Dustproof, antibacterial and ageing-resistant color master batch of polyethylene (PE) plastic slide, and preparation method of color master batch

A polyethylene plastic and anti-aging technology, which is applied in the field of plastic coloring, can solve the problems of many components in downstream molding processing, high consumption of antioxidants, and high energy consumption, and achieve simple feeding of downstream material molding processing and masterbatch molding The effect of low energy and antioxidant consumption and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

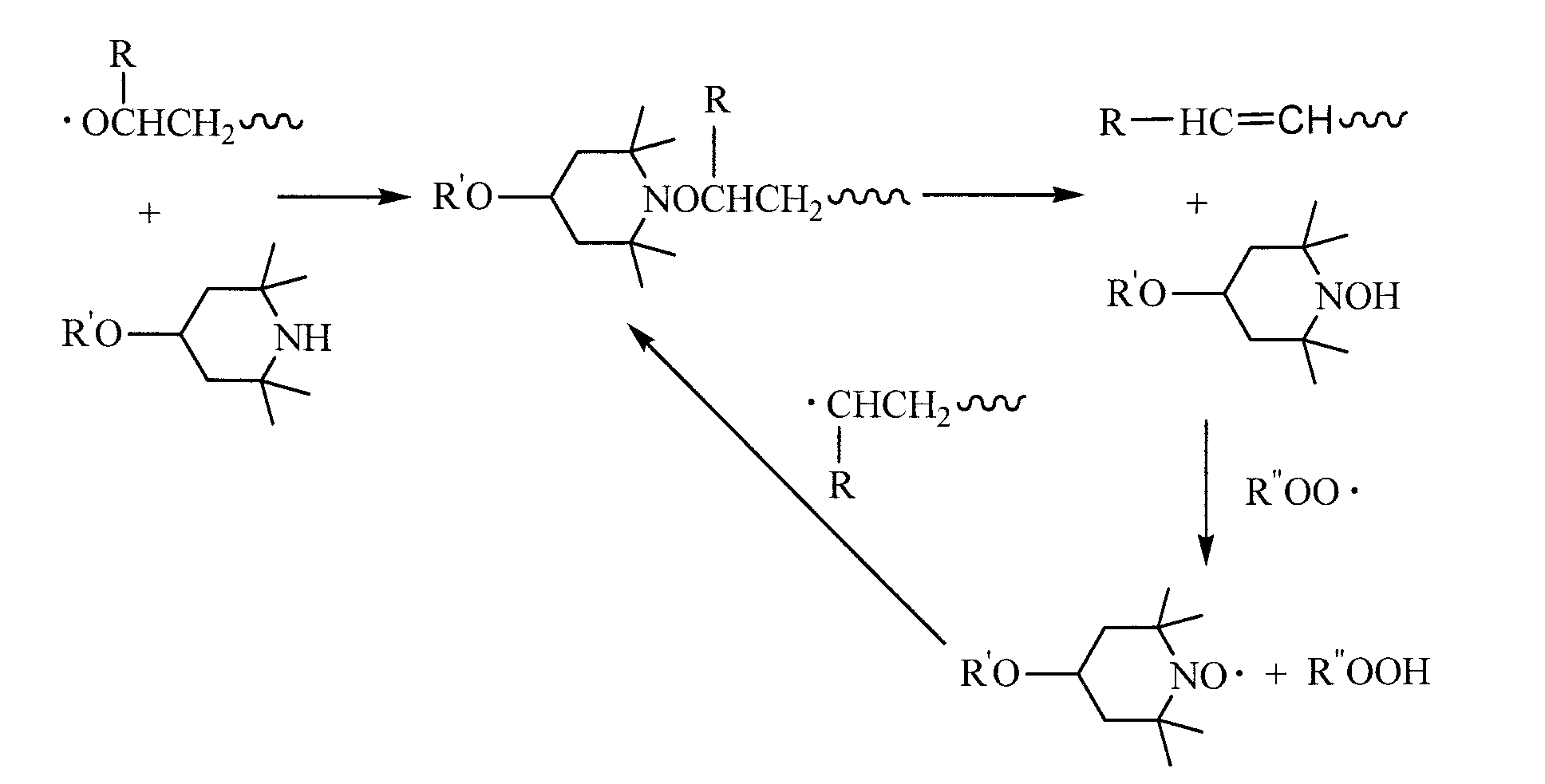

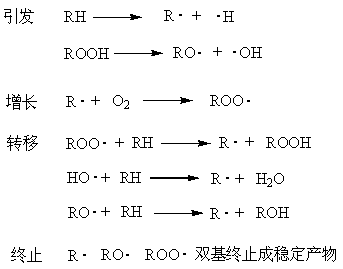

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. A dust-proof, anti-bacterial and aging-resistant multifunctional color masterbatch for polyethylene plastic slides, consisting of dust-proof agent, anti-bacterial agent, anti-aging agent, colorant, dispersing lubricant, compatibilizer and carrier resin , the percentage by weight of each component is: anti-dust agent: 13.5%; antibacterial agent: 20.0%; antiaging agent: 7.0%; coloring agent: 20.0%; Resin: 29.0%.

[0031] The dustproof agent is composed of fatty acid amide and dodecylamine polyoxyethylene (2) ether in a weight ratio of 1:2;

[0032] The antibacterial agent is nano TiO2 powder loaded silver ion antibacterial agent;

[0033] The antioxidant is composed of light stabilizer UV-327, hindered amine light stabilizer 770, antioxidant 1010, antioxidant 1076 and auxiliary antioxidant DSTP in a weight ratio of 1:2:2:1:1;

[0034] Described coloring agent is made up of phthalocyanine blue system and nano CaCO3 by weight ratio 1:9;

[0035] Describ...

Embodiment 2

