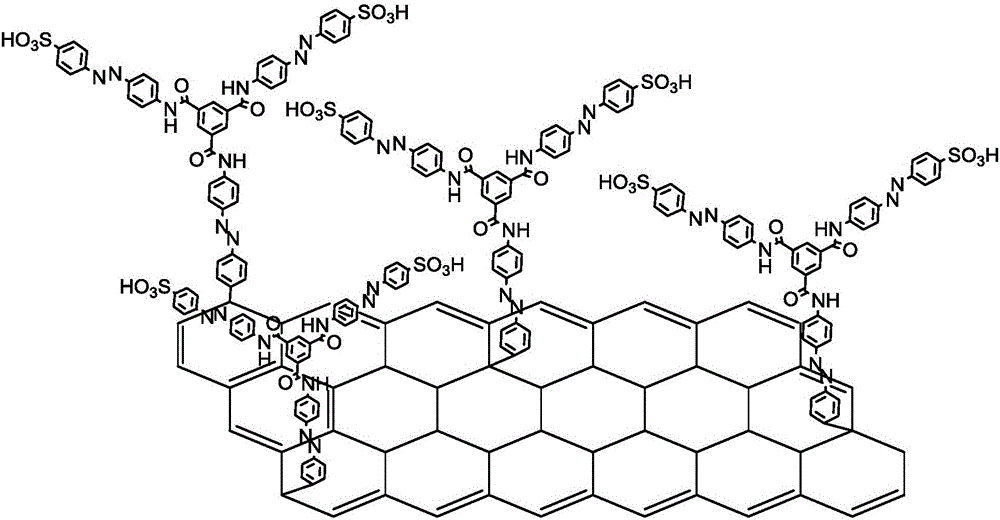

Tri-branched azobenzene/graphene composite energy storage material and preparation method thereof

A composite material, graphene technology, applied in the direction of sulfonic acid preparation, heat exchange materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

