Cooling Suit

a technology of cooling suit and body, applied in the field of cooling suit, can solve the problems of continuously and uselessly exuding perspiration, inability to obtain the required amount of heat radiation, and inability to protect the human body, etc., and achieve the effect of expanding an effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

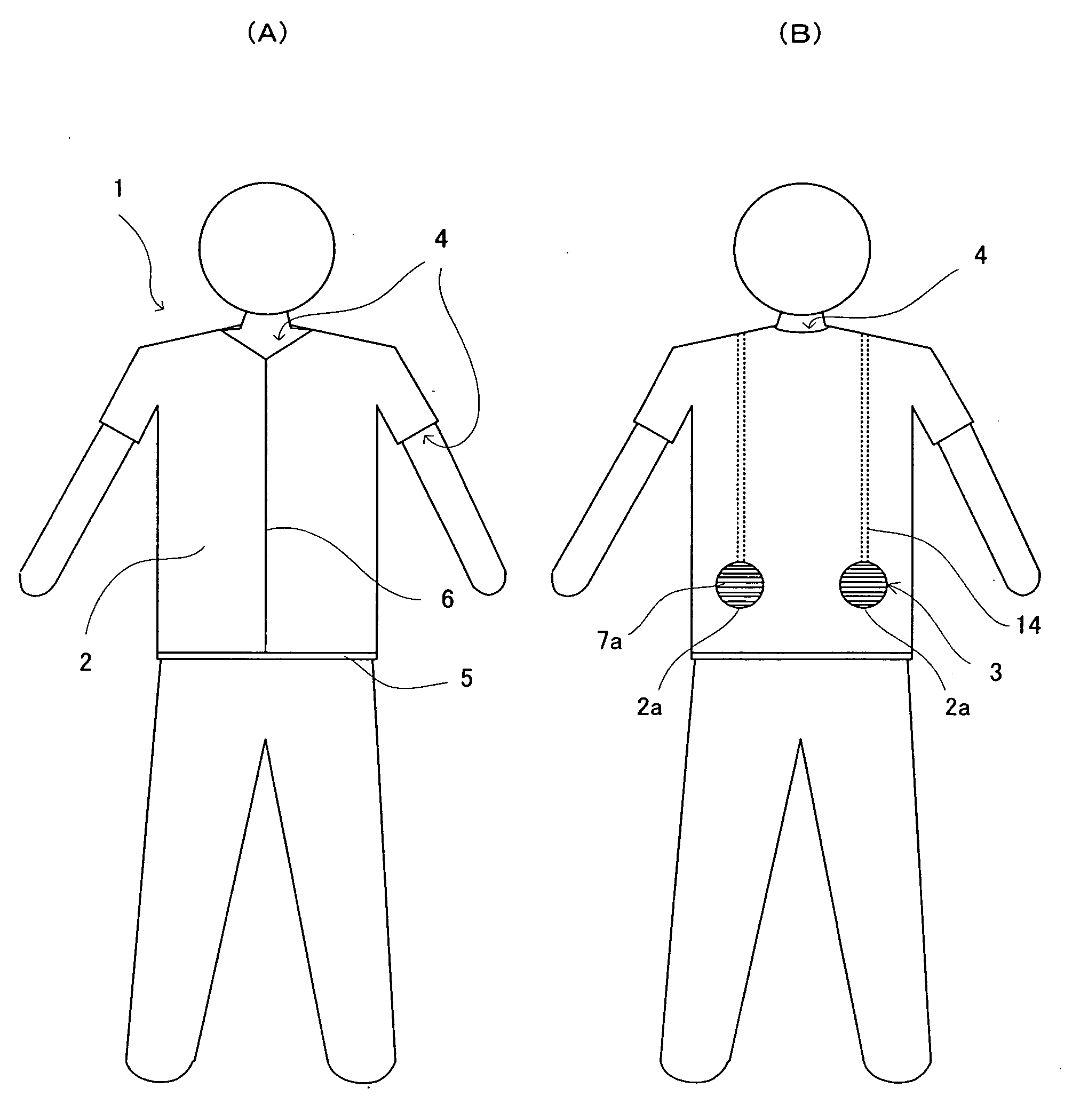

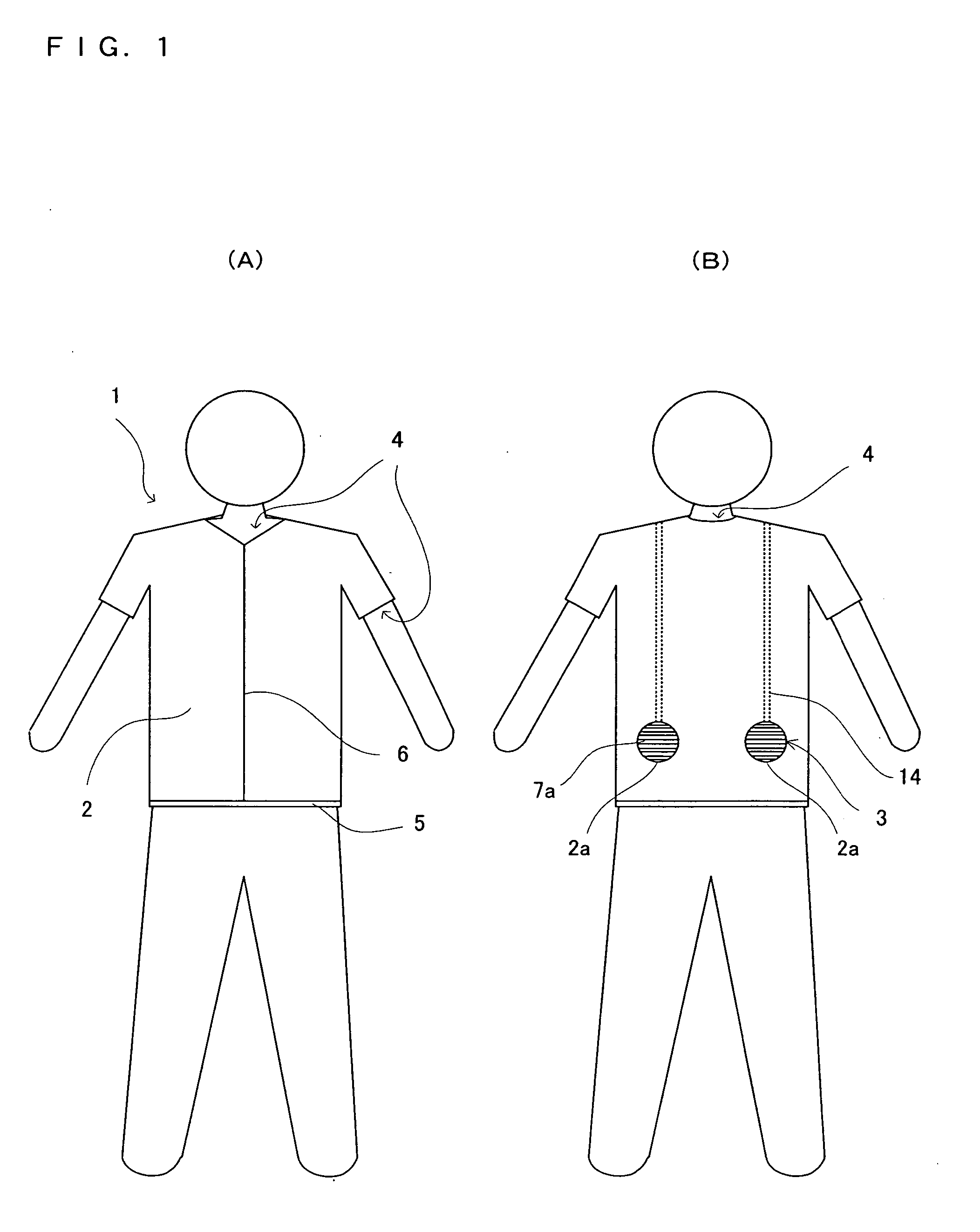

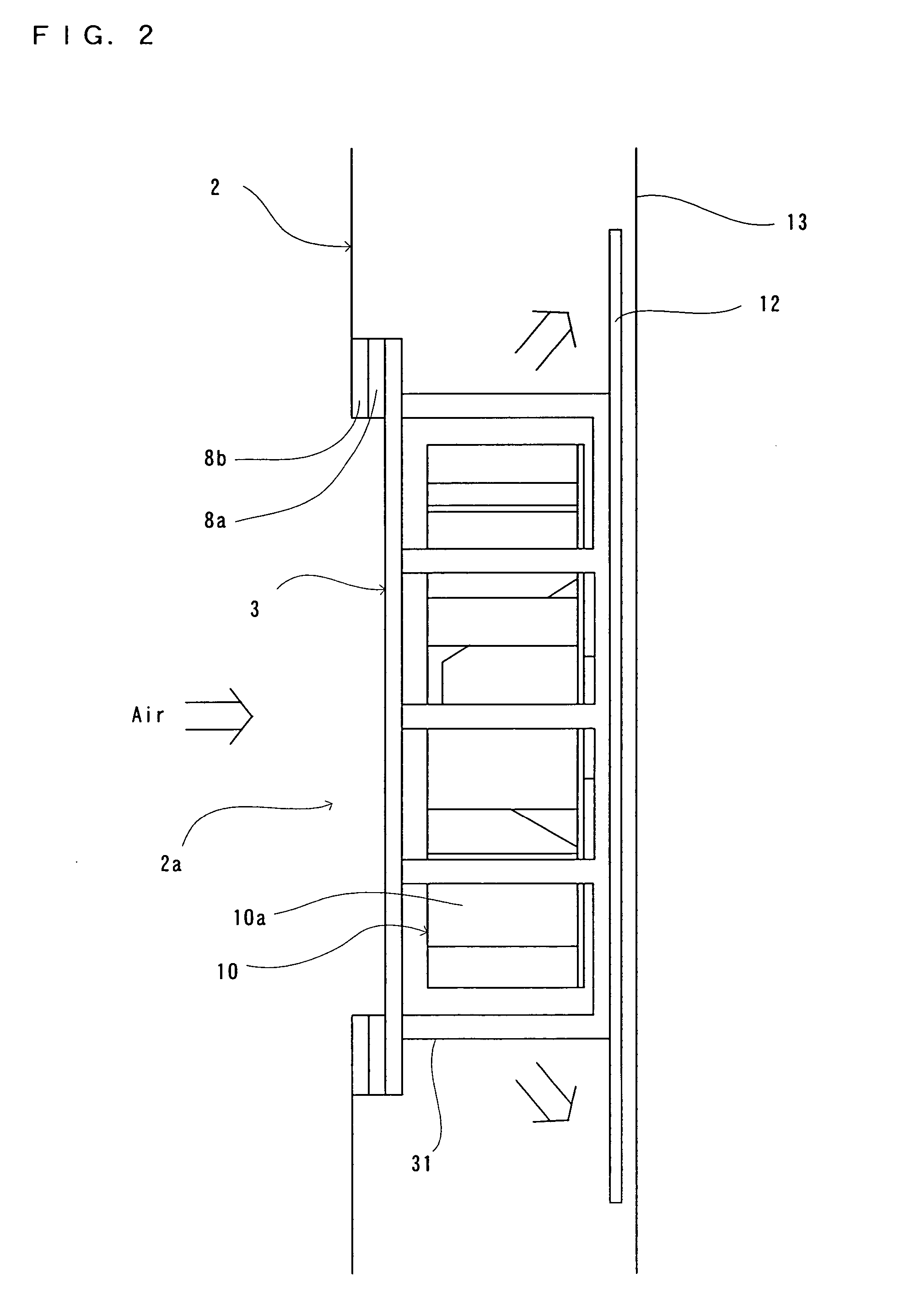

[0063] There will be explained a best mode for carrying out the present invention according to the present application. There is provided a cooling suit according to a first embodiment of the present invention applied to a short-sleeved jacket of a worksuit. FIG. 1A is a schematic front view of the cooling suit according to the first embodiment of the present invention when it is worn, and FIG. 1B is a schematic rear view of the cooling suit. As shown in FIG. 1, the cooling suit 1 of the first embodiment comprises: a garment or jacket 2 formed into a shape of a short-sleeved jacket and simultaneously serving as a guide sheet (the meaning of “guide” will be described later) which is less in air