Orange mix

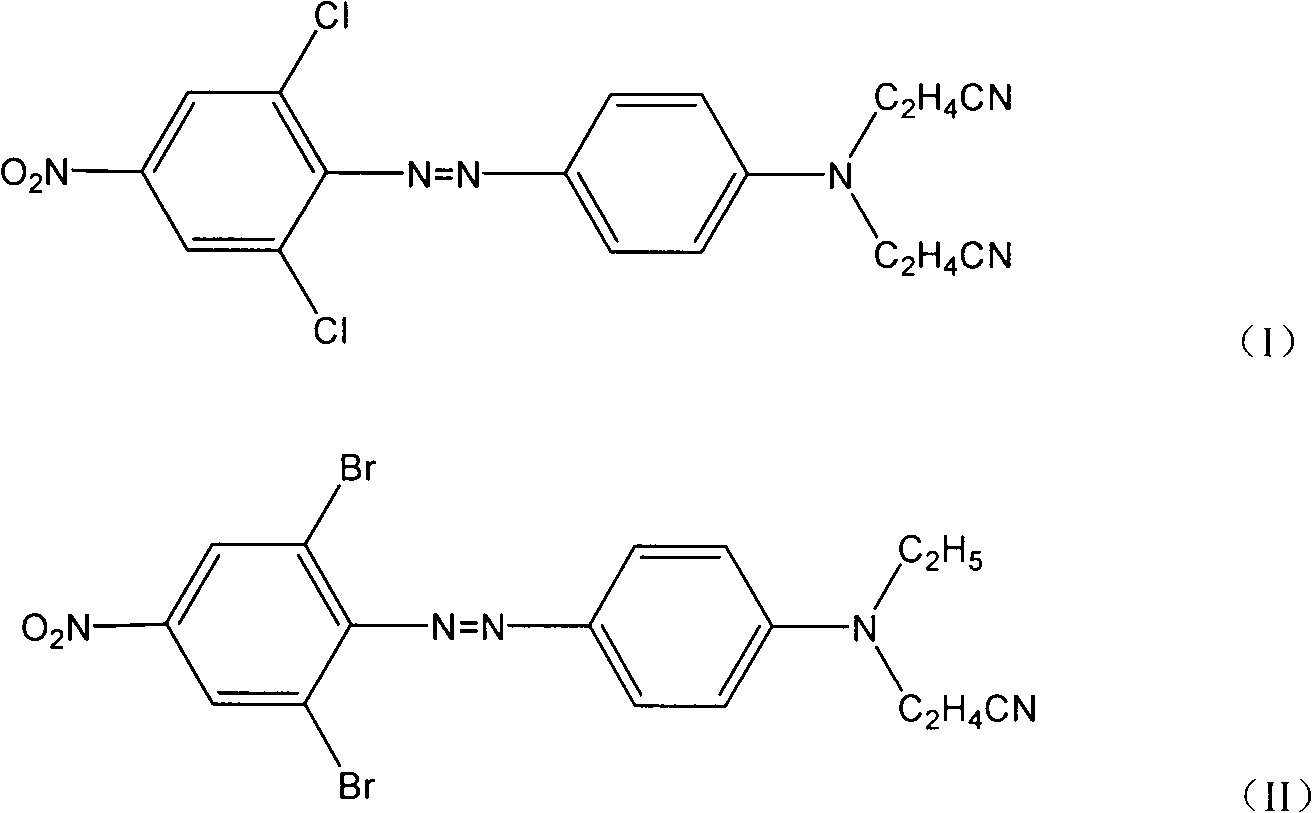

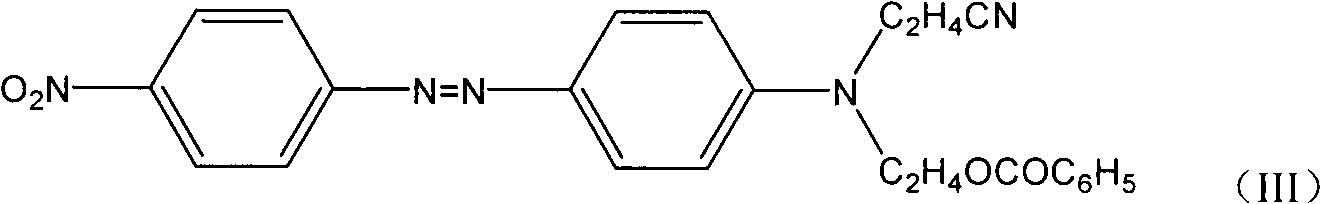

A mixture, orange technology, applied in the direction of dyeing, textile and papermaking, organic dyes, etc., can solve the problems of difficult color coordination of monomer dyes, difficult to dye evenly, deep dyeing, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

