 1, and in the formula (II), R5 is H, CH3, Cl or Br, R6 is H, Cl or Br, R7 is Cl or CH3, R8 is C1-C4 alkyl or cyanoethyl, and n is 1 or 2. The dye composition of the present invention has advantages of excellent fastnesses and good pH value dependence. The formula (I) and the formula (II) are represented in the instruction.

Owner:ZHEJIANG LONGSHENG GROUP +1

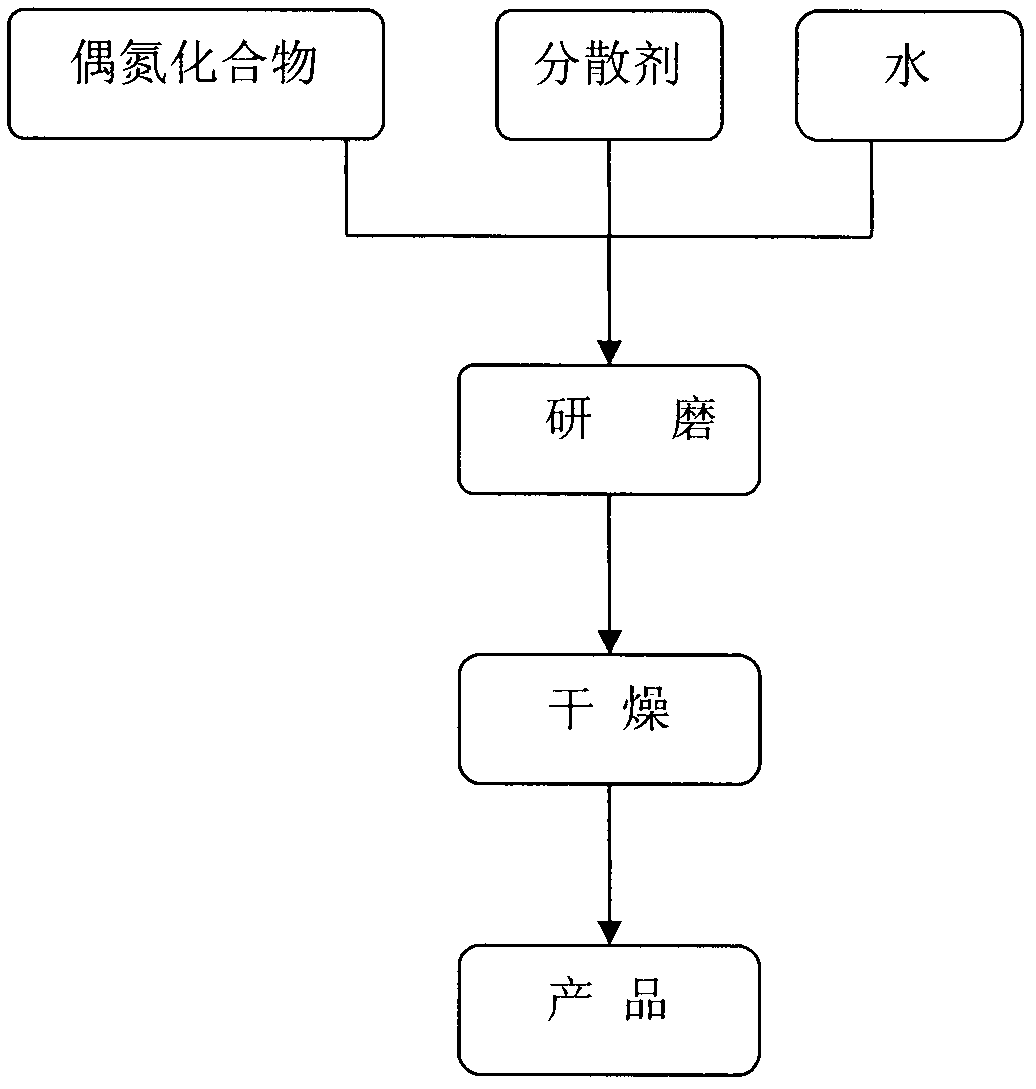

Production technology of disperse orange

The invention discloses a preparation method of disperse orange. The method comprises the following step of coupling diazonium salt and N-acetylyloxyethyl-N-cyanoethylaniline for 2h under the temperature of 25-35 DEG C to obtain the disperse orange, wherein the material adding sequence in the coupling reaction is that diazonium salt is added to N-acetylyloxyethyl-N-cyanoethylaniline. According tothe production technology, the requirements of people on environmental protection indexes can be met; the cost is decreased; the output is increased; the color of the product is consistatn with that produced by other technologies in the prior art.

