Patents

Literature

44results about How to "Realize green and clean production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

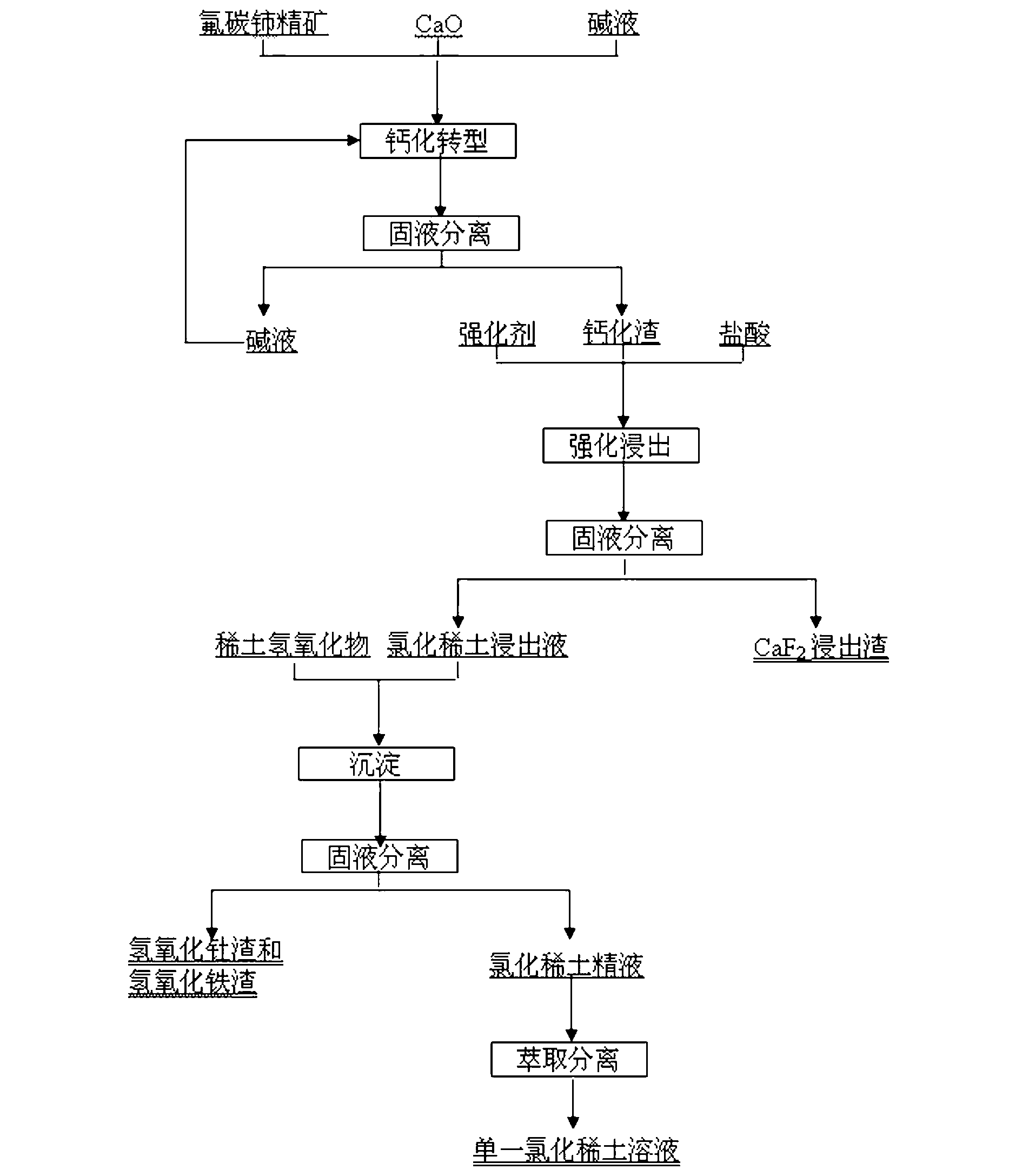

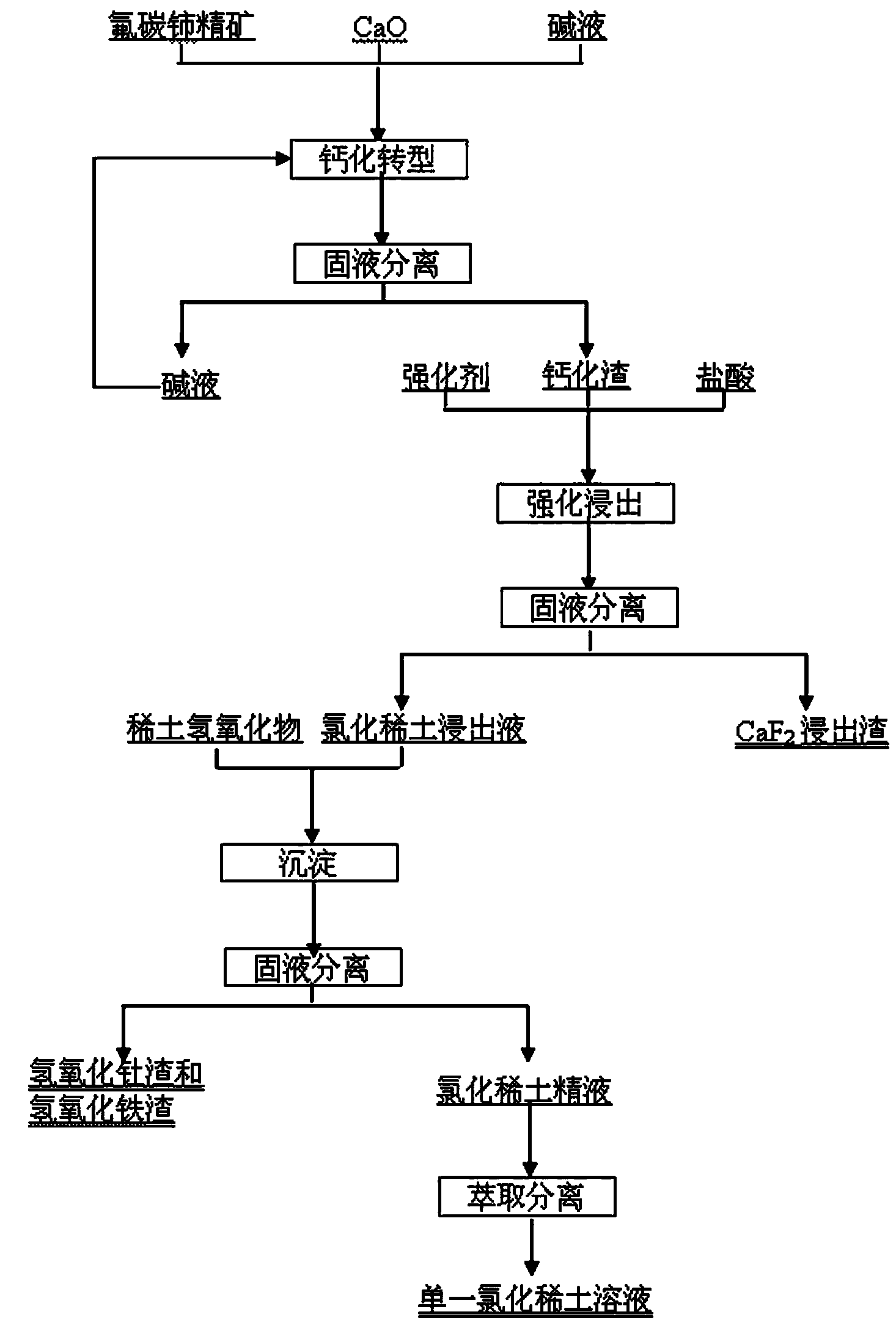

Method for decomposing bastnaesite through calcification transformation-leaching

The invention belongs to the technical field of rare earth metallurgy, and particularly relates to a method for decomposing bastnaesite through calcification transformation-leaching. The method comprises the following the steps of: carrying out activation pretreatment on rare earth ore concentrate, carrying out calcification transformation pretreatment on the activated ore, carrying out acid leaching on transformed slag, extracting rare earth chloride fine liquid to finally obtain a solution with thorium-iron slag and cerium chloride or lanthanum chloride or praseodymium chloride or neodymium trichloride, and efficiently separating valuable elements such as a rare earth element, a fluorine element and a thorium element. According to the method, energy consumption and fuel consumption are reduced, and when the low-temperature baking is carried out below 500 DEG C, only carbonates are decomposed, so that the reaction activity of the rare earth ore concentrate is supplied, and simultaneously the waste of fluorine resources and the emission pollution are avoided; and therefore, the method belongs to a green clean technology.

