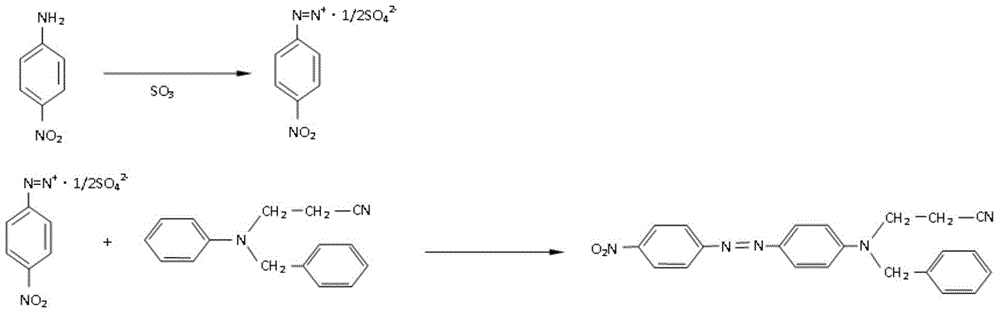

One-pot-method synthesis process for disperse orange 288

A synthesis process, the technology of disperse orange, which is applied in the field of disperse orange 288 one-pot synthesis process, can solve the problems of environmental damage around the pigment factory, restricting the sustainable development of the industry, and high corrosion of equipment, so as to achieve high product yield and less three wastes , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The Disperse Orange 288 prepared in Example 1 is an orange-red powder, the content detected by liquid chromatography is ≥93.2%, and the yield is 92.8%.

[0031] In a word, the preparation method of the present invention takes p-nitroaniline as raw material, adopts sulfur trioxide and sodium nitrite diazotization reaction and one-pot coupling with N-cyanoethyl-N-benzylaniline to obtain the product disperse orange 288, the process is easy to operate, the product yield is high, the purity is high, and the three wastes are less, realizing green and clean production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com