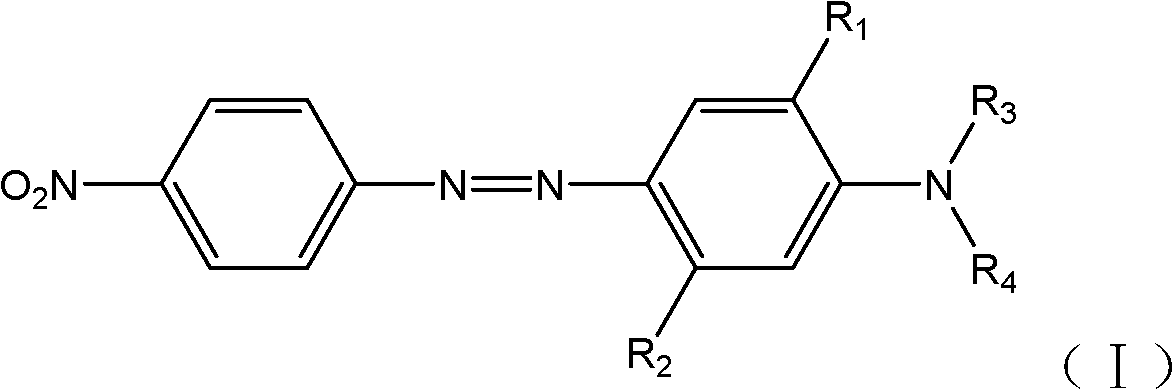

Monoazo dye compound and orange to red dye composition

A technology of monoazo dyes and red dyes, which is applied in the field of orange to red dye compositions, can solve the problem of high price, and achieve the effects of low cost, excellent application effect and excellent fastness to sublimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Diazo process

[0058] In a 250ml flask, add 38g of water, 70g of 31% hydrochloric acid, and 20.7g (percentage) of p-nitroaniline, and beat for 2 hours at 20-30°C. After beating, add 120g of ice, add 36g of 30% sodium nitrite solution at one time, and continue to stir and react for 3 hours within the range of 0-5°C.

[0059] (2) Coupling process

[0060] In a large beaker of 2000ml, add 1000g of water, 1g of Pingpingjia, 1g of sulfamic acid, 39.9g (percentage) of N-ethyl-N-methoxycarbonylmethyl-m-acetamidoaniline (raw material 2), Stir and beat for 30-45 minutes, and control the temperature at 15-25°C. After the beating is completed, the ice bath is cooled to 0-5°C and kept warm, and the heavy nitrogen solution is added dropwise within 1.5 hours. After the dropwise addition of diazo is completed, continue the heat preservation reaction for 2 hours, heat up to 50° C. for another 1 hour heat preservation, filter with suction, and wash with water to PH=6 to 7 to obt...