Owner:NORTHEASTERN UNIV

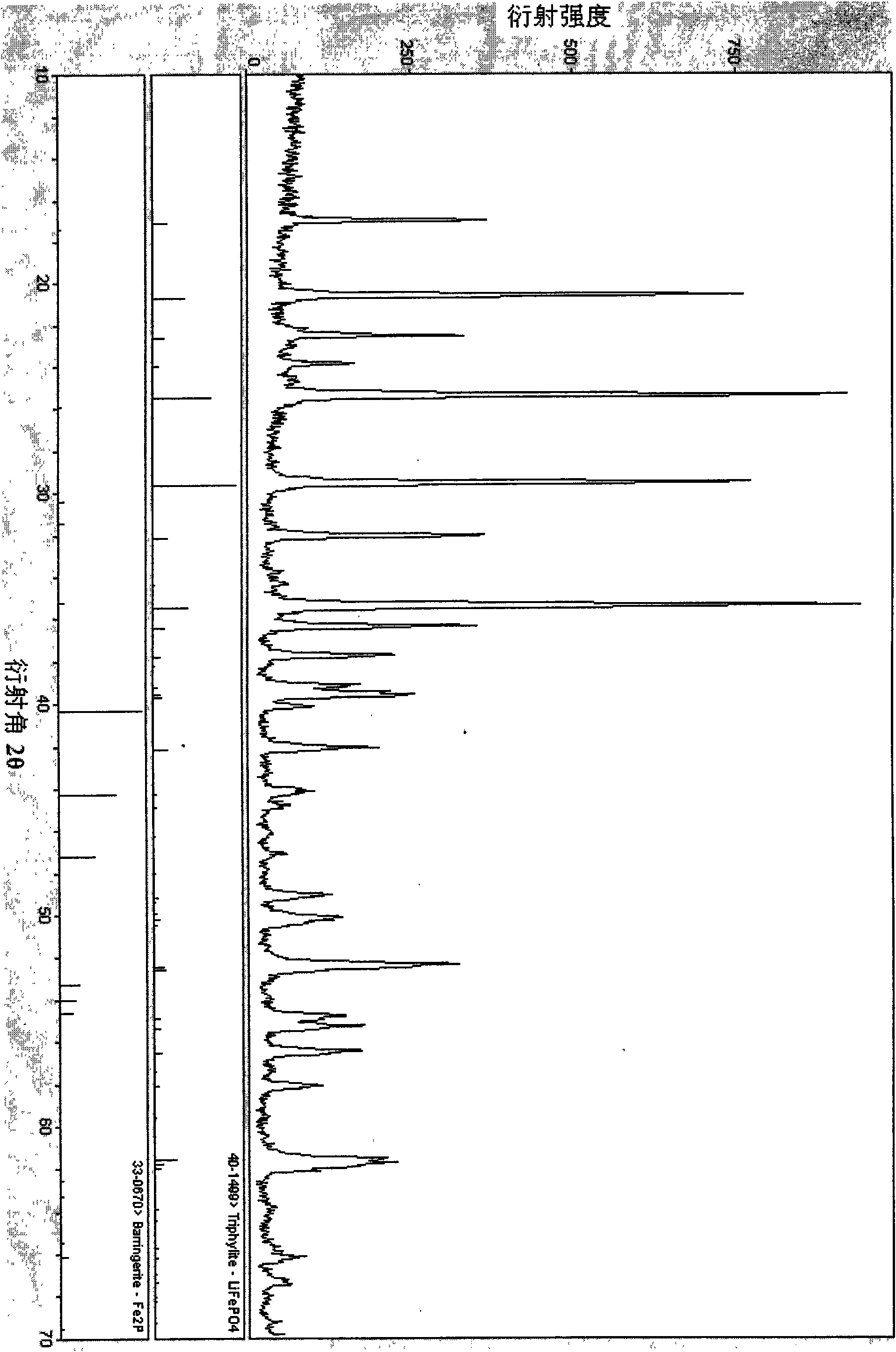

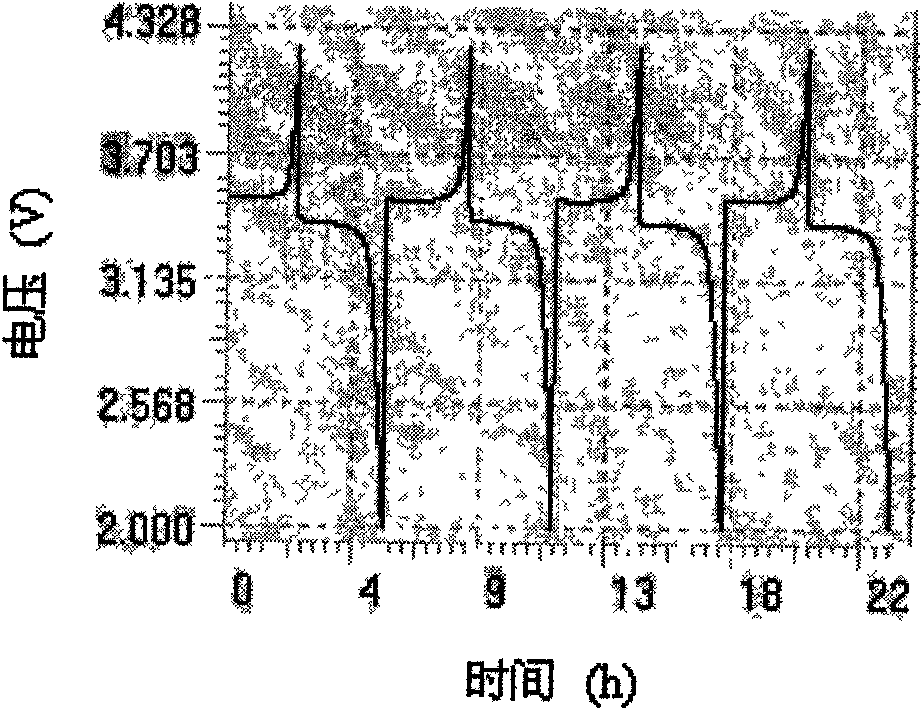

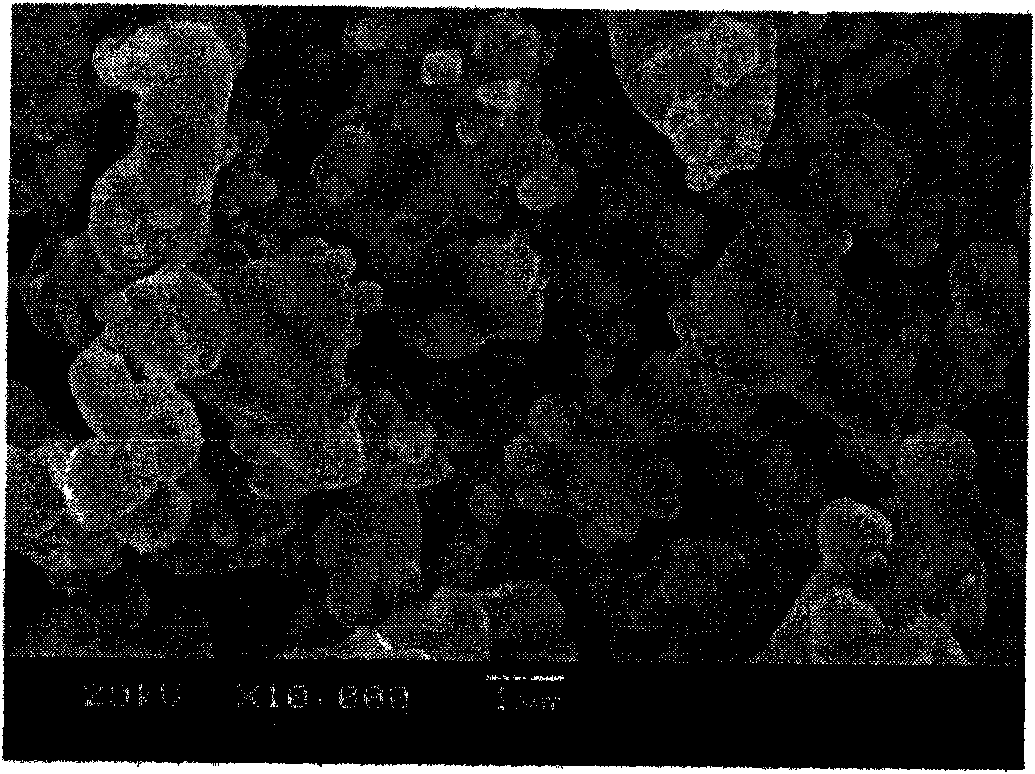

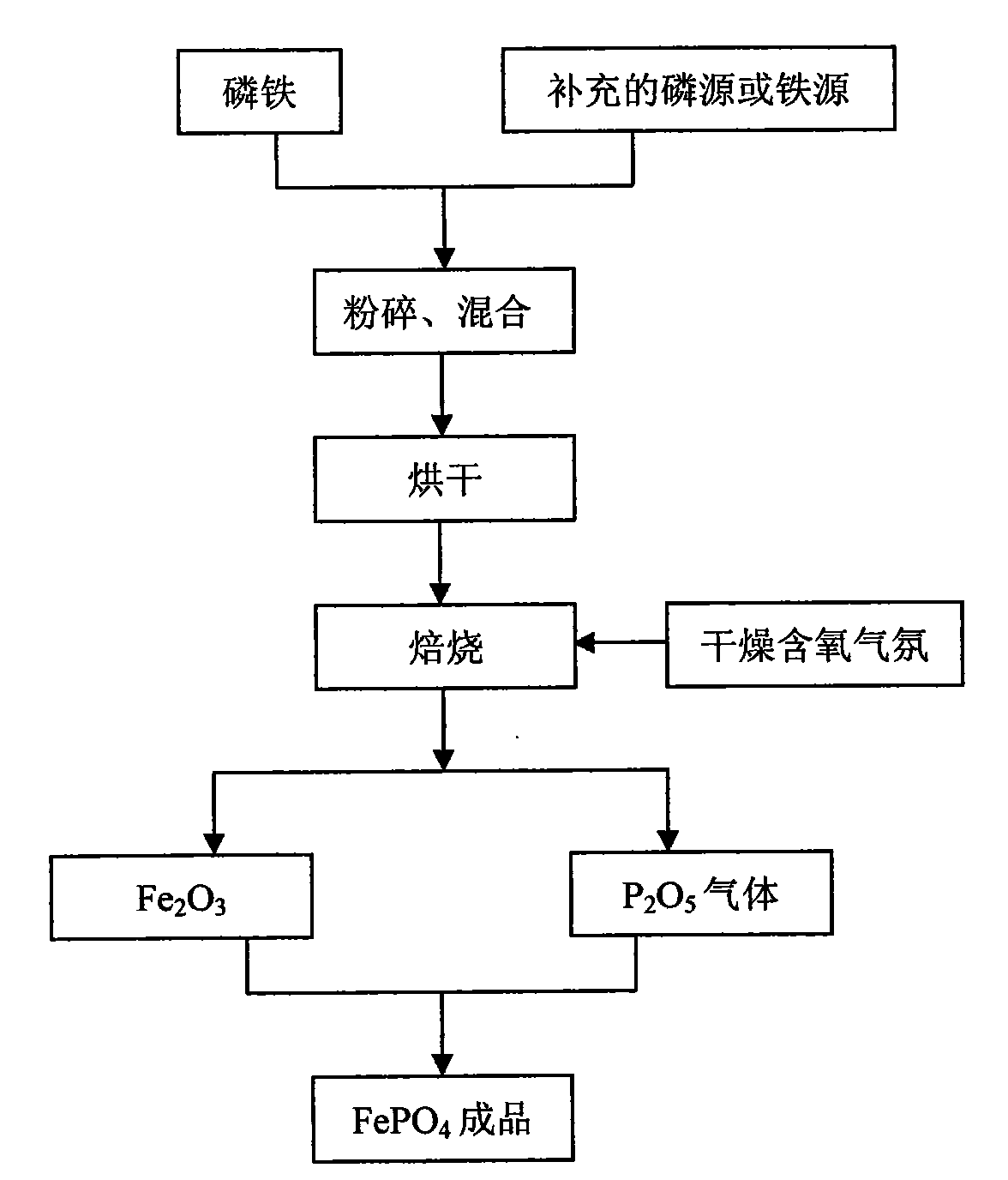

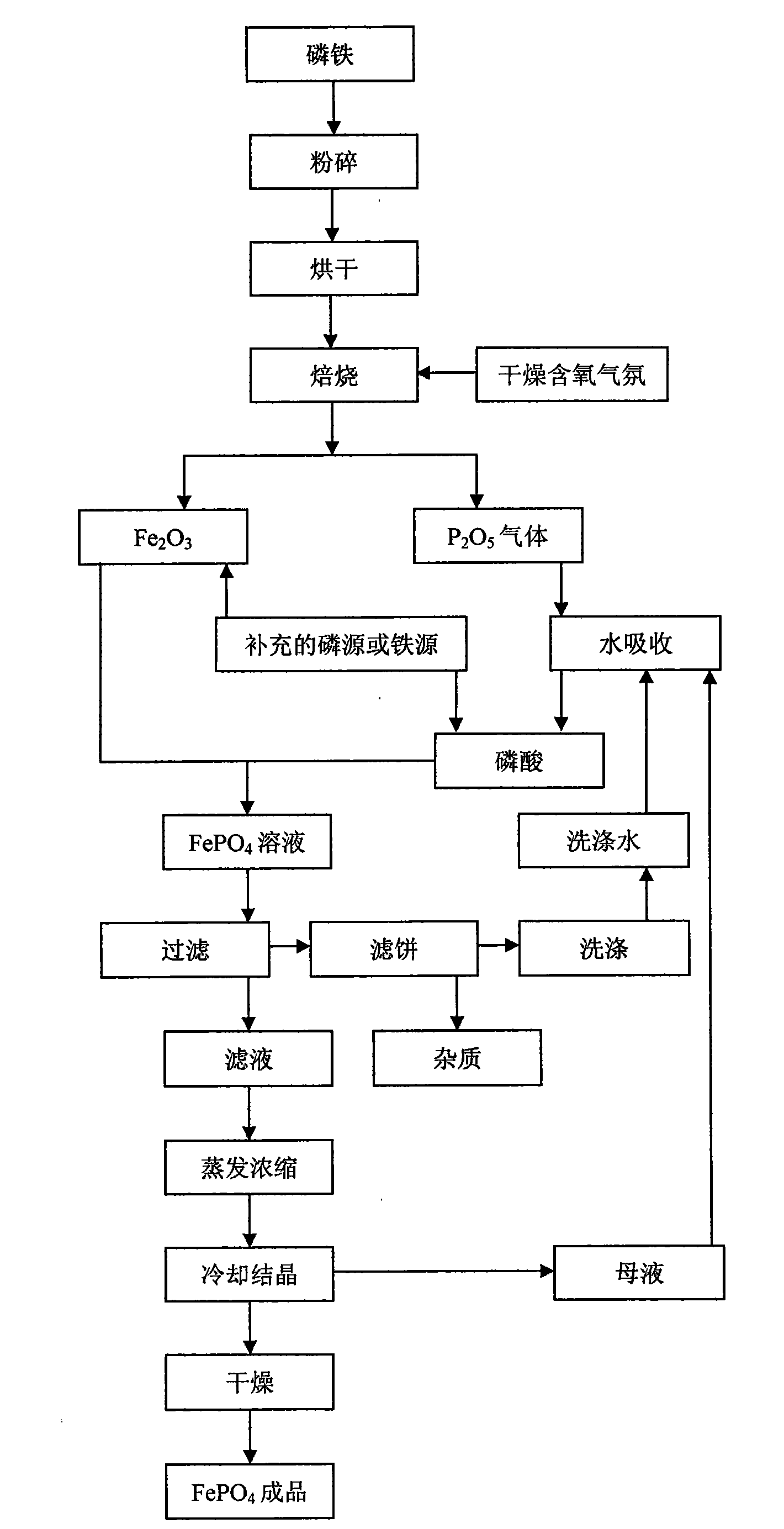

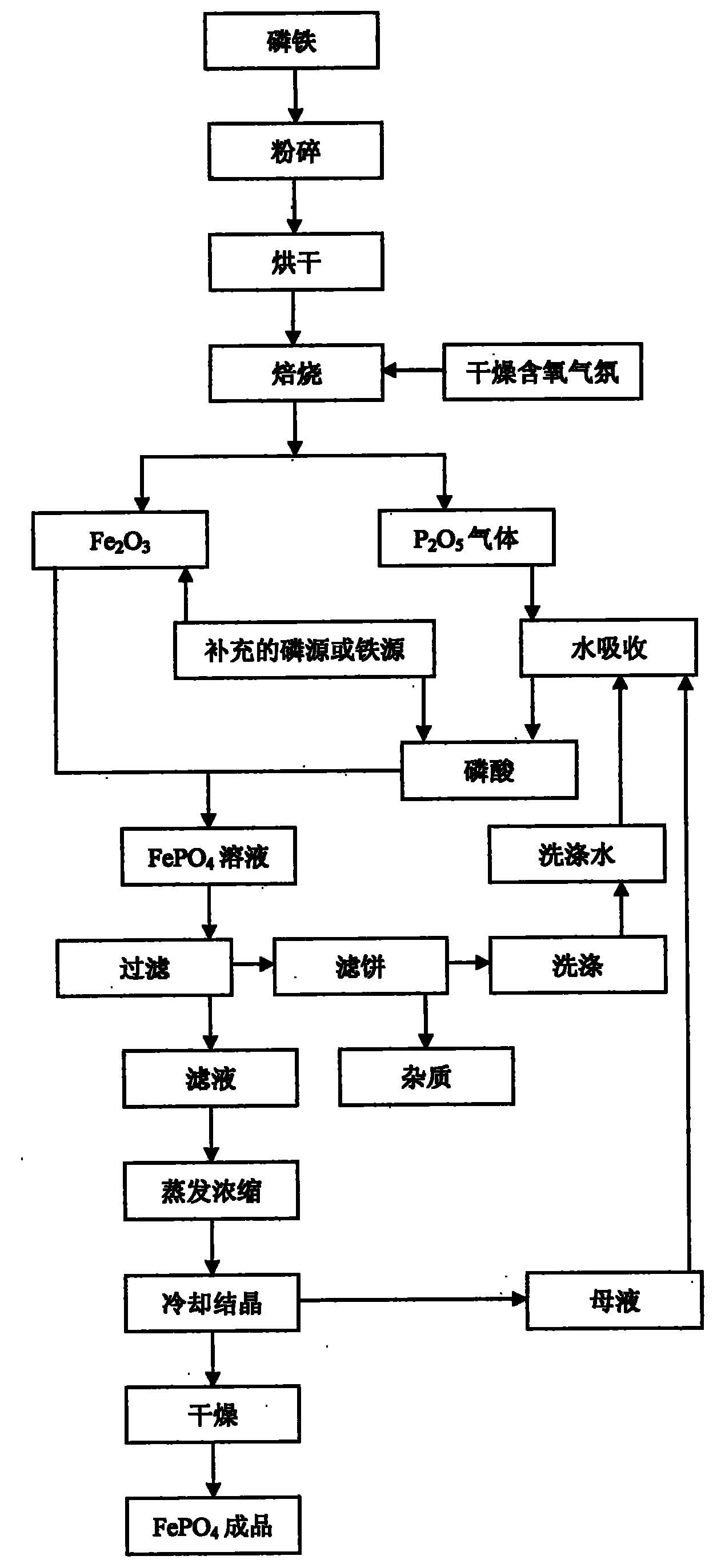

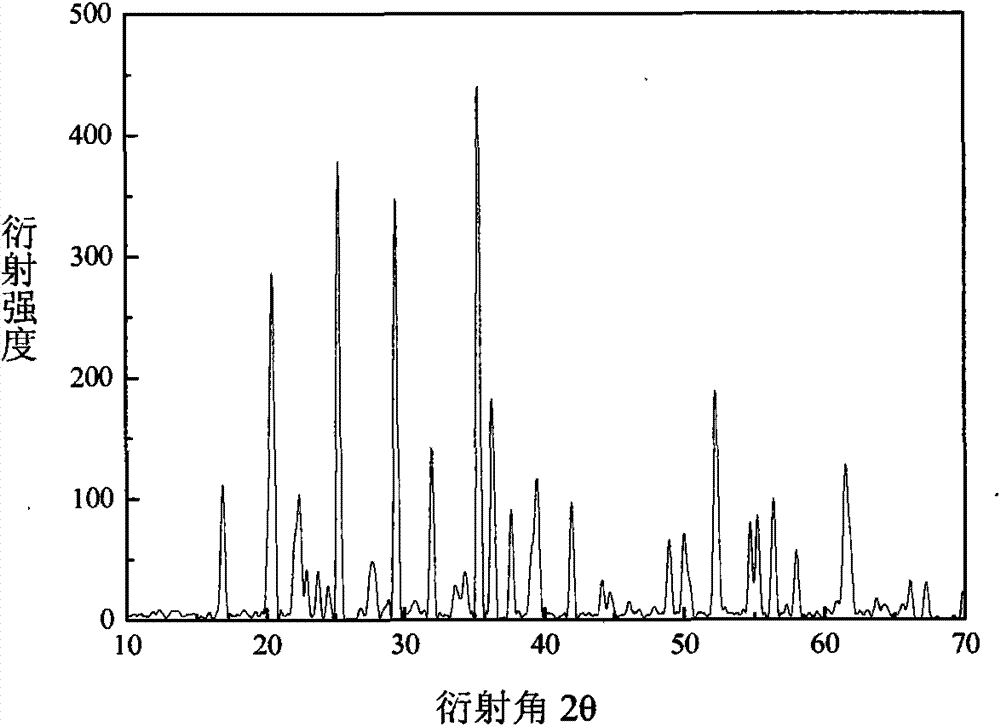

Process for preparing LixFeyPzO4 from ferrophosphorus

InactiveCN101659408AOvercome the problem of difficult ratioReduce or eliminate emissionsPhosphorus compoundsLithiumResource utilization

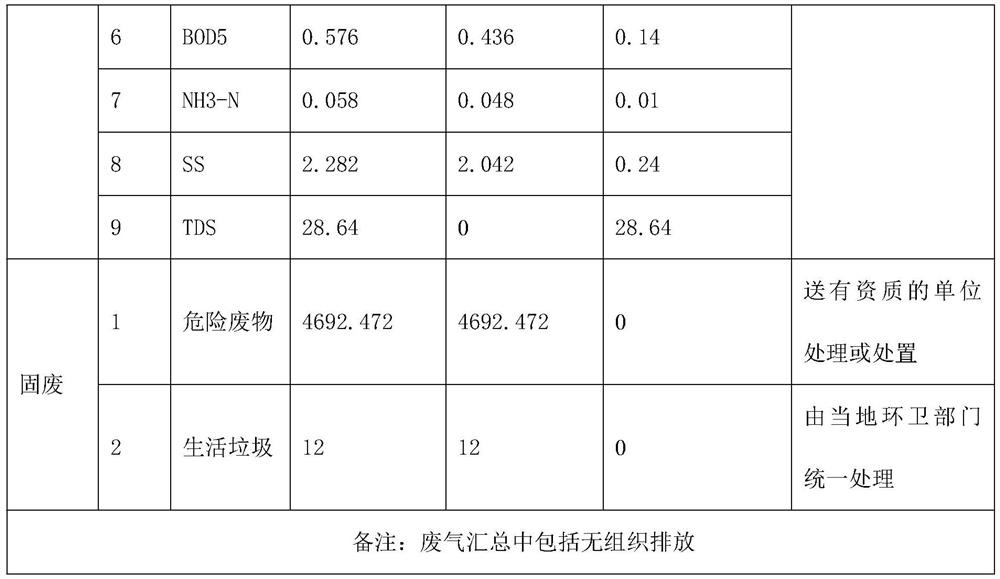

The invention relates to a process for preparing LixFeyPzO4 from ferrophosphorus, especially for preparing LiFePO4, LiFe2 / 3PO4 and Li4 / 7Fe4 / 7P8 / 7O4. A phosphorus source or an iron source which needs supplementing is determined according to the ferrophosphorus and the composition of the LixFeyPzO4 to be prepared. The phosphorus source or the iron source is supplemented according to a mol ratio of 1.0:(0.2-5.0):(0.2-1.5) among total phosphorus elements, total iron elements and total lithium elements. A lithium-containing substance is added and then evenly mixed with the ferrophosphorus. The mixture is then roasted for 0.2-35 hours at the temperature of 400-900 DEG C so as to obtain the LixFeyPzO4. By means of reaction design, raw material combination and byproduct reaction, the process can be a clean production process realizing zero emission. The process adopts the ferrophosphorus as the raw material for preparing the LixFeyPzO4 and has wide raw material source, low cost, high resourceutilization rate and little pollution. The reaction