Owner:DONGYING ANNUOQI TEXTILE MATERIALS +4

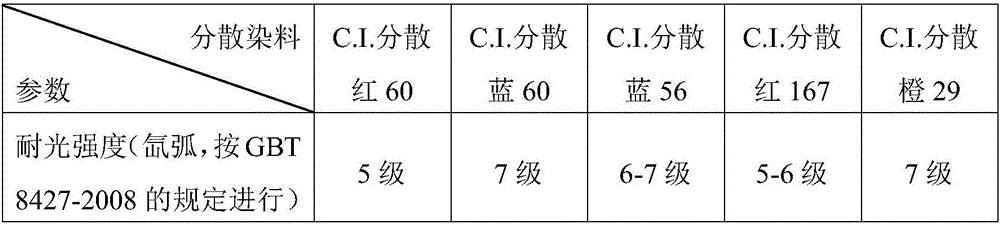

Disperse dyestuff composition with high color fastness to sunlight as well as preparation method and application thereof

ActiveCN106009775AImprove stabilityHigh fastnessOrganic dyesDyeing processDisperse orangeHot Temperature

The invention discloses a disperse dyestuff composition with high color fastness to sunlight as well as a preparation method and application thereof. The disperse dyestuff composition is prepared from the following components in parts by weight: 1 to 20 parts of C.I. disperse red 60, 2 to 50 parts of C.I. disperse blue 60, 1 to 40 parts of C.I. disperse blue 56, 1 to 20 parts of C.I. disperse red 167 and 2 to 50 parts of C.I. disperse orange 29. The disperse dyestuff composition with high color fastness to sunlight, disclosed by the invention, has considerably high stability and color fastness to the sunlight at a high temperature; particularly, the change of the color fastness to sunlight is relatively small under a long-period illumination condition and the requirement on the color fastness to sunlight of textiles for automobiles can be met.

Owner:杭州欣阳精细化工有限公司

Dispersing orange dye composition and dispersing dye

The invention discloses a dispersed orange dye composition, which is composed of 1-99% one or several dye A with formula (I) and 1-99% one or several dye B with formula (II), wherein the composition can be microparticled into liquid pattern, cream pattern or powder and particle pattern, which makes polyester fiber material display yellow to orange to red.

Owner:ZHEJIANG LONGSHENG GROUP

Admixture of composite dispersed orange dye

InactiveCN101092524ABalanced sublimation fastnessSolve the problem of serious shade changeOrganic dyesPolyesterFiber

This invention discloses disperse orange dye mixture with improved sublimation fastness, whose general chemical formula is shown in chemical formula (I). The sublimation fastness of the disperse orange dye mixture is improved to 3.5 grade. The disperse orange dye mixture, together with disperse blue 2BLN and disperse red with the same sublimation fastness, can constitute conventional commercialized dyes with various colors, which have balanced sublimation fastness. Compared with the traditional ternary dye mixture composed of disperse blue 2BLN, disperse yellow E-RG and disperse red 3B, the disperse orange dye mixture can avoid the serious chromatic light change problem caused by ununiform sublimation of different components during middle-depth dyeing of polyester fibers and fabrics. The disperse orange dye mixture can obviously improve chromatic light change before and after setting, and has a high qualification rate. The disperse orange dye mixture can also be used in direct dyeing. In chemical formula (I), RA is dimethyl sulphonylamino or nitro; RB and RC are halogen or H.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

Disperse orange dye composition

The invention discloses a disperse orange dye composition. The composition is mainly composed of, by weight, 1-30% of a component A, 30-90% of a component B and 5-50% of a component C. The component A is one or more compounds selected from compounds as shown in the formula (I). The component B is one or more compounds selected from compounds as shown in the formula (II). The compound C is one or more compounds selected from compounds as shown in the formula (III). The disperse orange dye composition has characteristics of sublimation resistance, friction resistance and excellent washing fastness and the like when applied in dyeing of hydrophobic fiber.

Owner:浙江龙盛染料化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com