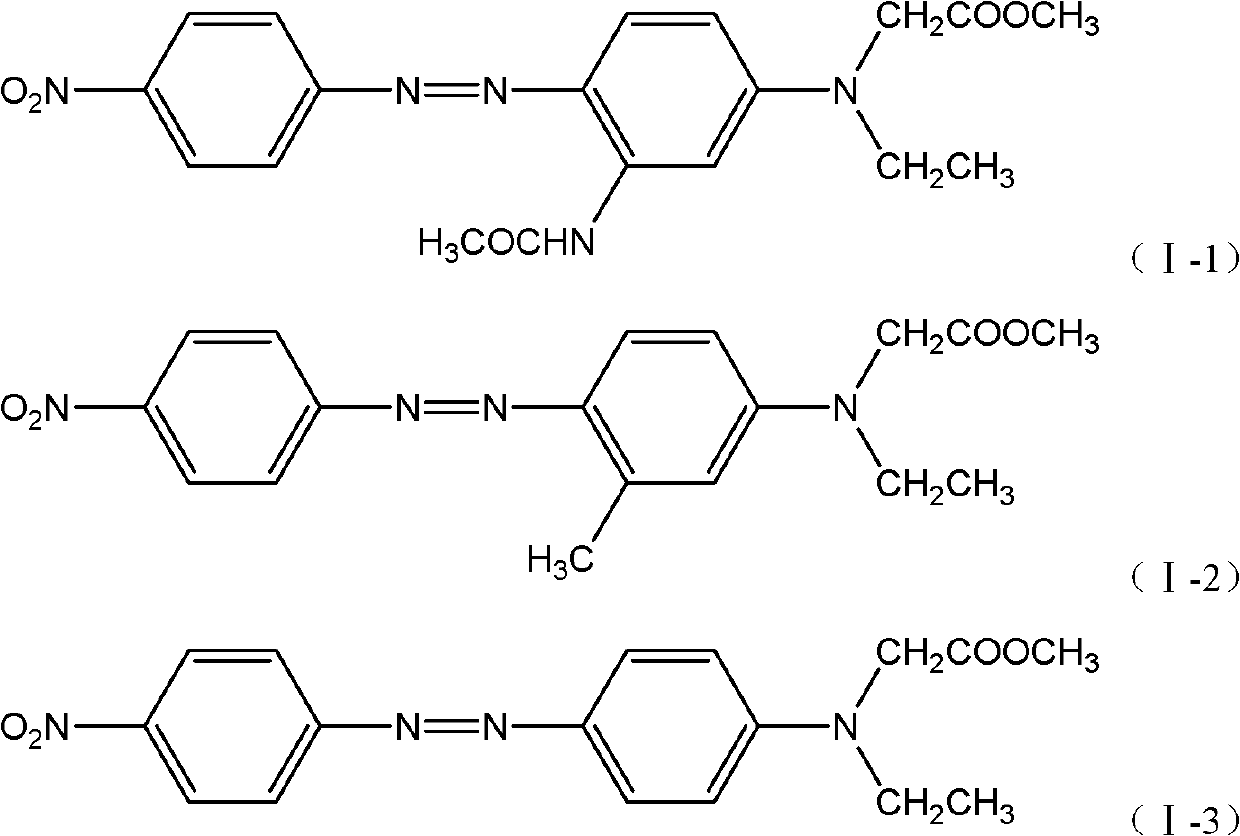

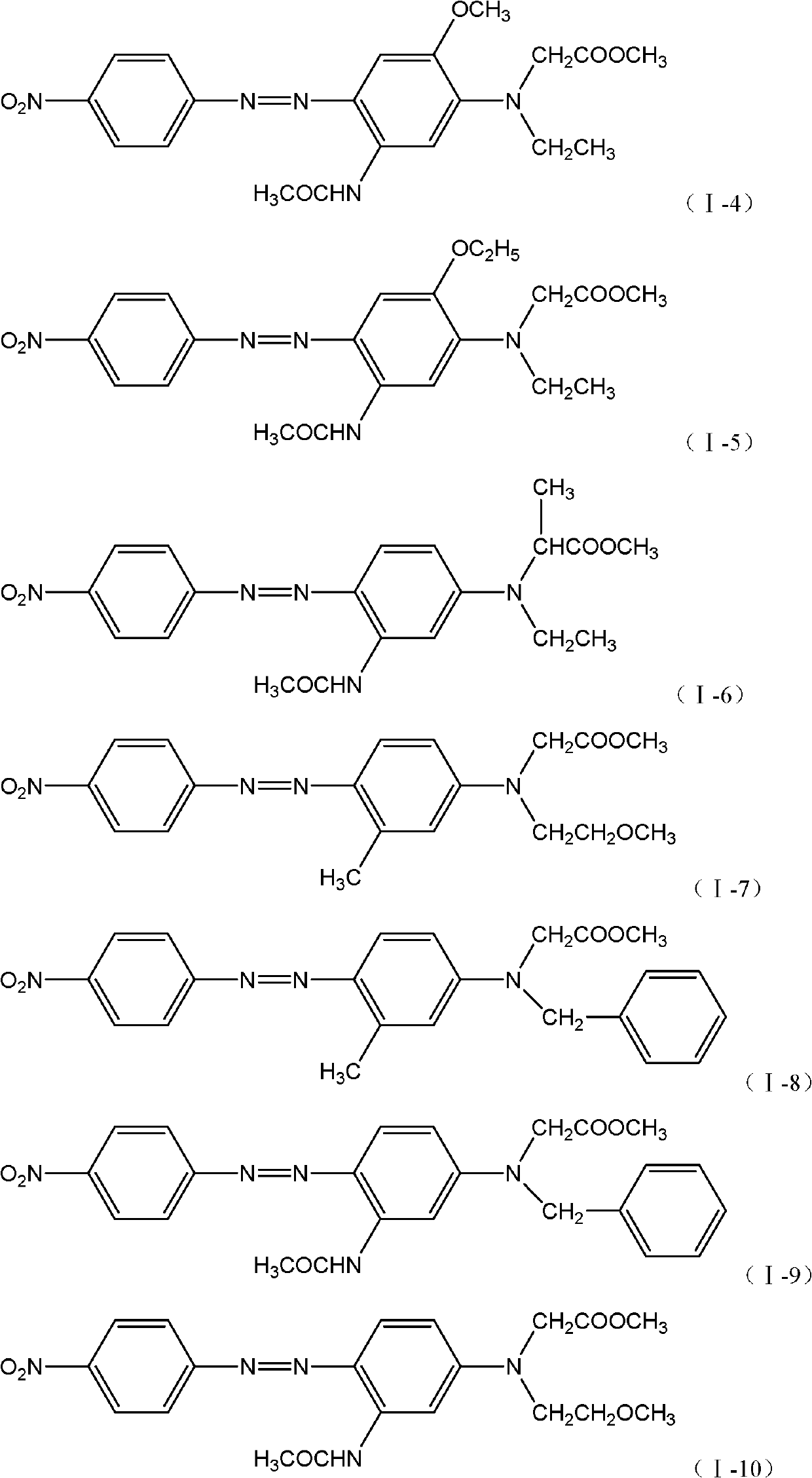

Embodiment 2~20

[0064] According to the preparation method described in Example 1, the raw material 2 is replaced by the components shown in Table 1 in equimolar amounts, and the dye compound according to the present invention can be prepared.

[0065] Table 1

[0066]

[0067]

Embodiment 13

[0069] 58 grams of component A of formula (I-1), 42 grams of component B of formula (III-1), 200 grams of dispersant MF, and 800 grams of water were blended, ground, dispersed and dried to obtain the finished product. The dye can provide red color with excellent fastness properties to the fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com