process has relatively low demand on apparatuses. The preparation process is simple, realizes easy oxygen amount control in the reaction process, short production flow, low investment and good benefit, has good application value and is suitable for large-scale, industrial and low-cost preparation of LixFeyPzO4.

Owner:SICHUAN UNIV

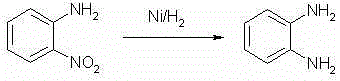

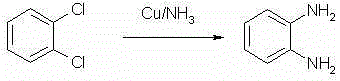

Green synthetic method of preparing o-phenylenediamine by reducing o-nitroaniline

ActiveCN105130821ARealize green and clean productionHigh reaction yieldOrganic compound preparationAmino compound preparationGreen cleaningO-nitroaniline

The invention relates to a green synthetic method of preparing o-phenylenediamine by reducing o-nitroaniline, wherein the method includes following steps: with o-nitroaniline as a substrate, dissolving the o-nitroaniline in water or in a mixed liquid composed of water and a co-solvent, and adding a supported catalyst under a carbon monoxide atmosphere, wherein the supported catalyst includes a supporter and a catalyst body supported thereon, and performing a reaction to prepare the o-phenylenediamine at 30-150 DEG C. In the method, the supported catalyst is used for preparing the o-phenylenediamine through reduction. The catalyst is high in selectivity and reaction yield and is mild in reaction condition. The method is environment-friendly in production system and less in treatment load of waste water, waste gas and solid waste, achieves green and clean production of the o-phenylenediamine, and is suitable for large-scale popularization.

