Production technology of disperse orange

A technology of azo compound and coupling reaction, which is applied in the field of chemistry, can solve problems such as product environmental protection indicators not up to standard, and achieve the effects of short time consumption, high output, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

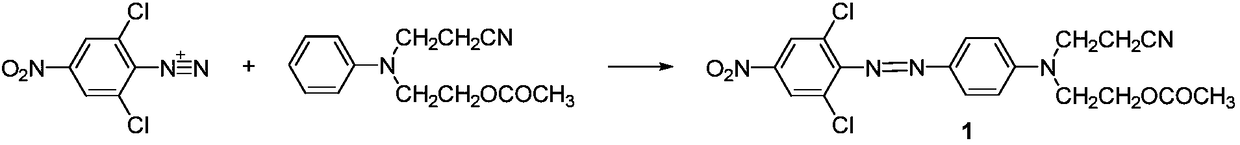

Method used

Image

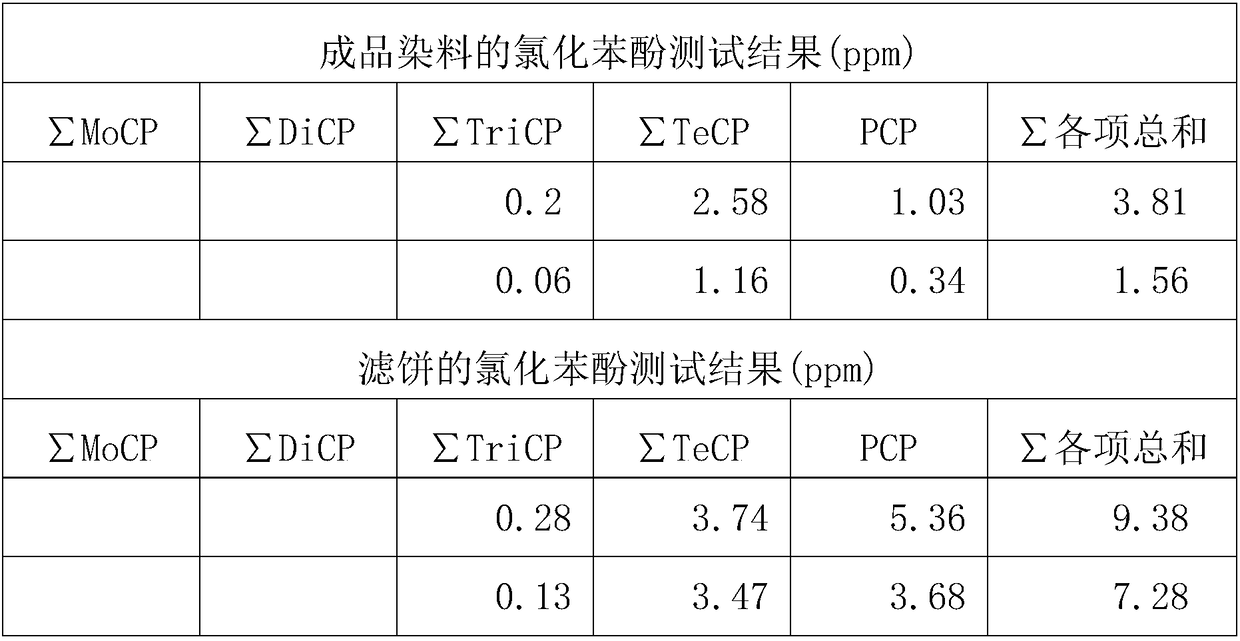

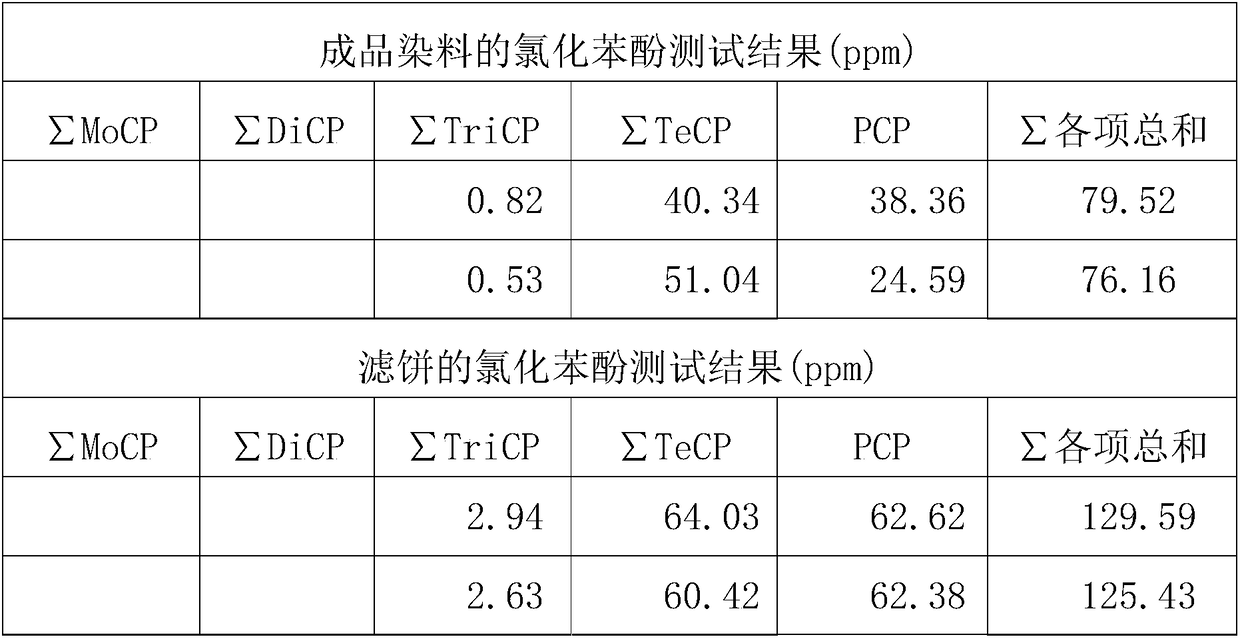

Examples

Embodiment 1

[0036] The present embodiment provides a kind of production technique of disperse orange, comprises the steps:

[0037] (1) Pump 1730kg of sulfuric acid (the concentration of sulfuric acid is 98%) and 1983kg of nitrosyl sulfuric acid solution (the concentration of nitrosyl sulfuric acid is 40%) into the enamel kettle, start stirring, open the frozen brine inlet and outlet valves, and control the temperature at 18- Between 22°C, 1300kg of 2,6-dichloro-4-nitroaniline was uniformly added within 3.6 hours. After adding the materials, keep the temperature at 20-22°C for 4 hours. After the heat preservation, cool down to below 20°C to obtain the diazonium solution for coupling.

[0038] (2) Add 40,000 kg of bottom water to the coupling pot, add ice to control the temperature at 20-25°C, add 19 kg of urea and 25 kg of MF, quickly add 1372 kg of N-acetoxyethyl-N-cyanoethyl aniline, and stir for 30 minutes, standby;

[0039] (3) After the beating time of N-acetoxyethyl-N-cyanoethylan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com