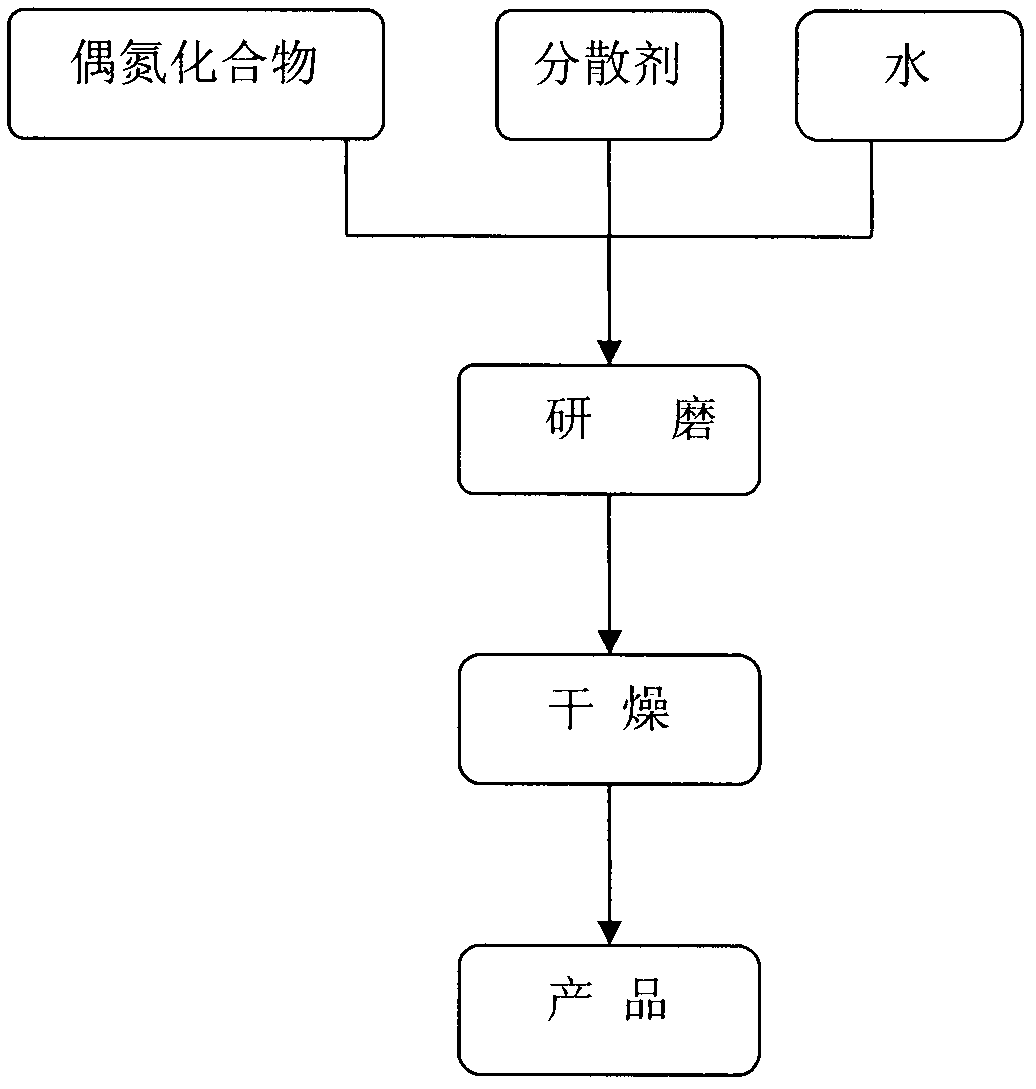

Method used

Image

Examples

Embodiment 1

[0016] Mix 10 grams of component A, 55 grams of component B, 35 grams of component C, and 100 grams of lignin 85A with water, grind and disperse with a grinder, and spray dry to obtain the finished product. The dye can provide an orange color with excellent fastness properties for fabrics.

Embodiment 2

[0018] Mix 15 grams of component A, 45 grams of component B, 40 grams of component C, and 100 grams of lignin 83A with water, grind and disperse with a grinder, and spray dry to obtain the finished product. The dye can provide an orange color with excellent fastness properties for fabrics.

Embodiment 3

[0020] Mix 60 grams of component A, 35 grams of component B, 5 grams of component C, and 100 grams of dispersant MF with water, grind and disperse with a grinder, and spray dry to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com