Owner:江阴市华亚化工有限公司

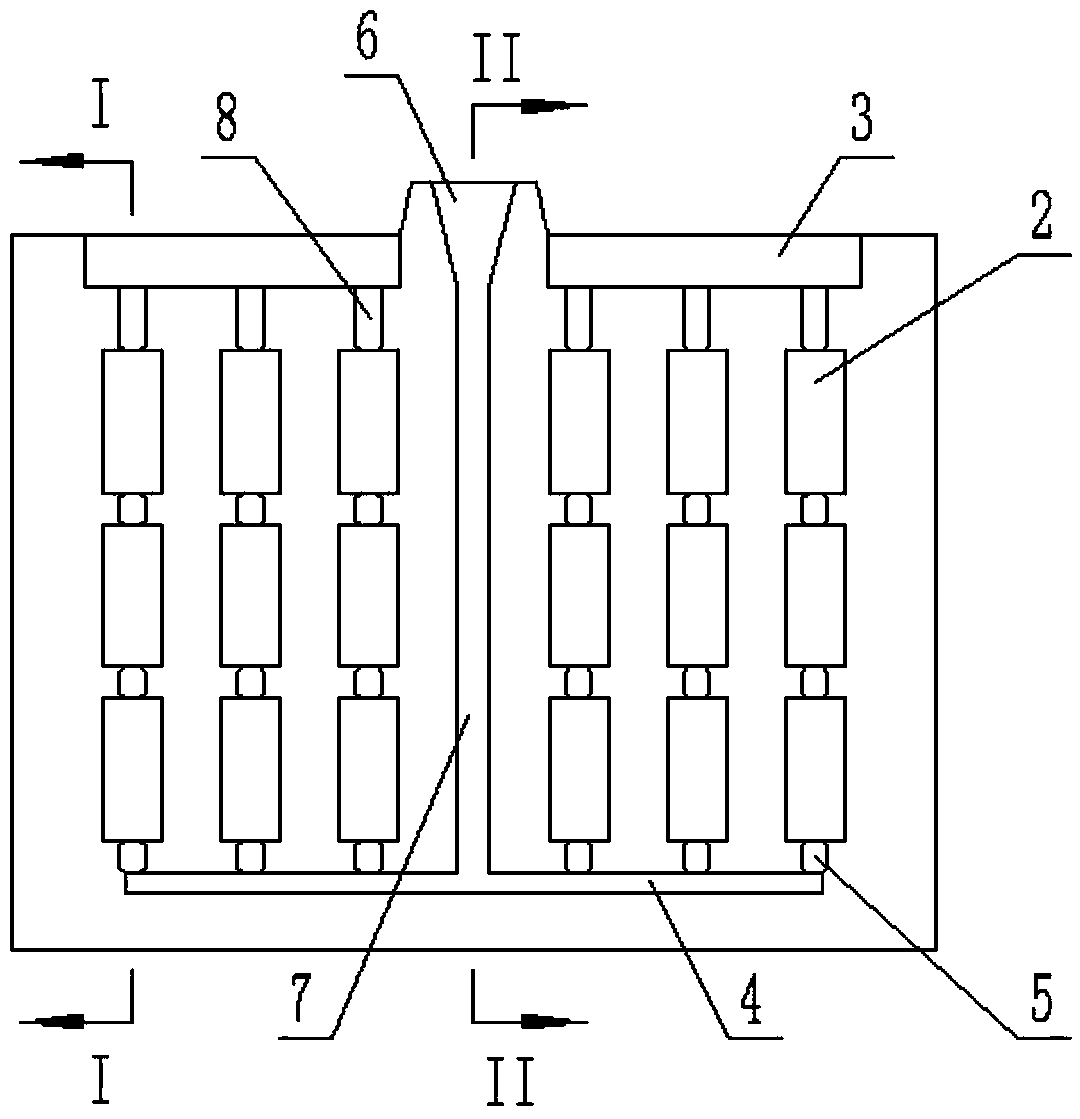

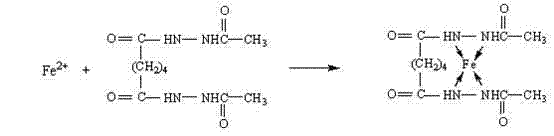

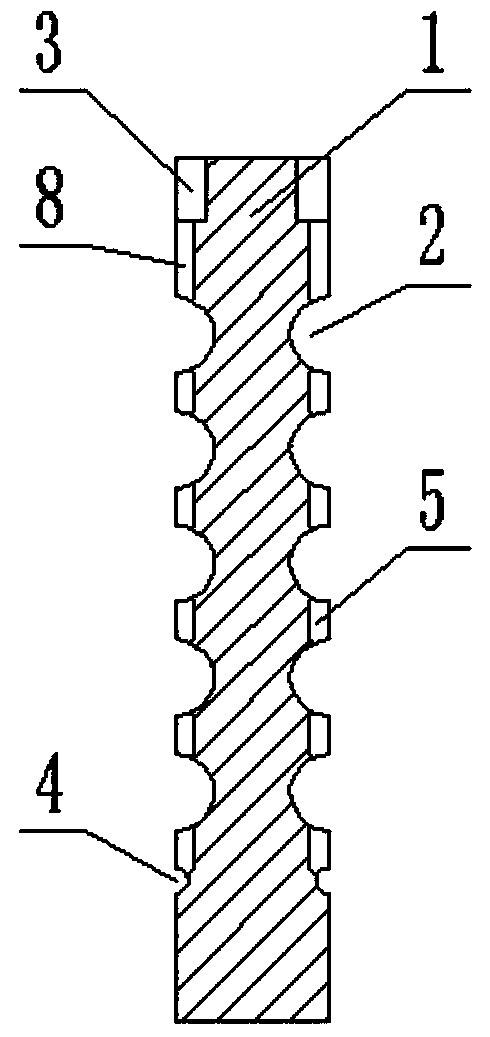

Two-sided casting mold for steel section stack boxes

InactiveCN104028705AReduce usageReduce manufacturing costFoundry mouldsFoundry coresComputer moduleEngineering

The invention discloses a two-sided casting mold for steel section stack boxes. The two-sided casting mold comprises module monomers, wherein a plurality of cavities arranged in line are formed in the front and back side surfaces of the module monomers; ingates are formed in the bottoms of all the cavities; the cavities in the same line are connected through the ingates; straight gates are formed in the middles of the front and back side surfaces of the module monomers; cross gates perpendicular to the straight gates are formed in the bottom ends of the straight gates; and the top ends of the cross gates are communicated with the ingates in the bottoms of the cavities in the lowest line. The cavities, the inner cross gates and the straight gates are formed in the front and back sides of one module monomer, that is, the casting can be finished for two sides; n-1 complete cavities can be formed through stacking n module monomers in production for casting; and compared with traditional 2n module monomers, the usage amount is largely decreased, and the production cost is largely reduced.

Owner:ZUNYI JIUZHI GENERAL MACHINERY

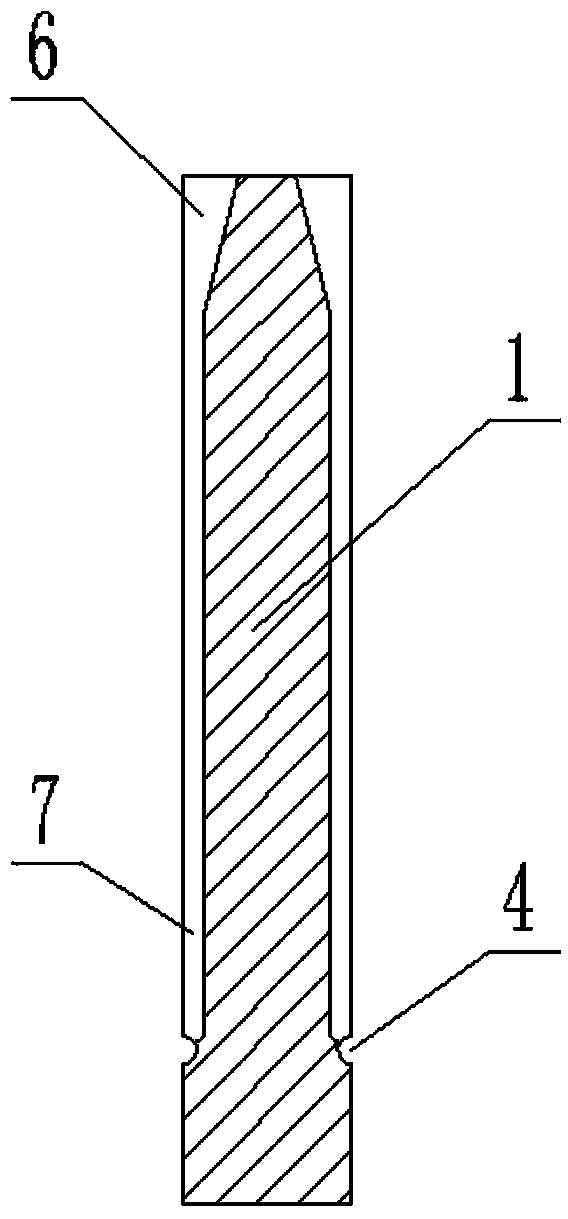

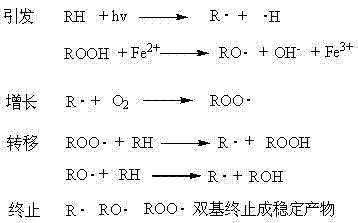

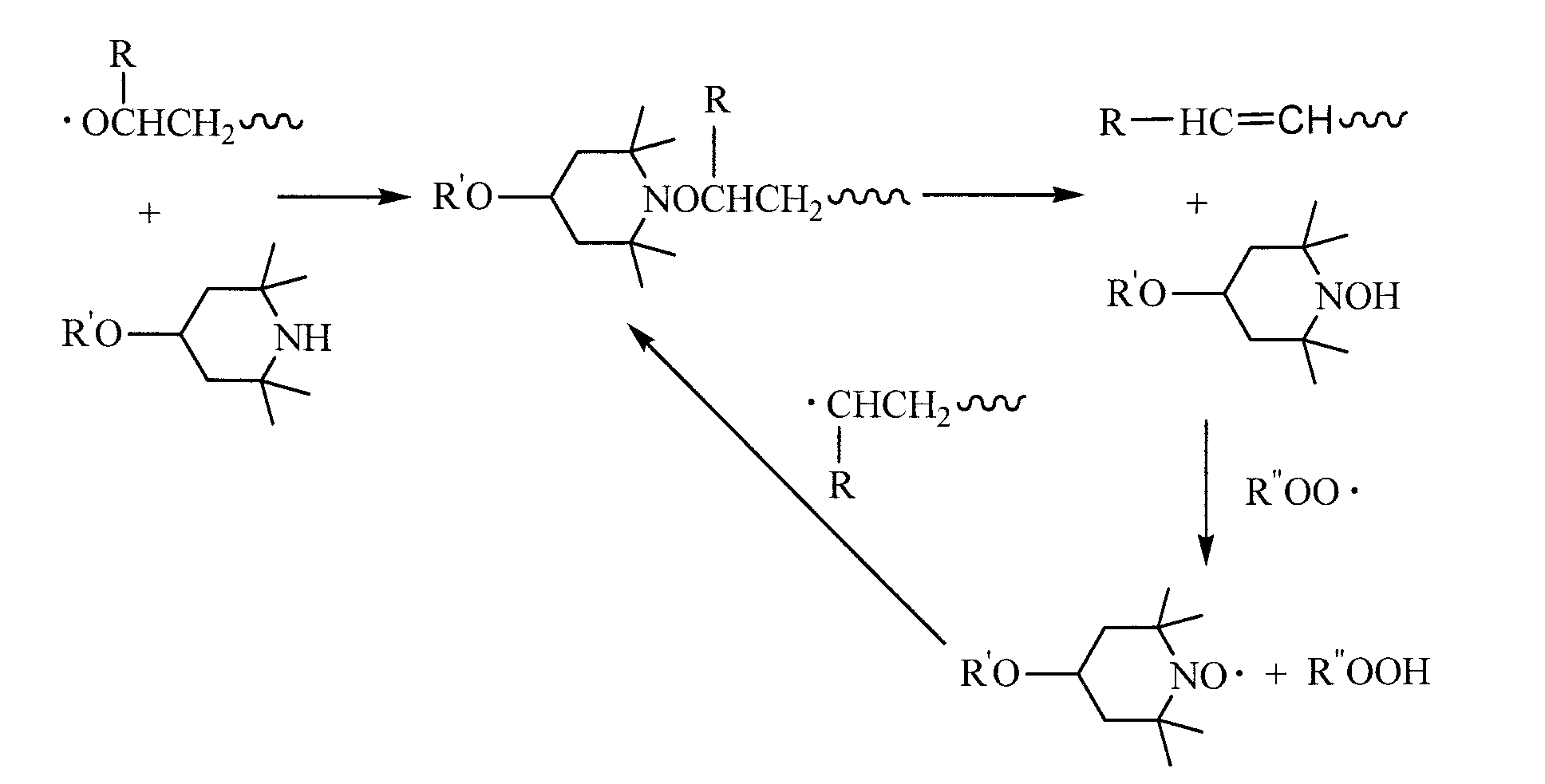

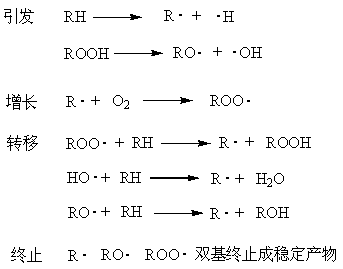

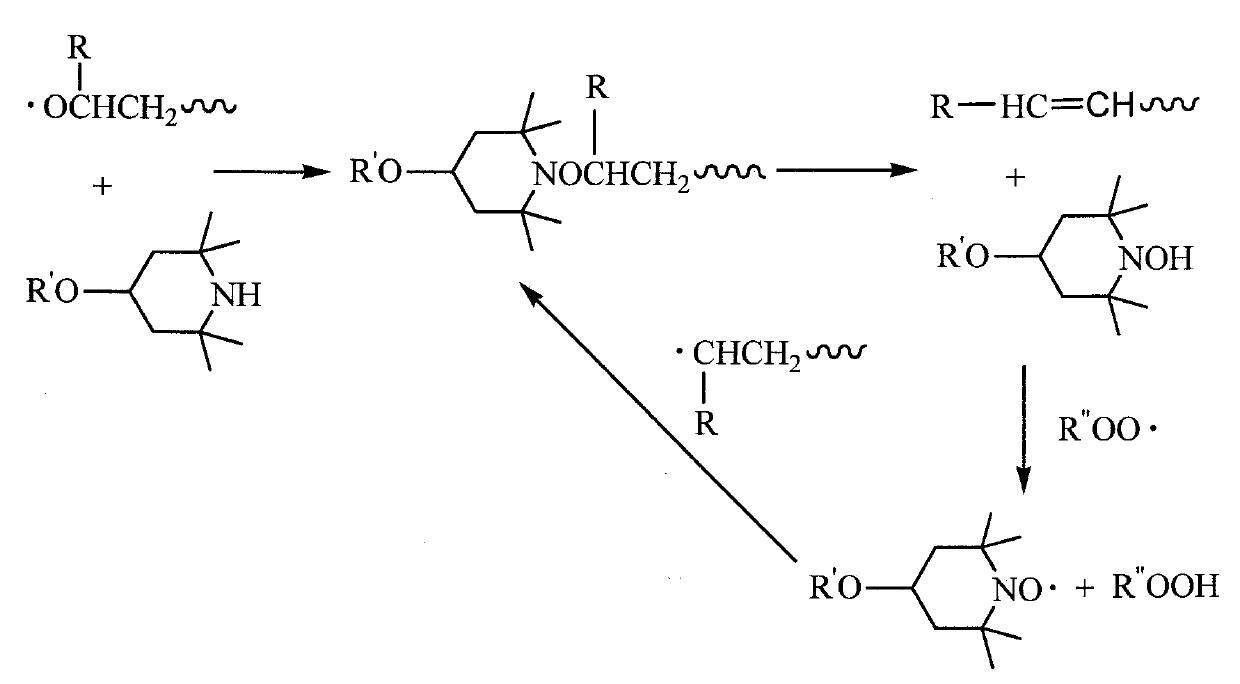

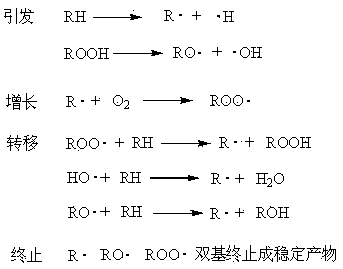

Dust-proof anti-aging black high-gloss ABS (acrylonitrile-butadiene-styrene) alloy and preparation method thereof