[0042] Embodiment 2. A dust-proof, anti-bacterial and anti-aging multi-functional masterbatch for polyethylene plastic slides, which consists of dust-proof agent, anti-bacterial agent, anti-aging agent, colorant, dispersing lubricant, compatibilizer and carrier resin , the percentage by weight of each component is: anti-dust agent: 13.5%; antibacterial agent: 20.0%; anti-aging agent: 7.0%; colorant: 20.0%; Resin: 29.0%.

[0043] The dustproof agent is composed of fatty acid amide and dodecylamine polyoxyethylene (2) ether in a weight ratio of 1:2;

[0044] The antibacterial agent is nano TiO2 powder loaded silver ion antibacterial agent;

[0045] The antioxidant is composed of light stabilizer UV-327, hindered amine light stabilizer 770, antioxidant 225, antioxidant 1076 and auxiliary antioxidant DLTP in a weight ratio of 1:2:2:1:1;

[0046] Described coloring agent is made up of transparent EG red system and nano CaCO3 by weight ratio 1:19;

[0047] Described dispersio...

Embodiment 3

[0054] Embodiment 3. A dust-proof, anti-bacterial and aging-resistant multifunctional color masterbatch for polyethylene plastic slides, consisting of dust-proof agent, anti-bacterial agent, anti-aging agent, colorant, dispersing lubricant, compatibilizer and carrier resin , the percentage by weight of each component is: anti-dust agent: 15.0%; antibacterial agent: 15.0%; antiaging agent: 7.0%; coloring agent: 20.0%; Resin: 32.0%.

[0055] The dustproof agent is composed of fatty acid amide and stearylamine polyoxyethylene (2) ether in a weight ratio of 1:2;

[0056] The antibacterial agent is nano TiO2 powder loaded silver ion antibacterial agent;

[0057] The antioxidant is composed of light stabilizer UV-327, hindered amine light stabilizer 770, antioxidant 1010, antioxidant 1076 and auxiliary antioxidant DSTP in a weight ratio of 1:2:2:1:1;

[0058] Described coloring agent is made up of transparent yellow G114# system and nanometer CaCO3 by weight 1:19;

[0059] De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com