leakage; parallel airstream generation devices 3 provided at the lower right and left of a back side of the garment, respectively, to introduce outside air to thereby generate airflows between the garment 2 and an undergarment or wearer's body and parallelly to the wearer's body; air exit port...

second embodiment

[0084] There will be explained a second embodiment of the present invention with reference to the drawings. The second embodiment is applied to a worksuit having a cooling capacity higher than that of the cooling suit of the first embodiment. The second embodiment has an air blowing capacity of about 20 m3 / H which is two times that of the first embodiment. The second embodiment is differentiated from the first embodiment, because, in the second embodiment: there is adopted a propeller as vanes of each parallel airstream generation device, instead of a vane wheel; there is provided a new air exit portion provided with an air permeation sheet, as an exit of air; and there is provided a fixation belt as fixation means for preventing a large fan from being swung due to a movement of a wearer's body. Other configuration is the same as that in of the first embodiment. Thus, like reference numerals as used in the first embodiment are used to denote elements of the second embodiment having ...

third embodiment

[0092] There will be explained a third embodiment of the present invention. The third embodiment is different from the first embodiment and second embodiment, in that the former includes a fixation belt having not only fans but also an electric-power source (battery), cords and the like, attached thereto. Other points are the same as those in the second embodiment. Thus, like reference numerals as used in the second embodiment are used to denote elements of the third embodiment having the same functions as the second embodiment, and the detailed description thereof will be omitted. FIG. 10A is a schematic view of this embodiment in a state where the fixation belt 160 of this embodiment is developed. The fixation belt 160 of this embodiment has a width larger than a diameter of each fan 3, and has two fans 3, electric power supply cords 32, and an electric-power source 33 detachably attached to the belt. Thus, the fixation belt 160 can be regarded as an item realized by eliminating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com