The invention relates to a dust-proof anti-aging black high-gloss ABS (acrylonitrile-butadiene-styrene) alloy which comprises the following components in percentage by weight: 48-60% of ABS resin, 22-30% of PMMA (polymethyl methacrylate) resin, 12-18% of compatilizer and 4-6% of dust-proof anti-aging high-gloss black master batch. The anti-aging agent and pigment carbon black in the dust-proof anti-aging high-gloss black master batch constitute an anti-aging system; and the carbon nanotubes, pigment carbon black and lauryl amine polyoxyethylene (2) ether constitute a dust-proof system, thereby effectively preventing aging of ABS, and satisfying the requirements of the high-gloss ABS alloy for coloration, color protection, gloss protection and dust-proofing. The preparation method comprises the following steps: preparing the dust-proof anti-aging high-gloss black master batch, and preparing the dust-proof anti-aging black high-gloss ABS alloy by using the master batch. The multifunctional master batch technique provided by the invention eliminates environmental pollution of dust, implements green clean production of the ABS resin and alloy, has the characteristics of low consumption of carrier resin and lubricating dispersant and low consumption of master batch processing energy and processing assistants, and can be widely applicable to formation processing of the ABS and alloy.

Owner:NANHUA UNIV +1

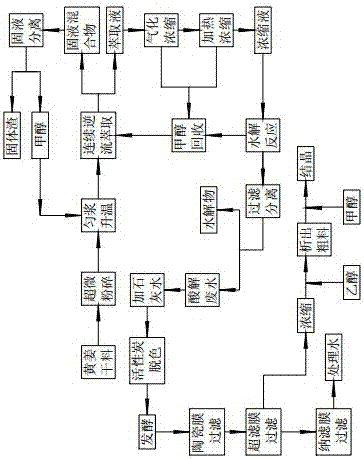

Method for intensively extracting polysaccharides from rice culture medium for cordyceps militaris

The invention discloses a method for intensively extracting polysaccharides from a rice culture medium for cordyceps militaris. The method comprises the following steps: carrying out superfine crushing, ultrahigh pressure treatment and ultrasonic intensified flash extraction on the cordyceps militaris culture medium, adding amylase to an extract solution to realize enzymosis, concentrating enzymatic hydrolysate, adding polyethylene glycol, sufficiently stirring and dissolving, standing over night, centrifuging, washing precipitate with edible alcohol, adding hot water to dissolve, removing insoluble substances, and drying to obtain the polysaccharides. According to the method disclosed by the invention, configuration guiding of a process for promoting effective dissolution of polysaccharides is highlighted according to the resource advantage of the rice culture medium for cordyceps militaris, the clean production ideal is embodied by technical model selection, by adopting novel physical and biological integrated means, polysaccharide recovery technical output characterized by high speed, high efficiency, time saving, low consumption and environmental friendliness is realized, and the edible safety of the extracted polysaccharides is ensured from the production link.

Owner:武汉添年科技有限公司

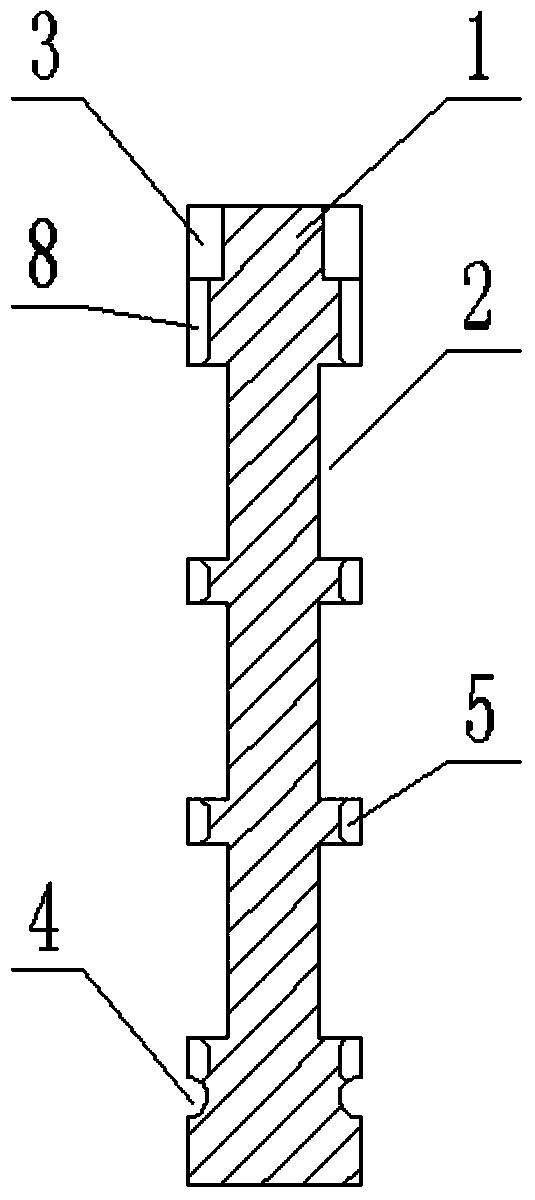

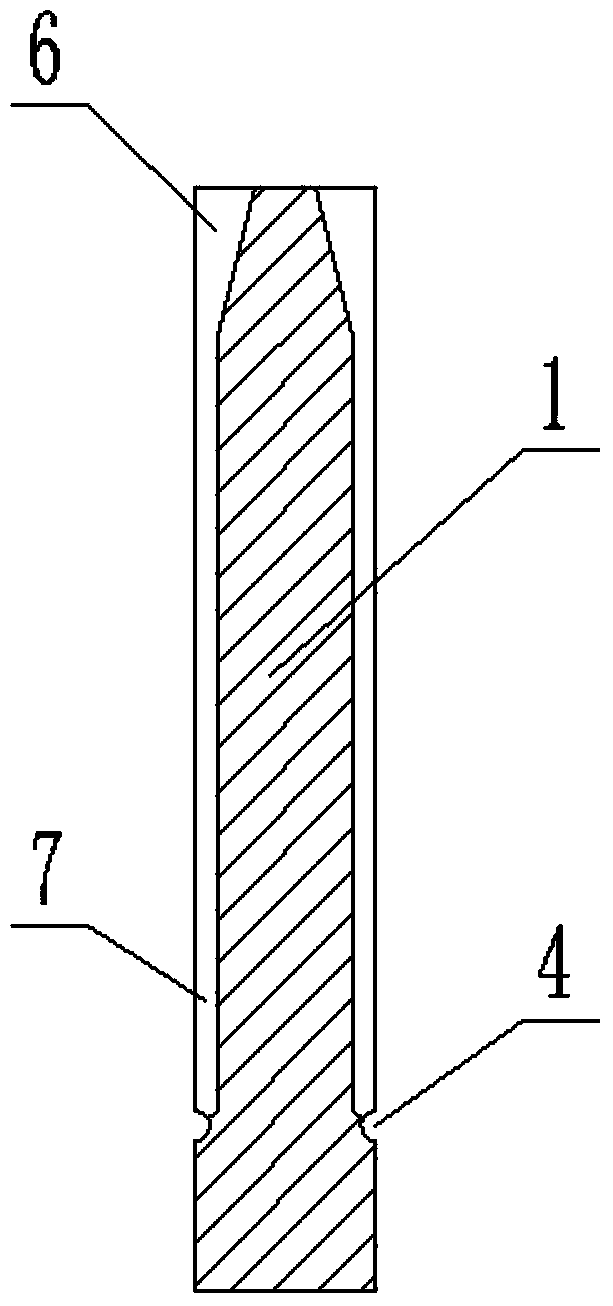

Two-sided casting mold of steel ball stack boxes

InactiveCN104028703AReduce usageReduce manufacturing costFoundry mouldsFoundry coresComputer moduleSteel ball

The invention discloses a two-sided casting mold of steel ball stack boxes. The two-sided casting mold comprises module monomers, wherein a plurality of half cavities arranged in lines are formed in the front and back side surfaces of the module monomers; the half cavities in the same lines are connected through ingates; straight gates are formed in the middles of the front and back side surfaces of the module monomers; cross gates perpendicular to the straight gates are formed in the bottom ends of the straight gates; and the top ends of the cross gates are communicated with the ingates in the bottoms of the cavities. The cavities, the inner cross gates and the straight gates are formed in the front and back sides of one module monomer, that is, the two sides can be cast; and the plurality of module monomers are stacked in the production to form the plurality of complete cavities for casting, so that the usage amount of the module monomers is largely decreased, and the production cost is largely reduced.

Owner:ZUNYI JIUZHI GENERAL MACHINERY

Chromium-containing waste water treating and chromium recycling method

InactiveCN108585339AEnable recyclingSolve pollutionWater contaminantsMultistage water/sewage treatmentChromium freeSludge

The invention discloses a chromium-containing waste water treating and chromium recycling method, and belongs to the field of waste water treatment and comprehensive utilization. The method includes the steps: adjusting chromium-containing waste water oxidation-reduction conditions and a pH (potential of hydrogen) value to be 4-11, and enabling chromium to transform into a chromium hydroxide colloid to precipitate; adding inorganic magnetic particles and organic binding agents according to the proportion of 1 / 10-10 times of the weight of chromium in chromium-containing waste water; sufficiently stirring and mixing mixture, and separating the mixture by a magnetic separation device to obtain magnetic particle-chromium hydroxide compounds and chromium-free or low-chromium-containing common waste water; soaking the magnetic particle-chromium hydroxide compounds into strong-alkali aqueous solution to dissolve out chromium ions, and performing magnetic separation to obtain magnetic particles and chromium salt solution; enabling the magnetic particles to be recycled, and crystallizing the chromium salt solution to obtain chromium salt products. According to the method, chromium can be directly extracted and separated from the chromium-containing waste water, the chromium-containing waste water is changed into chromium-free or low-chromium-containing common waste water, the waste water generated in subsequent chemical flocculation and precipitation treatment and chromium content in sludge can reach national emission standards, and chromium resources can further be recycled.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing pig feed rich in DHA through schizochytrium limacinum fermentation waste liquid

The invention discloses a method for preparing a DHA-containing pig feed through schizochytrium limacinum fermentation waste liquid. The method comprises the following steps: regulating the pH value of the schizochytrium limacinum fermentation waste liquid to be 6.5-7.5, and regulating the temperature to be 30-40 DEG C; according to a formula, crushing a pig feed comprising 55-75% of corn, 8-15% of wheat bran, 10-20% of soybean meal, 3-9% of rapeseed meal, 0.5-1.0% of calcium hydrophosphate, 0.8-1.3% of stone powder and 0.05-0.2% of L-lysine according to weight percentage, and mixing to obtain mixed powder; adding the pre-processed schizochytrium limacinum fermentation waste liquid into the mixed powder, stirring for 0.5-2 hours to obtain the DHA-containing pig feed, wherein the adding amount of the pre-processed schizochytrium limacinum fermentation waste liquid into each ton of the mixed powder is 10-30% v / w of the fed materials. According the method, the pig feed rich in DHA is produced through the schizochytrium limacinum fermentation waste liquid, so that a pollution problem caused by waste liquid discharge is solved, and the purpose of water conservation is realized.

