Disperse orange dye composition

A technology of orange dye and composition, which is applied in the field of disperse orange dye composition, and can solve the problems of poor compatibility and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

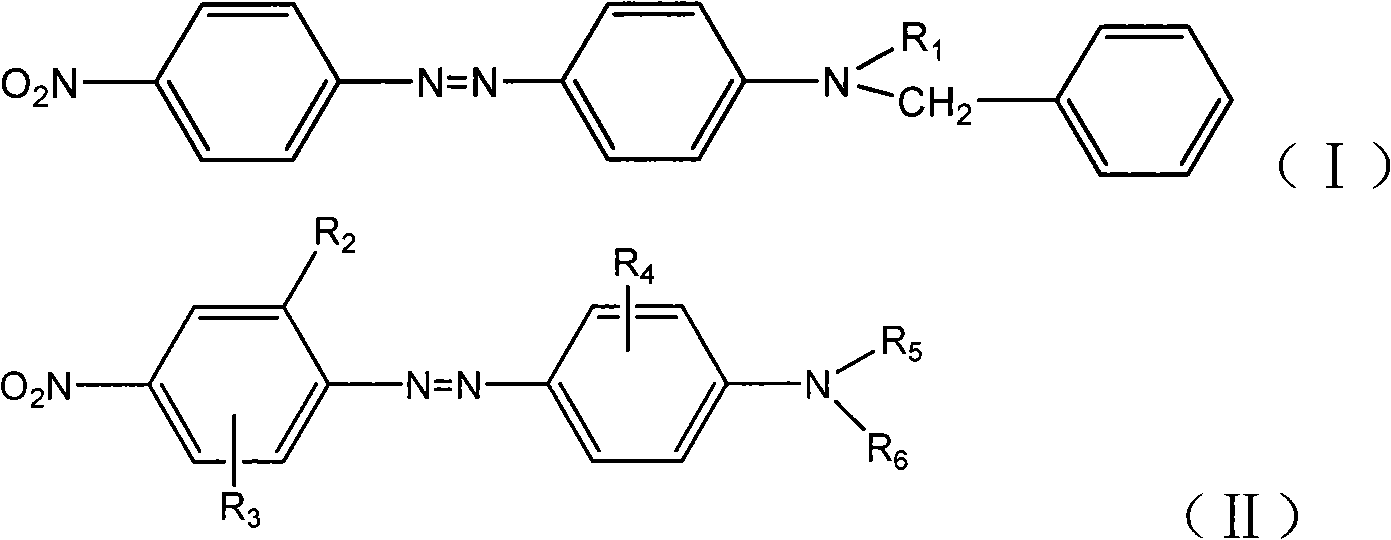

Method used

Image

Examples

Embodiment 1

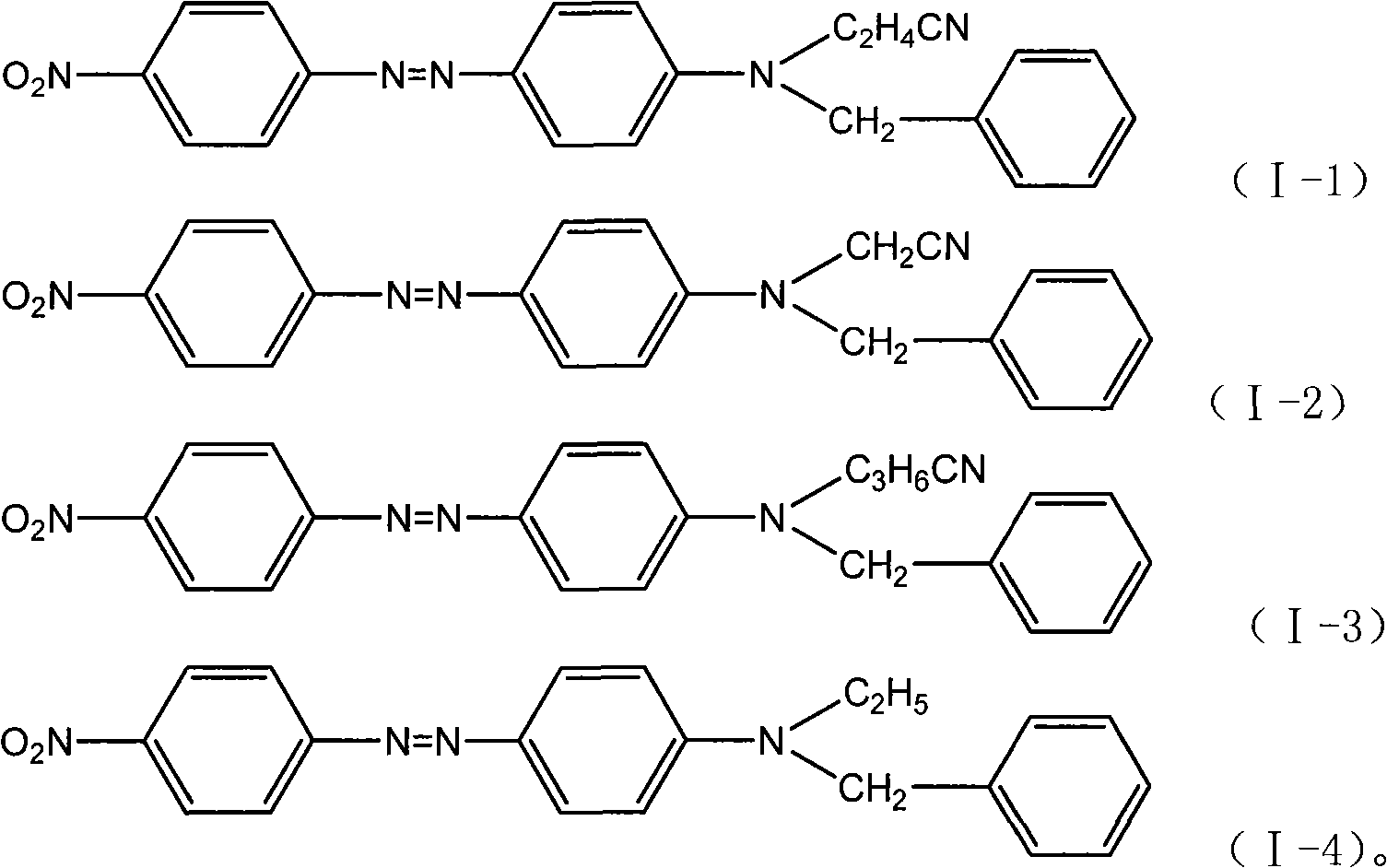

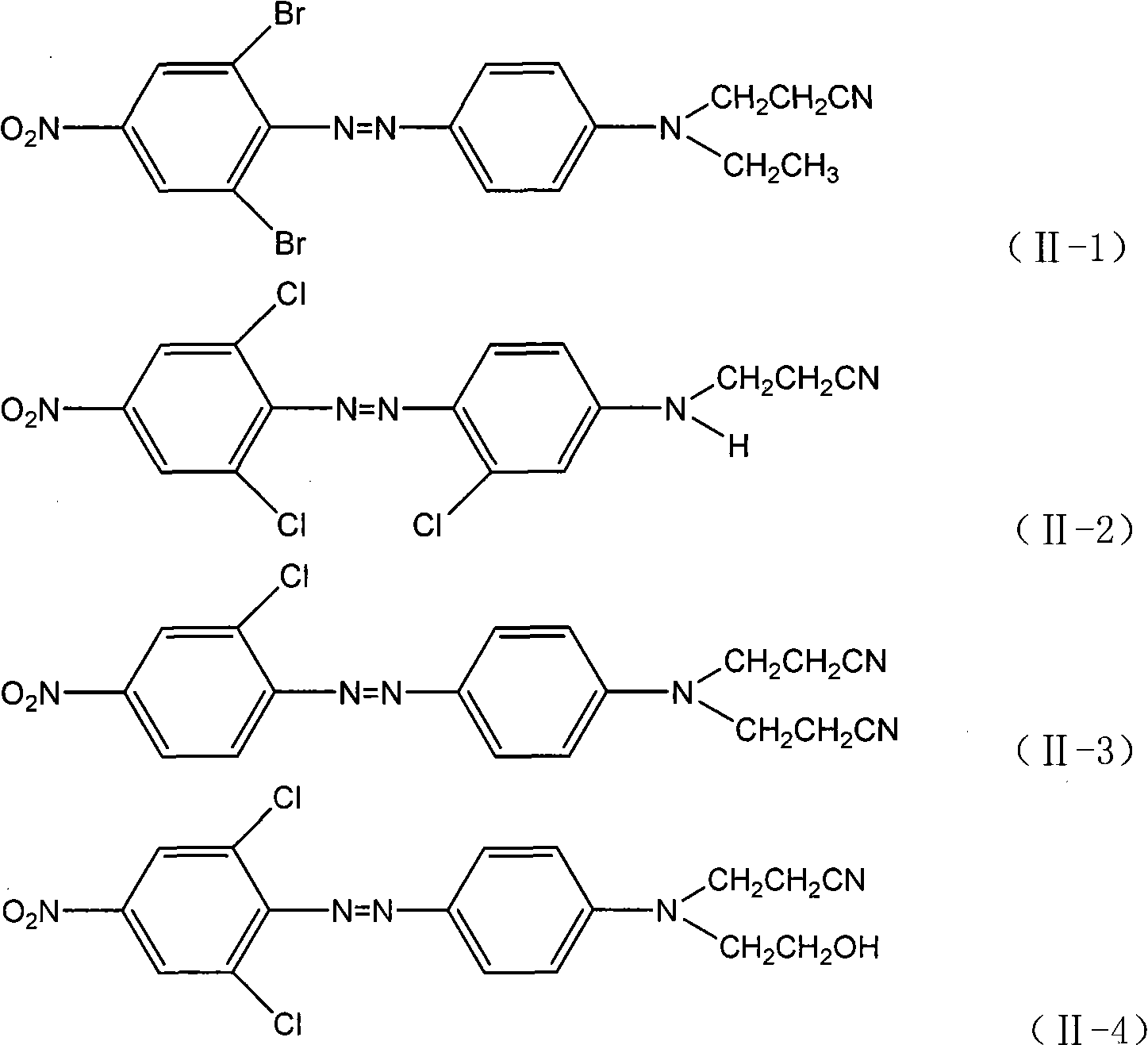

[0033] Take 40g of dye component A with structural formula I-1 and 60g of dye component B with structural formula II-1, add 105g of MF and 500g of water, make a pulp for color matching, check the shade, and spray dry. The dye can provide uniform and fastness to the fabric. Good performance orange.

Embodiment 2~16

[0035] According to the data shown in Table 1, after blending Component A, Component B, additives, and adding water (the amount of water is controlled to be twice the sum of Component A, Component B, and additives), grind and disperse with a grinder , and then spray dried to produce a finished product that imparts an orange hue to fabrics.

[0036] Table 1

[0037]

[0038] 4

(I-1)+(I-2)

(II-4)

(10+30)∶60

195g lignin 83A

5

(I-1)

(II-5)

50∶50

195g dispersant MF

6

(I-1)

(II-1)+(II-2)

60∶(20+20)

195g diffuser NNO

7

(I-1)

(II-1)+(II-6)

40∶(20+40)

195g diffusing agent CNF

8

(I-1)+(I-2)

(II-5)

(35+40)∶25

195g lignin 83A

9

(I-1)+(I-2)

(II-3)

(50+30)∶20

195g diffuser NNO

10

(I-1)+(I-3)

(II-3)

(44+25)∶31

195g dispersant MF

11

(I-1)+(I-4)

(II-4)

(20+30)∶50

95gMF+10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com