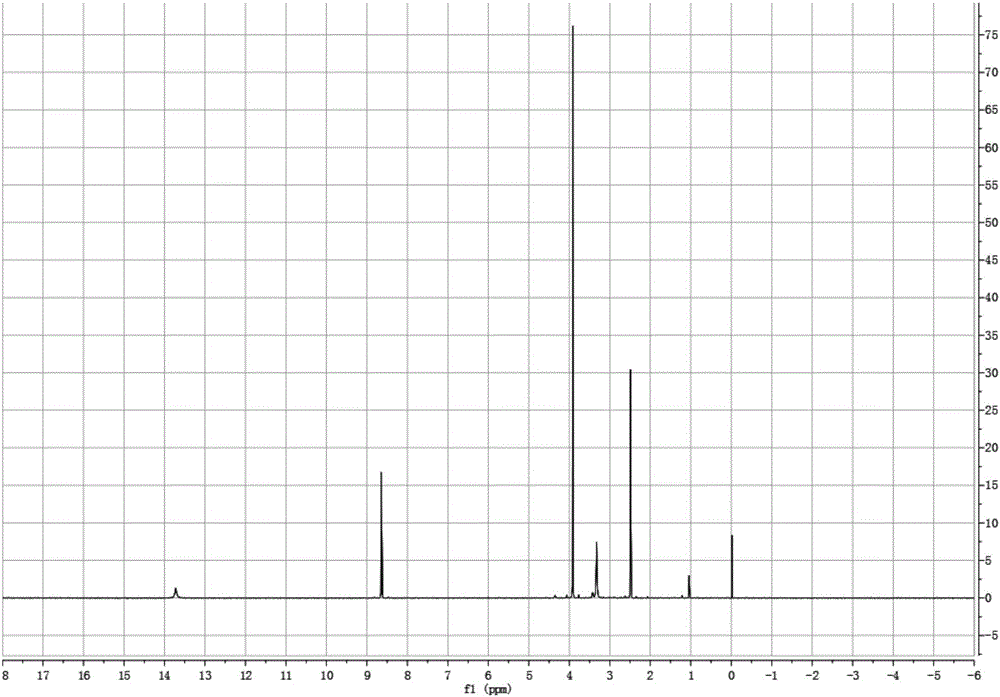

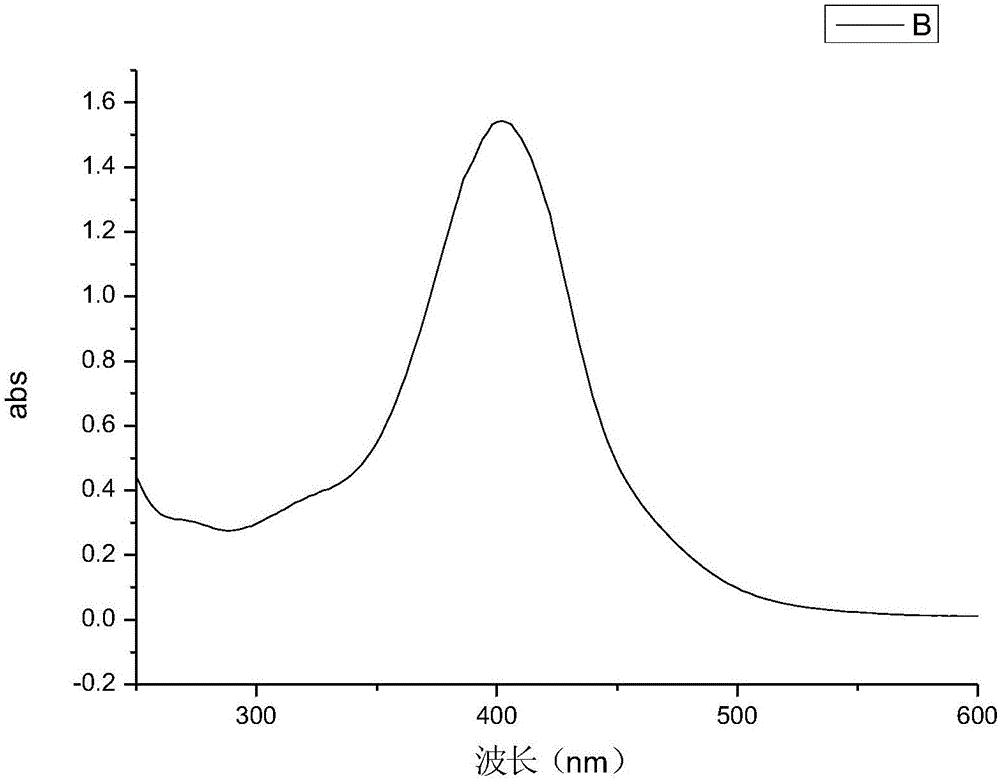

[0027] 1) Preparation of three-branch azobenzene:

[0028] ① Preparation of product (1): Dissolve 1-3 parts of trimethylbenzenetricarboxylate and 1-3 parts of NaOH in 5-20 parts of methanol, slowly heat up to its reflux temperature, and then react for 12-16 hours. The solvent was removed by rotary evaporation, and the resulting solid was dissolved with 1-5 parts of dichloromethane, and then saturated NaHCO 3 20-40 parts of the solution to extract the product. The aqueous phase was taken out and washed 2-4 times with 20-50 parts of dichloromethane, and finally adjusted to pH=1-3 with 10-15% HCL, and a white precipitate was precipitated. Wash the precipitate with water until neutral, and dry it in a vacuum oven to obtain the target product.

[0029] ② Preparation of product (2): Dissolve 1-2 parts of product (1) in 3-5 parts of NMP, add 0.5-1 part of thionyl chloride under nitrogen protection, Stir at ℃ for 30-60min. Add 1-3 parts of Disperse Orange 3 to the system, and sti...

Embodiment 1

[0037] 1) Preparation of three-branch azobenzene:

[0038] ① Preparation of product (1): Dissolve 10mmol trimethylbenzenetricarboxylate and 20mmol NaOH in 70ml methanol, slowly raise the temperature to its reflux temperature, and then react for 12h. The solvent was removed by rotary evaporation, and the resulting solid was dissolved in 15ml of dichloromethane, then saturated NaHCO 3 solution to extract the product. The aqueous phase was taken out and washed twice with dichloromethane, and finally the pH was adjusted to pH=1 with 10% HCL to precipitate a white product. Wash the precipitate with water until neutral, and dry it in a vacuum oven to obtain the target product.

[0039]② Preparation of product (2): Dissolve 5 mmol of product (1) in 30 ml of NMP, add 0.8 ml of thionyl chloride under nitrogen protection, stir at 0°C for 30 min, and then at 20°C for 30 min. Add 1.5 g of Disperse Orange 3 to the system, and stir at 25°C for 5 h. Finally, pour it into water to precipi...

Embodiment 2

[0047] 1) Preparation of three-branch azobenzene:

[0048] ① Preparation of product (1): Dissolve 20mmol trimethylbenzenetricarboxylate and 20mmol NaOH in 70ml methanol, slowly raise the temperature to its reflux temperature, and then react for 12h. The solvent was removed by rotary evaporation, and the resulting solid was dissolved in 15ml of dichloromethane, then saturated NaHCO 3 solution to extract the product. The aqueous phase was taken out and washed twice with dichloromethane, and finally the pH was adjusted to pH=1 with 10% HCL to precipitate a white product. Wash the precipitate with water until neutral, and dry it in a vacuum oven to obtain the target product.

[0049] ② Preparation of product (2): Dissolve 5 mmol of product (1) in 30 ml of NMP, add 0.8 ml of thionyl chloride under nitrogen protection, stir at 0°C for 30 min, and then at 20°C for 30 min. Add 1.5 g of Disperse Orange 3 to the system, and stir at 25°C for 5 h. Finally, pour it into water to precip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com