Owner:QINGDAO XUNON BIOLOGICAL ENG

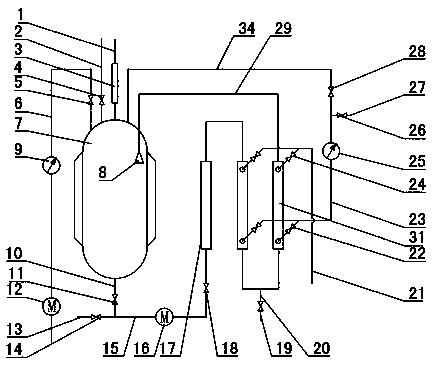

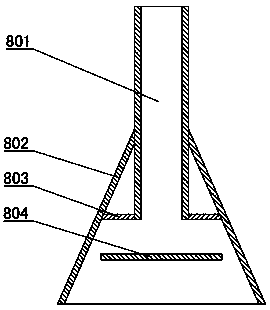

Method for reducing acid content of dimethyldichlorosilane hydrolysate

ActiveCN106397474AProportionally largeRealize green and clean productionSilicon organic compoundsHydrolysateChloride

Belonging to the field of chemical engineering, the invention relates to a method for reducing the acid content of a dimethyldichlorosilane hydrolysate. The method includes the steps of: (a) subjecting the dimethyldichlorosilane hydrolysate and a calcium chloride aqueous solution to countercurrent mixing and washing; (b) then continuously contacting the hydrolysate with a hydrochloric acid mass fraction gradually reduced aqueous phase, and performing full washing. On the basis of washing, the method provided by the invention introduces calcium chloride to increase the proportion of the hydrolysate and water, realizes rapid layering of the two, avoids emulsification phenomenon during washing, and improves the washing and acid removing effects. In addition, the method provided by the invention significantly reduces the consumption of washing water and lowers the production load, and the calcium chloride can be recycled, thus achieving green and clean production.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

Dustproof, antibacterial and ageing-resistant color master batch of polyethylene (PE) plastic slide, and preparation method of color master batch

The invention relates to a dustproof, antibacterial and ageing-resistant multifunctional color master batch of a polyethylene (PE) plastic slide. The dustproof, antibacterial and ageing-resistant multifunctional color master batch of the PE plastic slide comprises the following components in percentage by weight: 12.5 to 17.5 percent of dust preventive, 15.0 to 20.0 percent of antibacterial agent, 5.0 to 10.0 percent of anti-ageing agent, 17.5 to 22.5 percent of coloring agent, 7.5 to 12.5 percent of dispersing lubricant, 0.5 to 2.0 percent of compatilizer and 25.0 to 35.0 percent of carrier resin. A preparation method of the color master batch comprises the following steps of: adding the dust preventive, the antibacterial agent, the anti-ageing agent, the coloring agent, the dispersing lubricant and the carrier resin into a high-speed mixer and mixing for 10 to 20 minutes; adding the dust preventive and the compatilizer and stirring for 5 to 10 minutes; adding the mixed materials into a double-screw extruder and extruding at 140 to 150 DEG C; and cooling, drying, dicing and packaging to prepare the required master batch. The dustproof, antibacterial and ageing-resistant multifunctional color master batch can eliminate environmental pollution caused by dust in a downstream PE plastic forming process and realizes environment-friendly and clean production of the PE plastic. The dustproof, antibacterial and ageing-resistant multifunctional color master batch has the characteristics of small using amount of the carrier resin and the dispersing lubricant and low master batching forming energy and antioxidant consumption, and can be widely applied to coloring of the PE plastic.

Owner:中山市铁鹰塑胶有限公司 +1

Green and clean preparation method of vanadium compound

ActiveCN106892455AAvoid pollutionGreen Clean ProductionVanadium compounds preparationWater/sewage treatment by flocculation/precipitationIonCarbon black

The invention provides a green and clean preparation method of a vanadium compound. The preparation method comprises the following steps of: crushing and ball-milling raw materials; then adding a vanadium element converter or a barium compound; leaching a fired product with clean water; adsorbing and enriching vanadium by using an ion exchange resin, and performing purification to remove barium and impurities; performing counter-extraction to extract vanadium by using a strong alkaline solution to generate a NaVO4 solution and removing other metal ions or impurities which are not dissolved in alkali; adding an ammonium compound to generate ammonium metavanadate and washing the ammonium metavanadate with deionized water or distilled water and drying the same; adding a phosphate diester anti-precipitator, and performing filter pressing and packaging heavy metals; and adding white carbon black of superfine powder into the solution, wherein ammonia and nitrogen are adsorbed in the white carbon black, and the heavy metals are packaged after filter pressing. The method provided by the invention can effectively eliminate original impurities in the raw materials and other impurities generated in the treatment process, and can make full of vanadium-settling wastewater while fully extracting the vanadium compound, so that green and clean production in the production process is realized.

Owner:深圳力合通科技有限公司

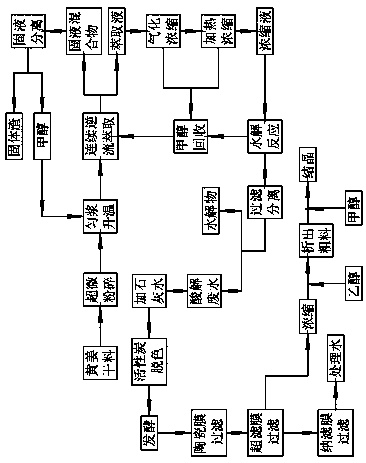

Process for producing saponin and rhamnose from turmeric

ActiveCN107417763ARealize green and clean productionHigh yieldSugar derivativesSteroidsAlcoholHydrolysate

A process for producing saponin and rhamnose from turmeric belongs to the technical field of saponin extraction. The method comprises the following steps of: (1) pulverizing a dried turmeric material; (2) mixing the sieved material with low molecular alcohol and stirring into homogenate; (3) heating the homogenate and then sending into a ceramic membrane extraction apparatus for extraction; (4) adding acid liquor into the concentrated mixed liquid for hydrolysis, filter pressing the solid-liquid mixture after hydrolysis, and drying to obtain a hydrolyzate; (5) mixing the hydrolyzate with petroleum ether, sending into the ceramic membrane extraction apparatus for extraction, performing crystallization separation on the extracted mixed liquid to obtain a saponin crystal substance; (6) adding the acid hydrolysis waste water in step (4) into lime water for neutralization, and then decolorizing, separating, concentrating and crystallizing to obtain the rhamnose. The process for producing saponin and rhamnose from turmeric achieves the clean production of the saponin, the acid hydrolysis waste water generated during production is less than 5% of a traditional process, and the yield of saponin is improved by 30% or above.

Owner:刘玉通

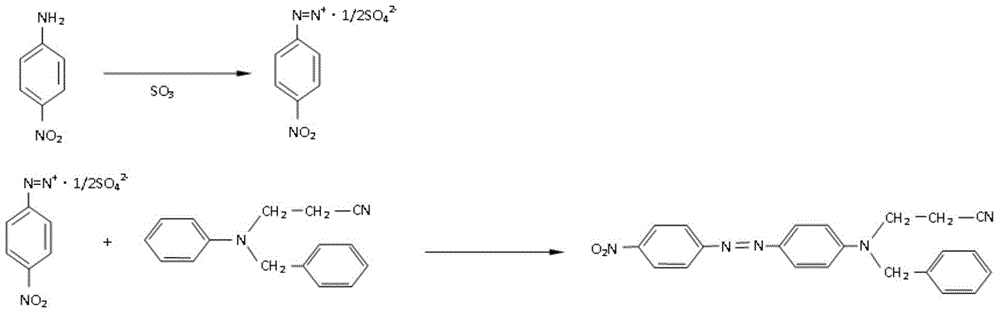

One-pot-method synthesis process for disperse orange 288

The invention relates to a one-pot-method synthesis process for disperse orange 288. The synthesis process comprises the following specific steps: (1) carrying out diazotization: adding p-nitroaniline into a proper volume of water, introducing a certain volume of sulfur trioxide gas into the water, carrying out pulping, adding a proper volume of ice into the pulp so as to cool the pulp to a temperature below 0 DEG C, rapidly adding a proper volume of 30% (mass percent) sodium nitrite solution into the cooled pulp, carrying out heat preservation, carrying out a test by adopting potassium iodide test paper (a reaction ends when the test paper becomes blue), adding a proper volume of aminosulfonic acid into the reacted solution so as to remove superfluous sodium nitrite, and adding a certain volume of OP-10 and Peregal O into the reacted solution; and (2) carrying out coupling. The synthesis process has the beneficial effects that the product, i.e., the disperse orange 288 is prepared through taking p-nitroaniline as a raw material, subjecting sulfur trioxide and sodium nitrite to a diazotization reaction and carrying out one-pot-method coupling with N-cyanoethyl-N-benzylaniline, the process operation is simple and convenient, the product is high in yield and high in purity, and the volume of waste gases, waste water and waste residues is small, so that environment-friendly and clean production is achieved.

Owner:浙江永合新材料科技有限公司

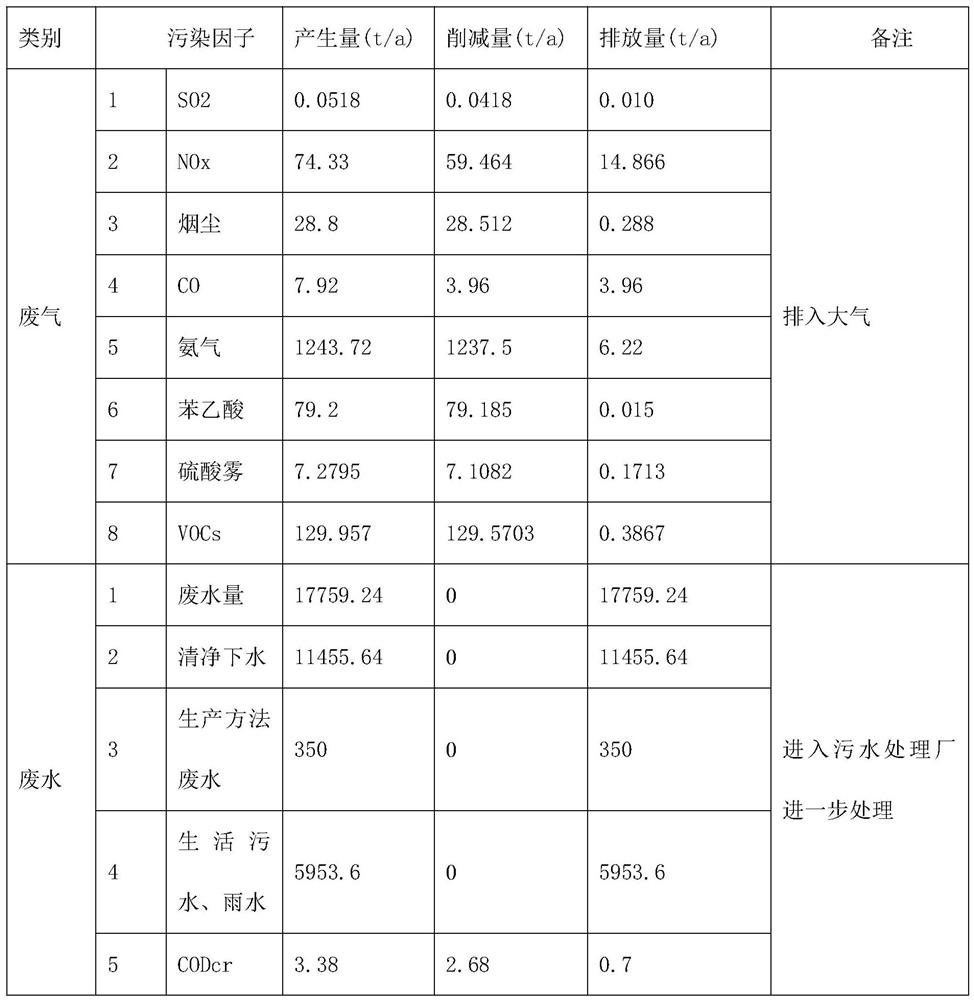

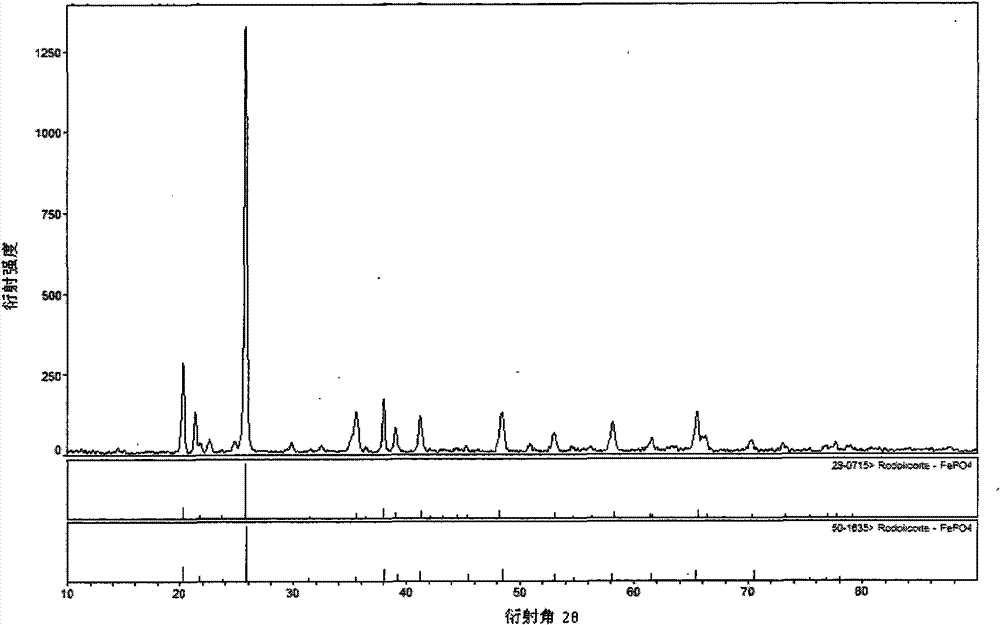

Method for preparing iron phosphate from ferrophosphorus

InactiveCN101659406BOvercome the problem of difficult ratioWide variety of sourcesPhosphorus compoundsResource utilizationLow demand

The invention relates to a method for preparing iron phosphate from ferrophosphorus. The ferrophosphorus is used as a part or the whole of a phosphorus source and an iron source for preparing the iron phosphate. The phosphorus source or the iron source is supplemented according to a mol ratio of (0.8-1.2):1.0 between total phosphorus elements and total iron elements. The ferrophosphorus is roasted in a dry and oxygen-containing atmosphere. The iron phosphate product is obtained by means of dry or wet oxidation product reaction. The method adopts the ferrophosphorus as the raw material for preparing the iron phosphate, makes full use of elements in the ferrophosphorus and creates a novel preparing process of iron phosphate. In addition, as the reaction process can be used for weakening or eliminating the influence of impurity elements in the ferrophosphorus on the iron phosphate product, the method indirectly purifies the ferrophosphorus and eliminates the influence of the impurities in the ferrophosphorus and the problem of severe corrosion caused by the existence of water during the roasting of ferrophosphorus. The reaction process has relatively low demand on apparatuses. The preparing method has simple process, short production flow and low production cost, is clean and environment-friendly, realizes high resource utilization rate, low investment and good benefit and is suitable for large-scale, industrial, low-cost and clean preparation of iron phosphate.

Owner:SICHUAN UNIV

Application of metal catalysts to catalyze the method for synthesizing two (dimethylaminoethyl) ethers

ActiveCN105837457BSolve pollutionRealize green and clean productionMolecular sieve catalystsOrganic compound preparationDistillationMetal catalyst

Owner:HEBEI HUAMAO WEIYE TECH CO LTD

Method for preparing epoxy fatty acid glycol ester by microwave method

InactiveCN105481800AShort reaction timeImprove production efficiencyOrganic chemistryEpoxyMicrowave method

The invention relates to a method for preparing epoxy fatty acid glycol ester by a microwave method. The method is characterized in that in a microwave reactor, 100 parts by weight of epoxy fatty acid methylester and 15 to 50 parts by weight of dihydric alcohol are mixed in a microwave reactor; N2 is introduced; the microwave power and the reaction time are regulated; the temperature of steamed-out gas is controlled not to exceed 150 DEG C; the reaction stops when no gas is steamed out; the epoxy fatty acid glycol ester is obtained. The microwave reactor is used for performing ester exchange reaction; the reaction time is short; the preparation efficiency is high; the reaction which cannot be performed or which is difficult to carry out under the conventional backflow condition is performed under the microwave radiation condition. When the epoxy fatty acid glycol ester prepared by the method is used, the molecular weight of an epoxy fatty acid plasticizer is increased; the extraction-resistant and volatilization-resistant performance of the epoxy fatty acid plasticizer in a PVC (polyvinyl chloride) product can be greatly improved.

Owner:QUANZHOU NAISI MATERIAL TECH

Phenylacetic acid production method

PendingCN113354528ALow costImprove product qualityChemical recyclingCarboxylic preparation from carbon monoxide reactionPtru catalystPhenylacetic acid

The invention discloses a phenylacetic acid production method, which belongs to the technical field of phenylacetic acid production. The phenylacetic acid production method comprises the following steps of raw material preparation, raw material mixing, synthesis reaction, oil-water phase separation, acidification reaction, crystallization, centrifugation, drying, MVR, condensed water purification and toluene rectification. According to the method, sodium cyanide is replaced with carbon monoxide, two highly toxic materials, namely sodium cyanide and benzyl cyanide, in the production process are reduced, the cost is lower, the product quality is better, and the method can be applied to wider fields due to the fact that the method does not contain cyanide; cyclic utilization of the catalyst, cyclic utilization of materials and cyclic utilization of water are achieved, the technology, the concept and the equipment are advanced, the system inclusiveness is extremely high, and discharge of process wastewater is completely eradicated.

Owner:李乾華

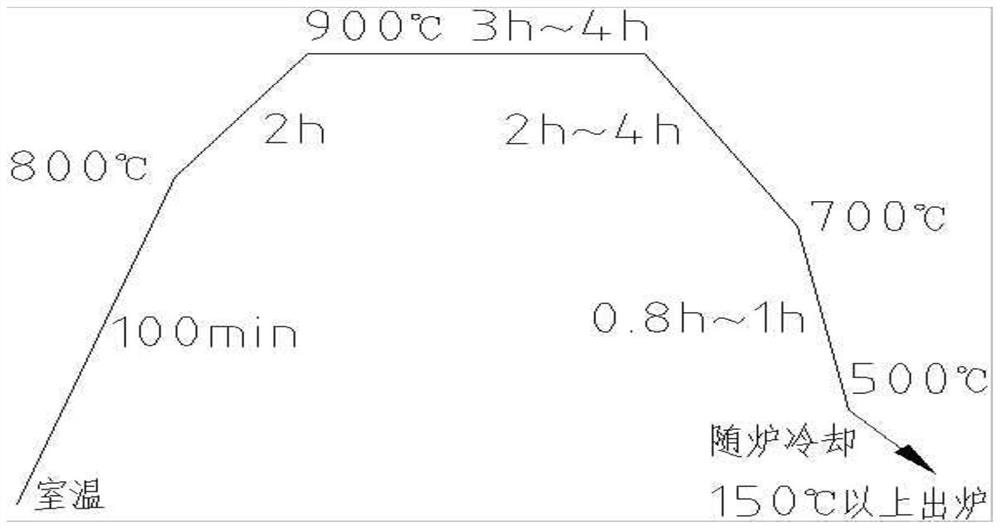

Vacuum annealing method for magnetic material

InactiveCN112359186AControl deformationImprove stress concentrationStress concentrationRoom temperature

The invention provides a vacuum annealing method for a magnetic material. The method adopts vacuum heat treatment equipment to carry out vacuum quenching with the vacuum degree of less than 6.67 * 10<-3> Pa. In order to ensure slow release of thermal stress and other stresses of the material, the room temperature is heated to 800 DEG C in the heating process, slow heating is carried out for 100 minutes, and slow cooling is carried out for 0.8-1 hour in the cooling process of 700-500 DEG C; and in order to ensure that the magnetic properties of the material meet the index requirements, heat preservation is carried out for 2 hours at 800-900 DEG C, heat preservation is carried out for 3-4 hours at 900 DEG C, and heat preservation is carried out for 2-4 hours in the cooling process at 900-700 DEG C. According to the method, large stress concentration at the position, prone to deformation, of the electromagnetic pure ferromagnetic material of a complex structure in the vacuum heat treatment process is prevented, meanwhile, it can be guaranteed that the magnetic performance of the material meets technological parameters of indexes, the deformation amount of the electromagnetic pure ferromagnetic material of the complex structure after heat treatment can be well controlled, the heat treatment procedure machining time is shortened, and energy conservation, consumption reduction and green and clean production are realized.

Owner:SHENYANG AEROSPACE XINGUANG GRP

Method for preparing FexPO4 by electrolyzing ferrophosphorus

InactiveCN102051629BOvercome the problem of difficult ratioEliminate consumptionElectrodesChemical industryElectrolysis

Owner:SICHUAN UNIV

A kind of technology that adopts turmeric to produce saponin and rhamnose

ActiveCN107417763BRealize green and clean productionHigh yieldSugar derivativesSteroidsAlcoholHydrolysate

Owner:刘玉通

Dustproof, antibacterial and ageing-resistant color master batch of polyethylene (PE) plastic slide, and preparation method of color master batch

ActiveCN103214721BMeet antibacterial requirementsMeet weather resistance requirementsAnti ageingLubricant

The invention relates to a dustproof, antibacterial and ageing-resistant multifunctional color master batch of a polyethylene (PE) plastic slide. The dustproof, antibacterial and ageing-resistant multifunctional color master batch of the PE plastic slide comprises the following components in percentage by weight: 12.5 to 17.5 percent of dust preventive, 15.0 to 20.0 percent of antibacterial agent, 5.0 to 10.0 percent of anti-ageing agent, 17.5 to 22.5 percent of coloring agent, 7.5 to 12.5 percent of dispersing lubricant, 0.5 to 2.0 percent of compatilizer and 25.0 to 35.0 percent of carrier resin. A preparation method of the color master batch comprises the following steps of: adding the antibacterial agent, the anti-ageing agent, the coloring agent, the dispersing lubricant and the carrier resin into a high-speed mixer and mixing for 10 to 20 minutes; adding the dust preventive and the compatilizer and stirring for 5 to 10 minutes; adding the mixed materials into a double-screw extruder and extruding at 140 to 150 DEG C; and cooling, drying, dicing and packaging to prepare the required master batch. The dustproof, antibacterial and ageing-resistant multifunctional color master batch can eliminate environmental pollution caused by dust in a downstream PE plastic forming process and realizes environment-friendly and clean production of the PE plastic. The dustproof, antibacterial and ageing-resistant multifunctional color master batch has the characteristics of small using amount of the carrier resin and the dispersing lubricant and low master batching forming energy and antioxidant consumption, and can be widely applied to coloring of the PE plastic.

Owner:中山市铁鹰塑胶有限公司 +1

A method for reducing acid content in dimethyldichlorosilane hydrolyzate

ActiveCN106397474BProportionally largeRealize green and clean productionSilicon organic compoundsHydrolysateChloride

Belonging to the field of chemical engineering, the invention relates to a method for reducing the acid content of a dimethyldichlorosilane hydrolysate. The method includes the steps of: (a) subjecting the dimethyldichlorosilane hydrolysate and a calcium chloride aqueous solution to countercurrent mixing and washing; (b) then continuously contacting the hydrolysate with a hydrochloric acid mass fraction gradually reduced aqueous phase, and performing full washing. On the basis of washing, the method provided by the invention introduces calcium chloride to increase the proportion of the hydrolysate and water, realizes rapid layering of the two, avoids emulsification phenomenon during washing, and improves the washing and acid removing effects. In addition, the method provided by the invention significantly reduces the consumption of washing water and lowers the production load, and the calcium chloride can be recycled, thus achieving green and clean production.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

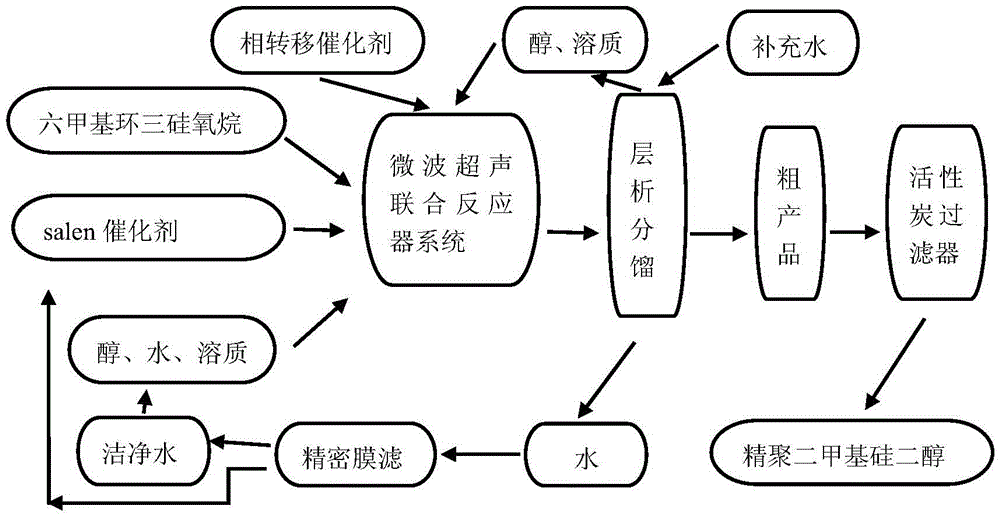

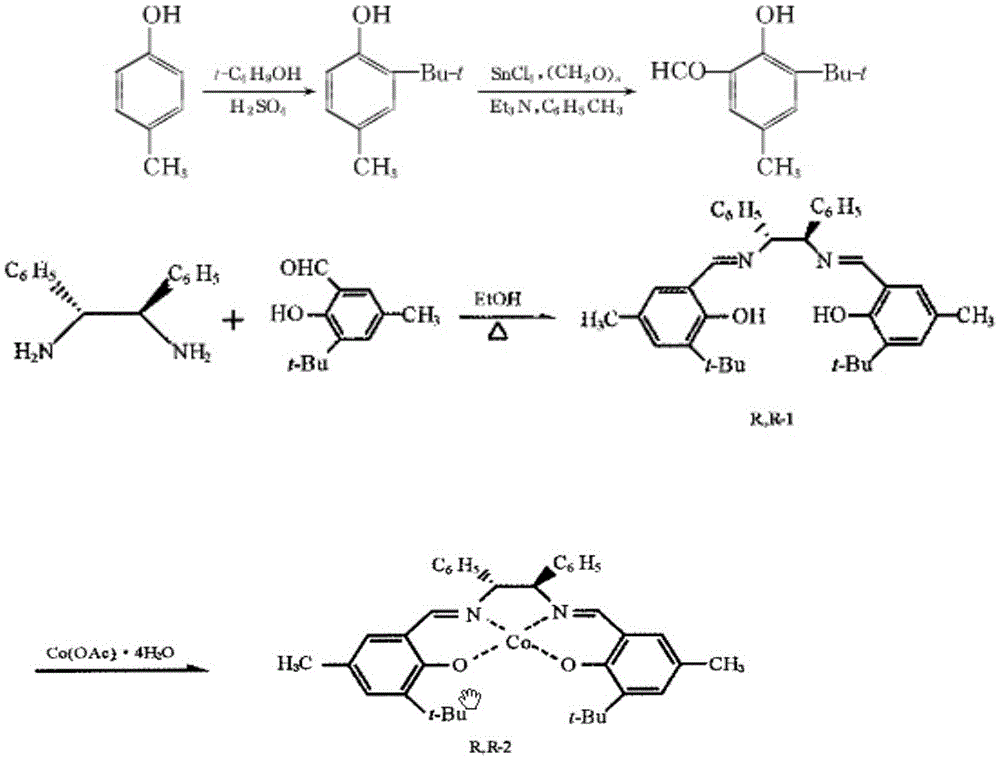

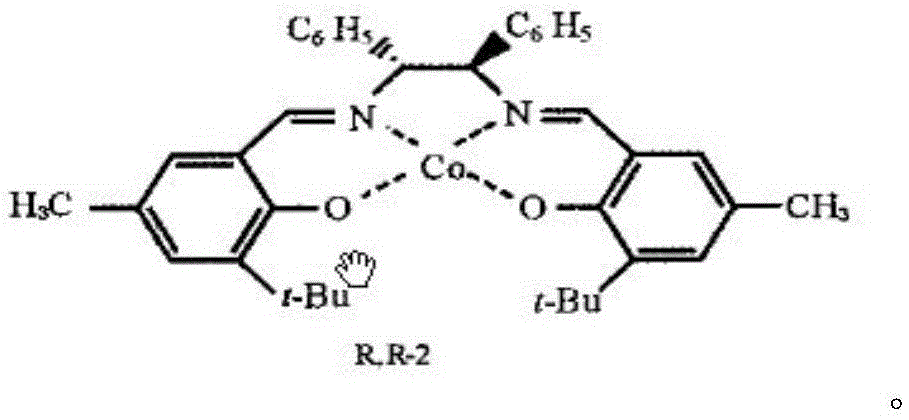

A kind of synthetic method of polydimethylsilanediol

InactiveCN104004009BAchieving zero emissionsReduce dosageSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholSynthesis methods

The present invention belongs to the field of organic chemistry, and particularly relates to a polydimethylsilanediol synthesis method. The method comprises the following steps: mixing hexamethyl cyclotrisiloxane, water, alcohol and cosolvent, then adding a supported chiral catalyst and a phase transfer catalyst, intensively mixing all the materials to form a miscible homogeneous phase and conducting reactions sufficiently to obtain the products of polydimethylsilanediol. The usage amount of hexamethyl cyclotrisiloxane, water and alcohol is determined according to the required polymerization degree of the products, and the specific ratio of hexamethyl cyclotrisiloxane, water and alcohol can be selected and adjusted according to the reaction formula. The method is green and environmental friendly, has zero discharge of wastewater and subsidiary reaction waste liquid, and truly achieves green and clean production in the premise of ensuring product quality.

Owner:杭州加农润滑材料有限公司

Water-based printing ink resin and preparation method thereof

ActiveCN103555050ARealize green and clean productionReduce pollutionInksNatural resin chemical modificationXylylenePolymer science

The invention relates to water-based printing ink resin and a preparation method thereof. Based on percentage by weight, the preparation method comprises the following steps: A, adding 30-35% of rosin resin into a reaction kettle; heating to 130-140 DEG C so as to melt the rosin resin; stirring, adding 6-10% of maleic anhydride and heating to 180 DEG C; insulating for 1-1.5 hours; then, adding 0.02-0.04% of zinc oxide and 1-5% of pentaerythritol; insulating for 0.5-1 hour and adding 6-10% of tung oil; insulating for 0.5-1 hour; B, cooling to 140 DEG C, adding 3% of xylene based on the total weight to reflux, heating to 180 DEG C, insulating for 0.5-1 hour, quickly heating to 270-275 DEG C, and insulating for 0.5-1 hour; C, cooling to 160 DEG C, and dropwise adding 1-5% of cholamine and 1-5% of butyl acetate; during dropwise adding, cooling from 160 DEG C to 120 DEG C, controlling the dropwise adding time within 1-1.5 hours; then, cooling to 80 DEG C and adding 8-12% of mixed alcohol; then, cooling to 60 DEG C and adding 10-15% of amine stabilizing liquid; insulating for 0.5-1 hour; finally, adding 15-25% of acetic ether, cooling to 40 DEG C and discharging.

Owner:NANHUA UNIV +1

ABS laser caving plastic having antibiotic function, and preparation method thereof

An ABS laser caving plastic having an antibiotic function comprises 75-85wt% of a transparent ABS resin, 5-10wt% of a PMMA resin, 3-8wt% of a PEG resin and 5-10wt% of a multifunctional color master batch. An antiseptic in the multifunctional black master batch forms an antibiotic system, and a complex antioxidant and PEG6000 together form a light and thermal stabilizing system, so the light degradation, photo-oxygen degradation and thermal oxygen degradation ageing of ABS can be effectively prevented, and requirements of the antibiotic performance and the laser caving performance of the ABS laser caving plastic are satisfied. The preparation method of the ABS laser caving plastic comprises a step of preparing the antibiotic laser caving multifunctional black master batch, and a step of preparing the ABS laser caving plastic having an antibiotic function through using the master batch. A multifunctional master batch technology provided in the invention eliminates the pollution of dusts to the environment, realizes the green and clean production of an ABS resin and an alloy, has the characteristics of less application amounts of carrier resins and a lubrication dispersant, low master batch processing energy and low processing assistant consumption amount, and can be widely used for the molding processing of ABS plastics.

Owner:NANHUA UNIV +1

Green and clean preparation method of vanadium compound

ActiveCN106892455BFully extractedEfficient removalVanadium compounds preparationWater/sewage treatment by flocculation/precipitationAmmonium compoundsAmmonium metavanadate

The invention provides a green and clean preparation method of a vanadium compound. The preparation method comprises the following steps of: crushing and ball-milling raw materials; then adding a vanadium element converter or a barium compound; leaching a fired product with clean water; adsorbing and enriching vanadium by using an ion exchange resin, and performing purification to remove barium and impurities; performing counter-extraction to extract vanadium by using a strong alkaline solution to generate a NaVO4 solution and removing other metal ions or impurities which are not dissolved in alkali; adding an ammonium compound to generate ammonium metavanadate and washing the ammonium metavanadate with deionized water or distilled water and drying the same; adding a phosphate diester anti-precipitator, and performing filter pressing and packaging heavy metals; and adding white carbon black of superfine powder into the solution, wherein ammonia and nitrogen are adsorbed in the white carbon black, and the heavy metals are packaged after filter pressing. The method provided by the invention can effectively eliminate original impurities in the raw materials and other impurities generated in the treatment process, and can make full of vanadium-settling wastewater while fully extracting the vanadium compound, so that green and clean production in the production process is realized.

Owner:深圳力合通科技有限公司

A method for strengthening the extraction of polysaccharides in Cordyceps militaris rice culture medium

The invention discloses a method for intensively extracting polysaccharides from a rice culture medium for cordyceps militaris. The method comprises the following steps: carrying out superfine crushing, ultrahigh pressure treatment and ultrasonic intensified flash extraction on the cordyceps militaris culture medium, adding amylase to an extract solution to realize enzymosis, concentrating enzymatic hydrolysate, adding polyethylene glycol, sufficiently stirring and dissolving, standing over night, centrifuging, washing precipitate with edible alcohol, adding hot water to dissolve, removing insoluble substances, and drying to obtain the polysaccharides. According to the method disclosed by the invention, configuration guiding of a process for promoting effective dissolution of polysaccharides is highlighted according to the resource advantage of the rice culture medium for cordyceps militaris, the clean production ideal is embodied by technical model selection, by adopting novel physical and biological integrated means, polysaccharide recovery technical output characterized by high speed, high efficiency, time saving, low consumption and environmental friendliness is realized, and the edible safety of the extracted polysaccharides is ensured from the production link.

Owner:武汉添年科技有限公司

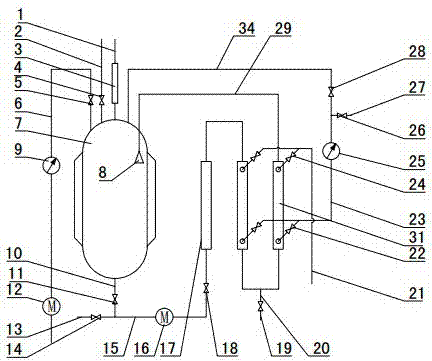

Water saving method in process of producing sodium gluconate through aspergillus niger fermentation

ActiveCN103468753BReduce dosageReduce consumptionMicroorganism based processesFermentationEvaporationReverse osmosis

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

A kind of calcification transition-leaching method for decomposing bastnaesite

The invention belongs to the technical field of rare earth metallurgy, and particularly relates to a method for calcification transformation-leaching and decomposition of bastnaesite ore, which is carried out according to the following steps: activation pretreatment of rare earth concentrate → calcification transformation pretreatment of activated ore → acid leaching of transformation slag → chlorine Rare earth semen is extracted, and finally a solution of thorium iron slag and cerium chloride, lanthanum chloride, praseodymium chloride or neodymium chloride is obtained to efficiently separate rare earth elements, fluorine elements, thorium elements and other valuable components. The invention reduces energy consumption and fuel consumption. Low-temperature roasting below 500°C only decomposes carbonate. It not only provides reactivity of rare earth concentrates, but also avoids waste of fluorine resources and emission pollution, and is a green cleaning process.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com